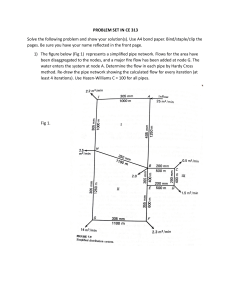

PIPE FABRICATION MATERIALS, DRAWING AND FABRICATION METHODS METALS AND ENGINEERING ENG2068 Pipe fabrication ENG2068 Materials, drawing and fabrication methods Copyright and Terms of Use © Department of Training and Workforce Development 2016 (unless indicated otherwise, for example ‘Excluded Material’). The copyright material published in this product is subject to the Copyright Act 1968 (Cth), and is owned by the Department of Training and Workforce Development or, where indicated, by a party other than the Department of Training and Workforce Development. The Department of Training and Workforce Development supports and encourages use of its material for all legitimate purposes. Copyright material available on this website is licensed under a Creative Commons Attribution 4.0 (CC BY 4.0) license unless indicated otherwise (Excluded Material). Except in relation to Excluded Material this license allows you to: Share — copy and redistribute the material in any medium or format Adapt — remix, transform, and build upon the material for any purpose, even commercially provided you attribute the Department of Training and Workforce Development as the source of the copyright material. The Department of Training and Workforce Development requests attribution as: © Department of Training and Workforce Development (year of publication). Excluded Material not available under a Creative Commons license: 1. The Department of Training and Workforce Development logo, other logos and trademark protected material; and 2. Material owned by third parties that has been reproduced with permission. Permission will need to be obtained from third parties to re-use their material. Excluded Material may not be licensed under a CC BY license and can only be used in accordance with the specific terms of use attached to that material or where permitted by the Copyright Act 1968 (Cth). If you want to use such material in a manner that is not covered by those specific terms of use, you must request permission from the copyright owner of the material. If you have any questions regarding use of material available in this product, please contact the Department of Training and Workforce Development. Training Sector Services Telephone: 08 6212 9789 Email: sectorcapability.ip@dtwd.wa.gov.au Website: www.dtwd.wa.gov.au First published 2013 ISBN 978-1-74205-902-0 © WestOne Services 2013 All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of WestOne Services. Whilst every effort has been made to ensure the accuracy of the information contained in this publication, no guarantee can be given that all errors and omissions have been excluded. No responsibility for loss occasioned to any person acting or refraining from action as a result of the material in this publication can be accepted by WestOne Services. Published by and available from WestOne Services 1 Prospect Place West Perth WA 6005 Tel: (08) 9229 5200 Fax: (08) 9227 8393 Email: sales@westone.wa.gov.au Website: www.westone.wa.gov.au This product contains various images ©Thinkstock 2013, used under licence. These images are protected by copyright law and are not to be reproduced or re-used in other materials without permission from the owner of Thinkstock. Data Chart at Appendix 1 has been reproduced with the permission of MRC Global Australia. Contents Chapter 1 – Introduction to pipe fabrication 5 About pipe fabrication.......................................................................................................5 Codes and standards.......................................................................................................6 Approval of piping systems..............................................................................................7 Pipe fabrication abbreviations..........................................................................................8 Chapter 2 – Materials 13 Piping systems...............................................................................................................13 Pipe................................................................................................................................16 Pipe fittings.....................................................................................................................18 Flanges...........................................................................................................................29 Gaskets..........................................................................................................................37 Valves.............................................................................................................................40 Bolts...............................................................................................................................54 Brackets and hangers (support).....................................................................................58 Identification of piping.....................................................................................................73 Chapter 3 – Drawing 75 Types of drawings..........................................................................................................75 Types of projection.........................................................................................................82 Parallel line.....................................................................................................................92 Piping symbols...............................................................................................................98 Dimensioning and line types........................................................................................107 Chapter 4 – Fabrication methods 115 Pipe fabrication.............................................................................................................115 Preparing for fabrication...............................................................................................116 Fabrication process......................................................................................................123 Welding process...........................................................................................................129 Appendix 1 – MRC Data Chart © WestOne Services 2013 135 3 4 ENG2068 © WestOne Services 2013 Chapter 1 – Introduction to pipe fabrication About pipe fabrication Pipelines are used to transport fluids, including vapours, gases, slurries and powders which flow through pipes at various pressures and temperatures. The transmission of these materials invariably subjects the pipe to intense stresses and strains and this demands the highest possible performance from the pipe. All pipework must be designed and fabricated in a way that ensures the safety of plant operators, the plant, the public and the environment. The fabricator is responsible for the quality of the pipework and pipe fabrication must be carried out in accordance with all relevant standards and specifications. One faulty weld could lead to damage costing millions of dollars, personal injury and in serious cases even death. Welded pipe systems demand the highest degree of excellence in materials and quality of work. Because high standards are required, the cost of pipework is extremely high. Typical costs for pipework in a manufacturing plant are shown in Table 1.1. Field labour costs 47% Material costs 23% Design engineering costs 20% Table 1.1: Fabrication costs It is essential that pipework is fabricated by suitably trained and competent tradespersons. © WestOne Services 2013 ENG2068 5 Codes and standards To ensure the highest standards of uniformity, safety and work quality, most piping systems are designed, welded, installed and tested to rigid specifications or codes. The most commonly used codes for welded pipework in Australia are as follows. Standards Australia International Limited (SAI) ● AS/NZS 3992:1998/Amdt 1:2000 Pressure equipment – Welding and brazing qualification ● AS/NZS 4645.2:2008 Gas distribution networks - Steel pipe systems ● AS 2885.4-2010 Pipelines - Gas and liquid petroleum - Submarine pipeline systems ● AS 1796-2001 Certification of welders and welding supervisors ● AS 1074-1989 Steel tubes and tubulars for ordinary service ● AS 4458-1997 Pressure equipment – Manufacture ● AS 4041-2006 Pressure piping American Society of Mechanical Engineers (ASME) ● ASME IX Piping systems in connection with power boilers, nuclear vessels and unfired pressure vessels American Petroleum Institute (API) ● API Std 1104 (R2010) Welding of Pipelines and Related Facilities – 20th Edition, includes Errata 1 (2007) and 2 (2008) American National Standards Institute (ANSI) ● ANSI/ASME B31.3 Chemical plant and petroleum refinery piping ● ASME B36.10M-2004 Welded and Seamless Wrought Steel Pipe Some insurance companies, manufacturers and the military forces set up their own codes to cover the fabrication and welding of pipeline systems. All codes are developed to establish uniform minimum standards for: ● piping material ● fabrication and welding procedures ● quality of work ● qualification of personnel ● inspection and testing. These standards ensure that there is maximum protection against accidents occurring when the piping is in service. 6 ENG2068 © WestOne Services 2013 Approval of piping systems There must be a high degree of quality control when high-pressure pipe systems are being fabricated to ensure that they meet the specifications of the relevant codes. The inspecting authority may be the machinery inspection branch of the state or territory government, the insurance company underwriting the job or the representatives of the client for whom the pipework is being fabricated. The quality control program includes the following steps. 1. Approval of the design of the pipe system. 2. Approval of the fabricator who may have to prove that there is adequate equipment and expert personnel to successfully meet the requirements of the relevant code(s). 3. Frequent checks to ensure that the specified material is being used. 4. Approval of welding procedures and regular inspections to ensure that these procedures are being followed. 5. Qualification of welders who are tested to ensure that they are capable of carrying out the approved procedures successfully. 6. Non-destructive testing as required by the code(s). 7. Post-weld heat treatment as required by the code(s). 8. Final hydrostatic testing or alternative testing method. Fabricators are responsible for the quality of the work they perform and for the coordination of all inspection and testing procedures as required by the relevant code(s). © WestOne Services 2013 ENG2068 7 Pipe fabrication abbreviations Abbreviation Definition ANSI American National Standards Institute ASME American Society of Mechanical Engineers ASTM American Society for Testing and Materials API American Petroleum Institute AWS American Welding Society ASSY assembly BB bolted bonnet BC bolt circle BE bevelled ends (for welding) BF blind flange BM bill of material BOP bottom of pipe BLDG building BW butt weld ˚C degrees Celsius centre-line 8 CH. OP. chain operated CI cast iron CO2 carbon dioxide COND condensate CORR corrosion or corrosive CONC concentric CPLG coupling CS carbon steel, cast steel or cold spring Ø diameter DIA or D diameter DF drain funnel DWG drawing ECC eccentric EFW electric fusion welded EL elevation ELL elbow ENG2068 © WestOne Services 2013 Abbreviation Definition ERW electric resistance welded FF flat faced or full faced FFW field fit and weld FIG figure or figure number FLG flange FOB flat on bottom FW field weld GA general arrangement GALV galvanised GJ ground joint GR grade HC hydrocarbon HDR header ID inside diameter IDD inside depth of dish INS insulate INV invert (inside bottom of pipe) LC lock closed LO lock open LR long radius M&F male and female MFG manufacture or manufacturing MI malleable iron MIN minimum MW mitre weld NC normally closed NO normally open NS nominal size OD outside diameter plate PCD pitch circle diameter PE plain end (not bevelled) P&ID Pipe and instrument diagram © WestOne Services 2013 ENG2068 9 Abbreviation 10 Definition PFD Process flow diagram PI point of intersection PR pair RED reducer REINF reinforce RF raised face RTJ ring type joint (sometimes just designated RJ) SCH schedule SCRD screwed SMLS seamless SO slip on S.O. steam out SPEC specification SQ square SR short radius SS stainless steel STD standard STL steel STM steam SW socket weld SWG swage SWP standard working pressure SC sample connection TC test connection TE threaded end TEMP temperature T&C thread and coupled T&G tongue and groove TOC top of concrete TOS top of steel TYP typical VET vertical WB welded bonnet ENG2068 © WestOne Services 2013 Abbreviation Definition WE weld end WN weld neck WT weight XH extra heavy XXH double extra heavy XS extra strong XXS double extra strong © WestOne Services 2013 ENG2068 11 12 ENG2068 © WestOne Services 2013 Chapter 2 – Materials Piping systems There are three common methods of joining piping, each with its own advantages and disadvantages. Butt welded piping systems are used for most process, utility or service piping. Butt welding is the most practicable way of obtaining strong, leak-proof joints; especially on larger piping. The pipe and fitting used have, or are prepared with, standard weld preparation. They require high levels of workmanship in their assembly and welding. B Detail B Scale 1/2 Fig 2.1: Butt welded piping system © WestOne Services 2013 ENG2068 13 Socket-welded piping systems are used for lines of small diameter which carry flammable, toxic or expensive materials where no leakage is permitted. They are easier to assemble and weld than butt welds and no weld metal can enter the bore. The pipe end is finished square and fitted into the fittings, usually with a 1.5 mm gap. This gap sometimes pockets liquids and is not recommended if severe erosion of crevice corrosion is anticipated. C Detail C Scale 1/2 Fig 2.2: Socket-welded piping system 14 ENG2068 © WestOne Services 2013 Screwed piping systems are used for small lines, usually of 50 mm diameter and are easily assembled using standard fittings. The removal of metal to create the thread is a disadvantage and fatigue strength is poor. There is no need for coded welders when a screwed pipe system is used except where seal welding is undertaken. Only butt welded and socket welded systems will be dealt with in this text. A Detail A Scale 1/2 Fig 2.3: Screwed piping system © WestOne Services 2013 ENG2068 15 Pipe Pipe is specified by stating its nominal size (NS), which is only approximate. Nominal size is neither the inside nor the outside diameter and it is necessary to use standard tables or manufacturers’ tables to ascertain these two dimensions exactly. Pipe thicknesses are often described as ‘standard’ (STD), ‘extra strong’ (XS) and ‘double extra strong’ (XXS). However, most manufacturers have adopted the American piping code classification which classifies pipes into a schedule system. The mass of the pipe is referred to as the schedule of pipe, and may vary from Schedule 10 to Schedule 160. As the schedule number increases so does the wall thickness, and as a consequence the inside diameter reduces. The outside diameters remain constant enabling standardisation of pipe brackets or threading. The exact wall thickness can be determined from standard tables. Pipe nominal size versus actual outside pipe diameter Schedule pipe wall thickness NS 100 pipe SCH 10 SCH 40 NS 100 114.3 (+14.3) NS 150 168.3 (+18.3) NS 200 219.1 (+19.1) NS 250 273.1 (+23.1) Nominal pipe size 3.05 6.02 SCH 80 8.56 SCH 160 13.49 Pipe wall Outside diameter Fig 2.4: Comparison of nominal size and schedule for 100 NS pipe 16 ENG2068 © WestOne Services 2013 Pipes are sometimes referred to as tubes. The primary difference is in how they are measured, Boiler tubes and tubing are known by their outside diameter and their wall thickness. Both dimensions are required when ordering. Carbon steel pipe Carbon steel (CS) pipe is by far the most common pipe used and it is supplied to strict specifications. Straight seam-welded and spiral-welded pipe is made from plate, and seamless pipe is made by piercing solid billets. CS pipe is strong, weldable, durable, ductile, machinable and cheaper than most other materials. If CS pipe can meet the requirements of pressure, temperature, corrosion, resistance and hygiene, it is a cost effective choice. CS pipes in common use are manufactured to the following standards: ●● ASME B36.10M-2004 Welded and Seamless Wrought Steel Pipe ●● AS 1074-1989 Steel tubes and tubulars for ordinary service ●● BS 1387:1985 Specification for screwed and socketed steel tubes and tubulars and for plain end steel tubes suitable for welding or for screwing to BS 21 pipe threads. Dimensions for pipes covered by these standards are, for practical purposes, the same. © WestOne Services 2013 ENG2068 17 Pipe fittings A pipe fitting may be defined as any type of pipe connector that is used to: ●● make a connection ●● change the size or direction of pipes or ●● change the pipe specification from one material to another. Fittings are classified by the method of end fixing, eg. butt welding, socket-welding, screwed or flanged and by name, eg. 90° and 45° elbows, reducing elbows, short and long radius bends, equal and unequal tees, concentric and eccentric reducers and stub ends. How are fittings rated? Fittings are rated by nominal working pressure in cold, non-shock conditions. Pressure rating Manufacturer’s weight Schedule no. Pressure rating PSI kPa 2000 13 790 STD 40 3000 20 670 XS 80 6000 41 340 XXS 160 Table 2.1: Relationship between PSI, kPa and the schedule Socket weld fittings are not manufactured in 2000 PSI (13 790 kPa). 18 ENG2068 © WestOne Services 2013 Butt welded fittings Butt welded fittings have a 30° truncated edge with a designed weld preparation consisting of a root gap and landing that is welded. Types in common use are shown in Figure 2.5. 180o Long radius Weld ELL 90o Short radius Weld ELL Straight tee 180o Short radius Weld ELL 90o Long radius Weld ELL Reducing tee 90o Reducing long radius Weld ELL Concentric reducer Cap 45o Long radius Weld ELL Eccentric reducer Fig 2.5: Butt welded fittings © WestOne Services 2013 ENG2068 19 Preparation for butt welds Unless the piping system is of a large enough diameter to permit internal access, butt welds must possess sound and smooth root penetration when welded from the outside. To achieve this, the weld preparation requires careful attention and the root face, root gap and root alignment are all critical. A single-Vee preparation is most common with the dimensions as shown in Figure 2.6. 300 +7½ -0 1.5 mm 2 - 3 mm Fig 2.6: Preparation for butt weld Butt weld elbows Elbows are fittings which are used to change the direction of flow. They are available for changes in direction of 180°, 90° and 45°. The 180° elbow is also referred to as a ‘return bend’. All butt weld elbows are supplied with bevelled ends. The 90° butt weld elbow is used to make a 90° offset-in any direction. It is available in short and long radius. The radius of the fitting is important when calculating cutting sizes as it must be subtracted in order to achieve correct centre line dimensions. The long radius elbow is most common, and equals one-and-a-half times the nominal pipe diameter from the face of the weld preparation to the elbow’s centre-line. Unless otherwise specified long radius elbows will always be supplied. 1½ × NPS 90o Long radius weld ELL 1 × NPS 90o Short radius weld ELL Fig 2.7: Short and long butt welding elbows 20 ENG2068 © WestOne Services 2013 When an offset is required where the angle is not than the standard fitting, it is customary to use a 90° or a 45° elbow and cut to the desired angle. Critical dimensions of elbows and other fittings can be obtained from standard tables. Reducing elbows Reducing elbows facilitate a change in line size along with a 90° change in direction. The centre-line radius is one and a half times the nominal size of the larger end. Fig 2.8: Reducing elbow Return bends Return bends are used to change the direction of piping through 180°. Long radius returns have a radius of 1½ × NS, ie centre to centre distance of 3 × NS. 3 × NS 2 × NS 180o Long radius weld ELL 180o Short radius weld ELL Fig 2.9: Return bends © WestOne Services 2013 ENG2068 21 Lap joint stub ends Lap joint stub ends are flared pipes that accommodate slip on flanges. They are supplied mainly in material other than carbon steel, eg stainless steel. As an economic measure carbon steel flanges are used as an alternative to stainless steel flanges. The flanges are allowed to float free and can swivel which is useful when pipes are being aligned. Fig 2.10: Lap joint stub end Reducers Reducers are used to join a smaller pipe to a larger one. Reducers are available in two types – eccentric and concentric. Eccentric reducers are used when the top or bottom of the line needs to be kept level. Fig 2.11: Concentric and eccentric reducers 22 ENG2068 © WestOne Services 2013 Butt welding tees Butt welding tees are used to make 90° branches from the main run of pipe and may be either straight or reducing. Reducing tees have a 90° branch smaller than the main line. Tees with branches larger than the main line are seldom used, as they must be made to order. Fig 2.12: Straight and reducing tees How to specify tees Equal tees are abbreviated, eg a NS 150 mm straight tee = NS 150 EQ tee. Reducing tees are specified in the following order: Run inlet Run outlet Branch NS 100 NS 100 NS 80 Specified red tee: 100 × 100 × 80 Laterals Laterals let branches enter at odd angles to the main run and both straight and reducing laterals are available. 45° straight laterals are the most common and are available in STD or XS weights. Reducing laterals and laterals at odd angles usually require special order. Reducing laterals are ordered in a similar way to ordering reducing tees, except that the branch angle is also stated. © WestOne Services 2013 ENG2068 23 Fig 2.13: A lateral Caps Caps are used to seal off the ends of pipes. Fig 2.14: A cap Socket-welded fittings Socket-welded fittings allow for easy fabrication and fit-up of piping. Square end preparation of the pipe is all that is required and fillet welds are used, preferably made in two passes. Lower levels of operator skill are required to assemble and weld socket joints than are required for butt joints. The socket-welding system is preferable to the screwed system as it is simpler to assemble and avoids the possibility of leakage which sometimes arises in screwed joints. 24 ENG2068 © WestOne Services 2013 Elbows Socket-welding elbows are available to make changes in direction of 90° or 45°. Fig 2.15: A socket-welding elbow Tees Tees make 90° socket-welded branches either as straight or reducing tees. Fig 2.16: A socket-welding tee Laterals Laterals are available to make 45° branches. Fig 2.17: A socket-welding lateral © WestOne Services 2013 ENG2068 25 Coupling Full couplings are used to join a pipe to a pipe or to a swage of the same diameter. Half couplings are also available but are not in common use as Sockolets® are generally preferred. Fig 2.18: Couplings Reducers Reducers are similar to couplings but are used to join pipes of different diameters. Fig 2.19: A reducer Reducer inserts Reducer inserts are used to connect smaller pipes to larger fittings. Fig 2.20: Reducer inserts 26 ENG2068 © WestOne Services 2013 Swaged nipple or ‘swage’ Swages are used to join socket-welded fittings of different sizes or to weld a socketwelded fitting to a butt welded fitting of a larger size. When ordering swages, it is necessary to specify nominal diameter, the weight of the pipes to be joined and the end preparation. Fig 2.21: A swaged nipple It is possible to make custom reducer inserts or tees by boring standard blanks. Normal specification tolerances call for a 1.6 mm shrinkage gap when assembling socket weld fittings Figure 2.22). Dimensions of socket weld fittings can be obtained from standard tables. Max 2 t Diametrical clearance 0.75 mm c t 1.5 mm approximately Not less than 3 t c-minimum — 1 ¼ t But not less than 3 mm t = nominal pipe wall thickness Fig 2.22: Section view of swage tolerances © WestOne Services 2013 ENG2068 27 Specialised weld fittings Specialised weld fittings are designed for making right-angle branch-type outlets such as tees, crosses and side outlets by welding. They are available in all common types of material, eg carbon steel, chrome/moly and stainless steel. Using specialised fittings eliminates the need for parallel line development. No templates are used and threading, forming or complicated fitting are not necessary. They are available to make butt welded, socket-welded and welded/screwed joints. Specialised fittings come in a range of sizes and are fully approved by most design codes. ® Weldolet® Butt-welded Elbolet® Sweepolet® Sockolet® Thredolet® Butt-welded Latrolet® Nipolet® Socket-welded Elbolet® Socket-welded Latrolet® Screwed Elbolet® Screwed Latrolet® Fig 2.23: Specialised weld fittings 28 ENG2068 © WestOne Services 2013 Flanges Flanges are used primarily as a way of connecting valves and fittings to pipes and they vary widely in size and type. They enable valves to be removed periodically for repair or replacement. Like pipe and pipe fittings they are made to strict code specifications. Flanges, like pipes, are referred to by nominal size and flange type, ie weld-neck flange, slip-on flange, as well as by class and the type of flange face. Flange types Flange types need to match the designed pressure and temperature ratings of piping systems. Weld neck flanges Weld neck flanges are distinguished from other types of flanges by their long tapered hub and gradual transition of thickness in the region of the butt weld joining them to the pipe. The hub provides an important reinforcement of the flange itself from the perspectives of strength and resistance to ‘dishing’. The smooth transition from flange thickness effected by the taper is extremely beneficial under repeated conditions of bending caused by pipeline expansion or other variable forces. It produces an endurance strength of weld neck flanged assembles equivalent to that of a butt welded joint which, if done properly, is the same as that of a seamless pipe. This type of flange is preferable for very severe service conditions such as high-pressure, sub-zero or elevated temperatures. Fig 2.24: A weld neck flange Slip-on flanges Slip-on flanges are used extensively because of their lower initial cost. They are easier to fix than a weld-neck type as the pipe does not require such accurate cutting and the ease of alignment to an assembly is simplified. However, the final installed cost is not much less than that of the weld-neck flange and their strength under internal pressure is approximately two-thirds that of weld-neck flanges with life under fatigue approximately one-third. © WestOne Services 2013 ENG2068 29 Fig 2.25: A slip-on flange Socket-welding flanges Socket-welding flanges are used fairly extensively in chemical process piping, as smooth, pocketless bore conditions can be obtained by grinding the internal weld flush. Their cost is about 10 per cent greater than the slip-on flange. Their static strength is about equal to welded slip-on flanges but their fatigue strength is 50 per cent greater. Fig 2.26: A socket-welding flange Lap joint flanges Lap joint flanges are used mainly with carbon or low alloy-steel piping systems where the services necessitate frequent dismantling for cleaning and inspection. They also simplify erection, as the flange can be swivelled to align bolt holes. They require lap joint stubs and the combined initial cost of the flange and stub is approximately one-third higher than a comparable weld-neck flange. Their pressure-holding ability is no better than slip-on flanges and the fatigue life of the assembly is approximately one-tenth of a weld-neck flange. They should not be used where severe bending stress occurs. 30 ENG2068 © WestOne Services 2013 Lap joint Slip on Fig 2.27: A lap joint flange Blind flanges Blind flanges are used to close off the ends of piping, nozzles or valves. Due to internal pressure acting to bend blind flanges at their centre, they are the most highly stressed of the flange types. Where severe water-hammer or temperature is a service factor consideration should be given to the use of closures made from weld-neck flanges and caps. Fig 2.28: A blind flange © WestOne Services 2013 ENG2068 31 Orifice flanges Orifice flanges are used to measure the flow rate of liquids and gases within a pipeline, thus eliminating the need for hot tapping or pipe modification. The orifice flange consists of two flanges with an additional tapped hole in each so that monitoring equipment, an orifice plate and jacking bolts can be attached. These facilitate the separation of flanges when they need to be inspected. Orifice flanges come in a range of nominal sizes and types, such as weld neck, slip on and screwed. A A A-A Fig 2.29: An orifice flange 32 ENG2068 © WestOne Services 2013 Flange facings There are many facings offered but only a handful are in common use. The main variables in flange facings are the profile of the flange face; the smoothness of the face; and whether or not the use of a gasket is employed. Raised face Raised face is by far the most common type used, accounting for approximately 80% of all applications. The face is raised 1.6 mm for Class 150 and Class 300 flanges, and 6.5 mm for other classes. The raised face is machine finished with either concentric or spiral grooves approximately 0.4 mm deep which bite into and hold the soft, flat gasket normally employed with this face type. 6 Fig 2.30: A raised face weld neck Flat face The most common use for flat face is for non-steel flanges such as cast iron or plastic. The gasket used has the same outside diameter as the flange. This reduces the danger of cracking the flange when tightened. Fig 2.31: A flat face weld neck © WestOne Services 2013 ENG2068 33 Ring joint Although expensive, the ring joint facing is the most efficient facing for high-pressure and high-temperature service. Both flanges of the pair are alike, with a groove machined into each face. (Flat bottom grooves are standard.) Oval or octagonal ring type gaskets are fitted into the groove before tightening. Fig 2.32: A ring joint weld neck Lap joint The lap joint flange in combination with the lap joint stub end provides a joint facing similar to that of a raised face flange. Slip on Lap joint Fig 2.33: A lap joint slip-on 34 ENG2068 © WestOne Services 2013 Male and female Male and female facings come in two standard types – one with a large male–female contact area and the other with a small male–female contact area. The large male–female contact area is excessive for use with metal gaskets and the small male–female contact is not suitable for use with screwed fittings of standard weight. The male face is usually 6.5 mm high (1/4”) and the female face is approximately 4.7 mm (3/16”) deep. Both faces are usually smooth and the outer diameter of the female face acts to locate and retain the gasket. Fig 2.34: Male and female butt welds Tongue and groove Tongue and groove fittings are designed to match each other and, although similar to male and female fittings, the grooves do not extend into the flange base. These types of flanges are self-aligning which is useful when bore alignment is critical. Tongue and groove fittings are available in all nominal sizes. © WestOne Services 2013 ENG2068 35 Fig 2.35: A tongue and groove butt weld Finish Finish refers to the surface texture of the flange face and may be either ‘serrated’ or ‘smooth’. A serrated finish is produced by machining grooves into the surface. A smooth finish is usually specially ordered and comes in two qualities – the regular smooth finish which shows no tool marks to the naked eye or the ‘cold water finish’ which is even smoother. The cold water finish is normally used without gaskets. Class rating Flanges are given a ‘class’ rating which refers to service pressure and temperature. The class of flange may be: 150, 300, 400, 600, 900, 1500, 2500. The number of boltholes in a flange varies with the size and class. For example, a class 150, 80 mm flange has four boltholes, and a class 150, 150 mm flange has eight boltholes. In a class 300, an 80 mm flange has eight boltholes and a 150 mm has twelve boltholes. The diameter of the bolthole also varies with class so that large diameter bolts may be used for additional strength in the heavier classes. Dimensions of each class of flange, and the dimensions of the bolts used by these flanges can be determined from standard tables. 36 ENG2068 © WestOne Services 2013 Gaskets Gaskets are used to provide leak tight joints between matching surfaces. Gasket materials vary widely and may include: ●● non-metals – such as paper and rubber ●● metals – such as copper, iron or stainless steel ●● combinations of metals and non-metals. The choice of gasket materials depends on factors such as service pressure, service temperature, corrosion, bolt loadings and cost. Gasket types Gasket types need to match the designed pressure and temperature ratings of piping systems and the flange type. Flat ring gaskets Flat ring gaskets are the most commonly used. They vary in thickness from approximately 0.2 mm up to approximately 6 mm (the former being the most common), and in width from approximately 6 mm upwards. Narrow gaskets are preferred, as they require lower bolt loadings to obtain an effective seal. However, they must not be too narrow, in case they become crushed or indented into the flange. Serrated gaskets Serrated gaskets are flat metal gaskets which have concentric grooves machined into their faces. The reduced surface area provided by the grooves allows an efficient seal at lower bolting loads. They are commonly used with smooth faced flanges where gaskets of soft material would be unsuitable. Fig 2.36: A serrated gasket Laminated gaskets Laminated gaskets are made up of a skin with a filler material. There are two basic types of laminated gasket: ●● flat jacketed ●● spiral wound. © WestOne Services 2013 ENG2068 37 Flat jacketed gaskets Flat jacketed gaskets can be used at higher temperatures than plain flat gaskets and they require lower bolt loads than flat metal gaskets. Fig 2.37: A flat jacketed gasket Spiral wound gaskets Depending on the type of metal–filler combinations, spiral-wound gaskets are suitable for raised face, flat faced and lap joint flanges at pressures up to 7000 kPa (1000 PSI) and temperatures up to 1000°C. Fig 2.38: Spiral wound gaskets Ring joint gaskets Ring joint gaskets are available with either an oval or octagonal cross-section. They can be used with all classes of flange, especially the 600 – 2500 lb classes. They are manufactured from soft iron, low-carbon steel, chromium and molybdenum steel and stainless steels For relatively low-temperature joints, plastic may be used to prevent corrosion or to provide electrical insulation. Fig 2.39: A ring joint gasket 38 ENG2068 © WestOne Services 2013 Insulating gaskets Gaskets made of non-conductive material together with insulating sleeves around bolts are used where it is necessary to provide electrical isolation between parts of a line. A guide to the suitability of gasket materials is provided in Table 2.2. Maximum service temperature °C Maximum pressure at temperature Synthetic rubber 120 450 kPa (60 PSI) Synthetic rubber with cloth insert 120 3450 (500) Teflon 250 2050 (300) Carbon steel 400 14 200 (2100) Stainless steel 650 17 250 (2500) S/S Teflon 250 S/S ceramic 1000 Material Ring type joint Spiral wound above 3450 (500) Table 2.2: Material gasket vs temperature and pressure © WestOne Services 2013 ENG2068 39 Valves The variety of valves available for use in piping systems is extensive. This is due to the range of functions that valves perform, the diversity of fluids carried, and the varying conditions under which valves must perform these tasks. Valves can be examined under the following headings: ●● basic parts ●● functions performed by valves ●● valve types ●● installation of valves ●● specification of valves. Basic parts of a valve Despite vast differences in valve design, common parts can be identified. Bonnet Stem Disc Seat Body Fig 2.40: Basic parts of a valve 40 ENG2068 © WestOne Services 2013 The body The body is the main structure of the valve which contains – or to which is attached – the other parts of the valve. The body must possess sufficient mechanical strength and sufficient resistance to corrosion, erosion and high temperature to meet service conditions. The material from which the valve body is made is important in this regard and common materials in use include carbon steel, low-alloy steel, bronze, brass, stainless steel and monel. The disc, seat and port The disc, seat and port arrangement is the means of controlling the flow of fluids through the valve. Regardless of shape and arrangement the disc is the moving part that directly controls the flow. The non-moving part upon which the disc bears is called the seat, and the port is the maximum internal opening through which the fluids can pass. The stem The stem is used to move the disc. It is usually a screwed rod, although in some cases fluid under pressure moves the disc. There are two basic stem types. ●● The rising stem – As the valve is operated, the stem rises, lifting the disc with it. The hand wheel can either rise with the stem, or the stem can rise through the hand wheel. Stem bushing Stem bushing Stem moves down through valve bonnet Stem moves up through stem bushing and handwheel Gate withdrawn from line of flow Gate seated to block line of flow Fully open Fully closed Fig 2.41: The rising stem © WestOne Services 2013 ENG2068 41 ●● The non-rising stem – The stem remains in the same position whether the valve is open or closed. The disc moves up the thread on the stem as the valve is operated. The screw is inside the bonnet and in contact with the fluid carried. Stem turns with handwheel but does not move up or down Gate threads down off stem and seats Gate threads up onto stem Fully open Fully closed Fig 2.42: The non-rising stem The bonnet The bonnet is the top housing of the valve. It provides a bearing in which the stem can run. It acts as a means of sealing the stem of the valve against leakage (usually by means of a gland and packing). There are three basic means of attaching the bonnet to the valve body. 42 ●● The screwed bonnet is generally used on small, low pressure valves. A problem which can sometimes occur with the screwed bonnet is that the bonnet can become unscrewed as the valve is operated. This is caused by a tight or ‘sticky’ stem. ●● The bolted bonnet is the most common type used in refinery applications. It is suitable for medium/high pressure applications. ●● The breech lock is a heavier more expensive bonnet, normally used for high pressure work. It employs a seal weld to guard against leakage. ENG2068 © WestOne Services 2013 The operator The operator is the method of actuating the valve. Valves may be operated manually: by the use of hand wheels, levers and chains, by geared hand wheels on larger valves or by powered operation employing electric, pneumatic or hydraulic actuators. Powered actuators are normally used when: ●● rapid opening or closing is required ●● the valve is operated very frequently ●● access to the valve is difficult ●● the operation of the valve requires great effort ●● valve operation present a safety hazard. Functions performed by valves Valves perform the following basic functions. ●● They shut off supply in a pipeline or they enable a piece of pipeline to be isolated so that repairs to piping or equipment can be carried out faulty or damaged items can be replaced, etc. This is a shut-off or stop valve. ●● They throttle, regulate or restrict the flow passing along a pipeline by partially closing the area of flow through the valve. ●● They redirect the flow at a branch line by changing the path along which the flow occurs. ●● They protect a system against excessive pressure or sudden increases in pressure. These are safety valves or relief valves. When the pressure in a line reaches a pre-set high pressure, the valve opens and allows the pressure to escape either to atmosphere or to another part of the system. Safety valves are generally used for steam, air or other gases. Relief valves are usually used for liquids. ●● They enable one part of a continuous system of piping to operate at a different pressure from another part. These are pressure-reducing valves (also known as pressure regulators) and are often used in air piping to reduce the compressor or main line pressure down to a low value for operation of low-pressure equipment. ●● They prevent flow in one direction along a pipe or they allow flow in one direction only. This valve is referred to as a non-return, or check or reflux valve. © WestOne Services 2013 ENG2068 43 Types of valves The type of valve to be used depends on the function it is to perform and the conditions under which it is expected to perform. The following types of valves can be used: ●● gate valve ●● globe valve ●● diaphragm valve ●● ball valve ●● taper plug valve ●● butterfly valve ●● check (non-return) valve ●● relief valve. Gate valve Because of the disc and seat design, the gate valve is for on–off use, and not for throttling applications. If gate valves are used for throttling applications, they may damage the disc and seat through erosion or vibration. Fig 2.43: A gate valve 44 ENG2068 © WestOne Services 2013 Globe valve The term ‘globe valve’ is applied loosely to a valve whose body is globeshaped or has globelike features. Globe valves are generally suitable for throttling applications, with the design of the valve determining how closely flow can be regulated. The direction of flow through a globe valve is usually from stem to seat to assist leaktight closure of the valve. Fig 2.44: A globe valve © WestOne Services 2013 ENG2068 45 Types of globe valves include: Angle globe valve An angle globe valve changes direction through 90°. Fig 2.45: An angle globe valve Needle valve A needle valve is a small valve used for precise flow control. Fig 2.46: A needle valve 46 ENG2068 © WestOne Services 2013 Wye valve Because of its smooth flow pattern, a wye valve is preferable for use with erosive fluids. Fig 2.47: A wye valve Diaphragm valve The diaphragm valve is generally used where particles or fibres are carried, eg slurries. The diaphragm is capable of sealing against these particles and it gives full, unrestricted flow in the fully open position. The disc is usually a rubber diaphragm. Handwheel Bonnet Stem Compressor Rubberised diaphragm Diaphragm weir seat Fig 2.48: A diaphragm valve © WestOne Services 2013 ENG2068 47 Ball valve A spherical ball is used to block the bore of this valve and cut off the flow. The ball, which has a hole through it, is rotated 90° by a lever and flow is permitted when the hole through the ball lies along the pipe axis. Lever handle Retainer nut Body Cartridge O-ring (top) Stem O-ring Stem Cartridge O-ring (bottom) Seat ring Ball Ball retainer Fig 2.49: A ball valve Taper plug valve Similar to a ball valve, a tapered (conically shaped) plug is used to seal the bore of the valve. A hole through the plug is used to permit flow when this hole is lined up with the axis of the pipe. Ball and plug valves are quick and easy to operate and require only a 90° turn of the lever to open or close the valve. When these valves are closed, they pocket fluid in the ball or plug, which may create problems when used with corrosive fluids. 48 ENG2068 © WestOne Services 2013 Stem Grounding spring Valve cap Adjuster rocker-arm adjustment TFE diaphram cap seal Valve body TFE sleeve positive shut-off plug and body seal Raised ribs, grooves, and recesses positively lock sleeve in body Tapered plug Fig 2.50: A taper plug valve Butterfly valve A butterfly valve has a circular disc, which is approximately the size of the pipe bore in diameter. This disc rotates around its centre, so that when closed, the disc completely covers and seals the bore of the pipe. When fully open, the disc thickness lies along the centre of the pipe. The contents of the pipe then pass down and past both sides of the disc. The butterfly valve has the advantage of 90° on–off operation and does not pocket fluids like the ball and plug valve. © WestOne Services 2013 ENG2068 49 Handle Stem Packing Body Disc Seat Closed Open Fig 2.51: A butterfly valve Check (non-return) valve Check valves permit flow in one direction only. The valve closes if flow is reversed. Swing check Lift check Fig 2.52: A check valve 50 ENG2068 © WestOne Services 2013 Relief valve Relief valves are used to prevent build-up of excessive pressure of gas or liquid in lines or vessels. They usually operate against a pre-set spring loading. Relief valves for gas are designed to permit a large flow; a small flow which will rapidly decrease pressure is usually all that is required for liquids. Fig 2.53: A relief valve Installation of valves Valves may be attached to lines or vessels by the following methods. Screwed attachments – Generally used on small diameter, low pressure lines. Flanged joints –The body of the valve is flanged to make it compatible with flanges of the same pressure rating. It offers the advantages of easy installation and removal, and is suitable for medium/high pressure applications. Butt weld attachments – The valve ends are supplied with standard weld preparation. Although difficult to fit and remove, this is the preferred method for extreme service applications. Weld procedures should be designed so as to minimise distortion of the valve body. © WestOne Services 2013 ENG2068 51 Wafer valves – These have no flanges of their own and are sandwiched between the flanges on the pipe ends. They are located and held in position by the bolts which pass between the pipe flanges. Because the pipe flanges are held a distance apart equal to the thickness of the wafer valve, longer bolts than usual will be required. The valve has flat faces which contact the flanges. Gaskets or O-rings are used to seal against leaks. The outer diameter of the body is made to suit the pitch circle diameter (PCD) of the bolts of the flange. The bolts go around the valve body rather than passing through it. Fig 2.54: A wafer valve These guidelines should be followed when valves are being installed. 