Mastering the Molding: A Guide to Selecting the Ideal Purging Material for Injection Molding

advertisement

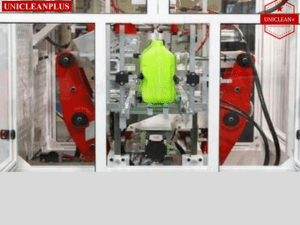

Mastering the Molding: A Guide to Selecting the Ideal Purging Material for Injection Molding Injection Molding is a widely used manufacturing process for producing high-quality plastic parts with precision and efficiency. However, over time, residue and contaminants can build up in the molding barrel and screw,, leading to defects and production issues. To combat this, Purging Materials are used to clean and maintain Injection Molding, ensuring optimal performance and product quality. Today, we’ll delve into the process of selecting the ideal Purging Material for Injection Molding, equipping you with the knowledge to streamline your production and achieve superior results. Understanding the Importance of Purging Materials Before diving into the selection process, it’s crucial to understand the significance of Purging Materials in Injection Molding. Purging Materials are designed to remove residual polymers, contaminants, and carbon deposits from the machine, preventing defects such as colour streaks, black specks, and dimensional inconsistencies. By using the right Purging Material, manufacturers can minimise downtime, reduce scrap rates, and maintain consistent product quality, ultimately maximising efficiency and profitability. Considerations for Selecting Purging Materials When selecting a Purging Compound for Injection Molding, several factors must be taken into account to ensure optimal performance and compatibility. These considerations include: Resin Compatibility: Choose a Purging Compound that is compatible with the resins being processed in the mold to effectively remove contaminants without leaving behind residue. Temperature Requirements: Consider the temperature range at which the material will be used and ensure that it can withstand the heat and pressure of the Injection Molding process without degrading or producing emissions. Cleaning Efficiency: Evaluate the effectiveness of the material in removing stubborn residues and contaminants from the machine, including colourants, additives, and processing aids. Safety and Environmental Impact: Prioritise Purging Materials that are non-toxic, environmentally friendly, and compliant with industry regulations to ensure the health and safety of workers and minimise environmental impact. Types of Purging Materials There are several types of Purging Materials available for Injection Molding, each offering unique benefits and applications. These include: Mechanical Purging Compounds: Designed to physically scrub the surface and remove contaminants through abrasive action, mechanical Purging Compounds are effective for cleaning stubborn residues and carbon deposits. Chemical Purging Compounds: Formulated with chemical agents that dissolve and disperse contaminants, chemical Purging Compounds offer a fast and efficient solution for purging colourants, additives, and other processing residues. Hybrid Purging Compounds: Combining the benefits of mechanical and chemical purging, hybrid Purging Compounds offer a comprehensive solution for cleaning Injection Molding machine and maintaining production efficiency. Testing and Evaluation Once you’ve identified potential Purging Materials, it’s essential to conduct thorough testing having free samples from the manufacturer and evaluating their suitability for your specific Injection Molding process. Perform trials using small quantities of the Purging Material and observe its cleaning effectiveness, compatibility with resins, and overall performance in real-world production conditions. Selecting the ideal Purging Material for Injection Molding is a critical step in ensuring optimal molding performance, product quality, and production efficiency. By considering factors such as resin compatibility, temperature requirements, cleaning efficiency, and safety, manufacturers can choose Purging Materials from UNICLEANPLUS that meet their specific needs and requirements. Calling them at +91 9021232809 you can have the right Purging Material in hand. To Read Our Published Blog: https://unicleanplus.wordpress.com/2024/03/28/mastering-the-molding-a-guide-to-selecting-the-idealpurging-material-for-injection-molding/ Thank You! UNICLEANPLUS Address : Bharatipolychem Pvt Ltd, Plot No-451 City: Lesliganj State: Jharkhand Zip: 822118 Country: India Phone: +91 9021232809 Website: https://www.unicleanplus.com/ Email: sales@bharatipolychem.com