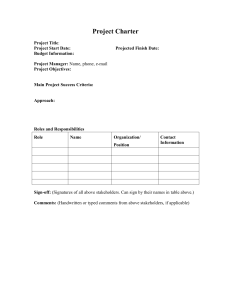

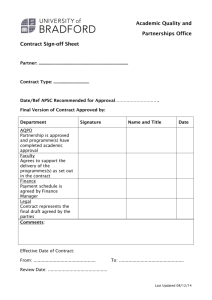

Agogo Integrated West Hub Development NON-CONFORMITY REPORT PART 1: DESCRIPTION AND REFERENCES - By Yinson Title: Performing Repairs of 48VE701 Without Approval by Company NCR No.: NCR-CACI-062 Rev.: 00 Nonconformity to: Contractual Requirements Date: 19th April 2024 Recipient: Carbon Circle Regulatory Requirements Management System Discipline: Mechanical (Equipment) Violated Requirements: (reference to document number with relevant section) 2101-YINS-00-R-SA-00009 Mechanical Technical Specification Pressure Vessel Package no.: Carbon System: Nil Area: Nil Capture Pkg Description: (Be Specific and Detailed with Supporting Evidence) Tag no: 48VE701 During daily site surveillance, it was observed that two of the nozzles (N3A,3B) on the Absorber Section 1 #48VE701 was relocated due to a level gauge obstruct with brazing of structural column. It is observed that a plate renewal has been performed on the vessel shell in place of the original penetration. In addition, the support for the new nozzle has been welded in the centre of the renewal plate. Reference to 2101-YINS-00-R-SAmay affect the operation, integrity, or inter-changeability of the pressure vessel. These works have been carried out and completed without notification or authorization by Yinson or the certifying authority, in this case it shall be DNV. Carbon Circle shall develop a Method Statement describing the steps taken to perform the repair and obtain the required approvals from Yinson and the certifying authority, so as to ensure that the repairs undertaken will not affect the operation or integrity of the pressure vessel. Yinson Issuer Signature: Name: Thamil Selvan Position: QC Rep Date: thamil. muthu 2024.04. 19 10:47: 20 +07'00' Approved by Yinson Quality Manager Name: Giovanni Brigidini Position: QC Manager Signature: Date: Digitally signed by: Giovanni Brigidini Date: 2024.04. 19 11:24:18 + 07'00' PART 2: CORRECTIONS (IMMEDIATE ACTIONS) - By Contractor within 1 Week Include Disposition 2.1. Develop Method Statement in which describing the steps taken to perform the repair. 2.2. Provide documents to prove that the repair undertaken will not affect the operation, integrity, or interchangeability of the pressure vessel. The provided document could be part of Method Statement itself or attached. Contractor PM/Dept. Mgr Closure Comments & Sign-Off Date Closed: Marius Thunes Yinson Representative Closure Comments & Sign-Off Yinson Quality Manager Sign-Off Verified & Accepted Date: Approved Date: PART 3: INVESTIGATION OF ROOT CAUSE (WHY IT HAPPENED) - By Contractor Cause(s): (List all the causes. Use 5 Whys. Effort should be appropriate to seriousness of finding) 3.1. Problem statement: The repair of the nozzles (N3A,3B) on the Absorber Section 1 #48VE701 had taken place without notification or authorization by Yinson or the certifying authority - DNV. This is agains the term in Mechanical Technical Specification 2101-YINS-00-R-SA-00009. 3.2. Root cause Analysis (Using 5W) Question 1: Why the repair is carried out without notification or authorization by Yinson or DNV? Answer 1: Because decision making based on assumption that the repair will not effect the operation, integrity, or interchangeability of the pressure vessel. <--- Root cause. Question 2: Why the discussion panel is not be able to detect this requirement extract from Mechanical Technical Specification 2101-YINS-00-R-SA-00009? Answer 2: Lack of awareness of the impact of the repair. Question 3: Why is not any verify step taken place after decision is made? Answer 3: No further verify taken because of the actual of progress of Absorber Section 1 #48VE701 is behind planning schedule. Investigator Signature: Name: Tien Hoang Dinh Position: Inspector Date: 26-Apr-2024 Approved by Yinson Quality Manager Name: Position: Signature: Date: PART 4: CORRECTIVE ACTIONS - By Contractor within 1 Month 4.1. Revised Project Planning - Assumption: Avoid making assumptions without documenting and communicating them clearly to relevant stakeholder. 4.2 Implemented Change Management Procedure and related forms to reduce the occurrence of this kind of event in the future. Contractor PM/Dept. Mgr Closure Comments & Sign-Off Date Closed: Marius Thunes Yinson Representative Closure Comments & Sign-Off Yinson Quality Manager Sign-Off Verified & Accepted Date: Approved Date: PART 5: PREVENTIVE ACTIONS - Verify after 3 Months (if necessary) 5.1 Monitoring the performance of the implementation and do the necessarily adjustment if Contractor PM/Dept. Mgr Closure Comments & Sign-Off Date Closed: Marius Thunes Yinson Representative Closure Comments & Sign-Off Yinson Quality Manager Sign-Off Verified & Accepted Date: Approved Date: