Big Pond Tanks - hrb hanseatic solutions

advertisement

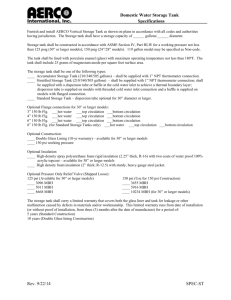

Big Pond Tank Mobile, Reusable Construction/Frac-Water Storage Manufactured to Your Specifications With a smaller site footprint and easier setup/tear down, Big Pond Tank saves you time and manpower, reducing your costs and allowing you to get your site up and running quickly. Additional savings will be realized in permitting, road impact (93% fewer trucks), heating, management and labor. The following capacities are available: • 24,000 bbl with a 125’ diameter footprint plus a 30’ work area • 35,000 bbl with a 150’ diameter footprint plus a 30’ work area • 48,000 bbl with a 175’ diameter footprint plus a 30’ work area *All work areas are outside the tank. Comparison Conventional Frac Tank vs Big Pond Tank Conventional Fracs • • • • • • • • DEQ permitting required in some areas Groundwater study required in some areas Intensive cost of site preparation for belowground pit Berm liner cost and/or reclamation of belowground pit 48-96 truck passes required to move 500-bbl frac tanks to each pad location Expensive heating and management costs of 4896 frac tanks Inspection, repair and corrosion monitoring necessary Approximately 40,000 ft2 required for frac tank water storage Big Pond Tank • • • • • • • • • • DEQ permitting not required in most areas Groundwater study not required Less expensive site preparation No reclamation necessary Easy, quick installation and teardown No more than 5 trucks to mobilize all components of one 35,000-bbl tank Unless temperatures stay below 20˚F, no heating required Simple manifold system; less prone to leak Careful liner installation and inspection should ensure a 99% leak-free tank ~30% less surface area required for this type of storage in lieu of frac tanks Installation & Teardown Timely & Efficient • Experienced crew of 6 people can install a 35,000-bbl tank, including liner, in less than 14 hours • Site prep: a level, compacted sub-base is required under the tank footprint along with a 30-foot work perimeter • Support equipment required for a normal install: telehandlers (JLG), articulated man lifts, scissor lifts, skid steer Specifications & Options Standard tanks are built to the following specifications: Options: • • External Manifold Delete standard 8” manifold Add 10” manifold Add 12” manifold Custom design according to customer spec • • • • • • • • • • 24,000, 35,000, and 48,000 bbl. capacities available 15 to 19 modular panels—12’ tall weighing from 5,500 to 6,600 lb. before paint/insulation Engineered, overlapping connection plates 3”×3” connection lugs with pins 2” foam insulation on exterior of panels; other options available Unique, easy-to-use liner connection clamps Specially designed BPT MobAssistTM for ease of handling panels. Lifting devices designed to fit a 10,000-lb JLG lift or equivalent Four 4” fill pipes One 8” external manifold with butterfly valve and suction manifold Two entry/exit ladders Eight temporary panel support bars Blast/paint, customer color choice Fill / Recirculation Lines Delete standard 4” fill lines Add 6” fill lines Add 8” fill lines custom design according to customer specs Ladder OSHA-approved ingress/regress ladder Lifting Device Additional lifting device(s) available Lifting a segment into place with BPT MobAssistTM (Gen I). Assembling the tank with liner ready for installation. Pad already in place. Tank in background being fitted with final panel; tank in foreground being filled with fresh water from vacuum trailers visible just over top of wall.