52 ●● The direction of flow through the valve must be correct. Where this is important, flow direction will be indicated on the valve body (usually by an arrow). ●● Valves should be placed in horizontal rather than vertical runs to facilitate the draining of the line when the valves are closed. ●● Heavy valves should be suitably supported. A minimum of 300 mm between flange and support should be allowed to facilitate installation and removal. ●● For aesthetic reasons, it is important to keep the centre-lines of valves at the same height and in line on the plan view. ●● There should be no safety hazards for the operator to contend with when accessing valves. ●● Lines carrying hazardous materials should have valves placed in such a way that the operator does not have to reach up to open or close them. ●● Valve stems should not point downward at any angle below the horizontal. This prevents sediment from collecting in the gland packing which may damage the stem. ●● Valve stems should not be pointed into walkways, etc. ENG2068 © WestOne Services 2013 Specification of valves Manufacturers use identification codes or model numbers to identify their valve; these are usually cast or stamped into the valve body. There is no standard system and each manufacturer uses their own so it is necessary to consult manufacturers’ catalogues to assist in the identification or ordering of valves. The important factors which determine the suitability of a particular valve for use are: ●● pressure rating ●● valve type (gate, globe, etc) ●● method of attachment ●● type of operator ●● disc and seat material ●● body material. These same factors are also used to classify the different valve models. © WestOne Services 2013 ENG2068 53 Bolts Bolts are used to assemble the piping system through the flanges. They are graded for tensile strength which is affected by temperature and pressure ratings of the piping system. Flange bolts Two types of bolts are available for the assembly and tightening of flanges: 1. the machine bolt, which uses one nut 2. the stud bolt, which uses two nuts. Fig 2.55: A machine bolt and a stud bolt Stud bolts have become the preferred method of bolting flanges. They offer the following advantages. ●● They can be removed easily (especially when corroded). ●● They are not easily confused with other bolts used on site. ●● They can be made from round stock. ●● The bolt sizes required for flanged joints are readily available from manufacturers’ tables. Procedure for application of bolt torque on flanged joints Step 1 Component parts must be aligned and clamped together with the hold down. Step 2 Stud (or bolt) threads in area of nut (or forged ring) engagement should be lubricated. The face of nuts (or bolt heads) should also be lubricated using a suitable lubricant. Step 3 All bolts should be installed so that torqueing requirements can be followed. 54 ENG2068 © WestOne Services 2013 Step 4 All bolts should be numbered so that torqueing requirements can be followed. Step 5 Torque should be applied in 20% (1/5) steps of required final torque, with all bolts loaded at each step before the next step is undertaken. Step 6 Bolts should be tightened in sequential order: 0°–180°, 90°–225° and 135°–315° at each step until final torque is reached. (See Figures 2.56 – 2.60.) Step 7 Rotational tightening should be used until all bolts are stable at final torque level; two complete times around are usually required. Bolt torque procedure 1 0° 8 5 315 ° 4 45 ° 270 ° 6 90 ° 225 ° 135 ° 180 ° 3 7 2 Sequential order Rotational order 1–2 1 3–4 5 5–6 3 7–8 7 2 6 4 8 Fig 2.56: Eight bolts per flange © WestOne Services 2013 ENG2068 55 Bolt torque procedure 1 12 8 4 10 0° 330 ° 300 ° Bolt torque procedure 16 5 8 30 ° 60 ° 270 ° 9 3 90 ° 240 ° 210 ° 6 120 ° 180 ° 2 12 7 4 14 11 0° 9 22½ ° 5 45 ° 292½ ° 67½ ° 270 ° 90 ° 247½ ° 6 150 ° 337½ ° 315 ° 1 112½ ° 225 ° 135 ° 202½ ° 157½ ° 180 ° 10 15 2 13 3 11 7 Sequential order Rotational order Sequential order Rotational order 1–2 1 1–2 1 2 3–4 5 3–4 9 10 5–6 9 5–6 5 6 7–8 3 7–8 13 14 9–10 7 9–10 3 4 11–12 11 11–12 11 12 2 13–14 7 8 6 15–16 15 16 10 4 8 12 Fig 2.57: 12 bolts per flange 56 ENG2068 Fig 2.58: 16 bolts per flange © WestOne Services 2013 Bolt torque procedure Bolt torque procedure 20 8 1 13 342 ° 0 ° 18 ° 324 ° 36 ° 306 ° 16 4 12 3 90 ° 252 ° 18 9 72 ° 270 ° 108 ° 234 ° 126 ° 7 216 ° 144 ° 198 °180 ° 162 ° 19 6 11 14 2 Sequential order 8 17 54 ° 288 ° 10 5 15 20 24 1 9 17 345 ° 0 ° 15 ° 330 ° 30 ° 315 ° 45 ° 300 ° 5 60 ° 13 12 285 ° 75 ° 21 4 270 ° 90 ° 3 255 ° 22 14 105 ° 240 ° 6 Rotational order 16 120 ° 225 ° 135 ° 150 ° 210 ° 7 195 ° 180 ° 165 ° 18 10 Sequential order 2 23 11 19 15 Rotational order 1–2 1 2 1–2 13–14 1 2 3–4 13 14 3–4 15–16 9 10 5–6 5 6 5–6 17–18 17 18 7–8 17 18 7–8 19–20 5 6 9–10 9 10 9–10 21–22 13 14 11–12 3 4 11–12 23–24 21 22 13–14 15 16 3 4 15–16 7 8 11 12 17–18 19 20 19 20 19–20 11 12 7 8 15 16 23 24 Fig 2.59: 20 bolts per flange © WestOne Services 2013 Fig 2.60: 24 bolts per flange ENG2068 57 Brackets and hangers (support) Piping systems may be subjected to a variety of stresses, which means that the pipework has to be supported. The lifespan of the pipe will be extended if appropriate supports are used to accommodate expansion and contraction due to environmental conditions. Stresses affecting pipe support The forces acting on pipework are: ●● the mass (weight) of the pipework and fluids carried by it ●● thermal expansion and contraction ●● vibration ●● settlement stresses. The mass (weight) of the pipework Piping systems may have considerable mass that needs to be supported; this factor is a major consideration in the design of pipework. For example, a reduction of mass is a significant reason for the widespread use of buttwelded piping systems. Pipework which is not suitably supported will sag, causing pockets of liquid which cannot drain from the pipe. Small-diameter pipes sag more easily than those of a larger diameter, and therefore require more support. Because of the high cost of pipe support, it is sometimes cheaper to simply use a larger diameter pipe, than to use a small-diameter pipe with support. Thermal expansion and contraction Changes in the temperature in piping due to variations in the ambient temperature or variations in the temperature of the fluids carried cause changes in the length of pipework. Changes in length depend on the variation in the temperature and the coefficient of expansion of the piping material. 58 ENG2068 © WestOne Services 2013 The expansion of carbon steel pipe can be determined from Table 2.3. 400 Temperature 0o C 300 200 100 75 50 25 0 3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 Expansion – mm per 10 m Table 2.3: Temperate vs expansion Piping systems and pipe supports must be designed with thermal expansion in mind. Piping systems which are too rigid may place excessive expansion and/or contraction forces on nozzles, flanges, couplings, etc. © WestOne Services 2013 ENG2068 59 Flexibility Expansion loops built into pipework are used to enable movement. An expansion loop is usually an offset-in piping made perpendicular to the pipe run by the use of standard materials – the greater the offset, the greater the amount of movement which can be absorbed. Double offset expansion bend Expansion square bend Expansion ‘U’ bend The greater the offset, the greater the amount of movement which can be absorbed. Fig 2.61: Expansion loops Flexibility can be built into piping systems by other design methods 60 ENG2068 © WestOne Services 2013 Limited flexibility Greater flexibility Fig 2.62: Flexibility options © WestOne Services 2013 ENG2068 61 Cold springing Cold springing involves offsetting branches during fabrication to minimise stresses placed on the piping when expansion occurs. The branch is pre-stressed to account for half the movement which would occur with thermal expansion. Hot position Cold position Expansion places high stress on branch pipe. E Expansion Cold position By cold springing joint excessive stress on branch pipe is minimised. Hot position E 2 Fig 2.63: Cold springing Vibration Vibration along with other stresses can significantly increase fatigue failure in piping systems. Where pipework and equipment are subject to load and vibration, the load carried and the vibration should be minimised. 62 ENG2068 © WestOne Services 2013 Gravitational load due to improperly supported pipe, combined with vibration from pump, leads to fatigue failure of cast iron flange. The suitably supported pipe reduces gravitational load on the cast iron flange, thereby reducing likelihood of fatigue failure. If the problem is considered significant enough to warrant it, a flexible coupling may also be used to minimise the effect of vibration. Flexible coupling Fig 2.64: Vibration © WestOne Services 2013 ENG2068 63 Settlement stresses The positional relationship of equipment placed on separate foundations may change as settlement of the foundations occurs. This may place excessive stress on interconnecting pipework. The problem can be overcome by allowing for this in the pipework. Settlement of foundations in direction shown may cause excessive stress on connecting pipe. The offset allows flexibility of the connecting pipe thereby minimising stress due to foundation settlement. Fig 2.65: Settlement stresses Types of pipe support Pipework can be supported by various mechanisms. Supports Supports are usually made from steel or concrete and are designed to support the weight of the pipework, usually from below. 64 ENG2068 © WestOne Services 2013 Fig 2.66: Pipe supports © WestOne Services 2013 ENG2068 65 Hangers Hangers are used to support pipework from above. Upper supports Midsections Pipe attachments Fig 2.67: Pipe hangers 66 ENG2068 © WestOne Services 2013 Guides Guides enable movement along the pipeline but prevent movement in other directions. Teflon pad Stainless steel Fig 2.68: Pipe guides Pipe-racks Pipe racks are used to support groups of pipes and are commonly seen only outside, as piping within buildings is usually supported from structural steelwork. A pipe rack consists of vertical members (stanchions) and a supporting horizontal platform on which the pipework rests. Pipe racks may be single or multi-decked depending on the size, the number of pipes to be carried, and the available space for the pipe rack. Pipe racks commonly serve secondary functions and generally support lighting, cable trays or utility stations. © WestOne Services 2013 ENG2068 67 Fig 2.69: Order of pipes Design guidelines for pipe racks 68 ●● Pipework must be placed in such a way that it provides ease of access to equipment for operation and maintenance. ●● Pipework must be placed so that it does not constitute a safety hazard. ●● Pipework should be placed so as to comply with recommended minimum clearances: ○○ above roadways – 6 m ○○ above walkways – 2 m ○○ operating space around equipment – 750 mm. ●● Large diameter pipes may be located 300–450 mm above or below ground because of their weight. Other piping should be suitably supported above the ground on pipe racks or supports. ●● Piping should be placed to the side of equipment rather than above it. ●● Large liquid-filled lines should be placed close to the stanchions on a pipe rack in order to avoid excessive stress on bents. ●● Hotlines that require expansion loops should be grouped together to the side of pipe racks with the largest lines outermost. ENG2068 © WestOne Services 2013 Fig 2.70: Pipes with expansion loops ●● Lines on pipe racks should be spaced with the outer edges of flanges a minimum of 25 mm apart, with the flanges offset a minimum distance of 300 mm. 25mm 300 minimum Fig 2.71: Minimum offset of flanges within the pipe rack ●● On pipe racks, a change in the horizontal direction of pipes should be accompanied by a change in elevation to prevent blocking of other lines on the pipe rack. ●● When designing pipe racks additional space (20–25%) must be allowed for to provide for future requirements. ●● The spacing of platforms depends on pipe sizes. However, it is customary to locate them approximately 8 m apart. ●● Pipe racks should be single deck if space permits. If multi-deck racks are used, sufficient space should be left between decks to take off branch lines. © WestOne Services 2013 ENG2068 69 Fig 2.72: Multi-deck pipe rack ●● A minimum distance beneath pipe racks should be maintained so that they can be accessed easily if work needs to be carried out at a later date. ●● Elevations should be set so that lines will drain. Positioning of pipe supports and hangers Support of pipework is expensive and piping support specialists are usually employed for large projects. Sections of piping should be supported, so that each section is in equilibrium and removing adjacent sections of piping or valves that need to be replaced will not upset the balance of the system as a whole. The weight of the piping should be shared equally among the pipe supports. Heavy fittings and valves will affect the centre of gravity (balance) of the pipework and allowances may need to be made for their removal. Additional supports can reduce balance or sagging problems but these will also increase costs. The best solution is to use fewer, well-placed supports. The diagrams that follow show the basic principles that may be applied to support pipework. Central support is OK for short or thick sections of pipe, but for long or small diameter pipes, ends sag downwards causing problems of removal or installation. 70 ENG2068 © WestOne Services 2013 Pipe sags in middle, preventing complete draining. Pipe is balanced and level, but necessitates the additional expense of three supports. Ends tend to sag and middle tends to rise due to uneven distribution of weight. Placement of supports as shown to keep each half of the pipe in equilibrium without sagging and without the need for additional hanger or support. 1 2 3 4 A cantilevered end will increase the load on support #4 and reduce the load on support #3. Position supports close to heavy valves where possible. © WestOne Services 2013 ENG2068 71 Tendency to sag around support. 1 Locate supports at, or as close to, riser as possible. Use additional support. 2 3 4 5 The pipeline is supported so that any of the flanged sections may be unbolted and removed without upsetting the balance of the line. Note that the support for section 5 is offset to allow for the weight of the valve. 72 ENG2068 © WestOne Services 2013 Identification of piping To eliminate hazards associated with piping that carries hazardous materials, Standards Australia International (SAI) has released AS 1345-1995 Identification of the contents of pipes, conduits and ducts. The code is designed to identify piping, ducts and conduits in general, and in ships and associated installations for safety purposes. The code does not apply to pipelines buried in the ground. The code cannot be expected to cover every particular industrial requirement and discretion should be used in its application. Colour codes The code uses ground colours to indicate the types of fluids carried by the pipelines. It also uses safety colours and lettering to provide additional information. Ground colours Colour Type of fluid green water silver steam brown oil violet acids and alkalis light blue air yellow ochre gases (except air) light orange electricity black other fluids Table 2.4: Ground colours Safety colours Colour Type of fluid red fire-fighting materials (water, foam, etc) safety yellow (with black stripes) dangerous materials safety yellow (with black trefoil) ionising radiation auxiliary blue fresh water (potable) Table 2.5: Safety colours © WestOne Services 2013 ENG2068 73 Application of colour codes Colours are applied directly to the pipe or, in the case of small pipes, over an area immediately behind the pipe. Or, coloured tags can be used, provided that they are attached securely to the pipe and are clearly visible. The ground colour is applied over the full length of the pipeline or over a minimum length of 400 mm, whichever is available. When used in conjunction with a safety colour, the ground colour is applied for a minimum length of 150 mm on each side of the safety colour. The safety colour is applied for a minimum length of 75 mm where it is clearly visible. The location of identification markings is at intervals of not more than 8 m and preferably adjacent to branches, junctions, valves, etc. AS 1345-1995 Identification of the contents of pipes, conduits and ducts should be applied. Requirements laid down in other standards should also be kept in mind. For example: 74 ●● AS 2885.4-2010 Pipelines - Gas and liquid petroleum - Submarine pipeline systems ●● AS/NZS 1596:2008 The storage and handling of LP Gas ●● AS 4041-2006 Pressure piping. ENG2068 © WestOne Services 2013 Chapter 3 – Drawing Types of drawings The main purpose of a technical drawing is to communicate fabrication requirements clearly and simply. To design process piping, five types of drawings are developed in sequence. These drawings are developed from the schematics and specifications for process piping prepared by the process engineer In order of development, the sequence is as follows: 1. general arrangement (GA) 2. process flow diagram (PFD) 3. piping and instrumentation diagram (P&ID) 4. plot plan layout 5. orthographic and isometric drawings. Pipe fabricators are required to work from drawings that will vary considerably. Pipework drawings in their presentation and adherence to relevant codes do not follow as strictly the standards laid down for other engineering drawings. The standards most applicable to pipework drawings produced in Australia are: ●● AS 1100.101-1992 Technical drawing - General principles ●● AS 1101.1-2007 Graphic symbols for general engineering - Hydraulic and pneumatic systems. General arrangement The piping plan or general arrangement (GA) drawing shows all major equipment to scale, its north/south and east/west orientation and all piping leading to and from the equipment. All instrumentation, access ladders and platforms are shown. The GA will usually show a plan view (top) with elevations (side) and section elevations, as well as all pipe dimensions and piping details including line numbers, size and specifications with the direction of flow noted for all lines, so that the draftsperson will have all necessary information to create the final fabrication drawings or isometrics. © WestOne Services 2013 ENG2068 75 1 F E D Issue Date 1 A 14-8-13 RL 000 RL 270 RL 550 RL 707 RL 850 RL 1270 Zone C RL 1400 BOP B A 201 300 ENG2068 300 76 © WestOne Services 2013 First issue C 1000 2 Amendments Change 500 300 2 700 785 1900 700 CC TB 3 ECN BY CKD 3 Finish STD WT Pipe Class 150 FLG’s Material Third angle A Record of Issue Drawn CC Traced TB Checked Approved Issued 14-8-13 563 Line 3 (50NB) 5 Fig 3.1: General arrangement Drawing practice AS 1100 Angular Linear Unless noted otherwise tolerances are: Line 3 (80NB) Line 1 (80NB/50NB) Line 1 (80NB/50NB) Line 1 (80NB) 4 A3 6 Size NTS N 7 Drawing exercise 24 DWG No 7 8 D C B A 8 1 SHT F E Drawing exercise Complete 3 isometric drawings & 3 material lists for each line Piping GA Scale Title 6 Dimensioning Dimensioning of GA drawings follows conventional drawing practice closely however, elevation (height) dimensioning needs special consideration. Before any building or erecting begins in the field, the site is made as flat as possible and, after levelling, is termed ‘finished grade’. The ‘highest point of finished grade’ becomes the datum from which all plant elevations are taken. This horizontal plane is given a ‘false’ or nominal elevation, usually 100. The nominal elevation of 100 ensures that foundations, basements, buried tanks, etc, will have positive elevations. ‘Minus’ elevations which may cause error and nuisance are avoided. Horizontal distances may be expressed as distances N, S, E or W to match distances on the plot plan. Dimensions may emanate from structural steelwork to aid in the location of the pipework within the plant. Dimensioning practices will be discussed in greater detail in this chapter. Process flow diagram (PFD) A process flow diagram (PFD) is an unscaled drawing or schematic which describes the process of transferring material by piping. It will: ●● state, for example, the materials to be conveyed by the piping ●● specify the rates of flow ●● list the pumps required ●● provide information such as pressure or temperature. At this point the pipe sizes, types of valves, etc, have not been determined. The PFD and specifications are then transferred to a piping and instrumentation (P&ID) diagram, plot plan or isometric drawing. © WestOne Services 2013 ENG2068 77 78 ENG2068 © WestOne Services 2013 1 Sour gas Absorber Makeup water 1 2 3 3 Lean amine Rich amine Bottom tray Top tray 2 Revision note File name PFD CW 6 FSCM NO Vapor Pump regenerator 9/9/2013 Contract No Re Issued Approved Check Drawn Size 6 Reflux Pump Bottom tray Top tray Condenser Lean amine Rich amine 5 Rev No Fig 3.2: Process flow diagram CW Sweet gas 4 7 DWG No 8 Process Flow Diagram NTS Scale Condensate 8 Signature Checked Steam Gas Date PFD1 Sheet 7 F E D C B A Piping and instrumentation diagram (P&ID) © WestOne Services 2013 Re Issued Approved Check 6 9/9/2013 Drawn Line A-256-1ʺ 3 2 Line B-256-3ʺ Fig 3.3: Piping and instrumentation diagram 7 DWG No P & ID PID1 Sheet PID File name Size 25 A-8975 Contract No 1 1 Note 15 2 3 34-27 4 5 Rev No RO AD Revision note 6 FSCM NO LGM 56 7 Date Line C-256-2ʺ Scale NTS 8 F E D C 8 Signature Checked B A The P&ID is similar to, but more detailed than, a PFD. It is a single-line schematic drawing that includes all major equipment items, instruments and controls, major valves and line sizes, It contains all the data necessary for the various design groups involved in the project to proceed to the next step in the design of the plant. ENG2068 79 Plot plan The draughtsperson produces a site plan which shows the whole site, including boundaries, roads, buildings, plant areas, etc. This allows the piping engineer to arrange equipment to optimise process requirements and design. When the site plan has been created and the GA drawings approved, they are then developed into ‘plot plans’ by the addition of dimensions and coordinates to locate all major items of equipment and structures. Dimensions and coordinates emanate from the plant datum point. Equipment coordinates are given to the centre-lines and, depending on the company, coordinates for pumps are given to the centre-lines of the pump discharge port. Pipeway Meters Instrument air plant Drover loop E 130.220 Process unit plot limit T 120 A E 140.000 T 20 A E 148.000 E 36 N 272.000 E 157.750 N 206.550 S 80 Pipeway E 170B E 159.000 E 60 A E 180.500 S 120 N 122.000 Roadway N 110.000 N 195.550 E 170A W 20 E 200.500 E 219.000 E 60 B E 227.650 E 240.000 T 120 B Control room Motor control room E 250.000 E 260.000 E 270.000 Pipeway V 220 E 250 Pipeway W 21 E 270 Hydro unit 250 KVA generator T 120 B Piping skid T 20 B E 345 E 300.000 V 250 Fig 3.4: Plot plan 80 ENG2068 © WestOne Services 2013 Orthographic and isometric drawings Orthographic and isometric drawings are representations of an object which are presented in alternative views so that they can be easily understood. T vieop w Top view Fro vie nt w Front view Pictorial view e Sidw vie Side view Orthographic view Isometric view Fig 3.5: Pictorial, orthographic and isometric representations of a box These drawings are used extensively in the development of process pipe systems. © WestOne Services 2013 ENG2068 81 Types of projection An essential factor in piping fabrication is the ability of the tradesperson to read technical drawings. The most common types of projection used in piping drawings are as follows. Note 1. All pipe schedule 80 2. All flanges class 300 3. Stud bolts used throughout Orthographic projection. 