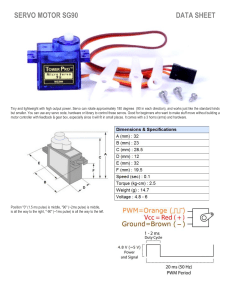

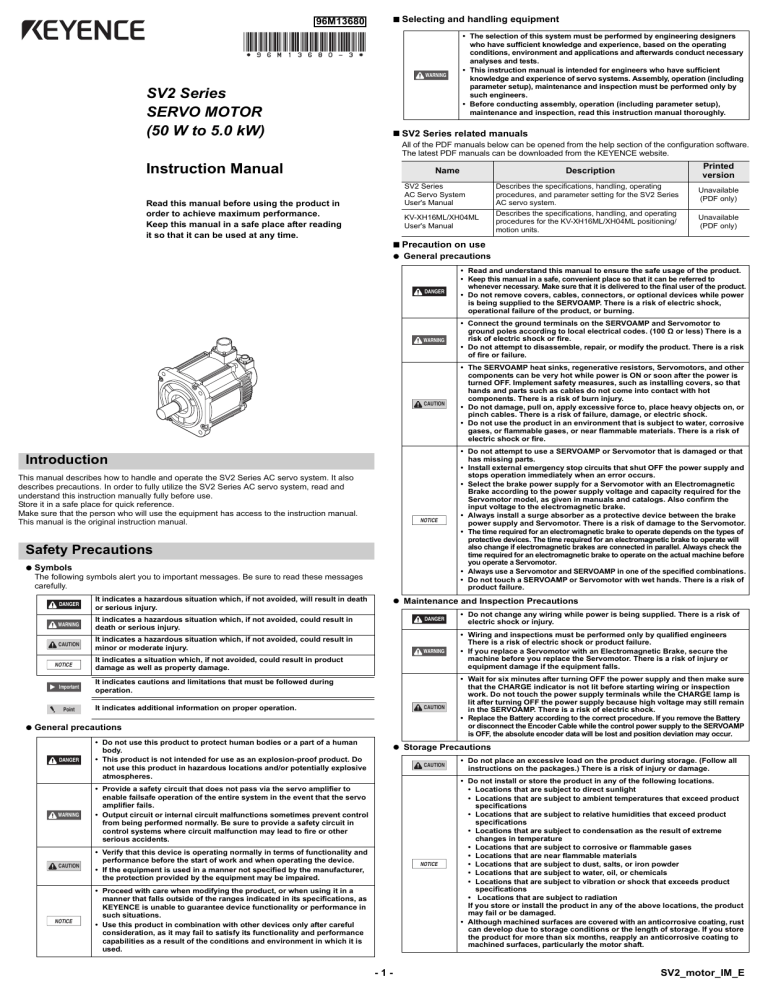

96M13680 Selecting and handling equipment WARNING SV2 Series SERVO MOTOR (50 W to 5.0 kW) • The selection of this system must be performed by engineering designers who have sufficient knowledge and experience, based on the operating conditions, environment and applications and afterwards conduct necessary analyses and tests. • This instruction manual is intended for engineers who have sufficient knowledge and experience of servo systems. Assembly, operation (including parameter setup), maintenance and inspection must be performed only by such engineers. • Before conducting assembly, operation (including parameter setup), maintenance and inspection, read this instruction manual thoroughly. SV2 Series related manuals All of the PDF manuals below can be opened from the help section of the configuration software. The latest PDF manuals can be downloaded from the KEYENCE website. Instruction Manual Name SV2 Series AC Servo System User's Manual Read this manual before using the product in order to achieve maximum performance. Keep this manual in a safe place after reading it so that it can be used at any time. Printed version Description KV-XH16ML/XH04ML User's Manual Describes the specifications, handling, operating procedures, and parameter setting for the SV2 Series AC servo system. Describes the specifications, handling, and operating procedures for the KV-XH16ML/XH04ML positioning/ motion units. Unavailable (PDF only) Unavailable (PDF only) Precaution on use General precautions DANGER • Read and understand this manual to ensure the safe usage of the product. • Keep this manual in a safe, convenient place so that it can be referred to whenever necessary. Make sure that it is delivered to the final user of the product. • Do not remove covers, cables, connectors, or optional devices while power is being supplied to the SERVOAMP. There is a risk of electric shock, operational failure of the product, or burning. WARNING • Connect the ground terminals on the SERVOAMP and Servomotor to ground poles according to local electrical codes. (100 Ω or less) There is a risk of electric shock or fire. • Do not attempt to disassemble, repair, or modify the product. There is a risk of fire or failure. CAUTION • The SERVOAMP heat sinks, regenerative resistors, Servomotors, and other components can be very hot while power is ON or soon after the power is turned OFF. Implement safety measures, such as installing covers, so that hands and parts such as cables do not come into contact with hot components. There is a risk of burn injury. • Do not damage, pull on, apply excessive force to, place heavy objects on, or pinch cables. There is a risk of failure, damage, or electric shock. • Do not use the product in an environment that is subject to water, corrosive gases, or flammable gases, or near flammable materials. There is a risk of electric shock or fire. NOTICE • Do not attempt to use a SERVOAMP or Servomotor that is damaged or that has missing parts. • Install external emergency stop circuits that shut OFF the power supply and stops operation immediately when an error occurs. • Select the brake power supply for a Servomotor with an Electromagnetic Brake according to the power supply voltage and capacity required for the Servomotor model, as given in manuals and catalogs. Also confirm the input voltage to the electromagnetic brake. • Always install a surge absorber as a protective device between the brake power supply and Servomotor. There is a risk of damage to the Servomotor. • The time required for an electromagnetic brake to operate depends on the types of protective devices. The time required for an electromagnetic brake to operate will also change if electromagnetic brakes are connected in parallel. Always check the time required for an electromagnetic brake to operate on the actual machine before you operate a Servomotor. • Always use a Servomotor and SERVOAMP in one of the specified combinations. • Do not touch a SERVOAMP or Servomotor with wet hands. There is a risk of product failure. Introduction This manual describes how to handle and operate the SV2 Series AC servo system. It also describes precautions. In order to fully utilize the SV2 Series AC servo system, read and understand this instruction manually fully before use. Store it in a safe place for quick reference. Make sure that the person who will use the equipment has access to the instruction manual. This manual is the original instruction manual. Safety Precautions Symbols The following symbols alert you to important messages. Be sure to read these messages carefully. DANGER It indicates a hazardous situation which, if not avoided, will result in death or serious injury. WARNING It indicates a hazardous situation which, if not avoided, could result in death or serious injury. CAUTION It indicates a hazardous situation which, if not avoided, could result in minor or moderate injury. NOTICE It indicates a situation which, if not avoided, could result in product damage as well as property damage. Important It indicates cautions and limitations that must be followed during operation. Point It indicates additional information on proper operation. Maintenance and Inspection Precautions DANGER • Do not change any wiring while power is being supplied. There is a risk of electric shock or injury. WARNING • Wiring and inspections must be performed only by qualified engineers There is a risk of electric shock or product failure. • If you replace a Servomotor with an Electromagnetic Brake, secure the machine before you replace the Servomotor. There is a risk of injury or equipment damage if the equipment falls. CAUTION • Wait for six minutes after turning OFF the power supply and then make sure that the CHARGE indicator is not lit before starting wiring or inspection work. Do not touch the power supply terminals while the CHARGE lamp is lit after turning OFF the power supply because high voltage may still remain in the SERVOAMP. There is a risk of electric shock. • Replace the Battery according to the correct procedure. If you remove the Battery or disconnect the Encoder Cable while the control power supply to the SERVOAMP is OFF, the absolute encoder data will be lost and position deviation may occur. General precautions DANGER • Do not use this product to protect human bodies or a part of a human body. • This product is not intended for use as an explosion-proof product. Do not use this product in hazardous locations and/or potentially explosive atmospheres. WARNING • Provide a safety circuit that does not pass via the servo amplifier to enable failsafe operation of the entire system in the event that the servo amplifier fails. • Output circuit or internal circuit malfunctions sometimes prevent control from being performed normally. Be sure to provide a safety circuit in control systems where circuit malfunction may lead to fire or other serious accidents. CAUTION • Verify that this device