TS Engineering Presentation Slides

advertisement

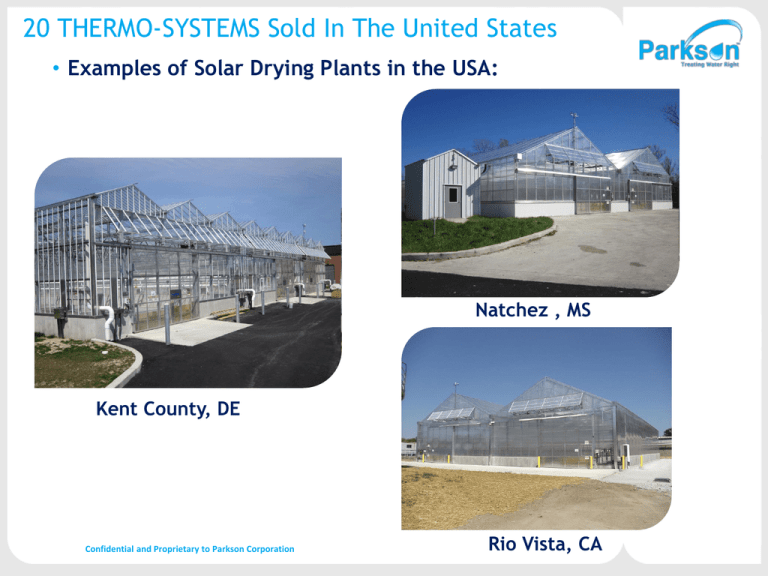

20 THERMO-SYSTEMS Sold In The United States • Examples of Solar Drying Plants in the USA: Natchez , MS Kent County, DE Confidential and Proprietary to Parkson Corporation Rio Vista, CA THERMO-SYSTEM® Active Solar Sludge Dryer Sludge Delivery: By Truck Confidential and Proprietary to Parkson Corporation Collection & Distribution: Wheel Loader 2 THERMO-SYSTEM® Active Solar Sludge Dryer Sludge Entry: Underground – Liquid Sludge Confidential and Proprietary to Parkson Corporation Sludge Entry: Underground – Dewatered Cake 3 TOUCH SCREEN HMI CONTROLS Enter the data into the THERMO-SYSTEM® PLC interface. Confidential and Proprietary to Parkson Corporation 4 THERMO-SYSTEM® Active Solar Sludge Dryer Sludge Tilling Machine: Electric Mole® Confidential and Proprietary to Parkson Corporation Electric Mole® accelerates the drying process 5 THERMO-SYSTEM® Active Solar Sludge Dryer Ceiling Fans: Convective Aeration & Drying Movi-Vent™ Air Circulation System Confidential and Proprietary to Parkson Corporation Exhaust Fans: Chamber Air Exchange 6 THERMO-SYSTEM: Standard Batch Operation Unloading Loading Drying Process 1 - 6 weeks (Dry solids to 75%+) 2h Confidential and Proprietary to Parkson Corporation 1h THERMO-SYSTEM® Active Solar Sludge Dryer Sludge Removal: Front-Wheel Loader Confidential and Proprietary to Parkson Corporation Sludge Removal: Front-Wheel Loader 8 THERMO-SYSTEM® Active Solar Sludge Dryer Mass reduction: 10MGD Plant Example De-watered dried 18,000 t/yr Evaporation: 14,400 t/yr 3,600 t/yr Active Solar Dryer 20% DS 60-90% DS Mass reduction approx. 85 % Confidential and Proprietary to Parkson Corporation 9 THERMO-SYSTEM® Active Solar Sludge Dryer Hauling reduction: 10MGD Example Evaporation: 14,400 t/yr Active Solar Dryer 900 Trucks / yr 180 Trucks / yr ~$450,000/yr savings for 10MGD plant with $40 per ton hauling and tipping fee costs Confidential and Proprietary to Parkson Corporation 10 Thermo-System O & M Requirements • Labor: 2 to 4 hours per batch • Operator attention: Minimal • Maintenance: Grease Electric Mole after every batch • Energy: ~ 30kWh per ton of water evaporated Typical O&M cost is extremely low ~ $5 per wet ton! Confidential and Proprietary to Parkson Corporation Installation Pictures Waimea, HI Waimea, HI 2 drying chamber (42’ x 204’) Drying Water Plant Residuals from 5% to 25% Dry Solids Confidential and Proprietary to Parkson Corporation Kent County, DE Kent County, DE 3 drying chambers (42’ x 204’) First all-glass, Venlo-truss construction by Parkson Better performance and durability! Confidential and Proprietary to Parkson Corporation Advantages of the THERMO-SYSTEM • Green, sustainable technology ―Low energy consumption - sun is primary energy source ―Very low operating costs • Robust, easy to operate ―Very low operator attention required ―Very low maintenance requirements • Flexible methods of operation • Proven technology - large installation base • Class A and Class B possible – Maximum disposal options Confidential and Proprietary to Parkson Corporation