IECC: What an Architect Needs to Know

advertisement

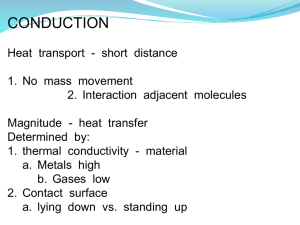

Credit(s) earned on completion of this course will be reported to AIA CES for AIA members. Certificates of Completion for both AIA members and non-AIA members are available upon request. This course is registered with AIA CES for continuing professional education. As such, it does not include content that may be deemed or construed to be an approval or endorsement by the AIA of any material of construction or any method or manner of handling, using, distributing, or dealing in any material or product. _______________________________________ ____ Questions related to specific materials, methods, and services will be addressed at the conclusion of this presentation. Course Description The State of Iowa has adopted the 2012 International Energy Conservation Code, we will look at the 2012 IECC and how the code impacts the commercial building envelope. Learning Objectives At the end of the this course, participants will be able to: 1. The participant will be able to identify the climate zone for the project location and choose the path of compliance that is appropriate with their design. 2. The 2012 International Energy Conservation Code will be compared to the 2009 and how they impact the building envelope. 3. Misconceptions, pitfalls and missed information critical to a complete COMcheck will be discussed. We will expolore presenters experience with COMcheck reviews over the past four years as well as details that need to be updated. IECC 2012 Commercial Energy code update Commercial Envelope Statewide Code Compliance June 1st 2014 Introduction David Ruffcorn, AIA Design/Energy Engineer Iowa State Fire Marshal’s Office Building Code Bureau • Commercial Energy Code Summary • Energy Codes 101 • Paths of compliance • Increased prescriptive insulation requirements – Table C402.2 • Manual daylighting controls for buildings seeking 30% < WWR ≤ 40%; • Skylights/daylighting for large (>10,000 ft2) spaces w/ tall (15’) ceilings; • Continuous air barrier requirement for most buildings – Mandatory • Hints for compliance • Details – We can do better! 6 Resources Published by: International Codes Council 10 11 100,000 CF Statement Review required by an Architect or Engineer Review Required. The plans and specifications for all buildings to be constructed which exceed a total volume of 100,000 cubic feet of enclosed space that is heated or cooled shall be reviewed by a registered architect or licensed professional engineer for compliance with applicable energy efficiency standards. • Statewide Code Compliance June 1st 2014 IECC Compliance - Two Climate Zones Iowa Has Two Climate Zones Zone 5 Zone 6 12 IECC Compliance - Three Options Prescriptive U-Factor and “UA” Alternatives Simulated Performance (software) R-values Table R402.1.1 U-factor Table C402.2 R402.1.3 - REScheck C402.3 - COMcheck Simulated Performance Alternative R405 - REMrate C407 – DOE II There are three paths of Compliance Prescriptive Trade-off Performance 13 Structure of the 2012 IECC Commercial Section Residential Section Ch. 1 C101 - Scope and Application / Administrative and Enforcement Ch. 1 Ch. 2 C201 - Definitions Ch. 2 Ch. 3 Ch. 4 Ch. 3 C301 - General Requirements Ch. 4 C401 - Commercial Energy Efficiency Ch. 5 C501 - Referenced Standards Index Ch. 5 Index R101 - Scope and Application /Administrative and Enforcement R201 - Definitions R301 - General Requirements R401 - Residential Energy Efficiency R501 - Referenced Standards 14 Building Types C 101.4 - Applicability – What is NOT covered under this code: C101.4.1 - Historic Buildings – State, National or Local historic property C101.4.3 – Exceptions for Additions, Alterations, Renovations or Repairs Exceptions – 1 to 8 C101.4.6 – Mixed occupancy – Where the building is covered by the IECC Residential Provisions C101.5.2 – Low Energy Buildings – with energy use below 3.4 Btu/h Sf of floor area for space conditioning purposes. 