Assessing Risk

advertisement

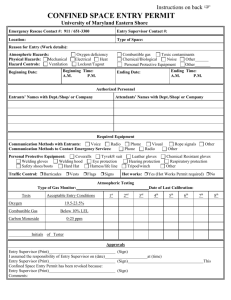

Assessing Risks and other Safe Systems Of Work Southampton 6th November 2014 SCOTT WARD My name is Scott WARD Working In the marine industry 25 years 8 years deep sea on container vessels, 15 years on Voith / ASD tugs Started my sea going career as a deckhand working my way up to Master Came ashore in 2012 to further a career in health and safety, after being part of a local safety committee for over ten years Graduate member of IOSH and now working towards full chartered membership Would like to ask a question What is the most important working component on board your tug ? Is it the towing winch ? A tug without a winch is surely just a boat ? The most important working component on board your tug ? Is YOU………. We are all unique, loved by family and friends We need to always safeguard ourselves against dangers. I do not want to stand here, preaching to You We all know how important safety is……. We all have stories we could share I want to spend this time refreshing, what You already know. I want to talk about: Risk Assessments Hierarchy of Risk control Permit to work Come on You must be getting excited now http://www.youtube.com/watch?v=3jLGkmOVtnI Risk Assessment A risk assessment is basically looking at the job before you start. Identifying all the hazards and who is at risk and by how much. Then putting actions in place to safeguard everyone. We all do this throughout the day……. When we cross the road When we get in the car When we tell our partner we are going to the pub and unsure when we will return (high risk) Key words in risk assessment are : A HAZARD is something that has the potential to cause harm. RISK is the chance, high or low, that somebody could be harmed by these and other hazards, together with the severity outcome. ALARP - As low as reasonably practicable; means weighing a risk against the trouble, time and money needed to control it to an acceptable level. RISK RATING this is the combination of Liklihood multiplied By actual severity CONTROL MEASURE is what we put in place to reduce the risks to an acceptable level. Once you have identified hazards, you need to put control measures in place to reduce these to an acceptable level Risk assessments need to carried out by law, all formal written risk assessments need to be reviewed Everyone should be involved when carrying out the risk assessments, (safety committee members) A fresh pair / unexperienced eyes can see the tasks completely different and should be respected……… For example during a towing job hazards could be: (These are all high risk hazards with a high potential) Speed - assisted vessel proceeding at a unsafe high speed when making fast Interaction – assisted vessel propeller wash may draw tug under the stern quarter Restricted visibility - dense fog, tug cannot visually see assisted vessel or direction of their towing gear Dangerous heaving line – when making fast, container twist locks used instead of monkeys fists Loss of water tight integrity – door left open on the main deck. Complacency - repeated operations over a long period of time, reducing risk perception during critical manoeuvres Unfamiliarised Tug Crew - not fully aware of the tugs limits and capabilities Collision – between tug and other vessels operating in the area Control measures in place to reduce risks Speed - safe speed agreed between the Pilot/ Master before towage operation Interaction – good communications maintained throughout the operations, warnings of all controlled engine movements Restricted visibility – clear operating limits defined in Company procedures Dangerous heaving line – Tug crew stand clear of working area, better education still required for ships crews to further reduce Open water tight door – use of open door alarm / indicating systems on board Complacency - keeping focused, sharing of ideas at industry forums. Unfamiliarised Tug Crew – correct training / appraisal forms carried out to overcome this Collision – competent professionally trained Masters / crews operating on our tugs. RA Template - pilot.xlsm http://www.youtube.com/watch?v=UeB7l_O8T6o Hierarchy of controlling risks Hierarchy of risk control Elimination - physically remove it, this is the most effective hazard control. For example: An AB must climb on to the monkey island to replace a navigation bulb; move the navigation light to the bridge deck, eliminating the need to climb. Substitution - second most effective hazard control, involves replacing something that produces a hazard (similar to elimination) with something that does not produce a hazard. For example: Companies stopped Manufacturing lead based paints and started producing acrylic based paints Engineered controls - third most effective means of controlling hazards is engineered controls. These do not eliminate hazards, but rather isolate people from hazards. For Example: Building a scaffolding platform around a radar during repair. Better hazard control than working aloft with a safety harness Administrative controls - Do not remove hazards, but limit or prevent people's exposure to the hazards. For Example: Completing road construction at night when fewer people are driving , employee training, and installation of signs and warning labels Hierarchy of risk control Personal protective equipment - is the least effective means of controlling hazards because of the high potential for damage to render PPE ineffective. For Example: Wearing a safety helmet and high visibility jacket when moving around in port areas What is a Permit to Work “A permit to work system is a formal safety control system designed to help prevent accidental injury to personnel, damage to plant, premises and product. A Permit to work is a Systematic formal checklist It helps reduces human errors (missing something) Would like to share a story with you all…. Examples of where a permit is required • Work in Unmanned Machinery Spaces • Entry into Enclosed or Confined Space • Machinery or Equipment • Hot Work • Working Aloft/ Overside • General Electrical (Under 1000 Volts) • Electrical High Voltage (Over 1000 Volts) Permit should be relevant and as accurate as possible, stating the location and details of the work Permit should specify the time period (not exceeding 24 hours) Only the work specified on the permit should be undertaken. Authorising officer retains responsible for the work until he has, either cancelled the permit or formally transferred it to another authorised person Person responsible for carrying out the specified work should counter sign the permit to indicate his understanding of the safety precautions to be observed. On completion of the work, the responsible officer needs to close out the work permit Person carrying out the specified work should not be the same, person as the authorising officer. Guidance can be found at: https://www.gov.uk/government/organisations/mari time-and-coastguard-agency http://www.hse.gov.uk/ https://www.gov.uk/government/publications/codeof-safe-working-practices-for-merchant-seamencoswp http://www.youtube.com/watch?v=AO01FcuWtxs Thank You For your time Any Questions? Scott.ward@svitzer.com Tel 07776494963