900 1000 Ø 200 NB 82 ENG2068 1300 L 20-1 900 900 900 L 20-2 Ø 50 NB 200 900 1200 L 20-3 EL 1500 EL 2290 B.O.P N Sockolet ® 1. © WestOne Services 2013 5 00 1 16 0-B L22 1 l 4 rizo 5 o nta ho 0 50 © WestOne Services 2013 2 9 9 10 3 17 7 18 16 0 50 16 4 50 F.F 8 .W 11 6 0 13 14 12 5 0 50 -B2 20 L2 1 -C 20 L2 0 70 15 N 0 90 0 55 -B3 20 L2 Signature Scale NTS Spool drawing W600SCO “ “ # 600LB XS “ “ “ “ SCH80 “ “ “ “ “ “ “ Spec Date 9 /11/2012 1 1 150 Lap-Joint 90 RF WN 150 RF WN Valves 150 Check 150 Diaphragm Flanges Fittings 150 45o Weld ELL 150 90o Weld ELL 150 EQ B.W. Tee 150 - 90 Conc. Red. 150 Stub end Pipe 150 NB x 330 150 NB x 515 150 NB x 372 150 NB x 420 90 NB x 560 150 N.B. x 150 N.B. x 150 N.B. x 900 Description Drawing No 6.36 17 18 1 1 3 1 13 14 15 16 2 1 1 1 1 1 1 1 1 1 1 1 Qty 9 10 11 12 1 2 3 4 5 6 7 8 Item Materials list 2. Isometric projection. ENG2068 83 Orthographic projection The views in orthographic projection are drawn as they would appear when the object is viewed perpendicular to its surface. Visible outlines are drawn as continuous, ‘full dark’ lines. Hidden detail is drawn as dashed ‘half dark’ lines. Usually more than one view is required to show the object in sufficient detail to avoid any misunderstandings. End view Side view Pictorial view Side view End view Orthographic view Fig 3.6: Two-line orthographic view In Figure 3.6, a simple shaft is shown in pictorial view and two views are shown in orthographic projection. The two views are necessary in this case to completely delineate the object. Perspective is not taken into account in orthographic views. There are two types of orthographic projection: 84 ●● first-angle projection ●● third-angle projection. ENG2068 © WestOne Services 2013 Third-angle projection is the preferred type while first-angle projection is used rarely in Australia. However, it is necessary to distinguish between the two types of projection to avoid confusion and enhance pipe fabricators’ understanding when reading drawings. First-angle and third-angle orthographic projections are very similar in that the views of the object do not change. The difference is in the positioning of the views. In first-angle projection, the projected view is placed behind the object relative to the viewer. In third-angle projection, the projected view is placed between the viewer and the object. Fig 3.7: Pictorial view of a tapered pin Fig 3.8: Projected end view of the pin (first-angle projection) Fig 3.9: Projected end view of the pin (third-angle projection) Third angle projection is used for all engineering drawings drawn in orthographic projection. This means that: a) a top view is placed above the viewed object (Figure 3.10 View ‘c’) b) a bottom view is placed below the viewed object (Figure 3.10 View ‘d’) c) a view from the left is placed to the left of the object (Figure 3.10 View ‘b’) d) a view from the right is placed to the right of the object (Figure 3.10 View ‘e’). © WestOne Services 2013 ENG2068 85 c e a b d View ‘c’ c b e d View ‘b’ View ‘a’ view ‘e’ View ‘d’ Fig 3.10: Comparison of orthographic and isometric views 86 ENG2068 © WestOne Services 2013 Isometric projection Isometric projection is a method which enables a three-dimensional picture of an object in one view to be drawn. Isometric drawings are made around three principal axes at 120° to each other so that each of the three faces is inclined equally towards the viewer. This means that the effect of perspective is equal on all sides, thus eliminating the need for faces to be drawn at different scales so that they appear in proportion. 1200 1200 1200 Fig 3.11: Isometric projection The isometric axis may be rotated so that different faces of the object may be viewed simultaneously. To p de Sid d En Si d e e d Bo tt om Si En En d m to t Bo Fig 3.12: Isometric axis © WestOne Services 2013 ENG2068 87 Spool drawings Isometric views showing details and dimensions of all lines are produced from the GAs. These are called isometric spool drawings or simply spool drawings. Spools A spool is an assembly of fittings, flanges and pipes that are to be prefabricated. It does not include bolts, gaskets, valves or instruments. Straight mill-run lengths of pipe over 6 m are usually not included in a spool, as such lengths may be welded into the system on erection. (On the ISO drawing, this is indicated by noting the length and stating ‘BY FIELD’.) A completed spool drawing will show: ●● title block information ●● the piping schedule ●● the orientation symbol ●● a view of the pipe spool ●● dimensions ●● adjoining pipe spools ●● the direction of flow of the conveyed fluid or gas. Each pipe spool drawing may also list the materials required for fabrication of the spool. 88 ENG2068 © WestOne Services 2013 Fig 3.13: Pipe spool drawing © WestOne Services 2013 ENG2068 89 F E D C B A 7 7 53 2 Issue 1 Date A 27-6-13 Zone First issue 53 1 2 Amendments Change Note 1. All pipe 80NB schedule 40 2. All flanges class 150 53 1 3 2 3 5 8 250 BOP 7 4 Drawing practice AS 1100 Angular Linear Unless noted otherwise tolerances are: 10 CC TB 11 ECN BY CKD 0 72 0 72 3 350 BOP Finish Material Third angle 0 54 6 4 0 450 BOP 1 N 12 A Record of Issue 0 54 Drawn CC Traced TB Checked Approved Issued 27-6-13 54 9 5 6 Size A3 NTS 6 7 Fittings Pipe Description DWG No 7 80NB Sched 40 pipe spools 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 Item Qty Scale Title 550 BOP 8 8 1 SHT Spec F E D C B A A pipe run in isometric is schematic in that pipes are shown by a single, bold line drawn along the pipe’s centre-line axis. Piping components are represented on the drawing by simple, stylised symbols which are widely accepted and more or less self-explanatory. The drawings are not to scale, although any details relevant to fabrication and erection are shown. Isometric spool drawings show the pipe spool as a pictorial view. This enables the fabricator to envisage what the finished spool will look like. The isometric spool drawings are sent to the shop fabricator. The drawings will usually show the complete line from one piece of equipment to another and give all the necessary information required for the fabrication and erection of the piping. The size of the prefabricated spool is limited by the shop fabricator’s means of transport but a spool is usually contained within a space of dimensions 12 m × 3 m × 2.4 m. 90 ENG2068 © WestOne Services 2013 The orientation symbol N N Orthographic Isometric Fig 3.14: Orientation symbols The orientation symbol or ‘north arrow’ appears on all piping drawings. The orientation symbol is of the utmost importance as it shows: ●● the direction of the piping run through the plant ●● the position of pipes relative to others ●● the relationship between pipes and other items of equipment. The symbol is normally placed in the top right-hand corner of the drawing. On an orthographic drawing, north is usually orientated towards the top of the page. On an isometric drawing, north is usually drawn up and to the right. South is opposite from north and points down and to the left. West is 90° from north however, in the isometric, it becomes the opposite 120° line – in this case, running up and to the left. East will be opposite to west and will run down and to the right. Pipelines running north/south or east/west will run parallel to the ground unless otherwise noted. Up N W Point of intersection S Down E Fig 3.15: Point of intersection Bisecting the north and west and the south and east reference lines is the up and down reference line. The point of intersection (PI) is the point from which all directions start. Any time the pipe has a turn – north, south, east, west, up and/or down – the pipe fabricator must imagine being at the PI to determine which way the pipe turns. © WestOne Services 2013 ENG2068 91 Parallel line Parallel line drawings are used to develop a two-dimensional template of a three-dimensional shape. End view 0 7 8 9 2 3 4 5 6 7 8 11 5 3 2 9 10 11 12 12 10 6 4 1 11 Side view 10 12 0 1 9 0 1 2 3 4 5 6 7 8 Parallel line Isometric Fig 3.16: Cylindrical development Parallel line development is a method which can be applied to any object whose sides are parallel to the axis; it is ideally suited to piping fabrication. Parallel line development process The parallel line method of development is used to obtain the ‘true shape’ of the object in a rolled-out form (also called the stretch out). This method of pattern development uses vertical parallel lines (also called generator lines) to obtain the true lengths. The true shape is also determined by intersection lines that form in conjunction with the vertical lines. Determining the fabrication method There are two choices when developing the parallel line method and that is either the construction of a pipe from plate or a template that wraps around the pipe. Both methods create a stretch out, by either the mean diameter (also known as the ‘neutral axis’ – an imaginary centre-line through the plate thickness) or outside diameters when calculating this length. The plate method requires the mean diameter in its calculation and the pipe wraparound uses the outside diameter. The correct use of the diameters is paramount as the stretch out lengths will differ for both. 92 ENG2068 © WestOne Services 2013 Construction of a pipe from plate The pattern is drawn on, or transferred to, the plate using a centre punch, rolled into the cylindrical shape and then cut to the pattern. During rolling (or pressing) operations, the inside of the bend will be compressed, and the outside of the bend will be stretched around the neutral axis. The neutral axis is the only part of the plate whose dimension is left unchanged by the forming operation. For this reason, it is necessary to base all calculations on the neutral axis when the metal is rolled into a circle. t Neutral axis ter iame This side gets compressed during rolling. nd Mea N A ID = MD + t This side is stretched during rolling. OD = MD + t Fig 3.17: Diameter of pipe Sleeve templates When working with piping, the most practical method of development is to make a template which is then used to mark out the pipe. Fig 3.18: Sleeve template Calculations for the template can be based on the outside diameter of the pipe. © WestOne Services 2013 ENG2068 93 Drawing steps The following example shows step by step the method of development of one half of a simple pipe joint (pipe A). These basic principles can be applied to more complex development problems. Step 1 Select the view which best shows the pipe to be developed and draw a ‘layout’ of the pipe to accurate size and shape. Step 2 Divide the pipe circumference into an equal number of spaces (12 spaces is suitable for most applications, more may be required for large diameter pipes, or where accuracy is important). Transfer these ‘ordinates’ to the pipe wall. Step 3 Number the ordinates in logical sequence consecutively around the pipe. 12 0 11 10 1 8 5 9 2 4 3 6 94 ENG2068 7 Note: Although any numbers will suffice, it is customary to start the numbering sequence with zero. © WestOne Services 2013 Step 4 Determine the circumference of the pipe using this calculation D×π=C ie the diameter (D) is measured and multiplied by Pi (π). The circumference is now the stretch out. 12 0 11 5 8 9 10 1 2 4 3 6 0 1 2 3 4 5 7 12 0 11 5 8 9 10 1 2 4 3 6 7 0 1 2 3 4 5 6 7 8 6 7 8 9 10 11 12 9 10 11 12 6 5, 7 4, 8 3, 9 10, 2 11, 1 12, 0 12 0 11 5 8 9 10 1 2 4 3 6 7 © WestOne Services 2013 0 1 2 3 4 5 6 7 8 9 10 11 12 Divide the stretch out into 12 or 24 equal parts. There is an option to divide the pattern into 24 parts which will create a smoother curve that eliminates gaps; however, 12 is usually sufficient. Step 5 Produce the points on the baseline upward, perpendicular to the baseline. (These represent the ordinates on the pipe.) Step 6 The height of each ordinate is the distance from the base of the pipe to the line of intersection. Transfer the ordinate heights horizontally across to the development. ENG2068 95 6 5, 7 4, 8 3, 9 2, 10 1, 11 0, 12 12 0 11 5 8 9 10 1 2 4 3 6 7 0 1 2 3 4 5 6 7 8 9 10 11 12 Locate and number each coordinate. 6 5, 7 4, 8 3, 9 2, 10 1, 11 0, 12 12 0 11 10 1 8 5 9 2 4 3 6 7 Step 7 As each ordinate height from the pipe layout meets its corresponding ordinate on the development, it will form a series of coordinates: eg 1,1:2,2:3,3 0 1 2 3 4 5 6 7 8 Step 8 Join the coordinates to produce the required development. 9 10 11 12 Development of custom branch connections The parallel line method of fabrication is used to create custom branch connections which may be required when a standard fitting is not suitable or available. There are two basic types of branch connection. ●● Set-in branches – where the branch line is set-into the wall of the main piping run. The hole in the main pipe is cut to the outside diameter of the branch line. Fig 3.19: A set-in branch 96 ENG2068 © WestOne Services 2013 ●● Set-on branches – where the branch line sits on the wall of the main piping run, the hole in the main pipe is cut to the inside diameter of the branch. Fig 3.20: A set-on branch The easiest and most practical way of preparing the joint for welding is to cut pipes with the torch held perpendicular to the surface of the pipe and grind the weld preparation afterwards. Acceptable methods of weld preparation are specified in: ●● AS 4458-1997 Pressure equipment – Manufacture ●● AS 4041-2006 Pressure piping. © WestOne Services 2013 ENG2068 97 Piping symbols Standard symbols are used to represent fittings and equipment on piping drawings. These symbols are used to show: ●● pipe ●● piping materials ●● direction of the piping run ●● changes of direction of the piping ●● methods of joining the pipe. To be able to understand and interpret spool drawings, pipe fabricators will have to be familiar with these symbols. The draughtsperson may use a certain amount of ‘artistic licence’ to make drawings cheaper to produce or clearer and easier to read. This means that there may be variations in the presentation of the symbols. An example of this may be seen in the representations of a weld-neck flange shown in Figures 3.21 and 3.22. Fig 3.21: Representations of a flange depicted with different line thicknesses Fig 3.22: Representations which show a flange more graphically for clarity Drawings may also be produced from copies of drawings made overseas where conventions vary slightly from Australian standard drawing practice. 98 ENG2068 © WestOne Services 2013 Symbols General Symbol Pipe – general symbol Pipe – concealed at section Pipe – in front of or above section Crossing pipe – not connected Crossing pipe – connected Tee – stub in Flexible hose Direction of flow Direction of fall – both types acceptable Butt weld Socket weld Screwed joint Site weld Reinforcement – saddle Reinforcement – wraparound, saddle Expansion joint Trap End cap Non-fixed support Anchor point Anchor block – at tee joint Joint – general symbol © WestOne Services 2013 ENG2068 99 Pipe equipment Symbol Apparatus – general symbol: it is preferred that the circular symbol be used for items in which there are rotating parts. For other apparatus, the rectangular symbol is used. Pump – Use Ø 10 circle Steam trap Strainer – general symbol Strainer – Y type Valves Symbol Valve – general symbol – also for shut-off and regulating valve – two-way Valve – general symbol – also for shut-off and regulating valve – angle Shut-off and regulating valve – three-way Reducing valve Diaphragm valve Safety valve Gate valve Globe valve Butterfly valve Check, non-return, reflux, one way valve Ball valve Needle valve Relief valve Plug valve Sprinkler head – on pipe Sprinkler head – upright Sprinkler head – pendant 100 ENG2068 © WestOne Services 2013 Control and regulating Symbol Hand-operated – general symbol Spring Weight Float Piston Diaphragm Electric motor M Solenoid Fitting Double line Butt welded Socket-welded 90° elbow Tee 45° elbow Lateral Eccentric reducer © WestOne Services 2013 ENG2068 101 Fitting Double line Butt welded Socket-welded End view Side view End view Concentric reducer Cap Specialised Fitting Weldolet Latrolet Sweepolet Nipolet Flange Symbol Mitres Weld neck M Slip-on M M M M M Blind Lap joint Orifice Reducing 102 ENG2068 © WestOne Services 2013 Symbol guide As a guide to the application of these symbols, consider the following information. • The general piping symbol is always shown as the darkest line on the drawing. For example, a section of piping with a reducer or other fitting would be shown with the piping drawn darkest and the fitting represented by a lighter line. • The symbol for a butt weld is shown by a dot at the location of the weld. • A butt weld made on site would be represented by a cross over the butt weld. Sometimes the letters FFW will accompany the site weld symbol. This stands for ‘field fit and weld’ which means that the joint is fitted and welded on site. To accommodate this FFW, approximately 150 mm of extra pipe is allowed. This 150 mm allowance is known as ‘green’. • All piping drawings indicate the direction of flow with an arrow. • Where pipes cross but are not connected, the pipe in the foreground is represented by a continuous line and the pipe in the background is broken where the lines cross. • A butt welded 90° elbow can be drawn two different ways.: © WestOne Services 2013 ENG2068 103 • While most fittings are represented by a single line, reducing fittings are drawn to shape and approximate scale. Butt-weld elbow Butt-weld reducing elbow • Where elbow symbols are used, they always represent a long radius elbow unless otherwise noted. • Tee connections may be made by the use of a standard fitting (tee) or by fabrication (known as a ‘stub-in’). Joint Tee Symbol Stub-in Symbols used to indicate change of direction Symbols are used to show changes in direction of the piping run. This is one of the more difficult aspects of pipework drawing to understand. It helps to keep in mind the way the joint would appear in third-angle projection. Pipe riser from bend This symbol shows a pipe which changes direction from horizontal to vertical going upwards towards the observer. ‘A’ Fig 3.23: Pipe riser from bend 104 ENG2068 © WestOne Services 2013 If the pipe terminates and is left open, it is normally shaded to indicate this. Or Pipe dropper from bend This is the opposite of the previous example. In this case, the vertical pipe runs away from the observer. ’A‘ Fig 3.24: A pipe dropper from bend. Combinations The following symbols are used in combination to show a pipe that changes from horizontal to vertical and back to horizontal. Fig 3.25: Symbols used in combination © WestOne Services 2013 ENG2068 105 Pipes which change direction at a riser or dropper can be represented by following the same principle. N Lower pipe runs North/South Upper pipe runs North/South Fig 3.26: Symbols used in combination Pipe riser from tee A Fig 3.27: A pipe riser from tee Pipe dropper from tee A Fig 3.28: A pipe dropper from tee 106 ENG2068 © WestOne Services 2013 Dimensioning and line types The dimensioning of piping drawings is in principle the same as for any other engineering drawing. For example, leader lines, dimension lines, arrowheads, line work and so on are all used in a similar way. Pipe fabricators need to be aware of the following points and differences when reading pipe drawings. General dimensional practice ●● Horizontal dimensions are given to vertical leader lines. ●● Principal dimensions are given to changes of direction. ●● Secondary dimensions are given to items of equipment such as reducers. ●● To aid erection a pair of dimensions locating the pipework to plant or equipment is usually given. ●● Although isometric drawings are not drawn to scale, valves and fittings are drawn reasonably proportional, especially where a fitting to fitting arrangement locates a valve. For example, in Figure 3.29, the valve is clearly at the elbow – not the tee. Fig 3.29: Isometric spool ●● Vessels and other equipment items are dimensioned to their centre-lines and the faces of flanges or nozzles. ●● The centre-line elevation of horizontal nozzles, and the face elevation of vertical nozzles are given for vessels and equipment. ●● Reducers not located by a fitting-to-fitting arrangement are dimensioned to their large end. © WestOne Services 2013 ENG2068 107 Single- and double-line comparison When orthographic projection is used, pipelines may be drawn as either single-line or double-line drawings. Double-line representation shows the two edges of the pipework and is usually used for pipes over Ø 350. Double-line drawings show a more graphic representation of the pipework; however, these are more difficult and more expensive to produce. Fig 3.30: Double-line pipe Single-line orthographic drawings represent the pipe by its centre-line only, which is drawn as a continuous heavy line (usually the darkest line on the drawing). The size of the pipe is shown by drawing a representation of the pipe end to scale, either at the end of the line or some other convenient place. Pipesize drawn to scale Fig 3.31: Single-line pipe On single-line diagrams, all fittings – except reducing fittings – are drawn single-lined. Single-line drawings are generally used for pipework under Ø 350. Single-line drawings with their use of stylised symbols are easier and quicker, and therefore cheaper to produce. Single-line drawings are easy to read, and this advantage, coupled with their lower cost, makes them the preferred type. Fig 3.32: Comparison of double-line drawing and single-line drawing 108 ENG2068 © WestOne Services 2013 Running dimensions Dimensions on piping drawings are not from a common reference point like they are in structural drawings; they are placed consecutively as running dimensions. Structural practice Piping practice Fig 3.33: Structural and piping practice Item number identification On all spool drawings, the line identification number is placed on the pipe. The adjoining spool piece is shown as a dashed line, and its identification number is given. The line identification number should be placed above the line representing the pipe, and elevations should be placed below it. C2 00 - L3 C2 0 atio 0 - L2 n 22 1.65 0 Elev Fig 3.34: Pipe identification © WestOne Services 2013 ENG2068 109 Use of levels and grids When a plant is designed, a system of levels is used to refer to elevations, and grids are used to make reference to horizontal dimensions. Levels are taken from the lowest part of the plant (datum), which is given a positive elevation, eg 30 m. This positive elevation enables sumps or other below-ground equipment to be dimensioned without the need for minus elevations. EL 38.000 EL 37.750 EL 35.000 EL 32.000 datum EL 30.000 EL 29.000 Fig 3.35: Elevations Grids are normally taken from the south-west corner of the plant. Distances north and east of this point are referenced. For example, the tower on the plot in Figure 3.36 is situated at N44.000, E20.000. 60― Roadway N 44.000 E 150.000 50― N 56.000 N 52.000 E 20.000 40― 30― 20― ― ― ― E 100.000 90 ― 80 ― 70 ― 60 ― 50 ― 40 ― 30 ― 20 ― ― 10 E 30.000 N ― 10― 100 120 130 140 Fig 3.36: A grid It is common practice to dimension pipework with reference to levels and grids, and also to give dimensions from structural steelwork within the plant. 