15 Building Types C101.4.3 – Exceptions for Additions, Alterations, Renovations or Repairs 16 Structure of the 2012 IECC Commercial Energy Efficiency Chapter 4 (CE) 17 Building Envelope Building Envelope consists of: Fenestration Ceilings Walls Above grade Below grade Mass walls Conditioned space Floors Slab Crawl space 18 2012 Commercial IECC Mandatory Requirements Mandatory Sections Regardless of Compliance Path C402.4 Air Leakage – With sections C402.4.1 through C402.4.8 Typo on C402.4.1.1 paragraph 3 recessed lighting fixtures shall comply with section C402.4.8 C403.2 Provisions applicable to all mechanical systems – With sections C403.2.1 through C403.2.11 C404 Service Water Heating – With sections C404.1 through 404.7.3 Cont….. 19 2012 Commercial IECC Mandatory Requirements Mandatory Sections Regardless of Compliance Path C405 Electrical Power and Lighting Systems – With Mandatory Sections C405.2 Lighting controls – With sections C405.2.1, C405.2.2, C405.2.3 and C405.2.4 C405.3 Tandom Wiring C405.4 Exit Signs C405.6 Exterior Lighting C405.7 Electrical Energy Consumption – Multi-Family C 408 Commissioning Mandatory from section C403.2.9 20 2012 Commercial Insulation and Fenestration by Climate Zone - Prescriptive Table C402.2 21 2012 Commercial Insulation and Fenestration by Climate Zone - Prescriptive Table C402.3 22 2012 Commercial Compliance Approach Trade-off Method Use when the envelope assemblies don’t fit in the prescriptive table Works for 95% of all projects Trades off over insulated areas for under-insulated areas Free and simple program Tied to table C402.2 23 2012 Commercial Compliance Approach Trade-off Method Don’t try to calculate the assembly U-value COMcheck does this MUCH better! 2012 Commercial Compliance Approach Performance Method State Requirements for Performance Energy Modeling Department of Energy DOEII – Energy Modeling Engine Software Free and simple programs, Energy Plus, eQUEST, EPquick OpenStudio Etc. The International Energy Conservation Code 2012 Section C407 outlines the Total Building Performance Method and ASHRAE 90.1 2010, Section 11.1 outlines the Energy Cost Budget Method. ASHRAE 90.1 2010 Appendix G can be used in specific circumstances but each project will need to be approved before using this method. The preferred method in Iowa is the ASHRAE 90.1 2007 Energy Cost Budget Method, the other methods can be used, only with prior approval. 25 Vertical Fenestration Requirement C402.3.1 – Prescriptive (Max area) Percentage of Vertical Fenestration Area to Gross Wall Area Allowed up to 30% maximum of above grade wall In Climate Zones 1-6, up to 40% maximum of above grade wall with daylighting controls 26 Increased Vertical Fenestration with Daylighting Controls – Prescriptive C402.3.1.1 Up to 40% vertical fenestration area allowed in Climate zones 1-6, provided No less than 50% of the conditioned floor area is within a daylight zone Automatic daylighting controls are installed in daylight zones; and Visual Transmittance of vertical fenestration is ≥ 1.1 times SHGC Exception: Fenestration that is outside the scope of NFRC 200 isn’t required to comply with VT 27 Skylight Minimum Fenestration Area C402.3.1.2 Prescriptive Limited to ≤ 3% of Roof Area Up to 5% allowed if automatic daylighting controls installed in daylight zones under skylights 28 Minimum Skylight Fenestration Area C402.3.2 – Prescriptive In certain types of enclosed spaces > 10,000 ft2 directly under a roof with ceiling heights > 15 ft total daylight zone under skylights to not be < ½ the floor area and to provide a minimum skylight area to daylight zone of either Minimum of 3% of roof area with a skylight VLT at least 0.40 OR