How close is your

company to Spend

Management Best

Practices?

Ariba Consulting

August 2011

© 2011 Ariba, Inc., All Rights Reserved. The contents of this document are confidential and proprietary information of Ariba, Inc.

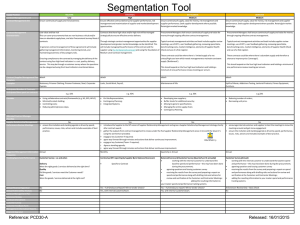

How close is your company to P2P Best Practices?

Traditional/Base line

Advanced

Best In Class

P2P processes for

spending and payment

No formal written P2P

processes.

Written P2P processes, but often not

followed by users or groups.

Electronic P2P policies are followed by all

groups and regions.

End user training

No formal training or only

done occasional.

Written manuals used to train new users.

Written, class room, and/or WBT (Web

Based Training)

Pre-spending approval

(PO/Contract)

Users can often order what

they want without a

PO/Contract.

Have PO/Contract process, but users

often do not use them (often claiming

“need now”” or “one time buy” as reason

for no PO/Contract).

All spending is pre-approved via

PO/Contract or uses an approved

exception process.

Approval workflow

Purchasing approvals are

manual.

Purchasing approvals are static electronic,

but are often not followed or Approvers do

not approve quickly.

Purchasing approvals are dynamic

electronic, with automated escalations to

support quick approvals.

PO/Contract execution

(signatures) and

transmission method

Original documents are

manually signed (wet

signature) and mailed.

Original or faxed documents are

manually signed and mailed, faxed, or

emailed.

Documents are electronically signed and

transmitted via EDI or Internet.

Invoice creation and

transmission method

Supplier creates invoice and

sends via mail.

Company creates invoice created from

PO/Contract

Supplier creates invoice from PO/Contract

and sends via EDI or Internet.

Invoices approvals and

supplier updates

Invoices are manually

matched (either 2 or 3 way

match). Supplier frequently

calls A/P for updates.

Some invoices are electronically auto

matched, but many are manually match.

Supplier often calls A/P

All invoices are auto matched. Minimal

creation of “after the fact” invoices.

Frequent use of Invoices created directly

from Contracts. Supplier gets updates

electronically, so seldom calls A/P.

Early pay discounts

Never take early pay payment

discounts (often since

approvals are too slow)

Take some early pay discounts, but

manual process limits use.

Electronic processes for approval and

discounting allows dynamic use of early

pay discounts

Payments

Payments by check.

Payment by check and purchasing

cards (Pcards).

Heavy use of electronic payments

(Pcards, Electronic Funds Transfer [EFT]).

Reporting

Reports are missing key P2P

information and are not

considered useful.

Reports have more information, but

users still need outside help to run key

reports. Few exception reports.

Automated reporting that highlights

exceptions. Reports can be run and

modified by users without outside help.

© 2011 Ariba, Inc., All Rights Reserved. The contents of this document are confidential and proprietary information of Ariba, Inc..

How close is your company to Contracts Best Practices?

Traditional/Base line

Advanced

Best In Class

No formal written contracts

processes, thus often use “third

party paper” instead of your own

contract Word file.

Have written contracts processes, but often

not followed by users or groups, and often

still use “third party paper”.

Have electronic contracts policies (with

checklist/tasks) that are followed by all groups

and regions. But still may have to use “third

party paper”.

End user training

No formal training or only done

occasionally.

Written documents (like Quick Reference

Guides) to train new users.

Written, class room, and/or WBT (Web Based

Training) are used for new users.

Types of contracts

electronically supported

No electronic contract system for

any type of contract (Buy side or

Sell side or Misc (like NDA)

Electronic contract system for at least one

type of contract.

Electronic contract system for all types of

contracts.

Approval workflow

Contract approvals are manually

done by paper signatures.

Contract approvals are static electronic, but

are often not followed or Approvers do not

approve quickly.

Contract approvals are dynamic electronic,

with clause level approvals, with automated

escalations if approvals are delayed..

Contract execution

(signatures) and

transmission method

Original documents are manually

signed (wet signature) and

mailed.

Original or faxed documents are manually

signed and mailed, faxed, or emailed.

Documents are electronically signed and

electronically transmitted.

Contract template (Word

file) used to create

contracts and for the

amendment process

Separate Word file used for

different contract types, with

manual Word file update of each

different Word file.

Correct Word files is electronically selected

for use with different contract types, with

manual Word file update of each different

Word file.

Correct Word file is electronically selected for

the correct contact type. Contract template

Word files are electronically mass updated for

common changes (via clause library)

Invoices for

goods/services covered

by contracts

Invoices are manually created

and mailed to your company.