is operating normally in terms of functionality and performance before the start of work and when operating the device. • If the equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired. NOTICE • Proceed with care when modifying the product, or when using it in a manner that falls outside of the ranges indicated in its specifications, as KEYENCE is unable to guarantee device functionality or performance in such situations. • Use this product in combination with other devices only after careful consideration, as it may fail to satisfy its functionality and performance capabilities as a result of the conditions and environment in which it is used. Storage Precautions -1- CAUTION • Do not place an excessive load on the product during storage. (Follow all instructions on the packages.) There is a risk of injury or damage. NOTICE • Do not install or store the product in any of the following locations. • Locations that are subject to direct sunlight • Locations that are subject to ambient temperatures that exceed product specifications • Locations that are subject to relative humidities that exceed product specifications • Locations that are subject to condensation as the result of extreme changes in temperature • Locations that are subject to corrosive or flammable gases • Locations that are near flammable materials • Locations that are subject to dust, salts, or iron powder • Locations that are subject to water, oil, or chemicals • Locations that are subject to vibration or shock that exceeds product specifications • Locations that are subject to radiation If you store or install the product in any of the above locations, the product may fail or be damaged. • Although machined surfaces are covered with an anticorrosive coating, rust can develop due to storage conditions or the length of storage. If you store the product for more than six months, reapply an anticorrosive coating to machined surfaces, particularly the motor shaft. SV2_motor_IM_E Transportation Precautions CAUTION • Transport the product in a way that is suitable to the mass of the product. • Do not hold onto the cables or motor shaft when you move a Servomotor. There is a risk of disconnection, damage, or injury. • When you handle a SERVOAMP or Servomotor, be careful of sharp parts, such as the corners. There is a risk of injury. • Do not place an excessive load on the product during transportation. (Follow all instructions on the packages.) There is a risk of injury or damage. NOTICE • A SERVOAMP or Servomotor is a precision device. Do not drop it or subject it to strong shock. There is a risk of failure or damage. • Do not subject connectors to shock. There is a risk of faulty connections or damage. • If disinfectants or insecticides must be used to treat packing materials such as wooden frames, plywood, or pallets, the packing materials must be treated before the product is packaged, and methods other than fumigation must be used. Example: Heat treatment, where materials are kiln-dried to a core temperature of 56°C for 30 minutes or more. If the electronic products, which include stand-alone products and products installed in machines, are packed with fumigated wooden materials, the electrical components may be greatly damaged by the gases or fumes resulting from the fumigation process. In particular, disinfectants containing halogen, which includes chlorine, fluorine, bromine, or iodine can contribute to the erosion of the capacitors. • Do not overtighten the eyebolts on a SERVOAMP or Servomotor. If you use a tool to overtighten the eyebolts, the tapped holes may be damaged. CAUTION • Observe the precautions and instructions for wiring and trial operation precisely as described in this document. Failures caused by incorrect wiring or incorrect voltage application in the brake circuit may cause the SERVOAMP to fail, damage the equipment, or cause an accident resulting in death or injury. • Check the wiring to be sure it has been performed correctly. Connectors and pin layouts are sometimes different for different models. Always confirm the pin layouts in technical documents for your model before operation. There is a risk of failure or malfunction. • Connect wires to power supply terminals and motor connection terminals securely with the specified methods and tightening torque. Insufficient tightening may cause wires and terminal blocks to generate heat due to faulty contact, possibly resulting in fire. • Use shielded twisted-pair cables or screened unshielded multitwisted-pair cables for I/O Signal Cables and Encoder Cables. • Observe the following precautions when wiring the SERVOAMP's main circuit terminals. • Turn ON the power supply to the SERVOAMP only after all wiring, including the main circuit terminals, has been completed. • If a connector is used for the main circuit terminals, remove the main circuit connector from the SERVOAMP before you wire it. • Insert only one wire per insertion hole in the main circuit terminals. • When you insert a wire, make sure that the conductor wire (e.g., whiskers) does not come into contact with adjacent wires. NOTICE • Whenever possible, use the Cables specified by KEYENCE. If you use any other cables, confirm the rated current and application environment of your model and use the wiring materials specified by KEYENCE or equivalent materials. • Securely tighten cable connector screws and lock mechanisms. Insufficient tightening may result in cable connectors falling off during operation. • Do not bundle power lines (e.g., the Main Circuit Cable) and low-current lines (e.g., the I/O Signal Cables or Encoder Cables) together or run them through the same duct. If you do not place power lines and low-current lines in separate ducts, separate them by at least 30 cm. If the cables are too close to each other, malfunctions may occur due to noise affecting the low-current lines. • Install a battery at either the host controller or on the Encoder Cable. If you install batteries both at the host controller and on the Encoder Cable at the same time, you will create a loop circuit between the batteries, resulting in a risk of damage or burning. • When connecting a battery, connect the polarity correctly. There is a risk of battery rupture or encoder failure. Installation Precautions CAUTION NOTICE • Do not touch the key slot with your bare hands on the shaft end on a Servomotor with a Key Slot. There is a risk of injury. • Securely mount the Servomotor to the machine. If the Servomotor is not mounted securely, it may come off the machine during operation. • Install the Servomotor or SERVOAMP in a way that will support the mass given in technical documents. • Install SERVOAMPs, Servomotors, and regenerative resistors on nonflammable materials. Installation directly onto or near flammable materials may result in fire. • Do not step on or place a heavy object on the product. There is a risk of failure, damage, or injury. • Do not allow any foreign matter to enter the SERVOAMP or Servomotor. There is a risk of failure