Provide a minimum skylight effective aperture of at least 1% Exceptions Climate zones 6-8 2 Spaces with LPDs < 0.5 W/ft Documented shaded spaces Daylight area under rooftop monitors is > 50% of floor area 29 Lighting Controls in Daylight Zones – Under Skylights C402.3.2.1 – Prescriptive All lighting in the daylight zone shall be controlled by multilevel lighting controls that comply with C405.2.2.3.3 Exceptions: Climate zones 6-8 Spaces with LPDs < 0.5 W/ft2 Documented shaded spaces Daylight area under rooftop monitors is > 50% of floor area 30 Increased Skylight SHGC C402.3.3.3 In Climate Zones 1-6, skylights above daylight zones with automated daylight controls are permitted a maximum SHGC of 0.60 31 Increased Skylight U-Factor C402.3.3.4 – Prescriptive Skylights above daylight zones with automated daylight controls are permitted a maximum U-factor of – – 0.9 in Climate Zones 1-3 0.75 in Climate Zones 4-8 32 New and Improved!!! And required regardless of compliance path! Air Barriers and Construction C402.4.1 and C402.4.1.1 – (Mandatory) 33 Air Barriers and Construction C402.4.1 and C402.4.1.1 - Mandatory Continuous air barrier required in: Iowa’s climate zones 5 & 6 Air barrier requirements: Placement allowed Inside of building envelope Outside of building envelope Located within assemblies composing envelope OR Any combination thereof Continuous for all assemblies part of the thermal envelope and across joints and assemblies Joints and seams to be sealed per C402.4.2 Recessed lighting to comply with C404.2.8. Where similar objects are installed that penetrate the air barrier, make provisions to maintain the air barrier’s integrity 34 Air Barrier Compliance Options C402.4.1.2 - Mandatory Three ways to comply with air barrier requirements Materials Assemblies Building 35 Air Barrier Materials (Compliance) C402.4.1.2.1 - Mandatory Materials with air permeance ≤ 0.004 cfm/ft2 under pressure differential of 0.3 in. w.g. tested in accordance with ASTM E 2178 These materials meet this requirement: Material Thickness (minimum) Plywood 3/8 in. Oriented strand board 3/8 in. Extruded polystyrene insulation board ½ in. Foil-faced urethane insulation board ½ in. Closed cell spray foam minimum density of 1.5 pcf 1-1/2 in. Open cell spray foam density between 0.4 and 1.5 pcf 4.5 in. Exterior gypsum sheathing or interior gypsum board ½ in. Cement board ½ in. Built up roofing membrane Modified bituminous roof membrane Fully adhered single-ply roof membrane A Portland cement/sand parge, stucco, or gypsum plaster 5/8 in. Cast-in-place and precast concrete Sheet metal or aluminum 36 Air Barrier Assemblies (Compliance) C402.4.1.2.2 OR Assemblies of materials and components (sealants, tapes, etc.) with average air leakage ≤ 0.04 cfm/ft2 under pressure differential of 0.3 in. w.g. tested in accordance with ASTM E 2357, 1677 or 283 These assemblies meet this requirement: Concrete masonry walls coated with one application either of block filler and two applications of a paint or sealer coating OR Portland cement/sand parge, stucco or plaster minimum ½ thick 37 Air Barrier Building Test (Compliance) C402.4.1.2.3 OR Air leakage rate of completed building tested and confirmed to not exceed 0.40 cfm/ft2 at a pressure differential of 0.3 inches water gauge per ASTM E779 or equivalent method approved by code official 38 Air Leakage C402.4.2 to C402.4.8 ( Mandatory) C402.4.2 Air Barrier Penetrations Penetrations of the air barrier and paths of air leakage shall be caulked, gasketed or otherwise sealed. C402.4.3 Air Leakage of Fenestration Shall meet Table C402.4.3 and tested to referenced standard. C402.4.4 Doors and Access Openings to Shafts, Stairways etc. Shall meet either C402.4.3 or shall be gasketed, weather stripped or sealed C402.4.5 Air Intakes, Exhausts, Stairways and Shafts Shall be provided with