Some invoices are created electronically

from the contract to reduce invoice errors.

Many invoices are created from contract by

suppliers/customers and electronically sent for

auto matching to contract before payment.

How is legal team

involved for contract

changes/edits

Legal team called for all changes

for all contacts (no pre-approved

alternate clauses used).

Legal team advice is in contract Word file

(must remove before executing) or in

associated separate document. Legal team

often called for routine changes. Use

common clauses in Word files.

Legal team advice is accessible from the

contract Word file but not part of the Word file.

Standard pre-approved alternate clauses

available so legal team only called for unusual

edits or situations.

Integration

Contracts software is stand alone.

Share contract base data (suppliers, users,

categories, etc) with other software system.

Contracts software integrated to other software

for base data, sourcing, procurement,

compliance, payment, etc.

Contract storage,

searching, reminders and

metrics.

Paper contracts stored in file

cabinets, and must be manually

searched. No electronic

reminders nor contract metrics.

Electronic storage, with electronic searching

of header data and electronic reminders of

upcoming contract expiration. Some

contract metrics.

Electronic storage, with electronic searching of

header data and document free text searching,

with electronic reminders of multiple events

(such as expiring certifications or contract

renewals). Use contract metrics.

Contract processes

(including editing and

amendments)

© 2011 Ariba, Inc., All Rights Reserved. The contents of this document are confidential and proprietary information of Ariba, Inc..

How close is your company to Sourcing Best Practices?

Traditional/Baseline

Advanced

Best In Class

Sourcing Process

No documented sourcing process

in place.

A sourcing process exists 65% of time,

however it is only partially in use, partially

automated and has limited visibility.

Fully documented sourcing process has been

agreed upon business-wide and is being used

across the organization 100% of the time.

Pipeline Planning/Knowledge

Management/Spend Under

Management

•Adhoc/reactive sourcing, no

strategic targets or goals

•Less than 40% of spend under

managed structure

•A list of projects exist, but without a

measured goals or strategic plan for

execution

•Over 40% spend under management by

sourcing teams

•Pipeline is established with targets, goals,

scheduled progress reviews and tracking via ESourcing tool

•About 75% of spend under management by

sourcing teams

Supplier Selection/

Performance

No certification/ framework/

structured research

A process, however with limited qualification

criteria, exists but is not always applied

A formal identification/certification process and

performance metrics exist, with minimum

requirements for various levels of spend

Data Collection/Quality

Consolidated spend data is not

available.

•Data can be extracted at the

Invoice/Purchase Order level with limited

descriptions of goods and services.

•Historic documentation exists but is not

centrally organized

•Consolidated data can be extracted including

Purchase Orders, requisitions, invoices, contracts,

sourcing projects, supplier performance metrics or

scorecards etc.

•Documents and Project Data are kept in one tool

available to teams for reference

Historical Spend/

Savings Goals

Limited/no data available, no

defined metrics

Historical/baseline spend is established.

Some documented definitions of savings

measurements

•Detailed process of agreeing upon baseline spend

and savings measurements, approved by Finance

and used as a metric for defining various approval

requirements in process.

•Average savings per event usually 2-3% higher

when processes/goals are in place.

Contracts

No integration/data sharing

Draft Contracts are sent out with RFP/RFQ,

but not no online link between the two

Data is shared between Sourcing Initiatives and the

Contract Repository in one software application to

enable contract lifecycle mgmt and compliance

*** Percentages reference Aberdeen Group 02.2007and 05.2008***

© 2011 Ariba, Inc., All Rights Reserved. The contents of this document are confidential and proprietary information of Ariba, Inc..

How close is your company to Sourcing Best Practices

continued…..

Traditional/Baseline

Advanced

Best in Class

Reporting

All reports are manually compiled

Limited data can be extracted from current

process/ application

All data can be extracted, pre-scheduled and

auto-emailed standard and custom reporting

E-Sourcing/

Technology

The process is entirely manual

Limited use (about 16% of spend) of an

online system which supports RFPs with

attachments and few Auctions, and limited

reporting.

•A sophisticated E-Sourcing tool is in place,

allowing online collaboration (internal & external),

multi-stage events, project management,

optimization, supplier scoring, with full export and

reporting capabilities.

•At least 30% of all sourcing initiatives are lead

via e-sourcing tool.

End user training

No formal training or only done

occasional.

Written manuals used to train new users in

system use.

Written, class room, and/or WBT (Web Based

Training) for e-Sourcing as well as industry

related skills training, change management

Integration

Entirely Manual

Some complementary technologies in place

Extended strategic sourcing footprint including

Spend Analysis, E-Sourcing, Contracts, as well

as external ERP, Legacy and PLM systems

*** Percentages reference Aberdeen Group 02.2007and 05.2008***

© 2011 Ariba, Inc., All Rights Reserved. The contents of this document are confidential and proprietary information of Ariba, Inc..

