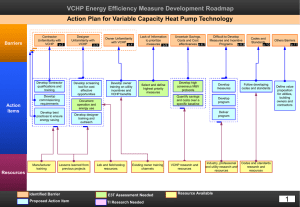

Major Difference between VRF HP`s and Conventional HP`s

advertisement

Variable Capacity Heat

Pump RTF Sub-Committee

February 27, 2013

VRF Fan Energy Use and Part-Load

Performance

Richard Raustad, Senior Research Engineer

Florida Solar Energy Center

rraustad@fsec.ucf.edu

Full-Load Cooling Performance

Controlled Region

Uncontrolled Region

Full-Load Heating Performance

Manufacturer Performance Correction

(surrogate for part-load performance)

170

136

102

68

34

0

21 kW

72 kBTU/hr

28.1 kW

96 kBTU/hr

EnergyPlus Cooling Model Inputs

AirConditioner:VariableRefrigerantFlow,

autosize,

3.802,

-5,

43,

!- Rated Total Cooling Capacity {W}

!- Rated Cooling COP {W/W}

!- Minimum Outdoor Temperature in Cooling Mode {C}

!- Maximum Outdoor Temperature in Cooling Mode {C}

VRFCoolCapFT,

!- Cooling Capacity Ratio Modifier Function of Low Temperature Curve Name

VRFCoolCapFTBoundary, !- Cooling Capacity Ratio Boundary Curve Name

VRFCoolCapFTHi,

!- Cooling Capacity Ratio Modifier Function of High Temperature Curve Name

VRFCoolEIRFT,

!- Cooling Energy Input Ratio Modifier Function of Low Temperature Curve Name

VRFCoolEIRFTBoundary, !- Cooling Energy Input Ratio Boundary Curve Name

VRFCoolEIRFTHi,

!- Cooling Energy Input Ratio Modifier Function of High Temperature Curve Name

CoolingEIRLowPLR,

CoolingEIRHiPLR,

CoolingCombRatio,

VRFCPLFFPLR,

!- Cooling Energy Input Ratio Modifier Function of Low Part-Load Ratio Curve Name

!- Cooling Energy Input Ratio Modifier Function of High Part-Load Ratio Curve Name

!- Cooling Combination Ratio Correction Factor Curve Name

!- Cooling Part-Load Fraction Correlation Curve Name (cycling losses)

Creating Performance Curves

• Raustad, R.A., 2012. Creating Performance Curves for

Variable Refrigerant Flow Heat Pumps in EnergyPlus,

FSEC-CR-1910-12.

https://securedb.fsec.ucf.edu/pub/pub_search

https://securedb.fsec.ucf.edu/pub/pub_show_detail?v_pub_id=4588

[59 F]

[60.8 F]

[64.4 F]

[68 F]

[71.6 F]

[75.2 F]

[41 F]

[50 F]

[86 F]

[95 F]

[78.8 F]

[-4]

[F]

[131]

Laboratory Measured Data

Full-load Cooling Performance

AHRI 1230

Buried TSTAT

setting

[-17.7]

[10]

[37.8]

[C]

[65.6]

[29.4/21.1]

[29.4/19.4]

[29.4/17.2]

[26.7/21.1]

[26.7/19.4]

[26.7/17.2]

[26.7/15.6]

[23.8/21.1]

[23.9/19.4]

[23.8/17.2]

[23.9]

[20.6]

WB

[17.8]

[15.0]

Normalized Capacity

Measured part-load operation

[15.3 kW]

Outdoor Temperature (F) [C]

[23.9 C]

[29.4 C]

[35 C]

[40.5 C]

[26.7 C/ 19.4 C]

[15.3 kW]

170

136

102

68

34

0

Model Characteristics

170

136

102

68

34

[kW]

[58.6]

Major Difference between VRF HP’s

and Conventional HP’s

• Avoid duct losses when using ductless terminal

units (no heat gain or leakage)

Major Difference between VRF HP’s

and Conventional HP’s

• Avoid duct losses when using ductless terminal

units (no heat gain or leakage)

Major Difference between VRF HP’s

and Conventional HP’s

• Avoid duct losses when using ductless terminal

units (no heat gain or leakage)

• Fan energy savings for ductless terminal units

Major Difference between VRF HP’s

and Conventional HP’s

• Avoid duct losses when using ductless terminal

units (no heat gain or leakage)

• Fan energy savings for ductless terminal units

• Moderate part-load

savings

170

136

102

68

34

[kW]

[58.6]

Major Difference between VRF HP’s

and Conventional HP’s

• Avoid duct losses when using ductless terminal

units (no heat gain or leakage)

• Fan energy savings for ductless terminal units

• Moderate part-load savings

• Space savings for refrigerant lines vs air ducts

Major Difference between VRF HP’s

and Conventional HP’s

• Avoid duct losses when using ductless terminal

units (no heat gain or leakage)

• Fan energy savings for ductless terminal units

• Moderate part-load savings

• Space savings for refrigerant lines vs air ducts

• Individual zone control

Future work

• Need more laboratory research and published

experimental data

• Better understanding of control logic

• Field demonstrations need more information

• Work closely with manufacturer’s

Questions?

Richard Raustad

rraustad@fsec.ucf.edu