110 ENG2068 © WestOne Services 2013 Flanged joints Dimensions are given to the faces of flanges. Most flanges have gaskets and the thickness of the gasket is indicated with ‘hash’ marks which show where the gasket is included in the valve dimension. The total dimension between the flange faces, including the gasket, should be given. Fig 3.37: Flange dimensions Valves 150 V136 Standard valves (especially butt- or socket-welded valves) are usually dimensioned to their centres. The valve stem is shown in its proper orientation, and the valve number is usually shown along the valve centre-line. Fig 3.38: Valve dimensions © WestOne Services 2013 ENG2068 111 Offsets An offset is a line running in a direction other than along the axes, ie other than up, down, north, south, east or west. It is sometimes difficult to determine the direction of an offset and a 45° offset in a horizontal direction may appear the same as a 45° offset in a vertical direction. If clarification is needed, a simple grid and note are usually provided. In this example, the pipe is drawn the same in both cases. It is the grid which determines the direction of the piping run. W Up N S E Down al o 45 l ta ic ert V o 45 n rizo Ho Fig 3.39: A simple offset Offsets and angles are not always what they appear to be when drawn in isometric projection. W C Up N S E Down B A Fig 3.40: A simple offset with a change of direction 112 ENG2068 © WestOne Services 2013 Angle ‘A’ is actually a right angle. Angle ‘B’ is drawn at 90° and shows a pipe changing direction from the vertical to run to north-east. Angle ‘C’ represents a horizontal offset from north. The basic symbols used to show pipe and changes of direction are used to show offsets. When interpreting symbols depicting offsets, it is important to keep in mind the view as it would appear in third-angle projection. The following figure shows a 45° elbow as it would appear in orthographic projection and as it would appear when represented symbolically. 45o Elbow – Orthographic 45o Elbow – Isometric Fig 3.41: 45° elbow – Orthographic and isometric Laterals or branch lines are shown in the same manner. Fig 3.42: Laterals or branch lines When an ellipse appears as it does in the examples above, it is always an indicator of an offset or a branch other than 90°. © WestOne Services 2013 ENG2068 113 Compound offsets Whereas an offset changes its orientation in two directions, eg up and to the west, or to the south and east, a compound offset changes its orientation in three directions at once. In Figure 3.43, the pipe runs upward to the west and to the north from the point of intersection. nsion Dime N P.I. Fig 3.43: A compound offset A compound offset is indicated by the ‘box’ shown in Figure 3.43. Lines (both the pipe and the box) are broken to indicate which is in the foreground, and the offset length is always dimensioned with a dimension line running parallel to the offset. Offset boxes should not be drawn as squares even when offset dimensions are the same in two or more directions. It is necessary to draw offset boxes as rectangles or the projection will appear incorrect with offsets running along the major axes. 114 ENG2068 © WestOne Services 2013 Chapter 4 – Fabrication methods Pipe fabrication Pipe fabrication involves assembling pieces such as elbows, tees and flanges into sections which, along with the pipe and all other equipment, can be accurately fitted together into the plant. Because of the cost and importance of such lines, pipe fabricators must assemble and weld pipes together with a high degree of precision. This requires careful thought and planning, accurate layout of work and control of welding operations as well as the competent use of jigs, templates and other precision tools. © WestOne Services 2013 ENG2068 115 Preparing for fabrication In preparation for fabricating, fabricators are required to calculate all the necessary pipes and fittings according to the drawing specifications. The pipe fabricator will need to take into consideration welding and tack welding processes along with any distortion that may arise from welding. The tools required for the fitting-up of pipes and flanges, such as pipe supports and clamps will also need some thought. Extracting information from drawings After careful scrutiny of the drawing, it is the fabricator’s job to check their interpretation of the drawing by quickly constructing a simple wire model of the pipe spool. The project design model may also be consulted (if available), especially for complex pipe spools. Construction of a wire model will help the fabricator with interpretation as well as with determining the best sequence of fabrication. Before fabrication starts, workshop sketches or isometric spool drawings are prepared from either general arrangements (GAs) or isometrics. These drawings contain all the information the fabricator needs to be able to fabricate pipes. The fabricator will also be supplied with accurate material take-off lists and a copy of the client’s fabrication specifications. 116 ENG2068 © WestOne Services 2013 Fig 4.1: Isometric spool drawing © WestOne Services 2013 ENG2068 117 0 50 1 16 0-B L22 1 4 rizo 5 o nta l ho 50 0 2 9 9 10 3 17 7 18 16 50 0 16 4 F.F 8 .W 11 6 0 50 13 14 12 5 0 50 -B2 20 L2 1 -C 20 L2 0 70 15 N 0 90 5 50 20 L2 -B3 Date 9 /11/2012 Signature Spool drawing W600SCO “ “ # 600LB XS “ “ “ “ SCH80 “ “ “ “ “ “ “ Spec Scale NTS 1 1 150 Lap-Joint 90 RF WN 150 RF WN Valves 150 Check 150 Diaphragm Flanges 150 Stub end 150 - 90 Conc. Red. Fittings 150 45o Weld ELL 150 90o Weld ELL 150 EQ B.W. Tee Pipe 150 NB x 330 150 NB x 515 150 NB x 372 150 NB x 420 90 NB x 560 150 N.B. x 150 N.B. x 150 N.B. x 900 Description Drawing No 6.36 17 18 1 1 3 1 13 14 15 16 2 1 1 1 1 1 1 1 1 1 1 1 Qty 9 10 11 12 1 2 3 4 5 6 7 8 Item Materials list Calculations To fabricate a spool system, the fabricator must be able to calculate the cutting length of pipes and take into account the sizes of fittings, flanges and weld preparation. The allowance for fittings and flanges can be gained from standard tables however the weld preparation may range from 2 mm to 3 mm. Y(2) Y(1) C(1) C(2) 0 Fig 4.2: Weld neck flange Y(1) C(2) Y(2) C(1) 0 Fig 4.3: Slip on flange Allowance for welding gap and weld shrinkage can be calculated in various ways and the weld gap required may vary. As a general rule the weld will shrink approximately half the root gap, so this needs to be considered when working out calculations. The fabricator may also want to confirm the weld shrinkage by completing a weld test and making adjustments as necessary. All the gaps noted in this text are 3 mm. 118 ENG2068 © WestOne Services 2013 400 A 500 B 500 400 A B Fig 4.4: Double-line and single-line orthographic view with dimensions To calculate pipes A and B, extract information such as the nominal size (NS) and schedule (SCH) from the drawing. ●● NS = 100 – the average diameter of the pipe ●● SCH = 40 – the thickness of the pipe ●● Class 150 Now we need to identify the lengths of each pipe, remember that the dimension lines work from the centres of the pipe. ●● Pipe A = 400 – the length of the pipe from the centres ●● Pipe B = 500 – the length of the pipe from the centres The lengths of the fittings now need to be worked out. (Fittings can measure from the centre to the face, or face to face; they are all obtained from charts.) © WestOne Services 2013 ENG2068 119 400 500 A 76 B 105 105 152 Fig 4.5: Double-line orthographic view with dimensions ●● Raised face weld neck (RFWN) = 76. This information is on the data charts under flanges to American standards column Y1. Different class options should be noted. ●● Equal tee = 105. This can be found on the data charts in the carbon steel butt welding fittings column marked ‘C’. ●● 90° long radius elbow 90ELB = 152. This can be found on the data charts in the carbon steel butt welding fittings column marked ‘A’. ●● The weld preparation gap = 3. ●● The weld shrinkage =1.5. Once this information has been determined, it can be applied to a simple equation, such as: Pipe A = 400 – 152 – 105 – 3 – 3 + 1.5 + 1.5 = 140 Pipe B = 500 – 105 – 76 – 3 – 3 + 1.5 + 1.5 = 316 Piping schedule The piping schedule is simply a materials list similar to that found on other engineering drawings. The schedule gives details of all the pipes, valves and fittings used to fabricate the pipe spool and is usually divided into sections for different materials such as tubes, fittings, valves, flanges, bolts. It contains all the materials needed to fabricate the pipe spool shown on the drawing, with each item clearly numbered. Standard abbreviations are always used in the piping schedule. 120 ENG2068 © WestOne Services 2013 Material list Description of item Description of item Nom size Sch Type or Std Qty Nom size Sch Type or Std Qty Flanges Flttings Tubes Mlsc Jolnts Bolts Valves Fig 4.6: A piping schedule Tools A pipe fabricator relies on a selection of quality tools to construct and align piping systems. These tools usually consist of a large plate square, a pipe square, level(s), a combination square, a protractor set, flange pins, wraparound tapes and a pipe alignment device. The only tools that pipe fabricators may not be familiar with are the wraparound tapes, flange pins and pipe alignment devices, which are specialised to the pipe fabrication trade. © WestOne Services 2013 ENG2068 121 The wraparound The wraparound – sometimes referred to as a ‘runaround’ – is a flat strip of flexible material about 1.5–3 mm thick, 75–100 mm wide and 450 mm or more long. It is made of any composition gasket material or leather belting. The edges must be perfectly straight. The length may vary, but the wraparound should be long enough to go around the pipe one-and-a-half times, so that it may be lined up to make it possible to obtain a straight line around the pipe. When laying out a straight line around a pipe, the wraparound should be placed on the pipe at the location of the centre-line, and the edges should be lined up. A chalk line should be drawn around the pipe with a piece of engineer’s chalk and using the edge of the wraparound as a guide. Fig 4.7: Using a wraparound Depending on the sizes of the pipes and fittings, lifting tackle may be necessary and chain blocks, turfers and cranes are often required. Three legged adjustable pipe stands, adjustable trestles and adjustable pipe rollers are essential for successful pipe fabrication. Ratchet line up clamp Pipe claw Figure 4.8: Typical pipe joint alignment devices Carelessness must be avoided when tools are being used as this will impair their accuracy. Levels and squares should be checked periodically, because a level that does not read correctly or a square that is ‘out of square’ can result in serious errors. 122 ENG2068 © WestOne Services 2013 Fabrication process The fabrication process requires tradespersons to assemble pipes and pipe fittings according to the spool drawing. Pipe fabricators need to take into consideration the size of the assembly, as transport may become an issue. Sub-assemblies are an effective way of transporting large projects. Assembly methods Before fabrication starts, the fabrication specifications, the weld procedure for fabrication tolerances, the dos and don’ts and weld preparations must be consulted. When the fabrication sequence and sub-assemblies have been identified, the sub-assemblies are broken into pipe runs and given numbers for easy identification. Cutting sizes are then calculated and the fabrication specification is checked to determine the shortest run of straight pipe that can have a welded joint. The fittings must be checked for size before the calculation of run lengths. Catalogues give nominal sizes, and actual sizes may vary. Assembly of sub-assembly Appropriate equipment such as marking out tables, adjustable pipe stands, levels, etc is used to set up and tack individual pipe components. Weld preparation root gap is determined from the welding procedure and by consulting the welding operator. The welding procedure will in most cases allow slight leeway to accommodate the specific requirements of the welding operator. Usually a piece of wire or a welding electrode of the correct diameter bent to a ‘V’ shape will give the required gap. Depending on the diameter of the pipe, four tack welds, 25 mm long and 90° apart are usually adequate. On large tubulars, it may be necessary to have tacks 150 mm long with multiple passes. As fabrication of sub-assemblies continues, the welding operator can be welding the rolling butts and flanges of the sub-assemblies. As work progresses, dimensions should be continually checked and shrinkage dimensions of welds checked and adjustments made, if appropriate. Distortion of sub-assemblies should also be monitored and corrected before incorporation into final assembly. If distortion occurs, the fabrication specification is checked to determine whether deviation is within acceptable limits. If not, it is rectified by applying spot heating (if permissible) or other means such as mechanical pressing. Welded sub-assemblies should be set up to comply with the configuration and dimensions on the fabrication drawing. Once tacked, the assembly is ready for welding. It is essential that the assembly is well supported and that all necessary precautions are taken to reduce distortion. Two or more sub-assemblies can often be tacked up and welded before incorporation into the final spool assembly. After welding, the assembly should be checked for distortion and dimensional accuracy and rectified if not within acceptable limits. © WestOne Services 2013 ENG2068 123 Cutting the pipe The process by which pipe is cut is determined by its ferrous or non-ferrous nature. There are several types of cutting machines available, both hand and mechanical. Tools such as pipe cutters, joint profile machines, oxy and plasma cutting tools are all appropriate for cutting pipe. To ensure accuracy of cut, a scribed line should be centre punched every 10 mm. Dividing the pipe surface into four equal parts The pipe fabricator is often required to divide the pipe surface into four equal parts this will aid in the assembly process. The four equal parts now become centre-lines from which to take measurements, and in which to locate fittings. The fabricator is required to follow these four steps to achieve this. 1. Wrap a strip of paper around the pipe. 2. Double the paper as shown in Figure 4.9 and double it again. This will divide the paper into four parts. The distance between an end and a crease, and between each crease, is equal to a quarter of the circumference. 3. Place the paper around the pipe. 4. Mark the pipe with engineer’s chalk at each crease and where the two ends meet. Fig 4.9: Dividing pipe surface into four equal parts 124 ENG2068 © WestOne Services 2013 Bevelling After cutting, weld preparation bevels should be prepared to weld procedure specification. If an oxy-cutting process is used, the pipe edge should be heated slightly to help produce a smooth cut face. Slag from the oxy cutting must be removed before bevelling starts. Excellent results can be produced manually with oxy cutting equipment if the bevel is made from the root face of the preparation, cutting back to the outer surface. With this technique, the distance from the top of the flame’s inner cone is slightly increased to ensure that the root face is not damaged by excessive heat. When oxy cutting is finished, the slag, oxide and burrs from both the bore and the external surface of the pipe should be removed. The preparation may be smoothed by grinding of filing. It is critical that weld preparations comply completely with the weld procedure specification, because incorrect weld preparation is often a reason for rejection of prepared butt joints by inspectors and welding operators. The following problems are common reasons for rejection: 1. not enough or too much, root face 2. not enough or too much, gap 3. misalignment 4. bevel not adequately prepared, ie inadequate bevel and not enough metal removed with round bevel surface (see Figure 4.10). Rounded face bevel restricts access to root. Fig 4.10: Unsuitable weld preparation © WestOne Services 2013 ENG2068 125 Lining up the pipe Correct alignment of the pipe and pipe fittings is one of the most important tasks performed by the pipe fabricator. The methods of ensuring correct alignment will vary depending on available equipment and there is no one ‘best system’. The procedures suggested here are common and will enable pipe to be quickly and accurately aligned using manual tools. Setting of flanges There are no hard and fast rules as to when to set flanges on the assembly; they may be placed on sub-assemblies to facilitate setting up and welding. However, it is generally deemed best practice to set up flanges once the pipe assembly has been completed, as this approach allows for any minor inaccuracies to be rectified as flanges are placed. Flanges are more likely to remain accurate and in correct alignment, as their final position after welding is not going to be influenced by the expansion and contraction stresses (distortion) of other welds in the assembly which may have to be welded after the flanges have been placed. Once the flanges have been placed, it is important to make sure that the assembly is level and accurately set. This can be done using appropriate tools such as spirit levels, plumb lines and squares. The pipe should also be checked to see that it is dimensionally correct to accept the flange. The flange should be positioned using a level, ensuring that the boltholes straddle the centre-line (unless otherwise stated). Flanges must be positioned equally around the pipe diameter. This can be made easier using small wedges which have been created by tapering the end of welding rod stubs. Four 25 mm long tacks are usually adequate, but it depends on the diameter of the flange. After the flanges have been tacked, it is important to check dimensions and hole positions. The flange is then ready for welding. Fitting up the pipes The two pipes to be welded must be properly and accurately aligned before they are welded. There must be no misalignment of the internal bore or the external surface of the pipe and the pipes and pipe fittings must be aligned so that the finished piping system will be in the correct location and orientation. Considerable skill is required to fit up two pipes in preparation for welding and this is an essential and fundamental part of the pipe fabricator’s responsibility. 126 ENG2068 © WestOne Services 2013 Tacking the pipe There are several ways in which pipe joints can be tack welded. Bridge tacks A rod or bar of base metal composition is used to bridge the root gap by tack welding to the groove sides. The bridge rod and tacks are not incorporated into the final joint, thus ensuring an accurate joint for the welding operator and eliminating the chances of a defective tack being incorporated into the final weld. Bridge tacks are normally placed by the pipe fabricator. Fig 4.11: Bridge tacks Integral tacks Integral tacks must be placed with care as they form part of the root run. For this reason, tacking is not normally done with stainless steel or alloy materials until pre-purging and purging have been completed. Both ends of the tack should be carefully ground to a feathered edge to allow the tie-in of the remainder of the root bead. Integral tacks must be done by a coded welder. Fig 4.12: Integral tacks © WestOne Services 2013 ENG2068 127 It is highly desirable that tack welds be removed as welding progresses. Green or run off The complete assembly shown on a spool drawing is seldom completely welded in the workshop due to allowances being made for site variation. Depending on the complexity of the pipe spool, it is often necessary to leave extra material length on the pipe to allow for site variations. This extra length is often called ‘green’ or ‘run off’. Usually 150 mm of ‘green’ is left when the drawing indicates a fit and field weld (FFW). In addition, selected flanges should only be tacked where possible to accommodate site variations and any inaccuracies of the fabricated spool. 128 ENG2068 © WestOne Services 2013 Welding process Several considerations need to be looked at when pipes are being welded together. These include the grade of material, the welding process and the thickness of the material. These factors determine the consumables, type of welding machine and the design of weld preparation according to standards. Preparing for welding Contaminants such as grease, oil, scale or rust will have harmful effects on the quality of the weld. All traces of the oxide produced by oxygen/fuel cutting must be removed by filing, grinding or wire brushing. The pipe fabricator/welder must also make sure that any other contaminants are removed before starting to weld. This can usually be accomplished by vigorous application of a wire brush. Stainless steels and other exotic alloys must be degreased with a suitable solvent immediately before welding. After cleaning, the piping should be handled with clean hands or clean gloves to ensure that the base metal and filler metal remain clean. Butt joints In butt joint preparation, two important factors emerge: ●● the shape of the groove, which relates to wall thickness ●● the pipe roundness, which affects accuracy. (If the pipe is out of round, the weld joint may be misaligned.) A small root face is recommended for good root penetration. Where a feathered edge is used, there is a tendency to melt away unevenly during welding. This makes it difficult to control the weld pool and can result in weld defects such as uneven penetration. A U joint is preferred for heavy wall pipe. Butt welds are usually single-Vee preparations with the dimensions shown, unless the piping system is of a large enough diameter that access is permitted. 30 ° + 7½ –0 1.5 - 3 mm 1.5 mm Fig 4.13: Single-Vee butt © WestOne Services 2013 ENG2068 129 For detailed information on butt weld preparation, refer to: ●● AS/NZS 3992:1998/Amdt 1:2000 Pressure equipment – Welding and brazing qualification ●● AS 4458-1997 Pressure equipment – Manufacture. Branch joints It should be noted that difficulties arise when setting up set-in branches. These joints should be only used where design conditions do not permit set-on type joints. Typical examples of the use of set-in joints are branch joints in pressure vessels, high operating pressures and corrosive media. The applicable codes mentioned previously contain recommendations. x x Y w Set-on unequal branch 45 ° min s g Section at X Set-on equal branch 45 ° min g g 3 mm Ledge Section at Y Section at W Fig 4.14: Set-on branches 130 ENG2068 © WestOne Services 2013 When the hole in the header is cut by oxygen fuel gas, the ledge illustrated should be obtained. This can be removed by grinding if required. Alternatively, if the hole in the header is prepared by machining, this ledge will not be obtained (see section at W). x x Y2 Y1 w s 60 ° min 45 ° min 45 ° min 45 ° s min g g g s g s = 1.5 mm ± 0.8 mm g = 2.5 mm ± 0.8 mm Fig 4.15: Set-in branches Flanges The clearance between the base of the flange and the outside diameter of the pipe should not typically exceed 3 mm at any one point, and the sum of the clearance diametrically opposite should not be more than 5 mm. The section of flange type and joint to be used will depend on the service requirements. © WestOne Services 2013 ENG2068 131 Weld neck flange 1 See recommended weld preparation. 2 Where access permits joint may be background and back welded. Fillet welded flange F 2 F1 1 F1 = 1.5t 2 F2 - t min t t F2 F1 t Hubbed flange 1 2 F1 - 1.5t but should not exceed 16 mm. F2 = t min t Fig 4.16: Weld specifications for flanges Distortion Distortion is easily controlled in pipe butt joints by ensuring that the heat input is equalised all around the joint. Fit-up is most important as an uneven root gap means that, where the gap is wider, more weld metal is required and the uneven shrinkage forces can cause distortion. Tacks must also be strong enough to hold the root gap even. Welders can sometimes be tempted – especially when settled into a comfortable position – to carry on with the next pass before completing the previous pass all around the joint. The unequal heat input obtained causes unequal shrinkage which results in angular distortion. Where two or more welders are welding the same joint, it is important that the welding procedure is balanced so that the heat input is even all around the joint. When pipe branch joints are being welded, it is advisable to tack weld a stay or stays to maintain the correct alignment. 