How close is your company to Spend Visibility Best

Practices?

Traditional/Base line

Advanced

Best In Class

Spend Visibility processes

No standard spend analysis program

or process

Manual processes for spend reports

Spend analysis projects executed on

ad hoc basis

Spend not visible/shared across

divisions, regions

Data housed at factory/site level, in

filing cabinets, desk drawers, etc.

40% of organization has a formal spend analysis

program

Semi-repeatable process for Spend Analysis

Some spend data cleansing and classification by

select groups

Spending analysis executed as part of sourcing

process

100% of organization has a formal spend analysis

program

Automation of spend analysis processes

Spending analysis projects part of sourcing,

compliance, budget, and other business processes

Standard spend data cleansing and classification

companywide

Dashboards created and maintained with

automated spend data

End user training

No formal training, as no

process/program exists

Written manuals used to train new users

Some ad hoc training, possibly limited power

user training

Written manuals, Class room and/or WBT (Web

Based Training) are used for new users

Refresh training on-demand

Go to power users for additional support

Types of spend visibility

systems

Spend data gathered manually from

a select sub-set of

financial/ERP/MRP systems

Data validation, cleansing, and

classification handled manually, as

needed, in a once-and-done manner

Spend data gathered from financial and

transactional systems using mix of manual and

flat file methods

Manual data cleansing and classification; some

internally developed formulas and routines

Highly automated spend data extraction, cleansing,

and classification

Advanced analysis and reporting capabilities

Rules created and implemented to further automate

enrichment process

Regular data refreshes for close-to-current

analytics

Knowledge Areas within the

organization

Spend analysis focus on a select

group of commodities

Spend data classified at a high level,

providing only summary information

No data refinement

Data collected to look at specific

opportunity, does not provide visibility

to identify opportunities

Spend analysis applied to largest spend only

Spend data classified at supplier level, little to no

parent/child analytics

Basic data refinement

Spend data classified at the item/invoice level,

comparisons of attributes across suppliers and

commodities

Data refined with contract, supplier, and part

information

Supplier enrichment

No supplier enrichment component

included in spend analysis

deliverables

Minimal supplier enrichment available

(normalized supplier names) but provided from a

third party and not integrated

Supplier enrichment wide and diverse including

parentage, financial info, risk scores, diversity

certificates, etc., and fully integrated and leverage in

commodity classifications

Market insight

Market insight not included in spend

analysis

Publicly available price indices assist in

identifying opportunities

Price indices, sourcing market knowledge, and

peer benchmarking information all available in order

to identify and prioritize opportunities

Sourcing pipeline building

strategy

Sourcing pipeline driven primarily by

expiring contracts

Sourcing pipeline consists of known categories

that are strategically managed

Sourcing pipeline managed through holistic spend

analysis of spend vs. market dynamics to constantly

identify new categories for sourcing as well as those

expiring and up for renewal

© 2011 Ariba, Inc., All Rights Reserved. The contents of this document are confidential and proprietary information of Ariba, Inc..

How close is your company to Spend Visibility Best

Practices? continued..

Traditional/Base line

Advanced

Best In Class

Compliance monitoring

No formalized way to monitor

compliance against approved suppliers,

contracts, etc.

Compliance monitoring possible only for spend

through procurement systems

Via spend analysis, all spend is subject to

compliance monitoring

Approval workflow

Spend data analysis approvals are

manually done by reviewing of paper

POs/Invoices

Spend data not normalized / classified

and in disparate systems

Designed manual collaborative process

to collect data in a repeatable manner

Ad hoc reporting

Semi-manual approval process of spend data

analysis via fax/email

Electronic approvals of spend data analysis done

via the formal/established spend analysis program

Automated refinement rules approval flow

Spend data storage,

collection, reporting and

transmission

Spend data not normalized / classified

and in disparate systems

Designed manual collaborative process

to collect data in a repeatable manner

Ad hoc reporting

<30% of spend data aggregated,

classified, and analyzed regularly

•Spend data aggregated in data warehouse but

with not normalized / classified

•*Designed established standard process for data

integration and enhancement

•Compliance reporting done on a quarterly basis

and ad hoc reporting for planning

•Custom mapping done to increase adoption

•Ad hoc data refinement done to increase

ownership of spend

Spend data aggregated and classified with

additional enrichment to add value / insight

>75% of ERP loads are on time and complete

Automated reporting presented on user

dashboards *Annual sourcing planning is driven by

enriched data *70-80%% of team members actively

participate in data refinement

Performance metrics

<30% of spend data aggregated,

classified, and analyzed regularly

<60% of spend data aggregated, classified, and

analyzed regularly

>85% of spend data aggregated, classified, and

analyzed regularly

© 2011 Ariba, Inc., All Rights Reserved. The contents of this document are confidential and proprietary information of Ariba, Inc..