dampers in accordance with C402.4.5.1 &2 C402.4.6 Loading Dock Weatherseals C402.4.7 Vestibules Required from a space 3,000 Sf in area or more. C402.4.8 Recessed Lighting All recessed luminaires shall be IC-rated and labeled as having a leakage rate of not more than 2.0 cfm@75 Pa 39 Additional Efficiency Requirements - Prescriptive One Additional Efficiency Feature Must Be Selected to Comply with the IECC More efficient lighting system (consistent with 90.1-2010), or More efficient HVAC system Installation of onsite renewables High Efficiency HVAC More Efficient Lighting System 3% of the regulated energy Onsite Renewables 41 Energy Code Plan Review What you need to know to pass the first time 42 Plan Review Submittal Hints What’s needed to pass Energy Code Plan Review….. Complete drawings, specifications and Energy Code documentation. The drawings, specifications and Energy Code must contain the same information. Architectural and MEP must use same code. Storefront windows and doors have different U-values so they must be specified in two locations. Update your standard specification – Construction materials change over the years so should your specification. COMcheck is only interested in the location and listed value of your insulation. Mechanical and Electric are really spread sheets. The values listed in your COMcheck should be in the specification or drawings exactly as noted. Update your standard details – We can do better! 43 Specifications to Review Specification Sections Always Under Review Section 07 2100 Thermal Insulation Section 07 5300 Elastomeric Membrane Roofing Section 07 7200 Roofing Accessories Section 08 4113 Aluminum-Framed Entrances and Storefronts Section 08 4413 Glazed Aluminum Curtain Walls Section 08 4523 Translucent Fiberglass Sandwich Panel Section 23 0719 HVAC Pipe Insulation Section 22 0719 Pipe Insulation 44 Specifications to Review Section 07 2100 Thermal Insulation PART 2 PRODUCTS 2.01 APPLICATIONS A. Rigid Insulation Under Concrete Slabs: Extruded or expanded polystyrene board. B. Rigid Insulation at Perimeter of Foundation: Extruded or expanded polystyrene board. C. Rigid Insulation Inside Masonry Cavity Walls: Extruded or expanded polystyrene board. 2.02 FOAM BOARD INSULATION MATERIALS A. Extruded Polystyrene Board Insulation: ASTM C 578, Type IV; Extruded polystyrene board with either natural skin or cut cell surfaces; with the following characteristics: 1. Flame Spread Index: 25 or less, when tested in accordance with ASTM E84. 2. Smoke Developed Index: 450 or less, when tested in accordance with ASTM E84. 3. Board Size: 48 x 96 inch. 4. Board Thickness: As indicated 45 Specifications to Review Section 07 5300 Elastomeric Membrane Roofing PART 2 PRODUCTS 2.04 INSULATION A. Polyisocyanurate Board Insulation: Rigid cellular foam, complying with ASTM C1289, Type II, Class 2, polymer bonded glass fiber mat both faces and with the following characteristics: 1. Board Thickness: 1.5 inch. 2. Board Edges: Square. 3. Tapered Units: Provide factory-tapered insulation boards fabricated to slope of 1/4 inch per 12 inches unless otherwise indicated. 4. Provide composite boards with oriented strand board laminated to one side in lieu of cover board when required by manufacturer to meet system warranty requirements. 46 Specifications to Review Section 07 7200 Roof Accessories PART 2 PRODUCTS 2.04 INSULATION 2.02 ROOF HATCHES A. Manufacturers - Roof Hatches: 1. Basis-of-Design: Bilco Co., Enhanced Performance E-50T. a. Subject to compliance with the specified requirements, provide the basis-of-design product or a comparable product approved by the Architect, prior to bid. B. Roof Hatches: Factory-assembled steel frame and cover, complete with operating and release hardware. 1. Style: Provide flat metal covers unless otherwise indicated. 