Bridge over BNSF 7 km East of Windham

advertisement

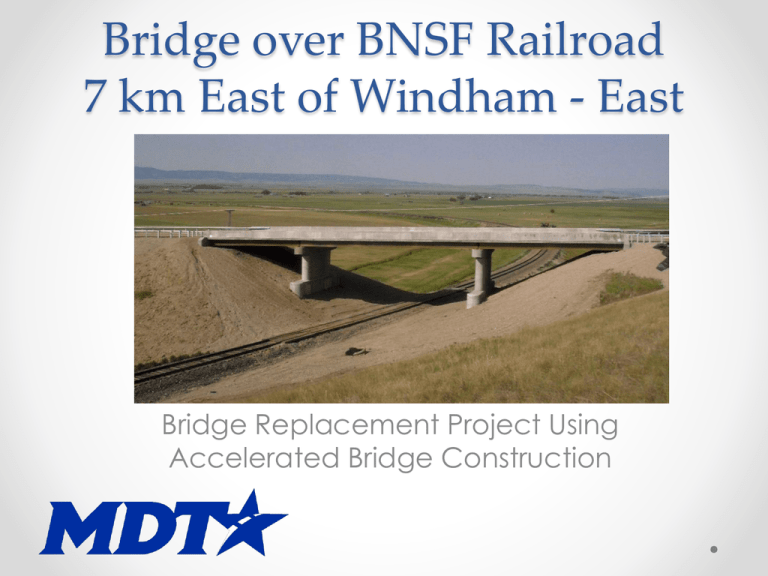

Bridge over BNSF Railroad 7 km East of Windham - East Bridge Replacement Project Using Accelerated Bridge Construction Project Location Existing Bridge o 3-Span Concrete Tee Beam o 123 Feet Long o 28 Feet Wide Approach Looking Southeast Profile Looking Southwest Design Parameters o o o o o o o National Highway Route 2500 vehicles per day (23% Trucks) Major truck route between Great Falls and Billings US Air Force Missile Route Grain Elevator in Moccasin BNSF Railroad Crossing Accident cluster at bridge New Bridge Requirements New width = 40 feet Increased railroad lateral clearance Increased railroad vertical clearance Avoid existing foundations (timber piles) Minimize grade raise to catch slopes on existing approaches – avoid sliver fills and new R\W o Minimize traffic disruptions o o o o o What are our options? o New Bridge on Offset Alignment o New Bridge on same alignment using On-site Detour o New Bridge on same alignment using Phase Construction o New Bridge on same alignment using Off-site detour and ABC Could Accelerated Construction work here?? o How long can we shut down bridge site? o How quickly can we build a new bridge? o How much building can be completed before with existing bridge in place? o Is there a reasonable detour route? Possible detour route o o o o o Secondary Highways – wide shoulders / flat slopes Similar detour length for thru-traffic Detour through town of Hobson – school crossing At-grade RR crossing in Hobson Many local detours possible (County Roads) ABC Planning Efforts o Contacts with o o o o o o o o o o Town of Hobson - Mayor Hobson School County Commissioners Trucking Industry – grain elevator Air Force Base BNSF Railroad Road User Cost Calculations Preliminary ABC Ideas Contract Time Estimates Local Events – Hay Days – Utica Montana What can we accelerate? What portion of construction takes the most time? o Foundation construction – 4 days/shaft or 4 piles/day o Drilled Shaft testing – 14 days before testing / longer if problems are encountered o Forming bent caps – 3 days each o Curing bent caps – 15 days per project o Deck forming – 20 days up to 300 feet o Deck curing and sealing – 28 days Allowing for some overlap……80 days for major items Potential Solutions o Foundations o What can we do while traffic is on existing bridge? o What foundation types will work? o Forming and curing bent caps o What cast-in-place can be done while traffic is on existing bridge? o Precast end and intermediate caps? o Deck forming and curing o Full-depth precast deck panels o Partial-depth o Stay-in-place Forms Divided Work Into Stages o What could be completed before detouring traffic o What would be accelerated while traffic is on detour route o What work could be done after traffic is moved back on new bridge Work Prior to Detouring Traffic Drilled 4 shafts outside the bridge limits and behind the existing intermediate bents. Cast struts/crash wall on top of and between shafts Cast walls on top of struts Day 1 Traffic on Detour o Removed span 2 deck and beams o Removed span 3 deck Day 2 o Removed span 3 beams o Removed bent 3 and 4 o Removed span 1 deck Day 3 o o o o Bent 4 – drove piles, formed and placed cap Bent 3 – Set cap and placed closure Removed span 1 beams Removed bents 1 and 2 Precast Pier Cap Day 4 o Bent 2 – Set cap o Bent 1 – drove piles Day 5 o Bent 2 – placed closure o Bent 4 –formed and placed cap Day 6 o Span 3 – Set girders and deck panels Day 7 o Sunday – no work Day 8 o Span 2 – Set girders and deck panels Day 9 o Span 1 – Set girders and half the deck panels Day 10 o Span 1 – Set remaining deck panels o Began forming closure pours Day 11 o Bents 1 & 4 – Formed and placed backwalls o Formed deck panel closure pours Day 12 o Continued forming deck panel closure pours Day 13 and 14 o Saturday and Sunday – No work Day 15 o Adjusted deck grades o Prepare for deck closure pours Day 16 and 17 o UHPC Closure Pours Day 18 and 19 o Removing form work and grinding joints o Fill low spots Day 20 and 21 o Weekend no bridge work – building approach fills Day 22 o More grinding and approach fills Day 23 o Tying barrier steel o Test run with slip form Day 24 o Approach work Day 25 o Slip formed barriers o Final grading along RR tracks Day 26 and 27 o More grading work o Approach rails Day 28 o Finished approach rails Day 29 o Opened to Traffic One day ahead of schedule (incentive/disincentive deadline) Now lets see that in fast motion Lessons Learned Project scheduling was intensive Design details are critical – things need to fit Allow adequate tolerance on precast elements UHPC is difficult to grind – reduce exposed area to minimize grinding o Have an Engineer on site during construction of critical elements – be prepared to make decisions o o o o Questions?? Project Contact: Jeff Olsen jolsen@mt.gov 406-444-7610