132 ENG2068 © WestOne Services 2013 Fig 4.17: A temporary stay to maintain alignment Where a number of branch joints are in close proximity to each other as in the branches from a header pipe, the problem of the header pipe becoming distorted needs to be avoided. One way of overcoming this problem is to attach a suitable strong back to the header pipe on the side opposite the branch welds. Fig 4.18: Minimising distortion in a header pipe Further information on welding can be found in the technical notes available for purchase from Welding Technology Institute of Australia. © WestOne Services 2013 ENG2068 133 MRC Data Chart reproduced with the permission of MRC Global Australia. 134 ENG2068 © WestOne Services 2013 Appendix 1 – MRC Data Chart Data Chart Pipe | Fittings | Flanges Face Side of Chart Reverse Side of Chart MRC Data Chart reproduced with the permission of MRC Global Australia. © WestOne Services 2013 ENG2068 135 MRC Offers the Following Products and Services in Australia 19 Service Locations $80M Stockholding MRO Solutions Project Supply Solutions Automation Solutions Carbon & Stainless Duplex & Alloy DisClaimer: The information contained in this data chart is provided in good faith, and every reasonable effort is made to ensure that it is correct and up to date. However MRC does not warrant the accuracy and completeness of the information within this data chart. Accordingly, this information is provided 'as is' without warranty of any kind. Any person relying on any of the information contained in this handbook or making any use of the information contained herein, shall do so at its own risk. To the fullest extent permitted by the applicable law, MRC hereby disclaims any liability and in no event shall MRC be liable for any damage including, without limitation, direct, indirect or consequential damages including loss of revenue, loss of profit, loss of opportunity or other loss arising from the use of or the inability to use the information contained in this handbook including damages arising from inaccuracies, omissions or errors. MRC Data Chart reproduced with the permission of MRC Global Australia. 136 ENG2068 © WestOne Services 2013 sTeel PiPes TO ameriCaN sTaNDarD asme B36.10 Dimensions (mm) Weight (kg/m) Nominal size Nominal Wall Thickness & Weight for Welded & seamless steel Pipe asme B36.10 Outside Diameter DN NPs mm sTD eXTra sTrONG XX sTrONG sCHeD. 10 sCHeD. 20 sCHeD. 30 6 1/8 10.3 – – – – – – – – 1/4 13.7 – – – – – – – – – 10 3/8 17.1 – – – – – – – – – 15 1/2 21.3 – – – – – – 3/4 26.7 – – – – – – – 25 1 33.4 – – – – – – 32 1 - 1/4 42.2 – – – – – – 40 1 - 1/2 48.3 – – – – – – 50 2 60.3 – – – – – – 65 2 - 1/2 73.0 – – – – – – 80 3 88.9 7.47 2.55 7.82 3.64 9.09 5.45 9.7 7.77 10.15 9.56 11.07 13.44 14.02 20.39 15.24 27.67 – 20 2.41 0.47 3.02 0.80 3.20 1.10 3.73 1.62 3.91 2.20 4.55 3.24 4.85 4.47 5.08 5.41 5.54 7.48 7.01 11.41 7.62 15.27 8.08 18.63 8.56 22.32 9.53 30.97 10.97 42.56 12.7 64.64 12.7 81.55 12.7 97.46 12.7 107.10 12.7 123.30 12.7 139.15 12.7 155.12 12.7 171.09 12.7 187.06 12.7 202.72 12.7 218.69 12.7 234.67 12.7 250.64 12.7 266.61 12.7 282.27 12.7 330.19 – 8 1.73 0.37 2.24 0.63 2.31 0.84 2.77 1.27 2.87 1.69 3.38 2.50 3.56 3.39 3.68 4.05 3.91 5.44 5.16 8.63 5.49 11.29 5.74 13.57 6.02 16.07 6.55 21.77 7.11 28.26 8.18 42.55 9.27 60.31 9.53 73.88 9.53 81.33 9.53 93.27 9.53 105.16 9.53 117.15 9.53 129.13 9.53 141.12 9.53 152.87 9.53 164.85 9.53 176.84 9.53 188.82 9.53 200.31 9.53 212.56 9.53 248.52 – – – – – – 4.78 1.95 5.56 2.90 6.35 4.24 6.35 5.61 7.14 7.25 8.74 11.11 9.53 14.92 11.13 21.35 101.6 4 114.3 125 5 141.3 150 6 168.3 200 8 219.1 250 10 273.1 300 12 323.9 350 14 355.6 400 16 406.4 450 18 457 500 20 508 550 22 559 600 24 610 650 26 660 700 28 711 750 30 762 800 32 813 850 34 864 900 36 914 1050 42 1067 sCHeD. 60 – – – – – – sCHeD. sCHeD. sCHeD. 100 120 140 sCHeD. 160 – – – – – – – – 17.12 41.03 19.05 57.43 21.95 79.22 22.23 107.92 25.4 155.15 25.4 186.97 – – – – – – – – – – – – – – – – – – 6.35 54.59 6.35 62.64 6.35 70.57 6.35 78.55 6.35 86.54 6.35 94.53 7.92 127.36 7.92 137.32 7.92 147.28 7.92 157.24 7.92 167.20 7.92 176.96 6.35 33.31 6.35 41.77 6.35 49.73 7.92 67.90 7.92 77.83 7.92 87.71 Std.W.T. 117.15 Std.W.T. 129.13 Std.W.T. 141.12 XS 202.72 XS 218.69 XS 234.67 XS 250.64 XS 266.61 XS 282.27 7.04 36.81 7.8 51.03 8.38 65.20 Std.W.T. 81.33 Std.W.T. 93.27 11.13 122.38 XS 155.12 XS 171.09 14.27 209.64 10.31 79.73 11.13 94.55 XS 123.30 14.27 155.80 15.09 183.42 17.48 255.41 10.31 53.08 XS 81.55 14.27 108.96 15.09 126.70 16.66 160.12 19.05 205.74 20.62 247.83 22.23 294.25 24.61 355.26 15.09 96.01 17.48 132.08 19.05 158.10 21.44 203.53 23.83 254.55 26.19 311.17 28.58 373.83 30.96 442.08 15.09 75.92 18.26 114.75 21.44 159.91 23.83 194.96 26.19 245.56 29.36 309.62 32.54 381.53 34.93 451.42 38.89 547.71 11.13 28.32 12.7 40.28 14.27 54.20 18.26 90.44 21.44 133.06 XXS 186.97 27.79 224.65 30.96 286.64 34.93 363.56 38.1 441.49 41.28 527.05 46.02 640.03 20.62 100.92 XXS 155.15 28.58 208.14 31.75 253.56 36.53 333.19 39.67 408.26 44.45 508.11 47.63 600.63 52.37 720.15 13.49 33.54 15.88 49.11 18.26 67.56 23.01 111.27 28.58 172.33 33.32 238.76 35.71 281.70 40.49 365.35 45.24 459.37 50.01 564.81 53.98 672.26 59.54 808.22 – – – – – – – – 15.88 271.21 15.88 292.18 15.88 312.15 15.88 332.12 15.88 351.7 – – – – – – – – – – – – – – 17.48 342.91 17.48 364.90 19.05 420.42 – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – sCHeD. 80 SAME AS EXTRA STRONG W.T. (X.S.) 3 - 1/2 SAME AS STANDARD W.T. (Std. W.T.) 90 100 sCHeD. 40 – – Formula to attain approximate mass in kilograms per metre (kg/m) for steel round Pipe and Tubing m = (D – t) t x 0.02466 Where: m = mass to the nearest 0.01 kg/m eXamPle: D = Outside Diameter in millimetres (To nearest 0.1mm for OD up to 406.4mm) (To nearest 1.0mm for OD 457mm and above) t = Wall Thickness to nearest 0.01mm Nominal Size DN300 NPS12 OD = 323.9mm W.T. = 9.53mm Step 1. 323.9 – 9.53 = 314.37 Step 2. 314.37 x 9.53 = 2995.9461 Step 3. 2995.9461 x 0.024 66 = 73.88kg/m 1 1 1 Steel Pipes to ASME B36.10 Stainless Steel Pipes to ASME B36.19 2 MRC Data Chart reproduced with the permission of MRC Global Australia. © WestOne Services 2013 ENG2068 137 2 2 sTaiNless sTeel PiPes TO ameriCaN sTaNDarD asme B36.19 Nominal size DN Outside Diameter (mm) 6 8 10 Nominal Wall Thickness & inside Diameter (mm) schedule 5s schedule 10s Wall Thickness inside Diameter Wall Thickness 10.29 – – 1.24 13.72 – – 1.65 17.15 – – 1.65 15 21.34 1.65 18.04 20 26.67 1.65 23.37 25 33.40 1.65 30.10 32 42.16 1.65 38.86 40 48.26 1.65 50 60.33 65 73.03 80 88.90 100 inside Diameter schedule 40s schedule 80s Wall Thickness inside Diameter Wall Thickness inside Diameter 7.81 1.73 10.42 2.24 6.83 2.41 5.47 9.24 3.02 13.85 2.31 7.68 12.53 3.20 10.75 2.11 17.12 2.77 15.80 3.73 13.88 2.11 22.45 2.87 20.93 3.91 18.85 2.77 27.86 3.38 26.64 4.55 24.30 2.77 36.62 3.56 35.04 4.85 32.46 44.96 2.77 42.72 3.68 40.90 5.08 38.10 1.65 57.03 2.77 54.79 3.91 52.51 5.54 49.25 2.11 68.81 3.05 66.93 5.16 62.71 7.01 59.01 2.11 84.68 3.05 82.80 5.49 77.92 7.62 73.66 114.30 2.11 110.08 3.05 108.20 6.02 102.26 8.56 97.18 125 141.30 2.77 135.76 3.40 134.50 6.55 128.19 9.52 122.25 150 168.28 2.77 162.74 3.40 161.47 7.11 154.05 10.97 146.33 200 219.08 2.77 213.54 3.76 211.56 8.18 202.72 12.70 193.68 250 273.05 3.40 266.24 4.19 264.67 9.27 254.51 12.70 247.65 300 323.85 3.96 315.93 4.57 314.71 9.52 304.08 12.70 298.45 350 355.60 3.96 347.68 4.78 346.05 - - - - 400 406.40 4.19 398.02 4.78 396.85 - - - - 450 457.20 4.19 448.82 4.78 447.65 - - - - 500 508.00 4.78 498.45 5.54 496.93 - - - - 600 609.60 5.54 598.53 6.35 596.90 - - - - 750 762.00 6.35 749.30 7.92 746.16 - - - - MRC Data Chart reproduced with the permission of MRC Global Australia. 138 ENG2068 © WestOne Services 2013 CarBON sTeel BUTTWelDiNG FiTTiNGs TO asme B16.9, B16.28 & Bs.1640 B16.9 LONG RADIUS WELDING ELBOWS, RETURN BENDS & CAPS B B16.28 SHORT RADIUS WELDING ELBOWS & RETURN BENDS K A E V D B A A 90° 15 20 25 32 40 50 65 80 90 100 125 150 200 250 300 350 400 450 500 600 750 900 21.3 26.7 33.4 42.2 48.3 60.3 73.0 88.9 101.6 114.3 141.3 168.3 219.1 273.1 323.9 355.6 406.4 457 508 610 762 914 sch. 20 sch. 30 — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — 6.35 7.04 — 6.35 7.80 — 6.35 8.38 6.35 7.92 9.53 6.35 7.92 9.53 6.35 7.92 11.13 6.35 9.53 12.70 6.35 9.53 14.27 7.92 12.70 15.88 7.92 12.70 15.88 Nominal size DN small end 25 32 40 50 65 80 90 20 15 25 20 15 32 25 20 15 40 32 25 20 15 50 40 32 25 20 65 50 40 32 25 80 65 50 40 32 25 90 80 65 50 40 std. Wt. 2.77 2.87 3.38 3.56 3.68 3.91 5.16 5.49 5.74 6.02 6.55 7.11 8.18 9.27 9.53 9.53 9.53 9.53 9.53 9.53 9.53 9.53 sch. 40 10.31 11.13 12.7 14.27 15.09 17.48 — 19.05 sch. 60 X stg. — — — — — — — — — — — — 10.31 12.70 14.27 15.09 16.66 19.05 20.62 24.61 — — 3.73 3.91 4.55 4.85 5.08 5.54 7.01 7.62 8.08 8.56 9.53 10.97 12.70 12.70 12.70 12.70 12.70 12.70 12.70 12.70 12.70 12.70 sch. 80 15.09 17.48 19.05 21.44 23.83 26.19 30.96 — — sch. 100 sch. 120 sch. 140 sch. 160 — — — — — — — — — — — — 15.09 18.26 21.44 23.83 26.19 29.36 32.54 38.89 — — — — — — — — — — — 11.13 12.70 14.27 18.26 21.44 25.40 27.79 30.96 34.93 38.10 46.02 — — — — — — — — — — — — — — 20.62 25.40 28.58 31.75 36.53 39.67 44.45 52.37 — — 4.78 5.56 6.35 6.35 7.14 8.74 9.53 11.13 13.49 15.88 18.26 23.01 28.58 33.32 35.71 40.49 45.24 50.01 59.54 - REDUCING TEES (B16.9) C C 20 180° Wall Thickness (mm) sch. 10 STRAIGHT TEES (B16.9) large end D D 90° SAME AS X. STG. Pipe OD mm 180° SAME AS STD. WT. Nom. size DN 45° D A C m H 28.6 28.6 38.1 38.1 38.1 47.6 47.6 47.6 47.6 57.2 57.2 57.2 57.2 57.2 63.5 63.5 63.5 63.5 63.5 76.2 76.2 76.2 76.2 76.2 85.7 85.7 85.7 85.7 85.7 85.7 95.3 95.3 95.3 95.3 95.3 28.6 38.1 38.1 47.6 47.6 47.6 57.2 57.2 57.2 57.2 60.3 57.2 50.8 44.5 69.9 66.7 63.5 57.2 82.6 76.2 73.0 69.9 69.9 92.1 88.9 82.6 79.4 38.1 50.8 50.8 50.8 50.8 50.8 63.5 63.5 63.5 63.5 76.2 76.2 76.2 76.2 88.9 88.9 88.9 88.9 88.9 88.9 88.9 88.9 88.9 102 102 102 102 Nominal size DN small end large end 100 125 150 200 250 300 350 100 90 80 65 50 40 125 100 90 80 65 50 150 125 100 90 80 65 200 150 125 100 80 250 200 150 125 100 300 250 200 150 100 350 300 250 200 150 a 7.47 38 7.82 38 9.09 38 9.70 47.5 10.15 57 11.07 76 14.02 95 15.24 114 16.15 133 17.12 152 19.05 190 21.95 229 22.23 305 25.40 381 25.40 457 — 533 — 610 — 686 — 762 — 914 — 1143 — 1372 B K 16 19 22 25.4 29 35 44.5 51 57 63.5 79 95 127 159 190 222 254 286 318 381 470 565 47.5 43 55.5 70 82.5 106 132 159 184 210 262 313 414 517 619 711 813 914 1016 1219 1524 — CONCENTRIC & ECCENTRIC REDUCERS (B16.9) M C C X.X. stg. D e. std. Nom. Wt. & size ex. stg. DN V — — 19 33 25.4 41 32 52 38 62 51 81 63.5 100 76 121 89 140 102 159 127 197 152 237 203 313 254 390 305 467 356 533 406 610 457 686 508 762 610 914 762 1143 914 1372 H 25.4 25.4 38.1 38.1 38.1 38.1 38.1 50.8 63.5 63.5 76.2 88.9 102 127 152 165 178 203 229 267 267 267 15 20 25 32 40 50 65 80 90 100 125 150 200 250 300 350 400 450 500 600 750 900 H C C m H 105 105 105 105 105 105 124 124 124 124 124 124 143 143 143 143 143 143 178 178 178 178 178 216 216 216 216 216 254 254 254 254 254 279 279 279 279 279 102 98.4 95.3 88.9 85.7 117 114 111 108 105 137 130 127 124 121 168 162 155 152 203 194 191 184 241 229 219 210 270 257 248 238 102 102 102 102 102 127 127 127 127 127 140 140 140 140 140 152 152 152 152 178 178 178 178 203 203 203 203 330 330 330 330 Nominal size DN small end large end 400 450 500 600 750 900 400 350 300 250 200 150 450 400 350 300 250 200 500 450 400 350 300 250 200 600 500 450 400 350 300 250 750 600 500 450 400 900 750 600 500 450 C m H 305 305 305 305 305 305 343 343 343 343 343 343 381 381 381 381 381 381 381 432 432 432 432 432 432 432 559 559 559 559 559 673 673 673 673 673 305 295 283 273 264 330 330 321 308 298 368 356 356 346 333 324 432 419 406 406 397 384 533 508 495 483 635 610 584 572 356 356 356 356 356 381 381 381 381 381 508 508 508 508 508 508 508 508 508 508 508 508 610 610 610 610 610 610 610 610 NOTE: All dimensions are in millimetres (mm) 3 3 Dimensions - Buttweld Fittings to ASME B16.9, B16.28 3 Flanges - Forged Steel to ASME B16.5 4 MRC Data Chart reproduced with the permission of MRC Global Australia. © WestOne Services 2013 ENG2068 139 4 4 FlaNGes TO ameriCaN sTaNDarDs DN 15 to 600 are to ASME B16.5 (BS 1560). DN 750 & 900 are to BS 3293 for Slip-On & Weldneck only. Threaded Flange 15 20 25 32 40 50 65 80 90 100 125 150 200 250 300 350 400 450 500 600 750 900 length Thru Hub Dia. of Thickness Dia. of Thrd. Weld Fig. of Fig. min. slip-On Bolt Neck Circle O C(1)* soc/Weld Y(1)* Y(1)* 90 11.5 16 48 60.5 100 13.0 16 52 70.0 110 14.5 17 56 79.5 120 16.0 21 57 89.0 130 17.5 22 62 98.5 150 19.5 25 64 120.5 180 22.5 29 70 139.5 190 24.0 30 70 152.5 215 24.0 32 71 178.0 230 24.0 33 76 190.5 255 24.0 36 89 216.0 280 25.5 40 89 241.5 345 29.0 44 102 298.5 405 30.5 49 102 362.0 485 32.0 56 114 432.0 535 35.0 57 127 476.0 600 37.0 64 127 540.0 635 40.0 68 140 578.0 700 43.0 73 145 635.0 815 48.0 83 152 749.5 985 54.0 † 89 130.2 914.0 1170 60.3 † 95 136.5 1086.0 PN150 (Class 900) Socket Welding (DN 15 - 80) Blind Flanges up to DN600 (Above DN600 see notes below † ) PN50 (Class 300) length Thru Hub Dia. Dia. of Thickness Dia. of Dia. of Thrd. No. of of No. of Weld Bolt Bolt of Fig. min. slip-On Bolt Bolts Fig. Neck Circle Holes Bolts Holes C(1)* soc/Weld O Y(1)* Y(1)* 16 4 95 14.5 22 52 66.5 16 4 16 4 120 16.0 25 57 82.5 20 4 16 4 125 17.5 27 62 89.0 20 4 16 4 135 19.5 27 65 98.5 20 4 16 4 155 21.0 30 68 114.5 22 4 20 4 165 22.5 33 70 127.0 20 8 20 4 190 25.5 38 76 149.0 22 8 20 4 210 29.0 43 79 168.5 22 8 20 8 230 30.5 44 81 184.0 22 8 20 8 255 32.0 48 86 200.0 22 8 22 8 280 35.0 51 98 235.0 22 8 22 8 320 37.0 52 98 270.0 22 12 22 8 380 41.5 62 111 330.0 26 12 26 12 445 48.0 67 117 387.5 30 16 26 12 520 51.0 73 130 451.0 33 16 30 12 585 54.0 76 143 514.5 33 20 30 16 650 57.5 83 146 571.5 36 20 33 16 710 60.5 89 159 628.5 36 24 33 20 775 63.5 95 162 686.0 36 24 36 20 915 70.0 106 168 813.0 42 24 35 28 1090 92.0 210 210 997.0 48 28 41 32 1270 105.0 241 241 1168.0 54 32 PN250 (Class 1500) length Thru Hub length Thru Hub Dia. Thickness Dia. Thickness Dia. of Dia. of Thrd. No. of of of Fig. min. Thrd. slip- Weld of of Fig. min. Weld Bolt Bolt slip-On Fig. Neck Circle Holes Bolts Fig. On soc/ Neck C(2)† C(2)† soc/Weld O O Y(2)† Weld Y(2)† Y(2)† Y(2)† 15 120 22.5 32 60 20 130 25.5 35 70 25 150 29.0 41 73 32 USE PN250 DIMENSIONS IN THESE SIZES 160 29.0 41 73 40 180 32.0 44 83 50 215 38.5 57 102 65 245 41.5 64 105 80 240 38.5 54 102 190.5 26 8 270 48.0 73 118 100 295 44.5 70 114 235.0 32 8 310 54.0 90 124 125 350 51.0 79 127 279.5 35 8 375 73.5 105 155 150 380 56.0 86 140 317.5 32 12 395 83.0 119 171 200 470 63.5 102 162 393.5 39 12 485 92.0 143 213 250 545 70.0 108 184 470.0 39 16 585 108.0 159 254 300 610 79.5 117 200 533.5 39 20 675 124.0 181 283 350 640 86.0 130 213 559.0 42 20 750 133.5 298 400 705 89.0 133 216 616.0 45 20 825 146.5 311 450 785 102.0 152 229 686.0 52 20 915 162.0 327 500 855 108.0 in millimetres 159 248 749.5 54 20 985 178.0 356 All dimensions are shown (mm) 600 1040 140.0 203 292 901.5 68 20 1170 203.5 406 Nominal size DN NOTes: * 1. The 2mm Raised Face is included in thickness C(1) and length through hub Y(1). This applies to PN20 and PN50 Pressure Ratings. † 2. The 7mm Raised Face is not included in thickness C(2) and length through hub Y(2). PN100, 150, 250 and 420 Pressure Ratings are regularly furnished with 7mm Raised Face which is additional to the flange thickness C(2) and Y(2). 3. Always specify bore when ordering weldneck flanges. Bore dimensions shown opposite also provide inside pipe diameters. larGe DiameTer FlaNGes aBOVe DN 600 † For Blind Flanges refer to MSS SP44. BS 3293 covers Slip-On and Weldneck but excludes Blind Flanges. MSS SP44 covers Blind and Weldneck but excludes Slip-On Flanges. BS 3293 Weldneck PN20 flange thickness, C(1), is less than MSS SP44 equivalents. API - 605 Dimensions for Large Diameter Flanges vary considerably from both BS 3293 and MSS SP44 — Details on request. PN100 (Class 600) length Thru Hub Dia. of Dia. of Dia. of Thickness Thrd. No. of Weld Bolt Bolt Fig. of Fig. min. slip-On Neck Circle Holes Bolts O C(2)† soc/Weld Y(2)† Y(2)† 95 14.5 22 52 66.5 16 4 120 16.0 25 57 82.5 20 4 125 17.5 27 62 89.0 20 4 135 21.0 29 67 98.5 20 4 155 22.5 32 70 114.5 22 4 165 26.5 37 73 127.0 20 8 190 29.0 41 79 149.0 22 8 210 32.0 46 83 168.5 22 8 230 35.0 49 86 184.0 26 8 275 38.5 54 102 216.0 26 8 330 44.5 60 114 267.0 30 8 355 48.0 67 117 292.0 30 12 420 55.5 76 133 349.0 33 12 510 63.5 86 152 432.0 36 16 560 66.5 92 156 489.0 36 20 605 70.0 94 165 527.0 39 20 685 76.5 106 178 603.0 42 20 745 83.0 117 184 654.0 45 20 815 89.0 127 190 724.0 45 24 940 102.0 140 203 838.0 52 24 1130 114.0 248 248 1022.0 54 28 1315 124.0 283 283 1194.0 67 28 PN420 (Class 2500) length Thru Hub Dia. of Dia. of Dia. of Thickness Thrd. No. of Weld Bolt Bolt Fig. of Fig. min. slip-On Bolts Neck Circle Holes O C(2)† soc/Weld Y(2)† Y(2)† 82.5 22 4 135 30.5 40 73 89.0 22 4 140 32.0 43 79 101.5 26 4 160 35.0 48 89 111.0 26 4 185 38.5 52 95 124.0 30 4 205 44.5 60 111 165.0 26 8 235 51.0 70 127 190.5 30 8 270 57.5 79 143 203.0 33 8 305 67.0 92 168 241.5 36 8 355 76.5 108 190 292.0 42 8 420 92.5 130 229 317.5 39 12 485 108.0 152 273 393.5 45 12 550 127.0 178 318 482.5 52 12 675 165.5 229 419 571.5 56 16 760 184.5 254 464 635.0 60 16 705.0 68 16 774.5 76 16 832.0 80 16 990.5 94 16 Dia. of Dia. of No. of Bolt Bolt Bolts Circle Holes 89.0 95.0 108.0 130.0 146.0 171.5 197.0 228.5 273.0 324.0 368.5 438.0 539.5 619.0 22 22 26 30 33 30 33 36 42 48 56 56 68 76 raised Face approximate Welding Neck Flange Bores - mm of Diam. Nominal O.D. Pipe all Press. size DN mm sCH. sCH. sCH. sTD. sCH. sCH. eXT. sCH. sCH. sCH. ratings mm 10 20 30 WT. 40 60 sTG. 80 100 120 35 15 21.3 15.8 13.9 43 20 26.7 20.9 18.9 51 25 33.4 26.6 24.3 64 32 42.2 35.1 32.5 73 40 48.3 40.9 38.1 92 50 60.3 52.5 49.2 105 65 73.0 62.7 59.0 127 80 88.9 77.9 73.7 140 90 101.6 90.1 85.4 157 100 114.3 102.3 97.2 92.1 186 125 141.3 128.2 122.3 115.9 216 150 168.3 154.1 146.3 139.7 270 200 219.1 206.4 205.0 202.7 198.5 193.7 188.9 182.6 324 250 273.1 260.3 257.5 254.5 247.7 247.7 242.9 236.5 230.2 381 300 323.9 311.1 307.1 304.8 303.2 295.3 298.5 288.9 281.0 273.1 413 350 355.6 342.9 339.8 336.6 336.6 333.3 325.4 330.2 317.5 307.9 300.0 470 400 406.4 393.7 390.6 387.4 387.4 381.0 373.1 381.0 363.5 354.0 344.5 533 450 457.0 444.5 441.4 434.9 438.2 428.7 419.1 431.8 409.5 398.5 387.4 584 500 508.0 495.3 489.0 482.6 489.0 477.8 466.8 482.6 455.6 442.9 431.8 692 600 610.0 596.9 590.6 581.1 590.6 574.6 560.4 584.2 547.7 531.8 517.6 857 750 762.0 746.2 736.6 730.2 743.0 736.6 1022 900 914.0 898.6 889.0 882.6 895.4 876.3 889.0 Same as EXT. STG. PN20 (Class 150) Nominal size DN Slip-On Flange Same as STD. WT. Welding Neck Flange 4 4 4 4 4 8 8 8 8 8 8 12 12 12 Nominal size DN 15 20 25 32 40 50 65 80 90 100 125 150 200 250 300 350 400 450 500 600 750 900 Nominal size DN 15 20 25 32 40 50 65 80 100 125 150 200 250 300 350 400 450 500 600 sCH. sCH. X.X 140 160 sTG 11.8 6.4 15.5 11.0 20.7 15.2 29.5 22.8 34.0 27.9 42.9 38.2 54.0 45.0 66.7 58.4 –– –– 87.3 80.1 109.6 103.2 131.8 124.4 177.8 173.1 174.6 222.3 215.9 222.3 266.7 257.2 273.1 292.1 284.2 333.3 325.4 377.9 366.7 419.1 408.0 504.9 490.5 MRC Data Chart reproduced with the permission of MRC Global Australia. 140 ENG2068 © WestOne Services 2013 BOlTiNG FOr aNsi FlaNGes BOlTiNG To suit R.F. Flange sizes DN 15 to 600 to ASME — B16.5 (BS. 1560) and DN 750 & 900 to BS. 3293 L L* Diameter of Bolts is shown in inches. For nominal diameters 1 inch and smaller, threads are U.N.C.; nominal diameters 1 - 1/8 inch and larger threads are 8 U.N. (8 T.P.I). Length of Bolts (L) is shown in millimetres rounded to the nearest 5mm. Stud Bolt lengths (L*) do not include the height of points. Machine Bolt lengths (L) include the height of point. The length shown includes the height of the Raised Face in all cases. *Point Height STUD BOLT WITH NUTS MACHINE BOLT WITH NUT PN 20 (Class 150) Nom Flge size DN No. Bolts Dia. Bolts ins. 15 4 20 4 25 PN 50 (Class 300) l PN 100 (Class 600) PN 150 (Class 900) l stud Bolts mm PN 250 (Class 1500) l Dia. No. Bolts stud Bolts Bolts ins. mm 3/4 4 105 PN 420 (Class 2500) l Dia. No. Bolts stud Bolts Bolts ins. mm 3/4 4 125 Nom Flge size DN stud Bolts mm mach. Bolts mm No. Bolts Dia. Bolts ins. l stud Bolts mm 1/2 65 55 4 1/2 80 5/8 75 60 4 5/8 90 4 3/4 115 4 3/4 125 20 4 5/8 80 65 4 5/8 90 4 7/8 125 4 7/8 140 25 55 4 5/8 80 65 4 5/8 100 4 7/8 125 4 150 32 70 60 4 3/4 90 75 4 3/4 105 4 1 140 4 1 1 1/8 170 40 80 65 8 5/8 90 75 8 5/8 105 8 7/8 145 8 1 175 50 75 8 3/4 100 85 8 3/4 120 8 1 160 8 1 1/8 195 65 75 8 3/4 110 90 8 3/4 125 8 7/8 145 8 1 1/8 180 8 1 1/4 220 80 90 75 8 3/4 110 95 8 7/8 140 - - - - 90 8 3/4 110 95 8 7/8 145 8 170 8 195 8 1 1/2 - 75 1 1/4 - 90 1 1/8 255 100 3/4 90 80 8 3/4 120 100 8 1 165 8 8 1 3/4 300 125 100 85 12 3/4 125 105 12 170 12 260 8 2 345 150 8 3/4 110 90 12 7/8 140 110 12 1 1 1/8 1 1/2 1 3/8 250 3/4 195 12 290 12 200 12 7/8 115 95 16 1 155 130 16 215 16 335 12 485 250 300 12 7/8 120 100 16 170 145 20 220 20 12 2 3/4 540 300 12 1 130 110 20 175 150 20 235 20 405 350 400 16 135 115 20 160 20 255 20 400 150 125 24 195 170 20 275 20 495 450 500 20 160 135 24 180 24 290 20 500 175 145 24 230 195 24 1 7/8 330 20 3 3 1/2 540 20 1 1/4 1 1/2 205 600 1 1/8 1 1/4 1 5/8 1 5/8 2 1/2 2 3/4 445 16 1 1/4 1 1/4 190 450 1 1 1/8 1 3/8 1 1/2 2 2 1/4 375 350 1 1/8 1 1/8 1 1/4 1 1/4 2 2 1/2 380 250 1 5/8 1 7/8 615 600 750 28 190 160 28 1 3/4 290 250 28 32 215 180 32 2 325 280 28 2 2 1/2 355 900 1 1/4 1 1/2 stud Bolts mm mach. Bolts mm No. Bolts Dia. Bolts ins. 1/2 60 45 4 1/2 65 50 4 4 1/2 65 55 32 4 1/2 70 40 4 1/2 50 4 5/8 65 4 5/8 90 80 4 5/8 90 90 8 5/8 100 8 5/8 125 8 150 8 200 l No. Bolts Dia. Bolts ins. USE PN250 DIMENSIONS IN THESE SIZES 400 1 1/4 1 1/8 190 8 195 12 1 3/8 1 3/8 220 12 235 12 1 3/8 1 1/2 255 16 275 16 1 5/8 1 7/8 285 16 325 16 2 2 1/2 345 16 435 16 asTm a193 Grade B7 Standard specification for alloy steel and stainless steel bolting materials for high temperature service. asTm a194 Grade 2H Standard specification for carbon and alloy steel nuts for bolts for high pressure and high temperature service. Standard specification for alloy steel bolting materials for low temperature service. Grade L7 covers alloy steel stud bolts. Grade L4 covers alloy steel nuts to suit Grade L7 stud bolts. FOr 1/2” 5/8” M14 3/4” M20 7/8” M24 1” M27 1 1/8” M30 1 1/4” M33 1 3/8” M36 1 1/2” M39 1 5/8” M42 1 3/4” M45 1 7/8” M48 2” M52 2 1/4” M56 2 1/2” M64 2 3/4” M72 5 5 Bolts & Studs for use with ASME B16.5 Flanges 900 inch/ metric Bolting interchangeable for asme B16.5 flanges as below maTerial sPeCiFiCaTiONs asTm A320 750 PN150, 250 & 420 - NOT LISTED IN BS 3293 Raised Face height of 2 mm for PN20 & 50 and 7 mm for PN100, 150, 250 & 420 is included in dimension L (Bolt Length). 