or fire. • Implement safety measures, such as installing a cover so that the rotating part of the Servomotor cannot be touched accidentally during operation. Operation Precautions • Do not install or store the product in any of the following locations. • Locations that are subject to direct sunlight • Locations that are subject to ambient temperatures that exceed product specifications • Locations that are subject to relative humidities that exceed product specifications • Locations that are subject to condensation as the result of extreme changes in temperature • Locations that are subject to corrosive or flammable gases • Locations that are near flammable materials • Locations that are subject to dust, salts, or iron powder • Locations that are subject to water, oil, or chemicals • Locations that are subject to vibration or shock that exceeds product specifications • Locations that are subject to radiation If you store or install the product in any of the above locations, the product may fail or be damaged. • Use the product in an environment that is appropriate for the product specifications. If you use the product in an environment that exceeds product specifications, the product may fail or be damaged. • A SERVOAMP or Servomotor is a precision device. Do not drop it or subject it to strong shock. There is a risk of failure or damage. • A Servomotor is a precision device. Do not subject the output shaft or the main body of the Servomotor to strong shock. • Design the machine so that the thrust and radial loads on the motor shaft during operation do not exceed the allowable values given in the manual. • When you attach the key to the motor shaft, do not subject the key slot to direct shock. • Do not allow any foreign matter to enter a SERVOAMP or a Servomotor with a Cooling Fan and do not cover the outlet from the Servomotor's cooling fan. There is a risk of failure. • If you use oil as the gear lubricant, always inject the specified oil before starting operation. • You can install the Servomotor either horizontally or vertically. However, if you install a Servomotor with an Oil Seal with the output shaft facing upward, oil may enter the Servomotor depending on the operating conditions. Confirm the operating conditions sufficiently if you install a Servomotor with the output shaft facing upward. Some Servomotors with Gears have restrictions on the installation orientation. Refer to the relevant technical documents. • If an installation orientation is specified for a Servomotor with a Gear, install the Servomotor in the specified orientation. There is a risk of failure due to oil leakage. • For a Servomotor with an Oil Seal, use the Servomotor with the oil seal in a lubricated condition with only splashing of oil. If the Servomotor is used with the oil seal under the surface of the oil, oil may enter the Servomotor, possibly resulting in failure. • The shaft opening of a Servomotor is not waterproof or oilproof. Implement measures in the machine to prevent water or cutting oil from entering the Servomotor. There is a risk of failure. • In an application where the Servomotor would be subjected to large quantities of water or oil, implement measures to protect the Servomotor from large quantities of liquid, such as installing covers to protect against water and oil. • In an environment with high humidity or oil mist, face Servomotor lead wires and connectors downward and provide cable traps. There is a risk of failure or fire due to insulation failure or accidents from short circuits. Wiring Precautions DANGER • Do not change any wiring while power is being supplied. There is a risk of electric shock or injury. WARNING • Wiring and inspections must be performed only by qualified engineers. There is a risk of electric shock or product failure. • Check all wiring and power supplies carefully. Incorrect wiring or incorrect voltage application to the output circuits may cause short-circuit failures. If a short-circuit failure occurs as a result of any of these causes, the electromagnetic brake will not work. This could damage the machine or cause an accident that may result in death or injury. WARNING • Always check safety when turning the servo amplifier on. Some unintended operations may be caused by just turning the servo amplifier on, leading to equipment damage or injury. • Before starting operation with a machine connected, change the settings of the switches and parameters to match the machine. Unexpected machine operation, failure, or personal injury may occur if operation is started before appropriate settings are made. • Do not radically change the settings of the parameters. There is a risk of unstable operation, machine damage, or injury. • Install limit switches or stoppers at the ends of the moving parts of the machine to prevent unexpected accidents. There is a risk of machine damage or injury. • For trial operation, securely mount the Servomotor and disconnect it from the machine. There is a risk of injury. • When an alarm occurs, the motor will coast to a stop or stop with the dynamic brake according to a setting in the SERVOAMP. The coasting distance will change with the moment of inertia of the load. Check the coasting distance during trial operation and implement suitable safety measures on the machine. • Do not enter the machine's range of motion during operation. There is a risk of injury. • Do not touch the moving parts of the Servomotor or machine during operation. There is a risk of injury. CAUTION • Do not use the electromagnetic brake built into a Servomotor to stop the Servomotor. The electromagnetic brake is designed to hold the motor shaft. It is not designed as a stopping device to ensure machine safety. Provide an appropriate stopping device on the machine to ensure safety. There is a risk of brake failure due to wear, damage to the machine, or injury. • Before you operate a Servomotor, supply power to the electromagnetic brake to release the electromagnetic brake. Refer to the timing charts in your Servomotor manual for details. • During trial operation, confirm that the electromagnetic brake works correctly. • When overtravel occurs, the power supply to the motor is turned OFF and the brake is released. If you use the Servomotor to drive a vertical load, set the Servomotor to enter a zero-clamped state after the Servomotor stops. Also, install safety devices (such as an external brake or counterweight) to prevent the moving parts of the machine from falling. • Always turn OFF the servo before you turn OFF the power supply. If you turn OFF the main circuit power supply or control power supply during operation before you turn OFF the servo, the Servomotor will stop as follows: • If you turn OFF the main circuit power supply during operation without turning OFF the servo, the Servomotor will stop abruptly with the dynamic brake. • If you turn OFF the control power supply without turning OFF the servo, the stopping method that is used by the Servomotor depends on the model of the