Pecan Irrigation-and the irrigation system installation at the GCREC

advertisement

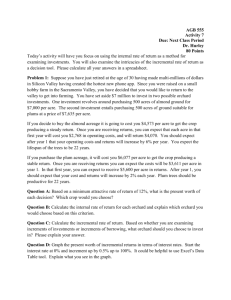

Bryan Wilkins In South Alabama we generally get enough rain in June and July to size our pecans. We don’t get enough steady rainfall during the critical August and September nut filling period to adequately fill the nuts out. Irrigation can make up the difference. Gives the best use of the available water supply by controlling the water flow to give maximum yields with the least amount of waste. Evaporation loss minimal because the water it applied below the soil surface Low pressure requirements=lower operating costs Lower labor requirements Irrigation can be applied anytime Fertilizer can be injected through the system Less disease and insect pressure Less wetted area means less weeds and restricts populations of potential pest hosts No wind effect, lets you irrigate around the clock It’s a permanent system Easily and readily adapted to automatic controls Provides improved infiltration in soils with low intake capacity Allows for the use of more saline water. Pecans have a very efficient water transport system Developed ability to avoid stomatal closure under high temps with adequate water Pecans are very inefficient users of water Require large amounts of water to support optimal growth and fruit production You must have a clean water supply. Adequate and dependable filtering systems are difficult to provide Clogged emitters that result from poor water filtration, algae, bacteria, sulfur, iron and calcium in the water. Non-uniformity of water discharged from the emitters. On sandy soils water is not evenly distributed , the water does not tend to move laterally causing insufficient root volume wetting and leaching of nutrients. Mice and rabbits and other animals cause damage by chewing on the flexible lines. Increased Nut Size/Quality, Nut Retention Minimizes Shuck Decline/Sticktights Enhances shuck split Reduces Severity of alternate bearing Ability to inject fertilizer and systemic insecticides 1 acre inch x 27,154 gallons/acre inch x 7 days = 3,879 gallons/acre/year 3,879 gallons 27 trees/acre = 144 gallons/tree/day 2 acre inches = 288 gallons/tree/day March April May June July August September October TOTAL 5” 4” 4” 4” 10” 10” 10” 8” 55” Water about every 6 weeks Mid-November End December First February TOTAL 2” 2” 2” 6” 4” Well pumping 85 gallons/minute Installed August 2012 Drip Irrigation components: drip tube with ½ gph inline emitters spaced 3 feet apart 2 lines per tree plowed in at the edge of the herbicide strip Cost of System: Parts and Labor: $700/Acre Well: 4 inch 5 HP $6200.00 The system is a continuous loop, live feed system. It has a 2” main feed line running through the center of the orchard. 1½” lines on the end of the rows supplying water. All drip lines are plugged connected to the main feed and the lines on the end of the row. This creates a continuous water supply that keeps the pressure up and waters more effectively all the way down the row. A siphon valve is installed to put acid and chlorine through the system periodically Acid will clean any mineral deposits that may block the emitters and chlorine will take care of algae and bacterial slime 2 Treatments: Irrigated and non-irrigated 5 Replications 3 Tree plots with the center tree being the record tree Non irrigated trees have the water shut off with ball valves Data to be collected: Date of shuck split Harvest date Percent of shuck tights Percent Kernel Total Yield QUESTIONS