Chapter 4: The Locomotive

advertisement

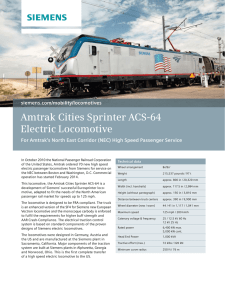

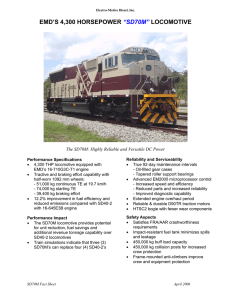

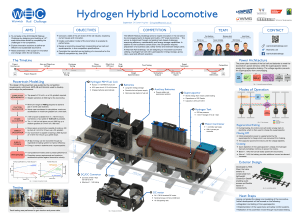

CHAPTER 4 The Locomotive Steam until mid 1950’s Types of Locomotives • • • • Steam Diesel-Electric Electric Hybrid Two Factors Determine the Ability of a Locomotive to Start, Accelerate, and Obtain Top Speed Tractive Effort • The Ability to Overcome Resistance -Starting, Grade, Wind, Curve, Rolling • Tractive Force = Weight of Drivers x Coefficient of Adhesion Horse Power (mainly 1,500 to 5,000 hp) • Rate of Doing Work • Drawbar Horsepower: horsepower available to haul Adhesion Control • Grip Rail without Slipping • Dependent on weather, rail conditions • Controlled automatically in modern locomotive • Sanding Tractive Force vs. Tonnage and Grade Performance Curve of the Locomotive (with train resistance for 420 tons trailing load of passenger stock) Different Horsepower Ratings • Not all engine power pulls train • On average, 82% of power is left to pull train Power Required vs. Speed and Grade Diesel–Electric Locomotive • Diesel Engine – Prime Mover • Turbocharger / Electronic Fuel Injection • Alternator / Generator / Fans / Batteries • AC/DC Traction Motors Locomotive Principal Components Radial Trucks Locomotive Controls • Minimum Levers, but Connected to Circuitry • “Microprocessor” Control • Display Screens • Interfaces with Primary Operator Six Axle, approx. 390,000 pounds vs. Four Axle, approx. 260,000 pounds Multiple Unit Arrangements Distributive Power / ECP Mid-Train or Rear End Slugs and Mates No Prime Mover Store Excess Power Provide Weight for Tractive Effort Maintenance and Life Span • Most New Locomotives can Self-Diagnose Problems • Different Inspections Mandatory at Daily, 92-days, Annual, and Biennial Periods • Remote Diagnostics • Average Locomotive Service is 20-25 Years • Used to be Returned to Manufacturer, but Now Sold to Smaller Railroads Genset and Hybrid Locomotives (Mainly for Switching) Genset – Multiple engine-generators per vehicle Hybrid – Operates on batteries that are charged overnight