SERVOAMP. For details, refer to the manual for the SERVOAMP. NOTICE • Always measure the vibration of the Servomotor with the Servomotor mounted to the machine and confirm that the vibration is within the allowable value. If the vibration is too large, the Servomotor will be damage quickly and bolts may become loose. • When you adjust the gain during system commissioning, use a measuring instrument to monitor the torque waveform and speed waveform and confirm that there is no vibration. If a high gain causes vibration, the Servomotor will be damaged quickly. • An alarm or warning may occur if communications are performed with the host controller while the 《KV STUDIO》or Digital Operator is operating. If an alarm or warning occurs, it may interrupt the current process and stop the system. Troubleshooting Precautions WARNING • The product may suddenly start to operate when the power supply is recovered after a momentary power interruption. Design the machine to ensure human safety when operation restarts. There is a risk of injury. CAUTION • When an alarm occurs, remove the cause of the alarm and ensure safety. Then reset the alarm or turn the power supply OFF and ON again to restart operation. There is a risk of injury or machine damage. • If the Servo ON signal is input to the SERVOAMP and an alarm is reset, the Servomotor may suddenly restart operation. Confirm that the servo is OFF and ensure safety before you reset an alarm. There is a risk of injury or machine damage. • The electromagnetic brake on a Servomotor will not ensure safety if there is the possibility that an external force (including gravity) may move the current position and create a hazardous situation when power is interrupted or an error occurs. If an external force may cause movement, install an external braking mechanism that ensures safety. Disposal Precautions Important SV2_motor_IM_E -2- • When disposing of the product, treat it as ordinary industrial waste. However, local ordinances and national laws must be observed. Implement all labeling and warnings as a final product as required. Precautions on Regulations and Standards CE Marking Keyence Corporation has confirmed that this product complies with the essential requirements of the applicable EU Directive(s), based on the following specifications. Be sure to consider the following specifications when using this product in the Member States of European Union. Checking Package Contents Remove the servo motor from the package and check that all the components listed below are included in the package. Check the combination of the servo amplifier and servo motor. Package contents Servo motor EMC Directive • Applicable Standard EN55011 EN61000-6-2 EN61000-6-4 EN61800-3 • Installation Conditions (Three-Phase, 200 VAC) Instruction Manual Shield box Brake power supply (5) L1, L2, L3 Clamp □ Servo U, V, W Clamp Noise filter (3) Brake □ Instruction Model name confirmation • 50 W to 750 W Servo motor L1C, L2C Surge absorber ENC Clamp Power supply: 3-phase 200 VAC Clamp SERVOAMP (4) Model Encoder Rated output Clamp PE (6) Rated torque Clamp MECHATROLINK- Ⅲ controller PORT1, PORT2 I/O Rated rotation speed STO Clamp I/O control device Maximum rotation speed Clamp (1) No. PE (2) Safety device Cable name • 1.0 kW to 5.0 kW Specifications (1) (2) (3) (4) (5) I/O Cable Safety Function Device Cable Motor Power Cable Encoder Cable Main Circuit/Control Circuit Power Cable Shielded cable Shielded cable Shielded cable Shielded cable Shielded cable (6) MECHATROLINK- Ⅲ Communication Cable Shielded cable Model Rated output Rated torque Rated rotation speed Remarks: These specifications do not give any guarantee that the end-product with this product incorporated complies with the essential requirements of EMC Directive. The manufacturer of the end-product is solely responsible for the compliance on the end-product itself according to EMC Directive. Maximum rotation speed Low-Voltage Directive This product complies with the following EN Standards and has been certified by TÜV SÜD Product Service GmbH. • Applicable Standard EN60034-1 EN60034-5 UL Certificate This product is an UL/c-UL recognized product. • UL File No. E223442 • Category PRHZ2, PRHZ8 • UL applicable standard UL1004-1 UL1004-6 • cUL applicable standard CSA C22.2 No.100 Type and Model of the Servo Motor The model name of the servo motor indicates the following. Servo amplifier and servo motor combinations SV2 - M 005 A K Servo amplifier and servo motor combinations are predefined. Check the table below to ensure that you are using the correct combination. Power supply voltage 200 V *1 Rated output Servo amplifier model Servo motor type M:Standard motor B:Electromagnetic brake motor Supported servo motor 50 W SV2-005L2 SV2- □ 005A ■ 100 W SV2-010L2 SV2- □ 010A ■ 200 W SV2-020L2 SV2- □ 020A ■ 400 W SV2-040L2 SV2- □ 040A ■ 750 W SV2-075L2 SV2- □ 075A ■ 1.0 kW SV2-100L2 SV2- □ 100A ■ 1.5 kW SV2-150L2 SV2- □ 150A ■ 2.0 kW SV2-200L2 SV2- □ 200A ■ 3.0 kW SV2-300L2 SV2- □ 300A ■ *1 5.0 kW SV2-500L2 SV2- □ 300A ■ *1 SV2- □ 500A ■ Rated output 005: 010: 020: 040: 075: 100: 150: 200: 300: 500: 1.0 kW 1.5 kW 2.0 kW 3.0 kW 5.0 kW Shaft type S: Straight K: Keyway Encoder type A:Absolute encoder • 50 W to 750 W model Model type Motor type Shaft type Standard motor Electromagne tic brake motor Ratings vary depending on the servo amplifier to be connected. NOTICE 50 W 100 W 200 W 400 W 750 W 50 W Model and rated output 100 W 200 W 400 W 750 W Straight Keyway Straight SV2-M005AS SV2-M010AS SV2-M020AS SV2-M040AS SV2-M075AS SV2-M005AK SV2-M010AK SV2-M020AK SV2-M040AK SV2-M075AK SV2-B005AS SV2-B010AS SV2-B020AS SV2-B040AS SV2-B075AS Keyway SV2-B005AK SV2-B010AK SV2-B020AK SV2-B040AK SV2-B075AK • 1.0 kW to 5.0 kW model Model type Motor type Shaft type Do not use combinations other than those listed above. Standard motor Electromagne tic brake motor -3- 1.0 kW Model and rated output 1.5 kW 2.0 kW 3.0 kW 5.0 kW Straight Keyway Straight SV2-M100AS SV2-M150AS SV2-M200AS SV2-M300AS SV2-M500AS SV2-M100AK SV2-M150AK SV2-M200AK SV2-M300AK SV2-M500AK SV2-B100AS SV2-B150AS SV2-B200AS SV2-B300AS SV2-B500AS Keyway SV2-B100AK SV2-B150AK SV2-B200AK SV2-B300AK SV2-B500AK SV2_motor_IM_E Part names and functions of the Servo Motor Specifications General specifications • 50 W to 750 W model Standard • 50 W to 750 W Electromagnetic brake motor Model type (4) Standard motor Model (SV2-) Electromagne tic brake motor Compatible servo amplifier (SV2-) Rated output [W] (1) (1) (4) (2) (2) Rated torque [N·m]*1 Momentary maximum torque [N·m] Rated current [Arms] Instantaneous maximum current [Arms] (5) (5) (7) (3) (3) (8) (8) • 1.0 kW to 5.0 kW model Standard Rated rotation speed [min-1] Maximum rotation speed [min-1] Torque constant [N·m/Arms] Rotor inertia moment [x 10-4 kg/m2] Electromagnetic brake motor (6) (1) (1) (4) (4) (2) (2) Rated power rate [kW/s] Rated angle speed [rad/s2] (5) (5) Ratio of allowable load to moment of inertia Standard motor Approx. Electromagne weight [kg] tic brake motor (7) (3) (8) No. Name (3) (8) Function (1) Motor power supply cable connector (2) Mounting holes (3) Output shaft (4) Encoder cable connector (5) Encoder Electromagnetic brake cable connector Used to connect the motor power supply cable. When shipped, the 50 W to 750 W type has a protective seal, and the 1.0 kW to 5.0 kW type has a protective cap attached. Used to mount the servo motor to equipment. (2 holes for the 50 W, and 100 W type servo motors, and 4 holes for 200 W to 5.0 k W servo motors) The rotating shaft of the servo motor. A keyway shaft is available in addition to a straight shaft. Used to connect the encoder cable. A cap is attached when shipped. The encoder is built in. Used to connect the electromagnetic brake. A cap is attached when shipped. Electromagnetic brake Flange An electromagnetic brake is built in. The surface of the servo motor that is mounted to equipment. (6) (7) (8) Specifications M005A □ M010A □ M020A □ M040A □ M075A □ B005A □ B010A □ B020A □ B040A □ B075A □ 005L2 010L2 020L2 040L2 075L2 50 100 200 400 750 0.159 0.318 0.637 1.27 2.39 0.557 1.11 2.23 4.46 8.36 0.55 0.85 1.6 2.5 4.4 2.0 3.1 5.8 9.3 16.9 3000 6000 0.316 0.413 0.444 0.544 0.584 0.0395 (0.0475) 0.0659 (0.0739) 0.263 (0.333) 0.486 (0.556) 1.59 (1.77) 6.40 (5.32) 40200 (33400) 15.3 (13.6) 48200 (43000) 15.4 (12.1) 24200 (19100) 33.1 (29.0) 26100 (22800) 35.9 (32.2) 15000 (13500) 15 times 10 times 12 times 35 times 0.3 0.4 0.8 1.1 2.2 0.6 0.7 1.4 1.7 2.8 Values in parentheses indicate the values for an electromagnetic brake motor. *1 Rated torque is the continuous allowable torque value in the following conditions: ・Ambient temperature: 40°C ・Attached aluminum heatsink (motor attaching portion) 50 W and 100 W: 200 x 200 x 6 [mm] 200 W to 750 W: 250 x 250 x 6 [mm] • 1.0 kW to 5.0 kW Model type Standard motor Model (SV2-) Electromagne tic brake motor Compatible servo amplifier (SV2-) Rated output [W] Rated torque [N·m]*1 Momentary maximum torque [N·m] Rated current [Arms] Instantaneous maximum current [Arms] Rated rotation speed [min-1] Maximum rotation speed [min-1] Torque constant [N·m/Arms] Rotor inertia moment [x 10-4 kg/m2] Rated power rate [kW/s] Rated angle speed [rad/s2] Ratio of allowable load to moment of inertia Standard motor Approx. Electromagne weight [kg] tic brake motor Specifications M100A □ M150A □ M200A □ M300A □ M500A □ B100A □ B150A □ B200A □ B300A □ B500A □ 100L2 150L2 200L2 300L2 500L2 500L2 0.85 k 1.3 k 1.8 k 2.4k 2.9k 4.4 k 5.39 8.34 11.5 15.1 18.6 28.4 14.2 23.3 28.7 45.1 54.0 71.6 6.9 10.7 16.7 19.6 23.8 32.8 17 28 42 56 70 84 1500 3000 0.859 0.891 0.748 0.848 0.848 0.934 13.9 (16.0) 19.9 (22.0) 26.0 (28.1) 46.0 (53.9) 46.0 (53.9) 67.5 (75.4) 20.9 (18.2) 3880 (3370) 35.0 (31.6) 4190 (3790) 50.9 (47.1) 4420 (4090) 49.5 75.2 (42.2) (64.2) 3280 4040 (2800) (3450) 119 (107) 4210 (3770) 5 times 3 times 5.5 7.1 8.6 13.5 17.5 7.5 9.0 11.0 19.5 23.5 Values in parentheses indicate the values for an electromagnetic brake motor. *1 Rated torque is the continuous allowable torque value in the following conditions: ・Ambient temperature: 40°C ・Attached iron heatsink (motor attaching portion) 1.0kW to 2.0kW: 400x400x20[mm] 3.0kW to 5.0kW: 550x550x30[mm] SV2_motor_IM_E -4- 5 times Torque-rotation speed characteristic SV2-M005A □ 0°C to +60°C (use under reduced ratings at +40°C or above) Minimum insulation resistance Allowable insulation withstand voltage UL/CSA standard Low-voltage directive CE Applicable marking standards EMI EMS North American EMI Regulation B 1 0.5 0 0 1 2 3 4 5 6 7 Rotation speed (×1000min-1) A 0 1 2 3 4 5 6 7 Rotation speed (×1000min-1) SV2-M075A □ 10 3 B 2 1 A A : Use region for continuous use 8 Torque (N·m) 4 B : Short-term operation region 6 B 4 Solid line: 3-phase, 200 VAC is input 2 A 0 Dotted line: single phase, 200 VAC is input 0 1 2 3 4 5 6 7 Rotation speed (×1000min-1) SV2-M100A □ SV2-M150A □ 6 3 Torque (N·m) Torque (N·m) 12 9 B A 10 5 Torque (N·m) 24 B 18 12 A 6 0 0 0.5 1 1.5 2 2.5 3 3.5 Rotation speed (×1000min-1) 0 0.5 1 1.5 2 2.5 3 3.5 Rotation speed (×1000min-1) SV2-M500A □ 75 48 B 12 A 0 0 0.5 1 1.5 2 2.5 3 3.5 Rotation speed (×1000min-1) 120 A 0 SV2-M300A □ NOTICE B 15 0 0.5 1 1.5 2 2.5 3 3.5 Rotation speed (×1000min-1) 24 30 20 0 36 SV2-M200A □ 25 60 80 60 45 A : B B : 30 15 A Use region for continuous use Short-term operation region Solid line: 3-phase, 200 VAC is input Dotted line: When combined with SV2-300L2 0 0 0.5 1 1.5 2 2.5 3 3.5 Rotation speed (×1000min-1) • Characteristics in the operation region for short time operation vary depending on the power supply voltage. • If the motor's power supply cable exceeds 20 m, the operation region for short time operation becomes smaller due to a great drop in voltage. SV2-□075□ 40 20 10 0 Electromagnetic Brake Specifications 80 60 20 0 10 20 30 40 50 60 70 100 Derating (%) 80 Derating (%) Derating (%) 100 Ambient operating temperature(℃) SV2-□100□/□150□ 40 Model (SV2-) 20 0 0 10 20 30 40 50 60 70 Ambient operating temperature(℃) • 50 W to 750 W 60 SV2-□200□ 0 Capacity (W) Rated voltage 10 20 30 40 50 60 70 Ambient operating temperature(℃) Rated current [A] (@ 20 ℃ ) Holding torque [N·m] Release time [ms] Operating time [ms] 120 Derating (%) A SV2-□020□/□040□ SV2-□010□ SV2-□300□/□500□ 80 B005A□ B010A□ B020A□ B040A□ B075A□ 5.5 5.5 6 24 VDC ±10% 6 6.5 0.23 0.23 0.25 0.25 0.27 0.159 60 100 0.318 60 100 0.637 60 100 1.27 60 100 2.39 80 100 B100A□ B150A□ B200A□ B300A□ B500A□ 10 10 • 1.0 kW to 5.0 kW 60 Model (SV2-) 40 Capacity (W) Rated voltage 20 0 NOTICE 10 20 30 40 50 60 Ambient operating temperature(℃) • The maximum ambient operating temperature is 60 °C. • Be sure to use servo amplifier and servo motor combinations in conditions which satisfy the derating specifications for each device. • The derating ratio is for when the average rotation speed is equal to or lower than the rated rotation speed. For cases where the average rotation speed exceeds the rated rotation speed, contact your KEYENCE representative. 100 80 80 SV2-□005□/□010□ 60 40 20 0 0 500 1000 1500 2000 2500 Altitude(m) SV2-□075□ 40 0 0.41 0.41 0.41 0.77 0.77 19.6 19.6 43.1 43.1 Release time [ms] Operating time [ms] 100 80 100 80 100 80 170 100 170 100 Electromagnetic brake release/operating times differ according to the discharge circuit. • For servo motors with electromagnetic brakes, there is a small backlash in the rotation direction of the motor output shaft, as backlash can occur on the electromagnetic brakes even when no power is supplied to the brakes. Backlash: 1.5° or below (when shipped) • When servo motors with electromagnetic brakes accelerate, stop, and decelerate, the brake discs may produce some abrasion noise. 100 60 20 18.5 120 SV2-□020□/□040□ Derating (%) 120 100 Derating (%) 120 18.5 12.7 Point The servo motor ratings are the continuous allowable values for use at altitudes of up to 1000 m. When using at altitudes higher than 1000 m, the heat dissipation effect of the air is reduced. Refer to the derating ratios shown in the figures below. 