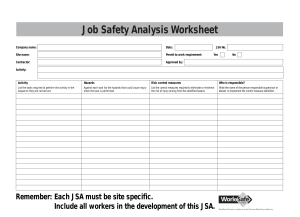

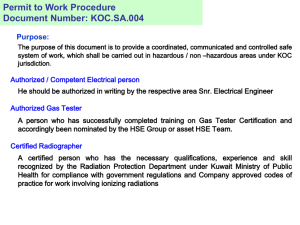

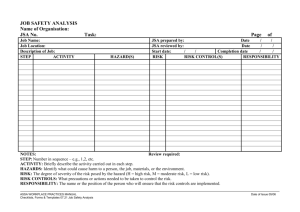

Job Safety Analysis Sheet JOB DESCRIPTION: Heat Treatment of a Pipe Spool JSA Ref. No. JSA / KOC / 30 Facility: Permit No. Date: Work Area / Equipment: PERSONAL PROTECTIVE EQUIPMENT & TOOLS: Hard Hat, Safety Shoes, Safety Goggles, Hand Gloves, Coverall, Heat Tracing, Temperature gauge, etc. SEQUENCE OF BASIC JOB STEPS POTENTIAL HAZARDS Non – compliance of KOC F & S Regulations and HSE MS Procedures Planning Unauthorized Personnel Presence of Flammable / Toxic vapor Yes / No PRECAUTIONS Refer HSEMS Procedures - Doc. No. SA.KOC.004 “Permit to Work” and Appendix - 10 “Electrical Work Safety” of KOC F & S Regulations. Obtain a Hot Work Permit & other associated permits from Asset Owner. Conduct Tool Box Talk. Barricade the area where Heat Treatment is to be carried out. Post warning notice. Ensure the area where heat treatment will take place is free from flammable / toxic vapor. Ensure the equipment / tool to be used for Heat Treatment (such as Heat Tracings, Cables, terminals, switches and panel etc) are free from defect and suitable for the temperature ratings of the system. Ensure proper insulation of heat tracing coil and terminals. Keep the area dry ensuring no water spillage. Do not bring any flammable liquid or gas at the location where heat treatment is under progress. Keep the fire extinguishers in ready condition. Do not touch the pipe segment which is being heat treated. Do not leave the tool or equipment in energized condition when the heat treatment is in progress. Isolate power to the equipment when not in use. Do not change (exceed / decrease) the Temperature or duration of heat treatment without permission from Inspection Engineer. Monitor the temperature in the heat treatment panel. Do not apply rapid heating or cooling of the pipe segment. Refer Heat Treatment Procedure or Contact Inspection Engineer in case of doubt. Ensure proper wind up & housekeeping at worksite. The accessories (heat tracing, cables, terminals) not being used must be disconnected and stored separately. Defective Tools / Equipment Electrical Shock Fire Burn Heat Treatment Un-attended Tool / Equipment Changing the Temperature or Duration of Heat Treatment Thermal Shock to Pipe Segment Windup & Housekeeping Scattered Material Additional Hazards (Other than indicated above) JSA Done By Name: KOC / ID. No. Controlling Team: Signature: Designation: Company: Contract No.(If Applicable): Date:

![HAND TOOLS[1124483H]](http://s3.studylib.net/store/data/025514400_1-94548f35c36937192e36e2d9ea621100-300x300.png)