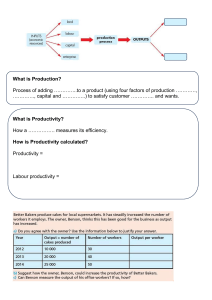

MANAGE LABOUR INTENSIVE CONSTRUCTION PROJECTS NQF Level 5 INTRODUCTION 1 INSTRUCTIONS CHECK THAT YOU HAVE RECEIVED EVERYTHING FOR THIS ON-LINE COURSE: • Portfolio of Evidence (PoE) • Learner Guide LIC 5 Manage LIC Projects • Assessments for PoE for LIC 5 • Presentations LIC 5 (folder with presentations for each of 5 specific outcomes) Copy these files to your computer INTRODUCTION TO LIC 5 • For Administrative questions, phone on 011 781 6222, • Your Facilitator will be Wim van Steenderen, a retired Civil Engineer. • To contact him use E-mail please, giving your full name and the course dates allocated: wim.van.steenderen@gmail.com and he will answer within a day or so. MANAGE LABOUR INTENSIVE CONSTRUCTION PROJECTS UNIT STANDARD 15162 SPECIFIC OUTCOME 1: DEMONSTRATE AN UNDERSTANDING OF LABOUR INTENSIVE CONSTRUCTION DOCUMENTATION 1.1 LIC PRINCIPLES DEFINITION of labour-intensive construction Modern Labour-intensive construction (and maintenance) is the economically efficient employment of as great a proportion of labour as is technically feasible to produce as high a standard of construction as demanded by the specification and allowed by the funding available. Modern labourintensive construction results in the generation of a significant increase in employment opportunities per unit of expenditure by comparison with conventional capital-intensive methods Explanation of terms • Economically efficient means that LIC optimises the labour content of a project; • Technical feasibility depends the demands of the specification and on innovative construction methods; • Significant increase is a three- to seven-fold increase in employment. • In summary: the labour content has been optimised and is generally between 30% and 70% of project costs. Percentage construction costs to labour: • Conventional machine-intensive construction: < 10% (mostly skilled) • Labour-enhanced construction: 15% to 20% • Labour intensive construction: 30% to 65% • Labour extensive: up to 100% but no product worth having CONVENTIONAL: BACK-ACTOR TRENCHING LIC: TRENCHING FOR WATER MAINS Reasons for using LIC methods • Unemployment • Housing and public works needed – opportunity for LIC if funding is available for training and development • Individual and community capacity – improve skills via LIC by training and practice • Alternatives? Appropriate or intermediate technology, but note huge gap between “no technology” and “intermediate technology” More reasons for using LIC methods • LIC projects usually have less environmental impact – smaller footprint • Local people are trained and hence can be employed in maintenance • Labour-intensive methods are feasible for a wide range of construction activities [see “Interim Guidelines” page 20] Caution LIC does NOT work for: • • • heavy compaction long distance transport use of noxious or poisonous substances Public Works Objectives • Employment and income for the poor • Use of training to provide long-term work opportunities • Shift the focus of construction towards LIC • Promote involvement of local communities • Optimise use of local resources • Develop manufacturing capacity in private sector • Impart skills through training Experience • In Botswana, Kenya, Lesotho and Malawi up to 1993: over 200 000 person-years of employment were created and over 15 000 km rural road constructed. Note that Botswana, Kenya and Lesotho all established LIC Training Centres, while Malawi used Kisii (Kenya). • Kenya and Botswana both established long term programmes within which the LIC work took place. The programmes allowed strong organisations to be set up. EXPERIENCE continued • In South Africa up to 2017 some projects were successful but many were not. Experience of the EPWP with a few exceptions was not even in the labour-enhanced category. Note that no LIC Training Centre has been established in SA. • All the LIC works in South Africa have been organised and managed as independent projects. No carry-over has ever been possible. Because there was no continuity, any training that might have been given was therefore lost Design of LIC works • NOTE THAT THE CONSTRUCTION METHOD IS THE “DESIGN DRIVER” • For conventional construction, machine accessibility is always in the designer’s thinking. • Similarly, for labour-intensive construction, the feasibility of construction by labour must always be in the designer’s thinking. Innovative designs are sometimes needed in order to make the design labour-friendly. Economic efficiency Labour-intensive construction methods maximise use of unskilled labour and minimise use of capital equipment to build works at speed, quality and cost comparable with those of other methods. • Productivity, when labour is working on task- or piecework is considerably higher than when working on a day work basis. • Individual or group tasks are preferred. • Not all work can be tasked! • Problems of managing large numbers of labourers can only be solved by training the supervisors at all levels (which takes time) and • By reaching agreement with all parties (Client, Consultant, Community, Trades Unions, etc) concerning all aspects of the project. • When productivity is low, work studies and innovative methods should be applied. 