10 DC24V+10%/-0% Rated current [A] (@ 20 ℃ ) Holding torque [N·m] NOTICE Using the servo motor at altitudes higher than 1000 m Derating (%) 0 0 1 2 3 4 5 6 7 15 EN55011 Class A, EN61800-3, EN61000-6-4 EN61800-3, EN61000-6-2 FCC Part15 B, ICES-003. Class A 100 0 0.25 1.5 • 1.0 kW to 5.0 kW EN60034-1, EN60034-5 120 B 0.5 0 1 2 3 4 5 6 7 Rotation speed (×1000min-1) The servo motor ratings are the continuous allowable values for use at ambient operating temperatures of up to 40 °C. For use at ambient operating temperatures of more than 40 °C, refer to the derating ratios shown in the figures below. 100 A 0 Using the servo motor at ambient operating temperatures of more than 40 °C 40 0.15 0.75 SV2-M040A □ UL: Class A, CE: Class B:SV2- □ 005A □ / □ 010A □ / □ 020A □ / □ 040A □ / □ 075A □ Class F: SV2- □ 100A □ / □ 150A □ / □ 200A □ / □ 300A □ / □ 500A □ 10 MΩ min. with 500 VDC megohmmeter 1500 VAC 1 minute UL1004-1, UL1004-6, CSA C22.2 No.100 Insulation class B 0.3 5 Torque (N·m) Shock resistance 490 m/s2 for two times with the servo motor flange used as reference surface SV2-□005□ 0.45 0 Indoors (no corrosive gas, flammable gas, oil mist, or dust) Max. 2000 m (can be used under reduced ratings at 1000 m or above) V15 Vibration resistance 60 2 20%RH to 80%RH (no condensation) • SV2-□005A□/□010A□/□020A□/□040A□/□075A□ 49 m/s2 on the servo motor flange surface (3 directions: up/down, left/right, back/forth) • SV2-□100A□/□150A□/□200A□/□300A□/□500A□ 49 m/s2 (up/down, left/right) and 24.5 m/s2 (back/forth) on the servo motor flange surface 120 2.5 1 -1) Rotation speed (×1000min (×1000min-1) -20°C to +60°C SV2-M020A □ 1.25 0.6 Torque (N·m) Totally enclosed, self-cooling, IP67 (excluding connectors and shaft opening) SV2-M010A □ 0.75 Torque (N·m) Torque (N·m) Absolute type (ABS) Enclosure rating Ambient operating temperature Ambient storage temperature Operating/storage ambient humidity Operating atmosphere Altitude Vibration class Environment • 50 W to 750 W Specifications Permanent magnet 22 bit Torque (N·m) Item Excitation method Encoder for Resolution position/speed Type detection Torque (N·m) Shared Specifications 80 60 SV2-□100□/□150□ SV2-□200□ 40 20 0 500 1000 1500 2000 2500 Altitude(m) 0 0 500 1000 1500 2000 2500 Altitude(m) 120 Derating (%) 100 SV2-□300□/□500□ 80 60 40 20 0 0 NOTICE 500 1000 1500 2000 2500 Altitude(m) • The maximum altitude is 2000 m. • Be sure to use servo amplifier and servo motor combinations in conditions which satisfy the derating specifications for each device. • The derating ratio is for when the average rotation speed is equal to or lower than the rated rotation speed. For cases where the average rotation speed exceeds the rated rotation speed, contact your KEYENCE representative. -5- SV2_motor_IM_E Overload Protection Characteristics Mounting requirements • 50 W to 750 W 10000 Rotation speed 10 min-1 or more 100 0 50 100 150 200 250 300 20 • 3.0 kW to 5.0 kW 10000 10000 1000 1000 150A 10 Detection time (S) 100 Heat radiation 100 150 200 250 300A 0 50 100 150 200 250 Torque command (expressed as rating) (%) 300 Before you attempt to perform any installation, read and understand the safety precautions that are given at the beginning of this document to help prevent bodily injury and equipment damage. Precautions on Installing the Servo Motor 60 40 120 100 80 60 SV2-□100□/□150□ SV2-□200□ 0 50 100 150 200 250 300 Heatsink size (mm) 20 0 50 100 150 200 250 300 Heatsink size (mm) SV2-□300□/□500□ 80 60 40 20 0 100 200 300 400 Heatsink size (mm) 0 0 100 200 300 400 500 600 Heatsink size (mm) Handling the cables Either standard or flexible cables can be used to connect the SV2 series. Do not excessively bend the cable and its lead wires, and do not apply tension stress to them. Recommended bend radius values are as follows. • Standard cable Recommended bend radius at fixed section Motor power cable 50 W to 400 W: R 15 or more 750 W: R 20 or more 1 kW to 5 kW: at least 3 times the cable's external diameter Electromagnetic brake power cable 1 kW to 5 kW: R 3 or more Encoder cable Total volume: R 15 or more * This cable cannot be used for applications where flexibility is required (for example, where the cable moves, or is twisted or rotated). • Flexible cable Recommended bend radius at a flexible section: R 90 or above Service life: Bent 10 million times or more Recommended bend radius at fixed section Motor power cable 50 W to 400 W: R 15 or more 750 W: R 20 or more Encoder cable Total volume: R 15 or more • Use the servo motor in an environment appropriate for the enclosure rating of the motor. Otherwise, this may cause malfunction. • The end of the motor shaft is coated with an anticorrosive agent. Be sure to wipe the agent off completely with a cloth soaked with cleaning solution before installation. Otherwise, the motor and mechanical system cannot be coupled properly. • Use dedicated flexible servo motor coupling to couple the motor with the target equipment. We recommend using two flat springs that allow for a small amount of eccentricity or declination. • Although the allowable coupling alignment tolerance differs according to the rotation speed and the coupling model, make sure it is 0.03 mm or below. Be sure to refer to the coupling manufacturer's catalog as well. Even if it is within the range above, adjust it so the alignment is as accurate as possible. • If the coupling produces unusual sounds, align the center again and adjust it so that no sound is produced. • Align the coupling while rotating the shafts on both ends. • As the absolute value encoder has a magnetic sensor attached, do not install equipment with a strong magnetic field (0.01 T (tesla) or 100 G (gauss) or higher in the encoder cover) near the servo motor. • Select an appropriate belt for the allowable radial load of the servo motor, and the motor output. Also bear in mind when choosing a belt that when the servo motor is accelerating the counterforce of the acceleration torque works as tension added to the initial belt tension. • When using a belt, select one so that the allowable radial load, including the deviation of the belt when rotating the shaft, is satisfied. Mounting the Servo Motor Mount the servo motor by following the instructions below. Connecting the flexible cable When connecting the flexible cable, follow the instructions below. • Twists in the cable Straighten the cable before connecting it. Check the indication on the surface to confirm that the cable is not twisted. Connecting a twisted cable may cause cable breakage. • Cable length Use cables of appropriate lengths. If the cable is too short, the tension at the fixed section may become too high. If the cable is too long, the slack in the cable may cause the cable to break. • Affixing the cables Do not fix the moving section of the cable. Affix as few sections of the cable as possible. Otherwise, stress may be concentrated at the fixed section, resulting in cable breakage. Make sure that no stress is applied to the connectors of the servo motor and amplifier. Otherwise, this