15 Use M16 5 Mass of Fittings & Flanges to ASME Standards 6 MRC Data Chart reproduced with the permission of MRC Global Australia. © WestOne Services 2013 ENG2068 141 6 6 sTeel PiPe, BUTTWelD FiTTiNGs & FlaNGes TO asme sTaNDarDs asme B36.10 steel Pipe Dimensions Pipe identification Nominal Outside Pipe size Diam. DN mm inside Diam. mm std. X.s sch. No. approximate mass of Popular sizes a.s.m.e Flanges Buttweld Fittings steel Pipe kg/m 90o l/r elbows kg/ea Tees equal kg/ea Con. & ecc. red. kg/ea PN20 (150) PN50 (300) PN100 PN150 (600) (900) sOW/ sW Thrded kg/ea W/N kg/ea Blind kg/ea sOW/ sW Thrded kg/ea W/N kg/ea Blind kg/ea W/N kg/ea W/N kg/ea 15 21.3 15.8 13.9 Std. XS 40 80 1.27 1.62 0.08 0.10 0.16 0.21 - 0.45 0.79 0.57 0.73 0.91 0.79 0.91 2.00 20 26.7 20.9 18.9 Std. XS 40 80 1.69 2.20 0.08 0.11 0.21 0.27 0.07 0.10 0.68 0.86 0.91 1.25 1.41 1.13 1.59 2.72 25 33.4 26.6 24.3 Std. XS 40 80 2.50 3.24 0.17 0.21 0.34 0.43 0.14 0.18 0.95 1.09 1.09 1.36 1.81 1.77 1.86 3.86 32 42.2 35.1 32.5 Std. XS 40 80 3.39 4.47 0.28 0.39 0.64 0.75 0.18 0.23 1.13 1.41 1.25 2.04 2.27 2.68 2.72 4.54 40 48.3 40.9 38.1 Std. XS 40 80 4.05 5.41 0.39 0.50 0.95 1.13 0.27 0.32 1.36 1.81 1.70 2.81 3.06 2.83 3.74 6.35 50 60.3 52.5 49.2 Std. XS 40 80 5.44 7.48 0.68 1.00 1.45 1.72 0.41 0.54 2.22 2.83 2.77 3.13 3.74 3.52 4.65 10.89 65 73.0 62.7 59.0 Std. XS 40 80 8.63 11.41 1.39 1.82 2.45 2.95 0.68 0.91 3.82 4.42 4.04 4.54 5.56 5.44 6.44 16.33 80 88.9 77.9 73.7 Std. XS 40 80 11.29 15.27 2.18 2.86 3.45 4.30 0.91 1.27 4.08 5.22 5.44 6.12 7.37 7.26 8.50 14.51 90 101.6 90.1 85.4 Std. XS 40 80 13.57 18.63 3.05 4.1 4.5 5.9 1.36 1.81 4.99 5.44 6.35 7.71 9.53 9.98 12.25 –– 100 114.3 102.3 97.2 Std. XS 40 80 16.07 22.32 4.2 5.7 5.7 7.3 1.59 2.18 5.94 7.48 7.37 9.53 11.79 11.79 17.24 23.13 125 141.3 128.2 122.3 Std. XS 40 80 21.77 30.97 6.8 10.0 9.1 11.8 2.7 3.8 6.12 9.53 9.07 12.70 15.42 15.88 30.84 39.01 150 168.3 154.1 146.3 Std. XS 40 80 28.26 42.56 10.9 16.3 13.6 19.0 3.9 5.4 8.16 11.34 12.70 16.33 19.96 20.87 34.02 49.90 200 219.1 202.7 193.7 Std. XS 40 80 42.55 64.64 21.8 33.1 25 33.5 5.9 8.6 12.70 19.05 21.77 25.40 32.21 38.10 52.16 84.82 250 273.1 254.5 247.7 Std. XS 40 60 60.31 81.55 38.6 52 41 54 10 14 17.24 25.40 31.75 35.38 44.00 53.34 90.36 121.56 300 323.9 304.8 298.5 Std. XS - 73.88 97.46 57 75 57 77 15 20 27.22 38.10 45.36 50.80 64.41 86.18 101.60 168.74 350 355.6 336.6 330.2 Std. XS 30 - 81.33 107.39 73 97 73 93 28 37 35.38 51.26 58.97 74.39 84.37 107.05 157.40 254.92 400 406.4 387.4 381.0 Std. XS 30 40 93.27 123.30 98 130 91 120 35 46 42.18 63.50 77.11 101.60 111.58 145.15 209.11 310.71 450 457 438.2 431.8 Std. XS - 105.16 139.15 120 165 135 190 40 53 52.62 68.04 102.51 126.10 138.35 181.89 217.27 419.12 500 508 489.0 482.6 Std. XS 20 30 117.15 155.12 150 200 168 245 61 82 65.32 81.65 123.38 149.69 174.63 231.33 312.98 527.98 600 610 590.6 584.2 Std. XS 20 - 141.12 187.06 220 280 240 350 77 95 91.63 118.84 203.21 222.26 247.21 342.92 443.16 680.39 750 762 743.0 736.6 Std. XS 20 176.84 234.67 332 440 388 484 107 143 142.88 163.29 326.59 367.41 421.84 680.39 589.67 975.22 900 914 895.4 889.0 Std. XS 20 212.56 282.27 481 638 588 731 129 172 217.72 235.87 510.29 544.31 589.67 1031.92 793.79 1564.89 DIMENSIONS MASS IN KILOGRAMS (kg) APPROXIMATE MASS PER UNIT FOR AUSTENITIC STAINLESS STEEL PIPE AND FITTINGS CAN BE OBTAINED BY APPLYING A FACTOR OF 1.015 MRC Data Chart reproduced with the permission of MRC Global Australia. 142 ENG2068 © WestOne Services 2013 meDiUm & HeaVY PiPe TO aUsTraliaN sTaNDarDs sPeCiFiCaTiON C250 pipe is manufactured and tested to meet the requirement of the following specifications: • AS 1074 Steel tubes and tubulars for ordinary service. • AS 1163 Structural steel hollow sections (Grade C250, C250L0). WOrKiNG PressUres – WelDeD JOiNTs eND PrOCessiNG OPTiONs Where AS 1074 pipe is used in pressure piping covered by AS 4041, the maximum pressure shall not exceed 1210 kPa for AS 1074 pipe up to and including DN 100 and 1030 kPa for AS 1074 pipe exceeding DN 100. • Roll Grooved Minimum Yield Strength 250MPa Minimum Tensile Strength 320MPa Minimum Elongation in 5.65 √So 20% sUPPlY CONDiTiONs Black/Painted/Galvanized/ILG Straightness Thickness Tolerance Dimension Tolerance Refer to Australian Standards Standard Length 6.5m Length Tolerance +50mm/-0mm CHs Grade C250 Dimensions • Shouldered • Threaded THreaDeD PiPe Screwed on one or both ends in accordance with AS 1074. The tapered Whitworth thread used complies with the requirements of AS 1722, Part 1 and is suitable for both parallel and taper threaded sockets. WOrKiNG PressUres – THreaDeD JOiNTs TaPer/Parallel THreaD meCHaNiCal PrOPerTies Surface Finish • Plain End Nom. size DN Water & inert Oil (mm) 25 32 40 50 65 80 100 125 150 kPa 2070 1720 1720 1380 1380 1380 1030 1030 860 med. Type of service Fuel Oil lPG Heavy med. & medium Heavy Press Temp o C kPa kPa kPa 2410 140 1030 100 2070 140 1030 100 2070 140 1030 100 1720 140 860 100 1720 – 860 100 1720 – 860 100 1380 – 690 100 1380 – – – 1030 – – – Other applications (including steam & Compressed air) Heavy Press Temp o kPa C 1210 192 1030 192 1030 192 860 192 860 192 860 192 850 192 – – – – medium Press Temp o kPa C 1210 100 1030 100 1030 100 860 100 860 100 860 100 690 100 – – – – mass and Bundling Data - Calculated in accordance with as 1163 Bundling mass Bundle Nominal mass lengths Per metres Per Dimenions Bundle Bundle kg/m m/tonne mm Heavy Press Temp o kPa C 1210 192 1030 192 1030 192 860 192 860 192 860 192 690 192 – – – – mass per Bundle Designation t do Nominal size DN (mm) (mm) (mm) WxH 6.5m m Black Galv. Black Galv. Black 20 M 350 306 127 825.5 1.56 1.62 642 613 1.29 1.32 350 372 372 383 383 436 436 422 422 533 533 445 445 508 508 571 571 698 698 660 660 127 91 91 61 61 61 61 37 37 37 37 19 19 19 19 19 19 13 13 10 10 825.5 591.5 591.5 396.5 396.5 396.5 396.5 240.5 240.5 240.5 240.5 123.5 123.5 123.5 123.5 123.5 123.5 84.5 84.5 65 65 1.87 2.41 2.94 3.10 3.80 3.57 4.38 5.03 6.19 6.43 7.93 8.37 10.3 9.63 11.9 12.2 14.5 16.6 17.9 19.7 21.7 1.93 2.49 3.02 3.20 3.90 3.68 4.49 5.18 6.33 6.61 8.12 8.58 10.5 9.88 12.2 12.4 14.3 16.9 18.2 20.1 21.57 535 415 340 322 263 280 228 199 161 156 126 120 96.8 104 84 82.2 69.1 60.2 55.9 50.7 45.9 522 406 330 310 255 270 221 192 157 150 123 116 94.4 100 81.7 79.8 67.4 58.6 54.6 49.3 46 1.54 1.43 1.74 1.23 1.51 1.41 1.74 1.21 1.49 1.55 1.91 1.03 1.28 1.19 1.47 1.5 1.79 1.4 1.51 1.28 1.38 1.59 1.47 1.78 1.27 1.54 1.46 1.78 1.25 1.52 1.59 1.95 1.06 1.30 1.22 1.5 1.54 1.82 1.43 1.54 1.31 1.41 26.9 x 2.6 CHS 3.2 CHS 33.7 x 3.2 CHS 4.0 CHS 42.4 x 3.2 CHS 4.0 CHS 48.3 x 3.2 CHS 4.0 CHS 60.3 x 3.6 CHS 4.5 CHS 76.1 x 3.6 CHS 4.5 CHS 88.9 x 4 CHS 4.9 CHS 101.6 x 4.0 CHS 4.9 CHS 114.3 x 4.5 CHS 5.4 CHS 139.7 x 5.0 CHS 5.4 CHS 165.1 x 5.0 CHS 5.4 CHS 20 H 25 M 25 H 32 M 32 H 40 M 40 H 50 M 50 H 65 M 65 H 80 M 80 H 90 M 90 H 100 M 100 H 125 M 125 H 150 M 150 H 306 327 327 337 337 384 384 374 374 472 472 397 397 454 454 509 509 382 382 451 451 tonnes Galv. m = medium, H = Heavy 7 7 7 Pipes to Australian Standards Medium/Heavy Pipes to Australian StandardsLight/Extra Light/Extra Light Light Pipes to Australian Standards 8 MRC Data Chart reproduced with the permission of MRC Global Australia. © WestOne Services 2013 ENG2068 143 8 8 liGHT/eXTra liGHT PiPe TO aUsTraliaN sTaNDarDs Grade C350 pipe is a lightweight, high strength pipe for general mechanical and structural applications. C350 is manufactured by coldforming and high frequency electric resistance welding. C350 is available in black, ILG and galvanized finishes. Also available with one or both ends swaged as follows: NB 20 Xl a l X sPeCiFiCaTiON GalVaNiZiNG Grade C350 pipe is manufactured and tested to meet the requirement of the following specifications: Grade C350 pipe is manufactured and tested to meet the requirement of AS 4792 Galvanized Coatings. • AS 1163 Structural Steel Hollow Sections (Grade C350, C350L0). Min. Ave Coating Mass 300g/m2 The coating adherence of the galvanizing is satisfactory for the pipe to be bent to a radius 6 times the diameter of the pipe. • AS/NZ 4792 Hot dip galvanized (zinc) coatings on ferrous hollow sections by a continuous or a specialised process. meCHaNiCal PrOPerTies WelDiNG Minimum Yield Strength 350MPa Minimum Tensile Strength 450MPa Minimum Elongation in 5.65 √So 20% The following consumables are recommended by AS 1554.1 when welding C350 sections. Manual metal-arc (MMAW) E41XX, E48XX Gas metal-arc (MIG) (GMAW) W50X sUPPlY CONDiTiONs 25 a a 32 a a 40 a 50 a a X Surface Finish Straightness Thickness Tolerance Dimension Tolerance Standard Length Length Tolerance Black/ILG/Galvanized Refer to Australian Standards 6.5m +50mm/-0mm Designation do t Nominal size DN (mm) (mm) (mm) mass and Bundling Data - Calculated in accordance with as 1163 Bundling mass Nominal mass Bundle lengths metres Dimenions Per Bundle Per Bundle kg/m m/tonne mm WxH 6.5m m Black Galv. Black Galv. 26.9 x 2.0 CHS 20 XL 350 306 127 825.5 1.23 1.29 814 767 1.010 1.070 2.3 CHS 20 LT 350 306 127 825.5 1.40 1.46 717 680 1.150 1.200 33.7 x 2.0 CHS 25 XL 372 327 91 591.5 1.56 1.64 640 602 0.920 0.970 2.6 CHS 25 LT 372 327 91 591.5 1.99 2.07 501 497 1.180 1.230 42.4 x 2.0 CHS 32 XL 383 337 61 396.5 1.99 2.10 502 473 0.790 0.830 2.6 CHS 32 LT 383 337 61 396.5 2.55 2.65 392 374 1.010 1.050 48.3 x 2.3 CHS 40 XL 436 384 61 396.5 2.61 2.73 383 364 1.030 1.080 Dimensions mass per Bundle tonnes Black Galv. 2.9 CHS 40 LT 436 384 61 396.5 3.25 3.36 308 295 1.290 1.330 60.3 x 2.3 CHS 50 XL 422 374 37 240.5 3.29 3.44 304 288 0.790 0.830 2.9 CHS 50 LT 422 374 37 240.5 4.11 4.25 244 234 0.990 1.020 76.1 x 2.3 CHS 65 XL 533 472 37 240.5 4.19 4.33 239 231 1.007 1.040 3.2 CHS 65 LT 533 472 37 240.5 5.75 5.94 174 167 1.380 1.430 88.9 x 2.6 CHS 80 XL 445 397 19 123.5 5.53 5.75 181 174 0.683 0.710 3.2 CHS 80 LT 445 397 19 123.5 6.76 6.98 148 143 0.840 0.860 101.6 x 2.6 CHS 90 XL 508 454 19 123.5 6.35 6.60 158 152 0.784 0.815 3.2 CHS 90 LT 508 454 19 123.5 7.70 8.04 129 124 0.960 0.990 100 XL 572 510 19 123.5 8.77 9.05 114 110 1.083 1.118 114.3 x 3.2 CHS 3.6 CHS 100 LT 572 510 19 123.5 9.83 10.11 102 98.6 1.214 1.249 139.7 x 3.0 CHS 125 XL 698 382 13 84.5 10.11 10.50 98.9 95.2 0.855 0.887 3.5 CHS 125 LT 698 382 13 84.5 11.76 12.10 85.1 82.4 0.993 1.022 165.1 x 3.5 CHS 150 LT 150 LT 660 451 10 65 13.95 14.40 71.7 69.4 0.907 0.936 NOTes: LT = Light, XL = Extra Light The term “tube” is synonymous with the term “pipe”. MRC Data Chart reproduced with the permission of MRC Global Australia. 144 ENG2068 © WestOne Services 2013 FlaNGes TO aUsTraliaN sTaNDarDs DIAM. RAISED FACE DIMENSIONS FOR LOOSE FLANGES FLAT FACE 1.6mm FLAT FACE COPPer allOY T.3 – Plate or Boss or Blank T.10 – Plate or Boss T.11 – Blank Table D Flange Drilling Nominal Thickness Bolt Dia. of size DN OD ** Circle No. of T3 Bolts T6 mm Dia. Bolts mm mm mm mm 15 95 6 5 67 4 M12 20 100 6 5 73 4 M12 25 115 8 5 83 4 M12 32 120 8 6 87 4 M12 40 135 10 6 98 4 M12 50 150 10 8 114 4 M16 65 165 11 8 127 4 M16 80 185 13 10 146 4 M16 100 215 16 10 178 4 M16 125 255 17 13 210 8 M16 150 280 17 13 235 8 M16 200 335 19 13 292 8 M16 250 405 19 16 356 8 M20 300 455 22 19 406 12 M20 350 525 25 22 470 12 M24 25 22 521 12 M24 400 580 450 640 29 25 584 12 M24 500 705 32 29 641 16 M24 600 825 35 32 756 16 M27 700 910 – 35 845 20 M27 750 995 – 41 927 20 M30 800 1060 – 41 984 20 M33 900 1175 – 48 1092 24 M33 1000 1255 – 51 1175 24 M33 1200 1490 – 60 1410 32 M33 DIAM. RAISED FACE OD mm 95 100 115 120 135 150 165 185 215 255 280 335 405 455 525 580 640 705 825 910 995 1060 1175 1255 1490 Table e Flange Drilling Thickness Bolt Dia. of ** Circle No. of T10 T11 Bolts T6 Dia. Bolts mm mm mm mm mm 6 6 6 67 4 M12 6 6 6 73 4 M12 8 8 7 83 4 M12 8 8 8 87 4 M12 10 10 9 98 4 M12 10 10 10 114 4 M16 11 11 10 127 4 M16 13 13 11 146 4 M16 16 16 13 178 8 M16 17 17 14 210 8 M16 17 17 17 235 8 M20 19 20 19 292 8 M20 22 25 22 356 12 M20 25 28 25 406 12 M24 25 32 29 470 12 M24 25 36 32 521 12 M24 29 41 35 584 16 M24 32 46 38 641 16 M24 38 – 48 756 16 M30 – – 51 845 20 M30 – – 54 927 20 M33 – – 54 984 20 M33 – – 64 1092 24 M33 – – 67 1175 24 M36 – – 79 1410 32 M36 Nominal size DN 15 20 25 32 40 50 65 80 100 125 150 200 250 300 350 400 450 500 600 OD mm 115 115 120 135 140 165 185 205 230 280 305 370 430 490 550 610 675 735 850 Thickness T10 mm T11 mm 10 10 11 11 13 13 14 16 19 22 25 32 35 38 41 44 48 51 57 11 11 12 13 14 16 17 19 23 27 30 39 45 52 58 64 71 78 92 Flange 57 57 64 76 83 102 114 127 152 178 210 260 311 362 419 483 533 597 699 OD mm 95 100 120 135 140 165 185 205 230 280 305 370 430 490 550 610 675 735 850 935 1015 1060 1185 1275 1530 T10 mm T11 mm 8 8 10 10 11 11 13 14 17 19 22 25 25 29 32 32 35 38 41 – – – – – – 8 8 10 10 11 12 13 15 17 20 23 28 32 37 42 47 52 57 68 – – – – – – ** T6 mm 10 10 10 13 13 16 16 16 19 22 22 25 29 32 35 41 44 51 57 60 67 68 76 83 95 83 83 87 98 105 127 146 165 191 235 260 324 381 438 495 552 610 673 781 4 4 4 4 4 4 8 8 8 8 12 12 12 16 16 20 20 24 24 M16 M16 M16 M16 M16 M16 M16 M16 M16 M20 M20 M20 M24 M24 M27 M27 M30 M30 M33 115 115 120 135 140 165 185 205 230 280 305 370 430 490 550 610 675 735 850 16 16 19 19 22 25 25 32 35 38 38 41 48 51 57 64 70 79 92 57 57 64 76 83 102 114 127 152 178 210 260 311 362 419 483 533 597 699 Drilling Bolt Dia. of Circle No. of Bolts Dia. Bolts mm mm 67 4 M12 73 4 M12 87 4 M16 98 4 M16 105 4 M16 127 4 M16 146 8 M16 165 8 M16 191 8 M16 235 8 M20 260 12 M20 324 12 M20 381 12 M24 438 16 M24 495 16 M27 552 20 M27 610 20 M30 673 24 M30 781 24 M33 857 24 M33 940 28 M33 984 28 M33 1105 32 M36 1194 36 M36 1441 40 M39 Nominal size DN 15 20 25 32 40 50 65 80 100 125 150 200 250 300 350 400 450 500 600 700 750 800 900 1000 1200 Table r Drilling Bolt Thickness Dia. † Dia. Circle of Dia. of OD r/F r/F Dia. No. Bolts Bolts mm * T6 mm * T6 mm mm mm mm mm 13 13 14 17 17 19 19 22 25 29 29 32 35 41 48 54 60 67 76 Table F Flange Thickness Table J Drilling 1.6mm WELD NECK FLANGE FOrGeD Or PlaTe sTeel T.6 – Plate or Boss or Blank, or Weldneck (except for valves) T.18– Plate or Blank or Weldneck (except for valves) FLAT FACE 1.6mm BOSS FLANGE – SLIP ON WELD OR SCR. B.S.P. Table H Flange DIAM. RAISED FACE PLATE FLANGE SLIP ON WELD BLANK OR BLIND FLANGE Flange Bolt of OD Thickness Dia. Circle No. of Dia. r/F Dia. Bolts Bolts mm * T18 mm mm mm mm 83 83 87 98 105 127 146 165 191 235 260 324 381 438 495 552 610 673 781 4 4 4 4 4 4 8 8 8 8 12 12 12 16 16 20 20 24 24 M16 M16 M16 M16 M16 M20 M20 M20 M20 M24 M24 M24 M27 M27 M30 M30 M33 M33 M36 115 115 125 135 150 165 185 205 240 280 305 370 430 510 585 640 735 805 – 19 19 22 22 25 25 29 32 35 41 44 51 60 70 79 89 98 105 – 64 64 76 76 89 102 114 127 152 178 210 260 311 362 419 483 572 622 – Drilling Nominal Bolt No. Dia. of size DN Circle of Bolts Dia. Bolts mm mm 83 83 95 98 114 127 146 165 197 235 260 324 387 457 527 584 673 730 – 4 4 4 4 4 8 8 8 8 12 12 12 16 16 16 20 20 20 – M16 M16 M16 M16 M20 M16 M20 M20 M24 M24 M24 M27 M27 M30 M33 M33 M36 M39 – 15 20 25 32 40 50 65 80 100 125 150 200 250 300 350 400 450 500 – NOTes: 1. All dimensions are in millimetres (mm). 2. Only metric preferred sizes listed, except for DN 750 which is a Nonpreferred size. ** 3. It is impractical to use flange thickness less than 12mm for Steel Plate Flanges. * 4. Thickness includes 1.6mm height for the Raised Face. † 5. The Raised Face is non-preferred for Table “H”. 6. It is normal practice to supply Steel Flanges to Tables A, D, C, E, F and H. — Flat Faced. 7. All copper alloy flanges shall be Flat Faced. 8. All flanges shall be drilled to Standard Tables unless otherwise specified. (For Bolt dimensions see separate page). imPOrTaNT: For DN 150 and DN 200 Flanges, the O.D. of pipe being used must be specified. Dimensions for Flange Tables A, C, K, S and T on application. 9 9 9 Flanges to AS.2129 Metric Bolts for use with AS.2129 Flanges 10 MRC Data Chart reproduced with the permission of MRC Global Australia. © WestOne Services 2013 ENG2068 145 10 10 i.s.O. meTriC HeXaGON sTeel BOlTs FOr Use WiTH as.2129 FlaNGes o o Steel hexagon Bolts and Nuts (XOX) are recommended for use within a temperature range of –50 C to +300 C. Outside of this temperature range, Stud Bolts should be used as recommended in AS.2528. A quick reference chart for sizing bolts and nuts for a range of regularly used standard flanges is given below: APPLICABLE TO PLATE & FORGED STEEL LOOSE FLANGES ONLY NOTe: Integral valve flanges quite often differ in thickness to equivalent loose flanges. When integral flanges are involved due allowance should be made to bolt lengths. Table D Nominal Flange size DN No. Bolts Per Flange 15 4 20 4 25 4 32 4 40 4 50 4 65 4 80 4 100 4 125 8 150 8 200 8 250 8 300 12 350 12 400 12 450 12 500 16 600 16 700 20 750 20 800 20 900 24 1000 24 1200 32 Temp in 0C -50 to 232 250 275 300 325 350 375 400 425 450 475 Max. Hydrostatic Test Pressure kPa Table e XOX Bolt & Nut dia. x lgth M12 x 40mm* M12 x 40mm* M12 x 40mm* M12 x 40mm* M12 x 40mm* M16 x 45mm* M16 x 45mm* M16 x 45mm* M16 x 45mm* M16 x 45mm* M16 x 45mm* M16 x 45mm* M20 x 55mm* M20 x 60mm* M24 x 75mm* M24 x 75mm* M24 x 80mm* M24 x 85mm* M27 x 100mm* M27 x 100mm* M30 x 120mm* M33 x 120mm* M33 x 140mm* M33 x 140mm* M33 x 160mm* No. Bolts Per Flange 4 4 4 4 4 4 4 4 8 8 8 8 12 12 12 12 16 16 16 20 20 20 24 24 32 Table F XOX Bolt & Nut dia. x lgth M12 x 40mm* M12 x 40mm* M12 x 40mm* M12 x 40mm* M12 x 40mm* M16 x 45mm* M16 x 45mm* M16 x 45mm* M16 x 45mm* M16 x 50mm* M20 x 60mm* M20 x 60mm* M20 x 70mm* M24 x 80mm* M24 x 85mm* M24 x 100mm* M24 x 100mm* M24 x 110mm* M30 x 130mm* M30 x 140mm* M33 x 150mm* M33 x 150mm* M33 x 170mm* M36 x 180mm* M36 x 200mm* XOX Bolt & Nut dia. x lgth XOX Bolt & Nut dia. x lgth 4 M12 X 40mm* 4 M16 x 45mm* 4 M12 X 40mm* 4 M16 x 45mm* 4 M16 X 45mm* 4 M16 x 50mm* 4 M16 X 45mm* 4 M16 x 55mm* 4 M16 X 45mm* 4 M16 x 55mm* 4 M16 X 50mm* 4 M16 x 60mm* 8 M16 X 50mm* 8 M16 x 60mm* 8 M16 X 50mm* 8 M16 x 65mm* 8 M16 X 60mm* 8 M16 x 70mm* 8 M20 X 70mm* 8 M20 x 80mm* 12 M20 X 70mm* 12 M20 x 80mm* 12 M20 X 75mm* 12 M20 x 90mm* 12 M24 X 85mm* 12 16 16 20 20 24 24 24 28 28 32 36 40 M24 X 100mm* M27 X 100mm* M27 X 120mm* M30 X 130mm* M30 X 140mm* M33 X 150mm* M33 X 160mm* M33 X 170mm* M33 X 180mm* M36 X 200mm* M36 X 220mm* M39 X 240mm* 16 16 20 20 24 24 Temperature / Pressure ratings for Carbon steel Flanges maximum allowable Pressure in kPa by Flange Tables (For approximate Psi divide by 7) D e F 700 1400 2100 650 1300 2000 600 1200 1800 570 1100 1700 550 1000 1600 500 950 1400 450 900 1300 400 800 1200 350 700 1000 1050 2100 3150 Length Table H No. Bolts Per Flange No. Bolts Per Flange M24 x 100mm* M24 x 110mm* M27 x 130mm* M27 x 140mm* M30 x 160mm* M30 x 170mm* M33 x 190mm* Bolt Diam. Flat faced joint illustrated Bolt lengths listed apply to flat-faced or 1.6mm raised face flanges with allowance for 1.6mm gasket thickness. *For approximate Stud Bolt Lengths take the XOX Bolt Length and add the metric diameter in mm rounded to the nearest 5mm increment up. Note: (This does not include length of point) This chart shows bolt diameters as recommended in AS.2129. Some of these are Non-preferred sizes e.g. (M27), (M33) and (M39) which are not readily available in Australia. Stud Bolts should be used as alternatives to bolts where the size is greater than M24 and it is therefore suggested that Stud Bolts as specified in AS.2528 or BS.4882 should be used. Inch series bolts interchangeable as follows: FOr Use FOr 1/4 “ 5/16” M6 7/8” M24 M8 1” 1 1/8” (M27) (M33) (M39) 3/8” M10 1/2” M12 5/8” M16 1 1/4” 1 3/8” 3/4” M20 1 1/2” Use M30 M36 BOlT HOle DiameTers For bolts to M24, clearance hole 2mm larger. Above M24, clearance hole 3mm larger. XOX BOlTs & NUTs XOX is the trade term used for H.R.H. commercial steel bolts and nuts. H.R.H. denotes Hexagon Head x Round Shank x Hexagon Nut. XOX Bolting H 3500 3300 3100 2900 2600 2400 2200 2000 1700 1300 900 Temp. Range: -50oC to +3000C Flange Specifications Table Bolts Nuts D, E, F AS 1110 Gr.4.6 or AS 1111 Gr.4.6 AS 1110 Gr8.8 AS 1112 Gr.5 H AS 1112 Gr.8 5250 MRC Data Chart reproduced with the permission of MRC Global Australia. 146 ENG2068 © WestOne Services 2013 mass CONVersiON CHarT The si unit of mass is the KilOGram – symbol kg The mass of an object is the quantity of matter it contains and is constant irrespective of the location or altitude. The weight of an object is the force exerted on it by gravity and thus varies from place to place and according to height above sea level or the distance from the Earth’s centre. (Hence weightlessness of astronauts in outer space). mass CONVersiON CHarT (A) To use, locate “given mass” in “given mass” column (coloured grey) whether lbs. or kg. (B) If “given mass” is in pounds (lbs.), read kilograms (kg) in right hand column. (C) If “given mass” is in kilograms (kg), read pounds (lbs.) in left hand column. (D) Example: (i) Given mass is 70 lbs = 31.75 kg from right hand column (ii) Given mass is 70 kg = 154.32 lbs. from left hand column lbs. 2.20 4.41 6.61 8.82 11.02 13.23 15.43 17.64 19.84 22.05 24.25 26.46 28.66 30.86 33.07 35.27 37.48 39.68 41.89 44.09 46.30 48.50 50.71 52.91 55.12 57.32 59.52 61.73 63.93 66.14 68.34 70.55 72.75 74.96 77.16 79.37 81.57 83.77 85.98 88.18 90.39 92.59 94.80 97.00 99.21 101.41 103.62 105.82 108.03 110.23 112.43 114.64 116.84 119.05 121.25 123.46 125.66 127.87 130.07 132.28 134.48 136.69 138.89 141.09 143.30 1 to 65 Given mass 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 kg lbs. 0.45 0.91 1.36 1.81 2.27 2.72 3.18 3.63 4.08 4.54 4.99 5.44 5.90 6.35 6.80 7.26 7.71 8.16 8.62 9.07 9.53 9.98 10.43 10.89 11.34 11.79 12.25 12.70 13.15 13.61 14.06 14.52 14.97 15.42 15.88 16.33 16.78 17.24 17.69 18.14 18.60 19.05 19.50 19.96 20.41 20.87 21.32 21.77 22.23 22.68 23.13 23.59 24.04 24.49 24.95 25.40 25.86 26.31 26.76 27.22 27.67 28.12 28.58 29.03 29.48 145.50 147.71 149.91 152.12 154.32 156.53 158.73 160.94 163.35 165.35 167.55 169.75 171.96 174.16 176.37 178.57 180.78 182.98 185.19 187.39 189.60 191.80 194.0 196.21 198.41 200.62 202.82 205.03 207.23 209.44 211.64 213.85 216.05 218.26 220.46 222.67 224.87 227.07 229.28 231.48 233.69 235.89 238.10 240.30 242.51 244.71 246.92 249.12 251.32 253.53 255.73 257.94 260.14 262.35 264.55 266.76 268.96 271.17 273.37 275.58 277.78 279.98 282.19 284.39 286.60 66 to 130 Given mass 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 kg lbs. 29.94 30.39 30.84 31.30 31.75 32.21 32.66 33.11 33.57 34.02 34.47 34.93 35.38 35.83 36.29 36.74 37.20 37.65 38.10 38.56 39.01 39.46 39.92 40.37 40.82 41.28 41.73 42.18 42.64 43.09 43.55 44.00 44.45 44.91 45.36 45.81 46.28 46.72 47.17 47.63 48.08 48.54 48.99 49.44 49.90 50.35 50.80 51.26 51.71 52.16 52.62 53.07 53.53 53.98 54.43 54.89 55.34 55.79 56.25 56.70 57.15 57.61 58.06 58.51 58.97 288.80 291.01 293.21 295.42 297.62 299.83 302.03 304.24 306.44 308.64 310.85 313.05 315.26 317.46 319.67 321.87 324.08 326.28 328.49 330.69 341.71 352.74 363.76 374.78 385.80 396.83 407.85 418.87 429.90 440.92 451.94 462.97 473.99 485.01 496.04 507.06 518.08 529.10 540.13 551.15 562.17 573.20 584.22 595.24 606.27 617.30 628.31 639.33 650.36 661.38 672.40 683.43 694.45 705.47 716.50 727.52 738.54 749.56 760.59 771.61 782.63 793.66 804.68 815.70 826.73 131 to 375 Given mass 131 132 133 134 135 136 137 138 139 140 141 142 143 144 145 146 147 148 149 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240 245 250 255 260 265 270 275 280 285 290 295 300 305 310 315 320 325 330 335 340 345 350 355 360 365 370 375 kg lbs. 59.42 59.88 60.33 60.78 61.24 61.69 62.14 62.60 63.05 63.50 63.96 64.41 64.87 65.32 65.77 66.23 66.68 67.13 67.59 68.04 70.31 72.58 74.84 77.11 79.38 81.65 83.92 86.18 88.45 90.72 92.99 95.26 97.52 99.79 102.06 104.33 106.60 108.86 111.13 113.40 115.67 117.94 120.20 122.47 124.74 127.01 129.28 131.54 133.81 136.08 138.35 140.62 142.88 145.15 147.42 149.69 151.96 154.22 156.49 158.76 161.03 163.30 165.56 167.83 170.10 838 849 860 871 882 893 904 915 926 937 948 959 970 981 992 1003 1014 1025 1036 1047 1058 1069 1080 1091 1102 1113 1124 1135 1146 1157 1168 1179 1190 1202 1213 1224 1235 1246 1257 1268 1279 1290 1301 1312 1323 1334 1345 1356 1367 1378 1389 1400 1411 1422 1433 1444 1455 1466 1477 1488 1499 1510 1521 1532 1543 380 to 700 Given mass 380 385 390 395 400 