1.2 LIC CONTRACT DOCUMENTS Contract documents comprise all the papers, specifications and drawings that describe a construction contract. Note that all tenders issued by public bodies must conform to the requirements laid down in the CIDB “Standard for Uniformity in Construction Procurement”, May 2010. Types of specification: end-result; method; standardised; particular. Method Specification This specification lays down the method that the Contractor must follow to produce the work to the required standard; no additional testing is needed. Note that the Contractor may be “in breach of contract” if he does not follow the method exactly! End Result Specification This specification lays down the quality requirements of the work without saying how it should be achieved. This gives the experienced contractor room to use his experience to achieve the final product however he feels best. No limitations are set on the methods or equipment that the contractor might use. Extensive quality testing is normally needed. Standardised Specifications are broad specifications that so cover a particular class of construction that they are applicable throughout the country. • Note that these specifications do not give project-specific information and so are inadequate on their own. • Examples are SABS 1200 and the COLTO Road and Bridges Specification Particular Specifications These are specifications specially written for the Project because no standardised specification covering the subject exists Types of contract • Employer appoints a design consultant • Employer appoints contractor: – Conventional contractor who constructs the Works; may use sub-contractors – Managing contractor who sub-contracts the work and manages and supports the subcontractors – Employer may engage and manage labour directly Specifications and Drawings LIC specifications are at present being drawn up by SANRAL and are planned to be issued as part of the updated COTO Road and Bridge Specification. Drawings should be made specifically for LIC – simple and easy to use. The site plan should be drawn on an orthophoto map. Photographs, with dimensions added, can be used as detail drawings; alternatively perspective sketches are useful. Contract Follow-Up • As-built drawings are essential, particularly for buried services. • As-built drawings record all construction changes and make final measurement and payment easier. 1.3 PROJECT SYSTEMS • Expanded Public Works Projects must adhere to the EPWP Guidelines. This includes the Client, the Consultant and the Contractor. • LIC qualifications are required by EPWP. • Training of the labour force must be arranged. • Recruitment of the labour must conform to the contract conditions. • Certain records must be kept and submitted. • Local resources should be used. Training • Training may be a contractual requirement. • Such training will be fully specified (check the contract document) • In any case, the Contractor will use local labour and they must be trained in order to be able to do their work. • Training must be given early and should be followed by practical application of the skills learned. Local Resources Use of local resources will increase the wages left in the community. • What local materials are there? • sand from river or borrow pit • stone for masonry or drainage works Can local manufacture be encouraged? • precast concrete products • window frames 1.4 THE ROLE AND PARTICIPATION OF LOCAL COMMUNITIES "Community participation" is an active process during which individuals, groups and organisations have the opportunity to be involved in and to influence the direction and the execution of development projects. 1.4.1 Community Participation • The aims of community participation are towards improving project efficiency and effectiveness, empowerment and building beneficiary capacity. • Community participation should start soon after project concept, should help to mould the concept and should continue to be involved in all decisions throughout the project process. • Good communication is essential, eg regular workshops 1.4.2 The Steering Committee Before the contract starts the Steering Committee should be chosen • Duties are: • advise the Contractor on communal affairs • public relations and communications • help set out employment conditions • labour relations Liaison Officer links Contractor to Steering Committee. 1.4.3 SUMMARY • Community participation is started by the Client and is continued by the Contractor who normally appoints a Liaison Officer to be the full-time intermediary. • Dispute resolution system must be created at start of construction contract and is run jointly by the community Steering Committee and the Contractor. • Regular information meetings are needed to keep the community informed of progress. 1.5 THE CONCEPT AND IMPLEMENTATION OF INTEGRATED ENVIRONMENTAL MANAGEMENT • Management of our environmental resources is essential to ensure sustainable human progress and human survival • In particular, environmental management is about how to manage and reduce the adverse construction impacts on the environment 1.5.1 Environmental Management of a construction site • The specification will state what precautions the Contractor must take to protect the environment from construction-related problems. • Strict control by the Contractor is needed for fire, oil spills, chemical spills, disposal of waste, soil erosion, invader plants, noise, etc, etc. • Note that the environmental impact from a labour-intensive construction site is normally much less that from a conventional construction site. 1.5.2 Practical Application Of Conservation Principles • Some of the environmental impacts due to road construction are: • destruction of natural vegetation, disturbance of the drainage patterns, visual impact of borrow pits, dust, noise, air pollution from engine exhausts, pollution of the soil by oil and fuel spillage, creation of temporary construction jobs. Practical Applications continued Some of the long-term environmental impacts of the roadway are: • disturbance of the drainage patterns leading to soil erosion, visual impact of borrow pits, traffic induced dust, noise and air pollution, safety hazard of traffic to the community, improved access to the community and by the community to shops, clinics and schools, possibly a few long-term jobs in road maintenance. Conclusions • The DESIGNER must see that the alignment of the road will minimise the adverse impacts upon the natural drainage patterns and visible scarring upon the land surface. • During the design and the construction of the roadway, much care must be taken of potential soil erosion problems. • The CONTRACTOR must finish off the borrow pits, spread topsoil across the road slopes and plant them with local vegetation.