may damage the connectors. • Distance from other cables Route the cables to prevent entanglement by providing sufficient intervals or installing divider plates between the cables. If the cables become entangled the cables will have limited movement, resulting in cable breakage. Orientation The servo motor can be installed in either a horizontal or a vertical orientation. • For installations with the shaft end facing upward, provide cable traps so that oil or water will not enter the servo motor. • For installations with the shaft end facing upward, take appropriate countermeasures to prevent oil or water from entering the shaft opening. Shaft end facing upward Shaft end facing downward Cable trap Servo Motor Enclosure Rating The enclosure rating of the servo motor is IP67. (Excluding connectors and shaft opening) If oil or coolant splashes onto the servo motor, take appropriate countermeasures such as installing a cover. SV2_motor_IM_E 80 When handling the connectors, follow the instructions below. • Before connecting the connectors, check that there is no dust or debris (metal particles, etc.) in the connecting section. • The motor power supply cable must be connected first to the servo motor. If the encoder cable is connected first, the encoder may be damaged due to the potential difference between the FG terminals. • Confirm that the wiring is correct before actually connecting cables. • Configure wiring so that no stress is applied to the connections. • Do not apply impacts to the connectors. As the connectors are made of plastic, they may be damaged. • When transporting the servo motor with the cables connected, be sure to hold the servo motor. Holding the cables during transportation will apply stress to the cables, which may cause connector damage or cable breakage. Installation Horizontal SV2-□075□ 100 Handling the connectors 10 1 20 50 100 150 200 250 300 Heatsink size (mm) 100 100 Torque command (expressed as rating) (%) NOTICE 60 120 0 500A 300 0 20 200A 50 80 40 40 100A 0 120 SV2-□020□/□040□ 100 350 Torque command (expressed as rating) (%) Heatsink Detection time (S) 60 40 • 1.0 kW to 2.0 kW 1 80 Derating (%) 1 Rotation speed Below 10 min-1 120 SV2-□005□/□010□ 100 Derating (%) 10 Derating (%) 120 Servo motor Derating (%) Detection time (S) 1000 The servo motor ratings (rated output, rated torque, and rated rotation speed) are the continuous allowable capacity when the motor is attached to the heatsink, and the ambient temperature is 40 ℃ . Even when the servo motor is mounted onto small equipment, provide an area sufficient for heat radiation to prevent a temperature increase of the servo motor. Attaching a heatsink or derating is required to limit the temperature increase within an appropriate range. Also, if the servo motor is covered with the equipment housing or is located near a heat generating object, take the following countermeasures: • Reduce the load ratio. • Review the heat radiation condition of the servo motor. • Install a cooling fan for forced cooling of the servo motor. The relationship between the heatsink (motor attaching portion) and derating is as follows: Derating (%) The following are overload detection level characteristics when the ambient temperature around the motor is 40°C and hot start is used. When the detection time is reached, the "Overload (Peak)" Alarm (710) or "Overload (Continuous)" Alarm (720) is issued. -6- Allowable Load This section shows the allowable radial load (the load applied perpendicular to the servo motor shaft) and the allowable thrust load (the load applied in parallel with the servo motor shaft) applied to the end of the servo motor shaft. Dimensions Standard motor SV2-M005A □ /M010A □ /M020A □ /M040A □ /M075A □ Radial load LM 2xφLZ R3 .7 LG ML L φL A 78 54 20 SV2- □ 010A □ 78 54 20 SV2- □ 020A □ 245 74 25 SV2- □ 040A □ 245 74 25 SV2- □ 075A □ 392 147 35 SV2- □ 100A □ 490 98 58 SV2- □ 150A □ 686 343 58 SV2- □ 200A □ 980 392 58 SV2- □ 300A □ 1470 490 79 SV2- □ 500A □ 1470 490 79 LE MD MW LR LC L Model Inspection Before you attempt to perform any maintenance or inspection, read and understand the safety precautions that are given at the beginning of this document to help prevent bodily injury and equipment damage. CAUTION LL • Before you perform any maintenance or inspection work, turn OFF the power supply, confirm that the CHARGE indicator on the front of the SERVOAMP has gone out, and then use a tester to check the voltage between the positive and negative terminals on the SERVOAMP. Start inspection work only after you have confirmed that the main circuit voltage has dropped. If there is any main circuit voltage left, the risk of electric shock still exists. Do not touch the Servomotor or any wiring. • All inspection and maintenance work must be performed only by qualified engineers. There is a risk of electric shock or injury. • Contact your Keyence representative for help with failures, repairs, or part replacement. Unit: mm SV2-M005A□ SV2-M010A□ SV2-M020A□ SV2-M040A□ SV2-M075A□ L LL LM LR LA 81.5 56.5 37.9 25 46 93.5 68.5 49.9 25 46 99.5 69.5 51.2 30 70 115.5 85.5 67.2 30 70 137 97 78.5 40 90 LB 30 0-0.021 30 0-0.021 50 0-0.025 50 0-0.025 70 0-0.030 LC LE LG LZ 40 2.5 5 4.3 40 2.5 5 4.3 60 3 6 5.5 60 3 6 5.5 80 3 8 7 S 8 0-0.009 8 0-0.009 14 0-0.011 14 0-0.011 19 0-0.013 MD MW MH ML 8.8 25.8 14 16.1 8.8 25.8 14 16.1 8.5 28.7 14.7 17.1 8.5 28.7 14.7 17.1 13.6 38 14.7 19.3 SV2-M100A □ /M150A □ /M200A □ /M300A □ /M500A □ L LL LR LE 36 LC Q LM φL φLBh7 Servo Motor Inspection Troubleshooting Daily Touch the motor and listen to the Contact your KEYENCE noise. representative. External inspection When the servo motor becomes dirty Clean the motor with air or a cloth. Insulation resistance measurement At least once a year Disconnect the servo motor from the servo amplifier and measure the insulation resistance with a 500 V megohmmeter. Resistance of 10 MΩ or more is a normal level. (Measure the section between any of the U, V, and W phases of the motor power line and F.G terminal.) Overhaul inspection At least once every 20,000 hours of operation or 5 years KB1 - If the resistance is less than 10 MΩ, contact your KEYENCE representative. Do not measure the insulation resistance of the encoder, or the withstand voltage of the servo motor. Contact your KEYENCE representative. Bearing Brake * 20,000 hours 20,000 hours Troubleshooting As the life-expectancy depends on the operating conditions, check for abnormalities in noise and vibration during inspection. As the life-expectancy depends on the operating conditions, check for abnormalities in noise and vibration during inspection, that the brakes release when powered, and that the brake operation time has not changed. Unit: mm KB2 The lifespan of each part is as shown below. For repair, contact your nearest KEYENCE office. Inspection period 4xφLZ 17 Guideline for Replacing Parts Part LG φSh6 Inspection description KL1 Inspection item Inspection period A 50 The inspection periods in the table below