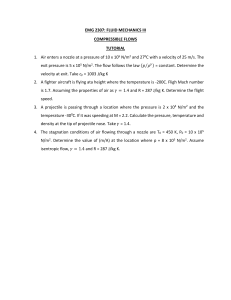

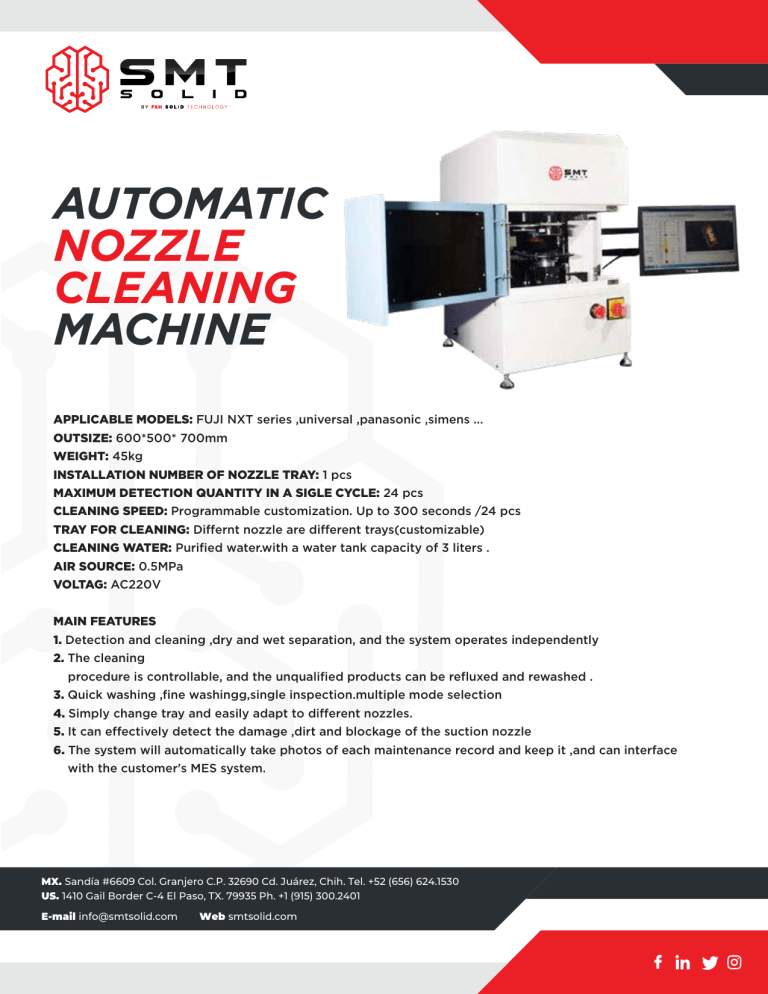

SMT SOLID HIGH Automatic Nozzle Cleaning Machine

advertisement

AUTOMATIC NOZZLE CLEANING MACHINE APPLICABLE MODELS: FUJI NXT series ,universal ,panasonic ,simens ... OUTSIZE: 600*500* 700mm WEIGHT: 45kg INSTALLATION NUMBER OF NOZZLE TRAY: 1 pcs MAXIMUM DETECTION QUANTITY IN A SIGLE CYCLE: 24 pcs CLEANING SPEED: Programmable customization. Up to 300 seconds /24 pcs TRAY FOR CLEANING: Differnt nozzle are different trays(customizable) CLEANING WATER: Purified water.with a water tank capacity of 3 liters . AIR SOURCE: 0.5MPa VOLTAG: AC220V MAIN FEATURES 1. Detection and cleaning ,dry and wet separation, and the system operates independently 2. The cleaning procedure is controllable, and the unqualified products can be refluxed and rewashed . 3. Quick washing ,fine washingg,single inspection.multiple mode selection 4. Simply change tray and easily adapt to different nozzles. 5. It can effectively detect the damage ,dirt and blockage of the suction nozzle 6. The system will automatically take photos of each maintenance record and keep it ,and can interface with the customer's MES system. MX. Sandía #6609 Col. Granjero C.P. 32690 Cd. Juárez, Chih. Tel. +52 (656) 624.1530 US. 1410 Gail Border C-4 El Paso, TX. 79935 Ph. +1 (915) 300.2401 E-mail info@smtsolid.com Web smtsolid.com Software automatic detection, photo archive High speed cleaning ,the fastest 360 seconds/24 pcs Before cleaning After cleaning Clean qualified nozzle Computer program control of cleaning mode Tray adapt different nozzle MX. Sandía #6609 Col. Granjero C.P. 32690 Cd. Juárez, Chih. Tel. +52 (656) 624.1530 US. 1410 Gail Border C-4 El Paso, TX. 79935 Ph. +1 (915) 300.2401 E-mail info@smtsolid.com Web smtsolid.com Inspect unqualified nozzle Nozzle inspected photos THE MAIN ADVANTAGE: • Nozzle cleaning: fast cleaning is realized by customizing high-speed airflow and up and down reciprocating motion, and the nozzle and nozzle plate are dry without water droplets after cleaning; • Scan code traceability: Built-in upper and lower light sources and cameras, can effectively read the QR code of various nozzles on the market, record the type and code of the nozzle, so as to realize the traceability and control of the whole process of the nozzle; • Damage detection: The surface cracks and damages of the nozzle can be effectively detected by taking pictures of the system camera and comparing and analyzing the software; 8 • Vacuum degree detection: The system has a built-in high-sensitivity sensor, which can effectively sense the airflow change in the nozzle hole, determine the vacuum degree of the nozzle, and ensure quality; • Through hole inspection: With a special camera and light source, the device can take pictures and test deeply into the nozzle hole to ensure that the inside of the nozzle hole is clean and undamaged; • Easy to operate: configure the computer, the software is easy to operate, can check the detection status of the nozzle at all times, the customer's application is easy, and the use is assured. MX. Sandía #6609 Col. Granjero C.P. 32690 Cd. Juárez, Chih. Tel. +52 (656) 624.1530 US. 1410 Gail Border C-4 El Paso, TX. 79935 Ph. +1 (915) 300.2401 E-mail info@smtsolid.com Web smtsolid.com Quick wash and dry Scan QR code Nozzle breakage detection Discrimination of vacuum degree Bad reflector Good reflector Through hole inspection Easily operation MX. Sandía #6609 Col. Granjero C.P. 32690 Cd. Juárez, Chih. Tel. +52 (656) 624.1530 US. 1410 Gail Border C-4 El Paso, TX. 79935 Ph. +1 (915) 300.2401 E-mail info@smtsolid.com Web smtsolid.com