File - Kensa Heat Pumps

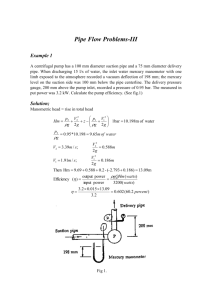

advertisement

Ground Loop Design www.kensaheatpumps.com Horizontal ground loops Heat Sources o Ground provides a highly efficient source of heat o Unaffected by air temperature Collector pipework laid horizontally Requires large land area Cost effective Slinkies Pre coiled pipework laid in trenches Requires large land area, but less digging Cost effective Vertical boreholes Closed loop pipework inserted into vertical hole Typically 100-150m deep o Recharged by solar energy and rainfall Most common in commercial buildings Space efficient o Ground type (thermal conductivity) needs to be factored into sizing calculations Surface water (closed loop) o Important not to over extract – sizing important Extracts ground water from an underground aquifer Efficient Costly o Ideal solution where surface water (eg lake) is available o Extremely efficient and cost effective Open loop Ground Loop Design www.kensaheatpumps.com Table 3 of MIS3005 can be used to help design the ground array in conjunction with MCS022 ground heat exchanger look up tables. www.kensaheatpumps.com 3 Bed Semi detached. From room by room heat losses:Space Peak Heat Load = 5.188 kW (6kW heat pump) Annual Energy load = 11212 kWh/y DHW load = 3438 kW/y Heating System Radiators with a flow temperature of 50C (3 stars) www.kensaheatpumps.com 14650 Kensa Room by room heat loss calculator 6 6 kW heat Pump at a flow temp of 50C 2442 11 1.7 Look up extraction tables www.kensaheatpumps.com www.kensaheatpumps.com 14650 Kensa Room by room heat loss calculator 6 6 kW heat Pump at a flow temp of 50C 2442 11 Southwest 1.7 Wet Clay 44 From MCS 022 www.kensaheatpumps.com 3.4 4235.3 96.25 5 481.3 500 From Heat Emitter Guide www.kensaheatpumps.com Property 2 Bed Detached Property Peak Heat Load 3.5kW Annual Energy Load 6580kWh DHW annual load = 2578kWh Underfloor at a flow temperature of 40C (5 stars) SPF 4.1 www.kensaheatpumps.com 9158 Kensa Room by room heat loss calculator 5.1 4kW heat Pump at a flow temp of 40C 1796 11 Southwest 1.7 Wet Clay 59 From MCS 022 www.kensaheatpumps.com 4.1 From Heat Emitter Guide www.kensaheatpumps.com Maximum Power Extracted from the ground:- [ Box 2] x 1000 x (1- ( 1/[ Box 7])) =5.1 x 1000 x (1-(1/4.1)) = 5.1 x 1000 x (0.756) = 3856 W www.kensaheatpumps.com 4.1 3856 65.36 5 326.8 400 From Heat Emitter Guide Slinkies Myths: You need less land area – FALSE You need less pipe – FALSE They are less efficient – FALSE They are more likely to freeze the ground than straight pipe – FALSE Facts: You need the same land area as a straight pipe collector There require only a fifth of the digging of a straight pipe collector Quicker, easier and more costeffective to install www.kensaheatpumps.com Slinkies Horizontal Slinky Trenches • Horizontally installed slinkies should be placed in a 1.2m wide by 1.2m deep trench. Vertical Slinky Trenches • Vertically installed slinkies should be placed in a 300-400mm wide by 2m deep trench. Separation Distances • Each trench should be separated by a minimum of 5m between centres Energy Absorption • For every 10m of slinky 1kW of energy can be absorbed from the ground. Trench Layout • Trenches do not have to be straight, they can twist and turn as long as the 5m separation distance is maintained. Crossing Services • Insulate about 1m either side of crossing point Unrolling a slinky www.kensaheatpumps.com www.kensaheatpumps.com Manifolds Kensa Supply An optional expansion vessel can be fitted to the slinky pipework. Subterranean manifolds Electrofusion joints 40 -32mm EF joints 63mm to the heat pump Above ground manifolds Compression Joints – Asymmetrical olives Pressure testing the slinkies Pressure test with water (generally safer) Remove all the air Pressure Test to EN805 Section 11.3.3.4 (See manual) www.kensaheatpumps.com Purging the Slinkies www.kensaheatpumps.com Antifreeze samples www.kensaheatpumps.com 2 independent antifreeze samples are required by MCS. Taken from the schrader values an hour apart. Tested using a refractometer and samples returned to Kensa. Beware some refractometers measure concentration some measure freezing temperature 20% concentration or -10C protection Installation of the heat pump www.kensaheatpumps.com Installation of the heat pump Flow to heating system from heat pump 28 mm OD www.kensaheatpumps.com Return from ground 28 mm OD. Connected via ‘L’ connector with a single 50mm Plasson connection termination. ‘Y’ Connector Return from heating system to heat pump. Connected via ‘Y’ connector 28mm OD Speedfit connection termination. Supply to ground 28 mm OD. Connected via ‘F’ connector with a single 50mm Plasson connection termination. ‘L’ Connector ‘F’ Connector Meter Ready Installations Pipe Diameter (mm) Total length of straight pipework required in return pipe (mm) Total length of straight pipework required in the flow pipe (mm) 15 300 175 22 440 175 28 560 175 35 700 175 42 840 175 www.kensaheatpumps.com Electrical Connections www.kensaheatpumps.com Simple diagnostics and fault finding. www.kensaheatpumps.com B readings and settings B01 – Heating Distribution Temperature B02 – Temperature of water returning from the ground arrays B03 – Temperature of water going out to ground arrays B04 – Refrigerant pressure www.kensaheatpumps.com Fault Codes www.kensaheatpumps.com Fault Codes www.kensaheatpumps.com