are a guide. Judge each part based on how it is being used and the environment and inspect them when necessary. Vibration and noise check φL H LC SV2- □ 005A □ 14.7 L (mm) φSh6 Allowable radial load (N) Allowable thrust load (N) MH Model LC φLBh7 Thrust load Model SV2-M100A□ SV2-M150A□ SV2-M200A□ SV2-M300A□ SV2-M500A□ L LL LM LR KB1 KB2 LA KL1 195 137 101 58 83 125 145 104 211 153 117 58 99 141 145 104 229 171 135 58 117 159 145 104 239 160 124 79 108 148 200 134 263 184 148 79 132 172 200 134 LB 110 0-0.035 110 0-0.035 110 0-0.035 114.3 0-0.025 114.3 0-0.025 LC LE LG LH LZ 130 6 12 165 9 130 6 12 165 9 130 6 12 165 9 180 3.2 18 230 13.5 180 3.2 18 230 13.5 S 24 0-0.013 *1 24 0-0.013 *1 24 0-0.013 *2 35 +0.01 0 *2 35 +0.01 0 Q 40 40 40 76 76 *1 *2 The shaft diameter (the S dimension above) of the SV2-M100A □ /M150A □ differs from the same capacity SV Series. The tolerance of SV2-M300A □ /SV2-M500A □ is as indicated, but it does not fit the tolerance zone class h6. The lifespans indicated are for reference only. The actual lifespans differ according to the environmental conditions and usage methods. -7- SV2_motor_IM_E Electromagnetic brake motor Shaft shape - Keyway SV2- B005A □ /B010A □ /B020A □ /B040A □ /B075A □ • SV2- □ 005A □ / □ 010A □ / □ 020A □ / □ 040A □ / □ 075A □ LM QK U LC φLBh7 φSh6 W 2xφLZ R3 .7 LG ML T LE LL Unit: mm SV2-B005A□ SV2-B010A□ SV2-B020A□ SV2-B040A□ SV2-B075A□ L LL LM LR LA 122 97 37.9 25 46 134 109 49.9 25 46 140 110 51.2 30 70 156 126 67.2 30 70 184 144 78.5 40 90 LB 30 0-0.021 40 2.5 5 4.3 30 0-0.021 40 2.5 5 4.3 50 0-0.025 60 3 6 5.5 50 0-0.025 60 3 6 5.5 70 0-0.030 80 3 8 7 8 0-0.009 8.8 25.8 14 16.1 8 0-0.009 8.8 25.8 14 16.1 14 0-0.011 8.5 28.7 14.7 17.1 14 0-0.011 8.5 28.7 14.7 17.1 19 0-0.013 13.6 38 14.7 19.3 LC LE LG LZ S MD MW MH ML SV2-□005A□ SV2-□010A□ SV2-□020A□ SV2-□040A□ SV2-□075A□ LR QK 25 14 25 14 30 14 30 14 40 22 S 8 0-0.009 8 0-0.009 14 0-0.011 14 0-0.011 19 0-0.013 W 3 3 5 5 6 T U 3 1.8 M3 screw 6 depth 3 1.8 M3 screw 6 depth 5 3 M5 screw 8 depth 5 3 M5 screw 8 depth 6 3.5 M6 screw 10 depth P • SV2- □ 100A □ / □ 150A □ / □ 200A □ / □ 300A □ / □ 500A □ (LR) (6) QK R1 SV2-B100A □ /B150A □ /B200A □ /B300A □ /B500A □ P LL LR Model LM Q LE LC φL H LC A KB1 KB3 LG φSh6 50 KL3 KL1 φLBh7 φL 4xφLZ Unit: mm Model SV2-B100A□ SV2-B150A□ SV2-B200A□ SV2-B300A□ SV2-B500A□ L LL LM LR KB1 KB2 KB3 KL1 KL3 LA 231 173 137 58 83 161 115 104 80 145 247 189 153 58 99 177 131 104 80 145 265 207 171 58 117 195 149 104 80 145 287 208 172 79 108 196 148 134 110 200 311 232 196 79 132 220 172 134 110 200 LB 110 0-0.035 130 6 12 165 9 110 0-0.035 130 6 12 165 9 110 0-0.035 130 6 12 165 9 114.3 0-0.025 180 3.2 18 230 13.5 114.3 0-0.025 180 3.2 18 230 13.5 LC LE LG LH LZ S Q *1 *2 SV2-□100A□ SV2-□150A□ SV2-□200A□ SV2-□300A□ SV2-□500A□ LR Q QK 58 40 25 58 40 25 58 40 25 79 76 60 79 76 60 S 24 0-0.013 *1 24 0-0.013 *1 24 0-0.013 *2 35 +0.01 0 *2 35 +0.01 0 W T U 8 7 4 M5 screw 12 depth 8 7 4 M5 screw 12 depth 8 7 4 M5 screw 12 depth 10 8 5 M12 screw 25 depth 10 8 5 M12 screw 25 depth P KB2 17 U Q L 36 T φSh6 Model Model MW LC LR L W MD P A 14.7 MH φSh6 φL *1 *2 The shaft diameter (the S dimension above) of the SV2- □ 100A □ / □150A □ differs from the same capacity SV Series. The tolerance of SV2- □ 300A □ /SV2- □ 500A □ is as indicated, but it does not fit the tolerance zone class h6. *2 *2 24 0-0.013 35 +0.01 24 0-0.013 *1 35 +0.01 24 0-0.013 *1 0 0 40 40 40 76 76 The shaft diameter (the S dimension above) of the SV2-B100A □ /B150A □ differs from the same capacity SV Series. The tolerance of SV2-B300A □ /SV2-B500A □ is as indicated, but it does not fit the tolerance zone class h6. WARRANTIES AND DISCLAIMERS (1) KEYENCE warrants the Products to be free of defects in materials and workmanship for a period of one (1) year from the date of shipment. If any models or samples were shown to Buyer, such models or samples were used merely to illustrate the general type and quality of the Products and not to represent that the Products would necessarily conform to said models or samples. Any Products found to be defective must be shipped to KEYENCE with all shipping costs paid by Buyer or offered to KEYENCE for inspection and examination. Upon examination by KEYENCE, KEYENCE, at its sole option, will refund the purchase price of, or repair or replace at no charge any Products found to be defective. This warranty does not apply to any defects resulting from any action of Buyer, including but not limited to improper installation, improper interfacing, improper repair, unauthorized modification, misapplication and mishandling, such as exposure to excessive current, heat, coldness, moisture, vibration or outdoors air. Components which wear are not warranted. (2) KEYENCE is pleased to offer suggestions on the use of its various Products. They are only suggestions, and it is Buyer's responsibility to ascertain the fitness of the Products for Buyer’s intended use. KEYENCE will not be responsible for any damages that may result from the use of the Products. (3) The Products and any samples ("Products/Samples") supplied to Buyer are not to be used internally in humans, for human transportation, as safety devices or fail-safe systems, unless their written specifications state otherwise. Should any Products/Samples be used in such a manner or misused in any way, KEYENCE assumes no responsibility, and additionally Buyer will indemnify KEYENCE and hold KEYENCE harmless from any liability or damage whatsoever arising out of any misuse of the Products/Samples. (4) OTHER THAN AS STATED HEREIN, THE PRODUCTS/SAMPLES ARE PROVIDED WITH NO OTHER WARRANTIES WHATSOEVER. ALL EXPRESS, IMPLIED, AND STATUTORY WARRANTIES, INCLUDING, WITHOUT LIMITATION, THE WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF PROPRIETARY RIGHTS, ARE EXPRESSLY DISCLAIMED. IN NO EVENT SHALL KEYENCE AND ITS AFFILIATED ENTITIES BE LIABLE TO ANY PERSON OR ENTITY FOR ANY DIRECT, INDIRECT, INCIDENTAL, PUNITIVE, SPECIAL OR CONSEQUENTIAL DAMAGES (INCLUDING, WITHOUT LIMITATION, ANY DAMAGES RESULTING FROM LOSS OF USE, BUSINESS INTERRUPTION, LOSS OF INFORMATION, LOSS OR INACCURACY OF DATA, LOSS OF PROFITS, LOSS OF SAVINGS, THE COST OF PROCUREMENT OF SUBSTITUTED GOODS, SERVICES OR TECHNOLOGIES, OR FOR ANY MATTER ARISING OUT OF OR IN CONNECTION WITH THE USE OR INABILITY TO USE THE PRODUCTS, EVEN IF KEYENCE OR ONE OF ITS AFFILIATED ENTITIES WAS ADVISED OF A POSSIBLE THIRD PARTY’S CLAIM FOR DAMAGES OR ANY OTHER CLAIM AGAINST BUYER. In some jurisdictions, some of the foregoing warranty disclaimers or damage limitations may not apply. BUYER’S TRANSFER OBLIGATIONS: If the Products/Samples purchased by Buyer are to be resold or delivered to a third party, Buyer must provide such third party with a copy of this document, all specifications, manuals, catalogs, leaflets and written information provided to Buyer pertaining to the Products/Samples. E 1101-3 SV2_motor_IM_E -8- Copyright (c) 2015 KEYENCE CORPORATION. All rights reserved. 13680GB 1118-3 96M13680 Printed in Japan