How close is your company to Supplier Management Best Practices?

Program Metrics

Laggards

Industry Norm

(49% of businesses)

(36% of businesses)

Best In Class

(15% of businesses)

Have no programs or processes in place, Have programs in place, have seen some

and are significantly behind industry

improvement (at <20%); generally

norm

measure <25% of suppliers

Have seen supplier performance

improve more than 20% since they

launched their program; measure well

over 25% of suppliers

Documented in shared project

folders/online; supporting data saved

each quarter, along with

comprehensive action plans to review

the following quarter.

Documentation

Documentation does not exist.

Saved in personal folders or shared drives

Lack of organized data or quarterly

performance plans.

Reporting & Charts

No reports exist, due to lack of

quantitative data

Reporting & trending are manual if it

exists; occurs only when users input their

information into a master database.

Reports populate based on userdefined KPIs; charts populate after

each review period & used to

graphically track performance.

Standardization across

groups/divisions

No standardization exists

Individual buyers have their own review

process.

Little to no standardization exists

Individual users may use standardized

scorecards, but have individual review

processes.

Pre-configured templates & processes

in place for various commodities

Allows for standardization &

repeatability

End user training

No formal training or only done

occasionally.

Written manuals used to train users, or

Written and/or WBT (Web Based

user is given a scorecard & told to fill it out.

Training) are used for new users.

Integration

No integration with other systems exist.

No integration with other systems exist;

data may be gathered manually from an

ERP system.

Integrated with sourcing software.

Supplier Information

Management

No onboarding process exists

Information gathered during RFI phases

stored on local and/or shared drives

Onboarding process exists; information is

collected & saved in paper format and/or

on a shared drive

Not indexed, so not searchable

Online onboarding process

Automated systems in place to capture

& report supplier information, diversity

information

Certificate expiration & document

management automated.

Supply Risk Management

Key metrics unmonitored; supplier

information found out through public

resources; IE, news.

Key financial metrics collected & tallied

Process in place as part of SPM to monitor

for a Risk scorecard.

key metrics; uses supplier performance as

Metrics gathered through subscriptionmetrics for risk, as financial information is

based resources in order to form

unavailable

holistic picture.

© 2011 Ariba, Inc., All Rights Reserved. The contents of this document are confidential and proprietary information of Ariba, Inc..

How close is your company to Performance Management Best Practices?

Laggards

Industry Norm

Best In Class

(49% of businesses)

(36% of businesses)

(15% of businesses)

Supplier Performance

Management

No process in place

Basic process with quantitative metrics &

yearly scorecards

Advanced, automated process with

quarterly reviews, quantitative &

qualitative measurements from surveys,

scorecards, & reports

SPM Publication Process

No formal publication processes in

place.

Relies on emailing suppliers; oftentimes

no surveys are published, so no

publication process in place.

Automated task lists clone & create new

scorecards on a quarterly basis;

publication takes minutes.

Cycle Time/Review Period

Yearly if at all.

Yearly except for riskiest suppliers

Quarterly

Scorecard Review Sessions

Account reviews are not guided by

quantitative metrics, as there is no

internal way to track the information

effectively.

Held in person or via teleconference.

Supplier receives scorecard during review

session.

Meetings for data validation rather than

corrective actions.

Live meetings. Supplier receives &

reviews scorecard prior to session, so

meeting can focus on constructive

dialogue & improvement plans.

Key Performance Indicators

Do not exist, except possibly from ERP

reports. (IE - Defective rate, on-time

delivery)

Quantitative metrics tabulated in an ERP

system, such as defective rate, on-time

delivery, & cost savings.

Other KPIs, if they exist, are yes/no

questions.

Comprehensive quantitative & objective

metrics, including ERP metrics, plus

survey metrics such as account

management from members of

organization

KPI Values

Do not exist

Quantitative measurements on a 0-100

scale

Qualitative measurements, if they exist,

are yes/no format.

Rigorous, multiple choice values for all

KPIs, with full customization of

responses, enables granular detail

# of Survey Respondents

Zero

Typically less than three

10+, accounting for divisions within

organization (IE, engineering, finance,

sourcing, cust. Service, etc.)

No automation.

Surveys, scorecards, & quarterly folders

automatically created from master copies

each quarter

Survey scores automatically average &

populate scorecards.

Automation

No automation

© 2011 Ariba, Inc., All Rights Reserved. The contents of this document are confidential and proprietary information of Ariba, Inc..