2. Mounting: Provide frames and curbs suitable for mounting on corrugated metal roof deck. 3. Size: 36" x 36" 4. Loads: Fabricate roof hatches to withstand 40-lbf/sq. ft. external and 20-lbf/sq. ft. internal loads. C. Frames/Curbs: One-piece curb and frame with integral cap flashing to receive roof flashings; extended bottom flange to suit mounting. 1. Material: Aluminum,.090 inch thick. 2. Insulation: 2 inch thick polyisocyanurate board with R-value of 12. 3. Interior Lid Liner: Manufacturer's standard metal liner of same material and finish as metal curt. 4. Exterior Curb Liner: Manufacturer's standard metal liner of same material and finish as metal curb. 5. Curb Height: 12 inches from surface of roof deck, minimum. 47 48 Specifications to Review Section 08 1113 Aluminum-Framed Entrances and Storefronts 1.02 Performance Requirements A. General Performance: Aluminum-framed systems shall withstand the effects of the following performance requirements without exceeding performance criteria or failure due to defective manufacture, fabrication, installation, or other defects in construction: 1. Movements of supporting structure indicated on Drawings including, but not limited to, story drift and deflection from uniformly distributed and concentrated live loads. 2. Dimensional tolerances of building frame and other adjacent construction. 3. Failure includes the following: a. Deflection exceeding specified limits. b. Thermal stresses transferring to building structure. c. Framing members transferring stresses, including those caused by thermal and structural movements to glazing. d. Noise or vibration created by wind and by thermal and structural movements. e. Loosening or weakening of fasteners, attachments, and other components. f. Failure of operating units. B. Wind Loads: As indicated on Drawings. C. Deflection of Framing Members: 1. Deflection Parallel to Glazing Plane: Limited to L/360 of clear span or 1/8 inch, whichever is smaller. D. Air Infiltration: Provide aluminum-framed systems with maximum air leakage through fixed glazing and framing areas of 0.06 cfm/sq. ft. of fixed wall area when tested according to ASTM E 283 at a minimum static-air-pressure difference of 6.24 lbf/sq. ft. E. Thermal Transmittance Test (Conductive U-Value) 1. Test in accordance with NFRC-102. 2. Conductive thermal transmittance fixed unit assembly (U-Value) shall not be more than 0.37 BTU/hr•ft²•ºF when glazed with 1 inch insulated - 1/4 inch clear low emissivity, 1/2 inch air, 1/4 inch clear glass. 49 Specifications to Review Section 07 4523 Translucent Fiberglass Sandwich Panel PART 2 PRODUCTS 2.04 Panel Construction A. Provide sandwich panels of flat fiberglass reinforced translucent face sheets laminated to a grid core of mechanically interlocking I-beams. The adhesive bonding line shall be straight, cover the entire width of the I-beam and have a neat, sharp edge. 1. Thickness: 2-3/4” 2. Light transmission: 12-15% 3. Solar heat gain coefficient 0.18. 4. Panel U-factor by NFRC certified laboratory: 2-3/4” thermally broken grid 0.14. 5. Complete insulated panel system shall have NFRC certified U-factor of 0.20. 50 Specifications to Review Section 23 0719 HVAC Pipe Insulation Section 22 0719 Pipe Insulation 51 Energy Code Plan Review Standard Details – We can do better! 52 Department of Energy Slab on Grade Details 53 Bad Practice – Non Thermally Broken Slabs 54 Bad Practice – What the? Bad Practice – Parapet Thermal Bridge 57 Bad Practice – Thermal Energy can rise? Bad Practice – Attic Knee Walls - Undetailed Attic Outside Walls 59 60 Building Science Corp’s Perfect Commercial Wall 61 Bad Practice – Missing Insulation 62 Resources www.energycodes.gov ICCSAFE.ORG Buildingscience.org 67 Questions 68 This concludes The American Institute of Architects Continuing Education Systems Course AIA Iowa Contact Information