405 410 415 420 425 430 435 440 445 450 455 460 465 470 475 480 485 490 495 500 505 510 515 520 525 530 535 540 545 550 555 560 565 570 575 580 585 590 595 600 605 610 615 620 625 630 635 640 645 650 655 660 665 670 675 680 685 690 695 700 kg lbs. 172.37 174.64 176.90 179.17 181.44 183.71 185.98 188.24 190.51 192.78 195.05 197.32 199.58 201.85 204.12 206.39 208.66 210.92 213.19 215.46 217.73 220.00 222.26 224.53 226.80 229.07 231.34 233.60 235.87 238.14 240.41 242.68 244.94 247.21 249.48 251.75 254.02 256.28 258.55 260.82 263.09 265.36 267.62 269.89 272.16 274.43 276.70 278.96 281.23 283.50 285.77 288.04 290.30 292.57 294.84 297.11 299.38 301.64 303.91 306.18 308.45 310.72 312.98 315.25 317.52 1554 1565 1576 1587 1598 1609 1620 1631 1642 1653 1664 1676 1687 1698 1709 1720 1731 1742 1753 1764 1775 1786 1797 1808 1819 1830 1841 1852 1863 1874 1885 1896 1907 1918 1929 1940 1951 1962 1973 1984 1995 2006 2017 2028 2039 2050 2061 2072 2083 2094 2105 2116 2127 2138 2149 2161 2172 2183 2194 2205 2425 2646 2866 3086 3307 705 to 1500 Given mass 705 710 715 720 725 730 735 740 745 750 755 760 765 770 775 780 785 790 795 800 805 810 815 820 825 830 835 840 845 850 855 860 865 870 875 880 885 890 895 900 905 910 915 920 925 930 935 940 945 950 955 960 965 970 975 980 985 990 995 1000 1100 1200 1300 1400 1500 kg 319.79 322.06 324.32 326.59 328.86 331.13 333.40 335.66 337.93 340.20 342.47 344.74 347.00 349.27 351.54 353.81 356.08 358.34 360.61 362.88 365.15 367.42 369.68 371.95 374.22 376.49 378.76 381.02 383.29 385.56 387.83 390.10 392.36 394.63 396.90 399.17 401.44 403.70 405.97 408.24 410.51 412.78 415.04 417.31 419.58 421.85 424.12 426.38 428.65 430.92 433.19 435.46 437.72 439.99 442.26 444.53 446.80 449.06 451.33 453.60 498.96 544.32 589.68 635.04 680.40 CONVersiON FaCTOrs 1 Pound (lb.) x 0.4536 = kilograms (kg) 1 kilogram (kg) x 2.2046 = pounds (lbs.) 11 11 Mass Conversion Chart © WestOne Services 2013 11 MRC Data Chart reproduced with the permission of MRC Global Australia. Flange Identification ENG2068 12 147 12 12 FlaNGe iDeNTiFiCaTiON CHarT A guide to the key dimensions of popular steel flange types size (mm) 15 20 25 32 40 50 65 80 100 Table / Class Diam. of Flange Bolt Circle Diam. No. of Bolts Diam. / length Bolts / studs steel Flanges Diam. Holes Flange Thickness Cast / Forged steel Table D Table E Table H ANSI 150 ANSI 300 ANSI 600 PN 16 Table D Table E Table H ANSI 150 ANSI 300 ANSI 600 PN 16 Table D Table E Table H ANSI 150 ANSI 300 ANSI 600 PN 16 Table D Table E Table H ANSI 150 ANSI 300 ANSI 600 PN 16 Table D Table E Table H ANSI 150 ANSI 300 ANSI 600 PN 16 Table D Table E Table H ANSI 150 ANSI 300 ANSI 600 PN 16 Table D Table E Table H ANSI 150 ANSI 300 ANSI 600 PN 16 Table D Table E Table H ANSI 150 ANSI 300 ANSI 600 PN 16 Table D Table E Table H ANSI 150 ANSI 300 ANSI 600 PN 16 95 95 115 89 95 95 95 100 100 115 98 117 117 105 115 115 120 108 124 124 115 120 120 135 117 133 133 140 135 135 140 127 156 156 150 150 150 165 152 165 165 165 165 165 185 178 191 191 185 185 185 205 191 210 210 200 215 215 230 229 254 273 220 67 67 83 60.3 66.7 66.7 65 73 73 83 69.8 82.5 82.5 75 83 83 87 79.4 88.9 88.9 85 87 87 98 88.9 98.4 98.4 100 98 98 105 98.4 114.3 114.3 110 114 114 127 120.6 127 127 125 127 127 146 139.7 149.2 149.2 145 146 146 165 152.4 168.3 168.3 160 178 178 191 190.5 200 215.9 180 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 8 8 4 4 4 8 4 8 8 4 4 4 8 4 8 8 8 4 8 8 8 8 8 8 M12 x 45 M12 x 45 M16 x 60 1/2 x 60 1/2 x 65 1/2 x 80 –– M12 x 45 M12 x 45 M16 x 60 1/2 x 65 5/8 x 75 5/8 x 90 –– M12 x 45 M12 x 45 M16 x 60 1/2 x 65 5/8 x 80 5/8 x 105 –– M12 x 50 M12 x 50 M16 x 65 1/2 x 70 5/8 x 80 5/8 x 100 –– M12 x 50 M12 x 50 M16 x 65 1/2 x 70 3/4 x 90 3/4 x 105 –– M16 x 60 M16 x 60 M16 x 75 5/8 x 80 5/8 x 90 5/8 x 105 –– M16 x 60 M16 x 60 M16 x 75 5/8 x 90 3/4 x 100 3/4 x 120 –– M16 x 60 M16 x 60 M16 x 75 5/8 x 90 3/4 x 110 3/4 x 125 –– M16 x 65 M16 x 65 M16 x 85 5/8 x 90 3/4 x 110 7/8 x 145 –– 14 14 18 16 16 16 14 14 14 18 16 20 20 14 14 14 18 16 20 20 14 14 14 18 16 20 20 18 14 14 18 16 23 23 18 18 18 18 20 20 20 16 18 18 18 20 23 23 18 18 18 18 20 23 23 18 18 18 18 20 23 26 18 5* 6* 13 11.5 14.5 14.5 –– 5* 6* 13 14 16 16 –– 5* 7* 14 14 18 18 –– 6* 8* 17 16 22 22 –– 6* 9* 17 17 22 22 –– 8* 10* 19 20 22 26 –– 8* 10* 19 23 26 30 –– 10* 11* 22 24 32 32 –– 10* 13 25 24 32 38 –– *It is impractical to use thickness less than 12.00mm for plate flanges. Dimensions AS 2129 – ANSI/ASME B16.5 MRC Data Chart reproduced with the permission of MRC Global Australia. 148 ENG2068 © WestOne Services 2013 FlaNGe iDeNTiFiCaTiON CHarT size (mm) 125 150 200 250 300 350 375 400 450 500 600 Table / Class Diam. of Flange Bolt Circle Diam. No. of Bolts Diam. / length Bolts / studs steel Flanges Diam. Holes Flange Thickness Cast / Forged steel Table D Table E Table H ANSI 150 ANSI 300 ANSI 600 PN 16 Table D Table E Table H ANSI 150 ANSI 300 ANSI 600 PN 16 Table D Table E Table H ANSI 150 ANSI 300 ANSI 600 PN 10 PN 16 Table D Table E Table H ANSI 150 ANSI 600 PN 10 PN 16 Table D Table E Table H ANSI 150 ANSI 300 PN 10 PN 16 Table D Table E Table H ANSI 150 ANSI 300 Table D Table E Table D Table E Table H ANSI 150 ANSI 300 Table D Table E Table H ANSI 150 ANSI 300 Table D Table E Table H ANSI 150 ANSI 300 Table D Table E Table H ANSI 150 ANSI 300 255 255 280 254 279 330 250 280 280 305 279 318 356 285 335 335 370 343 381 419 340 340 405 405 430 406 510 395 405 455 455 490 483 520 445 450 525 525 550 535 585 550 550 580 580 610 597 650 640 640 675 635 710 705 705 735 700 775 825 825 850 815 915 210 210 235 215.9 234.9 266.7 210 235 235 260 241.3 269.9 292.1 240 292 292 324 298.4 330.2 349.2 295 280 356 356 381 361.9 431.8 350 350 406 406 438 431.8 450.8 400 410 470 470 495 476.2 514.3 495 495 521 521 552 539.7 571.5 584 584 610 577.8 628.6 641 641 673 635 685.8 756 756 781 749.3 812.8 8 8 8 8 8 8 8 8 8 12 8 12 12 8 8 8 12 8 12 12 8 12 8 12 12 12 16 8 12 12 12 16 12 16 12 12 12 12 16 12 20 12 12 12 12 20 16 20 12 16 20 16 24 16 16 24 20 24 16 16 24 20 24 M16 x 65 M16 x 65 M20 x 95 3/4 x 90 3/4 x 120 1 x 165 –– M16 x 65 M20x 65 M20 x 95 3/4 x 100 3/4 x 125 1 x 170 –– M16 x 65 M20 x 65 M20 x 100 3/4 x 110 7/8 x 140 1 1/8 x 195 –– –– M20 x 75 M20 x 75 M24 x 120 7/8 x 115 1 1/4 x 215 –– –– M20 x 85 M24 x 85 M24 x 110 7/8 x 120 1 1/8 x 170 –– –– M24 x 95 M24 x 95 M27 x 130 1 x 130 1 1/8 x 175 M24 x 95 M24 x 95 M24 x 95 M24 x 100 M27 x 140 1 x 130 1 1/4 x 190 M24 x 95 M24 x 120 M30 x 160 1 1/8 x 150 1 1/4 x 195 M24 x 110 M24 x 110 M30 x 170 1 1/8 x 160 1 1/4 x 205 M27 x 120 M30 x 140 M33 x 200 1 1/4 x 175 1 1/2 x 230 18 18 22 23 23 29 18 18 22 22 23 23 29 22 18 22 22 23 26 32 22 22 22 22 26 29 35 22 22 22 26 26 26 32 22 25 26 26 30 29 32 26 26 26 26 30 29 35 26 26 33 32 35 26 26 33 32 35 30 33 36 35 42 22 14 29 24 35 45 –– 13 17 29 26 37 48 –– 13 19 32 29 41 56 –– –– –– 22 35 30 64 –– –– 22 25 41 32 51 –– –– 25 29 48 35 54 22 32 22 32 54 37 57 25 35 60 40 60 29 38 67 43 64 32 48 76 48 70 *It is impractical to use thickness less than 12.00mm for plate flanges. Dimensions AS 2129 – ANSI/ASME B16.5 13 13 © WestOne Services 2013 Flange Identification 13 MRC Data Chart reproduced with the permission of MRC Global Australia. ENG2068 Pressure - Stress Conversion Charts 14149 14 14 PressUre - sTress CONVersiON CHarT The SI unit of pressure and stress is the NEWTON PER SQUARE METRE which has been given the special name PASCAL – Symbol Pa. The pascal is too small for most normal uses and suitable multiple units preferred for Australia are: kilopascal: Symbol – kPa (= 1000 Pa) (1 N/m2 = 0.000145 lbf/in2 = 1Pa) megapascal: Symbol – MPa (= 1,000,000 Pa) (1 N/mm2 = 145 lbf/in2 = 1MPa) PSI (lbf/in2) to kPa • PRESSURE – STRESS CONVERSION CHART To use, locate “given pressure” in “given pressure” column (coloured grey) whether lbf/in2 or kPa. If “given pressure” is in pounds force per square inch (lbf/in2), read kilopascals (kPa) in right hand column. If “given pressure” is in kilopascals (kPa), read pounds force per square inch (lbf/in2) in left hand column. Example: (i) Given pressure is 100 lbf/in2 = 689 kPa from right hand column (ii) Given pressure is 100kPa = 14.50 lbf/in2 from left hand column (A) (B) (C) (D) 1 to 35 Given Pressure 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 lbf/in2 0.15 0.29 0.44 0.58 0.73 0.87 1.02 1.16 1.31 1.45 1.60 1.74 1.89 2.03 2.18 2.32 2.47 2.61 2.76 2.90 3.05 3.19 3.34 3.48 3.63 3.77 3.92 4.06 4.21 4.35 4.50 4.64 4.79 4.93 5.08 kPa lbf/in2 6.89 13.79 20.68 27.58 34.47 41.37 48.26 55.16 62.05 68.95 75.84 82.74 89.63 96.53 103.42 110.32 117.21 124.11 131.00 137.90 144.79 151.69 158.58 165.47 172.37 179.26 186.16 193.05 199.95 206.84 213.74 220.63 227.53 234.42 241.32 5.22 5.37 5.51 5.66 5.80 5.95 6.09 6.24 6.38 6.53 6.67 6.82 6.96 7.11 7.25 7.40 7.54 7.69 7.83 7.98 8.12 8.27 8.41 8.56 8.70 8.85 8.99 9.14 9.28 9.43 9.57 9.72 9.86 10.01 10.15 36 to 70 Given Pressure 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 kPa lbf/in2 248.21 255.11 262.00 268.9 275.79 282.69 289.58 296.48 303.37 310.26 317.16 324.05 330.95 337.84 344.74 351.63 358.53 365.42 372.32 379.21 386.11 393.00 399.90 406.79 413.69 420.58 427.48 434.37 441.26 448.16 455.05 461.95 468.84 475.74 482.63 10.30 10.44 10.59 10.73 10.88 11.02 11.17 11.31 11.46 11.60 11.75 11.89 12.04 12.18 12.33 12.47 12.62 12.70 12.91 13.05 13.20 13.34 13.49 13.63 13.78 13.92 14.07 14.21 14.34 14.50 15.23 15.95 16.68 17.40 18.13 71 to 125 Given Pressure 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 105 110 115 120 125 kPa lbf/in2 490 496 503 510 517 524 531 538 545 552 558 565 572 579 586 593 600 607 614 621 627 634 641 648 655 662 669 676 683 689 724 758 793 827 862 18.85 19.58 20.31 21.03 21.76 22.48 23.21 23.93 24.61 25.38 26.11 26.83 27.56 28.28 29.01 36.26 43.51 58.02 72.52 108.78 145.04 217.56 290.08 435.11 580.15 725.19 1,450.38 2,175.57 2,900.76 4,351.14 5,801.52 7,251.90 8,702.28 10,152.70 11,603.00 130 to 80,000 Given kPa Pressure 130 896 135 931 140 965 145 1000 150 1034 155 1069 160 1103 165 1138 170 1172 175 1207 180 1241 185 1276 190 1310 195 1344 200 1379 250 1724 300 2068 400 2758 500 3447 750 5171 1000 6894 1500 10,342 2000 13,790 3000 20,684 4000 27,579 5000 34,473 68,948 10,000 15,000 103,421 20,000 137,895 30,000 206,843 40,000 275,790 50,000 344,738 60,000 413.686 70,000 482,633 80,000 551,581 = mPa = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = = 0.90 0.93 0.97 1.00 1.03 1.07 1.10 1.14 1.17 1.21 1.24 1.28 1.31 1.34 1.38 1.73 2.07 2.76 3.45 5.17 6.89 10.34 13.79 20.68 27.58 34.47 68.95 103.4 137.9 206.8 275.8 344.7 413.7 482.6 551.6 NOTe: iT is UsUal FOr PressUres iN eXCess OF 1000 kPa TO Be eXPresseD iN meGaPasCals – mPa 1 megapascal (mPa) = 1000 kilopascals (kPa) = 1 newton per mm2 (N/mm2) = 145 lbf/in2 UseFUl CONVersiON FaCTOrs – aPPrOXimaTe mUlTiPlY TO OBTaiN Bars kg f/cm2 kg f / mm2 BY BY 1.0197 100.0 14.504 0.1 14.223 98.07 0.09807 1422.33 9.807 0.635 TO OBTaiN DiViDe kg f/cm2 kPa lbf/in2 MPa lbf/in2 kPa MPa lbf/in2 MPa ton f/in2 mUlTiPlY TO OBTaiN lb f/in2 (PSI) ton f/in2 BY BY 6.895 0.00689 15.444 TO OBTaiN DiViDe kPa MPa MPa aPPrOXimaTe eQUiValeNTs 1 Atmosphere (atm) = 14.696 lbf/in2 1 bar = 14.50 lbf/in2 1 kg f/cm2 = 14.22 lbf/in2 100 kPa (1 bar) = 14.50 lbf/in2 NOTE: lbf/in2 (pounds force per square inch) is often expressed as PSI (pounds per square inch) MRC Data Chart reproduced with the permission of MRC Global Australia. 150 ENG2068 © WestOne Services 2013 TemPeraTUre - CONVersiON CHarT The SI Unit of thermodynamic temperature is the KELVIN – Symbol K. For most practical purposes of temperature measurement and most calculations involving temperatures, DEGREE CELSIUS, symbol oC will be used. The name CELSIUS was adopted internationally in 1948 instead of Centigrade, to avoid possible confusion with the identically named unit of angle used in some European countries. TEMPERATURE CONVERSION CHART (A) To use, locate “given temperature” in “given temperature” column (coloured grey) whether oC or oF. (B) If “given temperature” is in degrees Celsius (oC), read degrees Fahrenheit (oF) in right hand column. (C) If “given temperature” is in degrees Fahrenheit (oF), read degrees Celsius (oC) in left hand column. (D) Example: (i) Given temperature is 35oC = 95oF from right hand column (ii) Given temperature is 35oF = 1.7oC from left hand column –320 to 27 C Given Temp. –196 –184 –173 –162 –151 –140 –129 –115 –101 – 90 – 84 – 79 – 73 – 68 – 62 – 57 – 51 – 46 – 40 – 34 – 29 – 23 – 17.8 – 17.2 – 16.7 – 16.1 – 15.6 – 15.0 – 14.4 – 13.9 – 13.3 – 12.8 – 12.2 – 11.7 – 11.1 – 10.6 – 10.0 – 9.4 – 8.9 – 8.3 – 7.8 – 7.2 – 6.7 – 6.1 – 5.6 – 5.0 – 4.4 – 3.9 – 3.3 – 2.8 –320 –300 –280 –260 –240 –220 –200 –175 –150 –130 –120 –110 –100 – 90 – 80 – 70 – 60 – 50 – 40 – 30 – 20 – 10 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 o 28 to 77 C Given Temp. – 2.2 – 1.7 – 1.1 – 0.6 0.0 0.6 1.1 1.7 2.2 2.8 3.3 3.9 4.4 5.0 5.6 6.1 6.7 7.2 7.8 8.3 8.9 9.4 10.0 10.6 11.1 11.7 12.2 12.8 13.3 13.9 14.4 15.0 15.6 16.1 16.7 17.2 17.8 18.3 18.9 19.4 20.0 20.6 21.1 21.7 22.2 22.8 23.3 23.9 24.4 25.0 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 F o –– –– –– –436 –400 –364 –328 –283 –238 –202 –184 –166 –148 –130 –112 – 94 – 76 – 58 – 40 – 22 – 4 14 32 33.8 35.6 37.4 39.2 41.0 42.8 44.6 46.4 48.2 50.0 51.8 53.6 55.4 57.2 59.0 60.8 62.6 64.4 66.2 68.0 69.8 71.6 73.4 75.2 77.0 78.8 80.6 o 78 to 235 o F 82.4 84.2 86.0 87.8 89.6 91.4 93.2 95.0 96.8 98.6 100.4 102.2 104.0 105.8 107.6 109.4 111.2 113.0 114.8 116.6 118.4 120.2 122.0 123.8 125.6 127.4 129.2 131.0 132.8 134.6 136.4 138.2 140.0 141.8 143.6 145.4 147.2 149.0 150.8 152.6 154.4 156.2 158.0 159.8 161.6 163.4 165.2 167.0 168.8 170.6 C Given Temp. 25.6 26.1 26.7 27.2 27.8 28.3 28.9 29.4 30.0 30.6 31.1 31.7 32.2 32.8 33.3 33.9 34.4 35.0 35.6 36.1 36.7 37.2 37.8 41 43 46 49 52 54 57 60 63 66 68 71 74 77 79 82 85 88 91 93 96 99 102 104 107 110 113 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 105 110 115 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 o 240 to 485 o F 172.4 174.2 176.0 177.8 179.6 181.4 183.2 185.0 186.8 188.6 190.4 192.2 194.0 195.8 197.6 199.4 201.2 203.0 204.8 206.6 208.4 210.2 212.0 221 230 239 248 257 266 275 284 293 302 311 320 329 338 347 356 365 374 383 392 401 410 419 428 437 446 455 C Given Temp. 116 118 121 124 127 129 132 135 138 141 143 146 149 152 154 157 160 163 166 168 171 174 177 179 182 185 188 191 193 196 199 202 204 207 210 213 216 218 221 224 227 229 232 235 238 241 243 246 249 252 240 245 250 255 260 265 270 275 280 285 290 295 300 305 310 315 320 325 330 335 340 345 350 355 360 365 370 375 380 385 390 395 400 405 410 415 420 425 430 435 440 445 450 455 460 465 470 475 480 485 o 490 to 2400 o F 464 473 482 491 500 509 518 527 536 545 554 563 572 581 590 599 608 617 626 635 644 653 662 671 680 689 698 707 716 725 734 743 752 761 770 779 788 797 806 815 824 833 842 851 860 869 878 887 896 905 C Given Temp. 254 257 260 266 271 277 282 288 293 299 304 310 316 321 327 332 338 343 349 354 360 366 371 377 382 388 393 399 404 410 416 421 427 432 438 443 454 468 482 510 538 566 593 621 649 704 760 816 1093 1316 490 495 500 510 520 530 540 550 560 570 580 590 600 610 620 630 640 650 660 670 680 690 700 710 720 730 740 750 760 770 780 790 800 810 820 830 850 875 900 950 1000 1050 1100 1150 1200 1300 1400 1500 2000 2400 o F o 914 923 932 950 968 986 1004 1022 1040 1058 1076 1094 1112 1130 1148 1166 1184 1202 1220 1238 1256 1274 1292 1310 1328 1346 1364 1382 1400 1418 1436 1454 1472 1490 1508 1526 1562 1607 1652 1742 1832 1922 2012 2102 2192 2372 2552 2732 3632 4352 CONVersiON FaCTOrs DeGrees FaHreNHeiT TO CelsiUs (oF – 32) x 5/9 = oC DeGrees CelsiUs TO FaHreNHeiT (oC x 9/5) + 32 = oF MRC Data Chart reproduced with the permission of MRC Global Australia. 15 © WestOne Services 2013 15 15 Temperature Conversion Conversion Chart Chart Temperature ENG2068 American AmericanStandard StandardFlanges Flanges 15 151 16 16 16 16 ameriCaN sTaNDarD FlaNGes TemPeraTUre / PressUre raTiNGs Temperature / Pressure ratings Carbon steel Pipe Flanges to aNsi / asme 16.5 - 1988 (Bs 1560) Forgings to asTm a105 and a350 - lF2 Forgings to asTm a181 Grade ii for Class 150 and 300 Only Temperature (oC) maximum Working Pressure in kPa by Classes (for approximate Psi divide by 7) Class 150 (PN20) Class 300 (PN50) Class 600 (PN100) Class 900 (PN150) Class 1500 (PN250) Class 2500 (PN420) -29 to 38 1960 5110 10210 15320 25530 42550 50 1920 5010 10020 15020 25040 41730 100 1770 4640 9280 13910 23190 38650 150 1580 4520 9050 13570 22610 37690 200 1400 4380 8760 13150 21910 36520 250 1210 4170 8340 12520 20860 34770 300 1020 3870 7750 11620 19370 32280 350 840 3700 7390 11090 18480 30800 375 740 3650 7290 10940 18230 30390 400 650 3450 6900 10350 17250 28750 425 560 2880 5750 8630 14380 23960 450 470 2000 4010 6010 10020 16690 475 370 1350 2710 4060 6770 11290 500 280 880 1760 2640 4400 7330 525 190 520 1040 1550 2590 4320 540 130 330 650 980 1630 2720 NOTe: Flanges above 600 NPA are not included in ANSI B16.5 and the class designations in these large diameters do not imply specific temperature / pressure ratings. MRC Data Chart reproduced with the permission of MRC Global Australia. 152 ENG2068 © WestOne Services 2013 aPi - Valve standards An Overview of the American Petroleum Institute - API - Valve Standards standard Description aPi sPeC 6D Specification for Pipeline Valves. API Specification 6D is an adoption of IO 14313: 1999, Petroleum & Natural Gas Industries-Pipeline Transportation Systems-Pipeline Valves. This International Standard specifies requirements and gives recommendations for the design, manufacturing, testing and documentation of ball, check, gate and plug valves for application in pipeline systems. aPi 526 Flanged Steel Pressure Relief Valves. The standard is a purchase specification for flanged steel pressure relief valves. Basic requirements are given for direct spring-loaded pressure relief valves and pilot-operated pressure relief valves as follows: orifice designation and area / valve size and pressure rating, inlet and outlet; materials; pressure-temperature limits; and centre-toface dimensions, inlet and outlet. aPi 527 Seat Tightness of Pressure Relief Valves R(2002). Describes methods of determining the seat tightness of metal and softseated pressure relief valves, including those of conventional, bellows and pilot-operated designs. aNsi / aPi sTD 594 Check Valves: Flanged, Lug, Wafer and Butt-Welding. API Standard 594 covers design, material, face-to-face dimensions, pressure-temperature ratings and examination, inspection and test requirements for two types of check valves. aPi 598 Valve Inspection & Testing. The standard covers inspection, supplementary examination and pressure test requirements for both resilient-seated and metal-to-metal seated gate, globe, plug, ball, check and butterfly valves. Pertains to inspection by the purchaser and to any supplementary examinations the purchaser may require at the valve manufacturer’s plant. aNsi / aPi 599 Metal Plug Valves - Flanged, Threaded & Welding Ends. A purchase specification that covers requirements for metal plug valves with flanged or butt-welding ends, and ductile iron plug valves with flanged ends, in sizes NPS 1 through to NPS 24, which correspond to nominal pipe sizes in ASME B36.10M. Valve bodies conforming to ASME B16.34 may have flanged end and one butt-welding end. It also covers both lubricated and non-lubricated valves that have two-way coaxial ports, and includes requirements for valves fitted with internal body, plug or port linings or applied hard facings on the body, body ports, plug or plug port. aNsi / aPi 600 Bolted Bonnet Steel Gate Valves for Petroleum and Natural Gas Industries - Modified National Adoption of ISO 10434: 1998. aPi 602 Compact Steel Gate Valves - Flanged, Threaded, Welding and Extended-Body Ends. The standard covers threaded-end, socketwelding-end, butt-welding-end and flanged-end compact carbon steel gate valves in sizes NPS4 and smaller. aNsi / aPi 603 Corrosion-Resistant, Bolted Bonnet Gate Valves - Flanged and Butt-Welding ends. The standard covers corrosion-resistant bolted bonnet gate valves with flanged or butt weld ends in sizes NPS 1/2 through 24, corresponding to nominal pipe sizes in ASME B36.10M, and Classes 150, 300 and 600, as specified in ASME B16.34. aNsi / aPi 607 Fire Test for Soft-Seated Quarter Turn Valves. The standard covers the requirements for testing and evaluating the performance of straightway, soft-seated quarter turn valves when the valves are exposed to certain fire conditions defined in this standard. The procedures described in this standard apply to all classes and sizes of such valves that are made of materials listed in ASME B16.34. aPi 609 Butterfly Valves: Double Flanged, Lug and Wafer-Type. The standard covers design, materials, face-to-face dimensions, pressuretemeprature ratings and examination, inspection and test requirements for gray iron, ductile iron, bronze, steel, nickel-base alloy, or special alloy butterfly valves that provide tight shutoff in the closed position and are suitable for flow regulation. aPi 6Fa Specification for Fire Test for Valves. The standard covers the requirements for testing and evaluating the performance of API Spec 6A and Spec 6D valves with automatic backseats when exposed to specifically defined fire conditions. aPi 6rs References Standards for Committee 6, Standardisation of Valves and Wellhead Equipment. aPi 11V6 Design of Continuous Flow Gas Lift Installation Using Injection Pressure Operated Valves. The standard sets guidelines for continuous flow gas lift installation designs using injection pressure operated valves. aNsi / aPi rP 11V7 Recommended Practice for Repair, Testing and Setting Gas Lift Valves. The standard applies to repair, testing and setting gas lift valves and reverse flow (check) valves. aPi 520-1 Sizing, Selection and Insallation of Pressure-Relieving Devices in Refineries: Part I - Sizing and Selection. The recommended practice applies to the sizing and selection of pressure relief devices used in refineries and related industries for equipment that has a maximum allowable working pressure of 15 psig (1.03 bar g or 103 kPa g) or greater. aPi 520-2 Recommended Practice 520: Sizing, Selection and Installation of Pressure-Relieving Devices in Refineries: Part II - Installation. The recommended practice covers methods of installation for pressure-relief devices for equipment that has a maximum allowable working pressure of 15 psig (1.03 bar g or 103 kPa g) or greater. It covers gas, vapor, steam, two-phase and incompressible fluid service. aNsi / aPi 574 Inspection Practices for Piping System Components. The standard covers the inspection of piping, tubing, valves (other than control valves) and fittings used in petroleum refineries. aNsi / aPi 576 Inspection of Pressure-Relieving Devices. The recommended practice describes the inspection and repair practices for automatic pressure-relieving devices commonly used in the oil and petrochemical industries. aNsi / aPi 608 Metal Ball Valves - Flanged and Butt-Welding Ends. The standard covers Class 150 and Class 300 metal ball valves that have either butt-welding or flanged ends and are for use in on-off service. 17 17 © WestOne 2013 APIServices -- Valve API ValveStandards Standards 17 MRC Data Chart reproduced with the permission of MRC Global Australia. ENG2068 UsefulConversion Conversion Factors Useful Factors 18 18153 18 18 UseFUl CONVersiON FaCTOrs – imPerial TO meTriC (approx.) “SI” denotes the International System of Metric Units adopted in Australia This table may be used in two ways: (1) Multiply Column A by Column B to obtain Column C; or (2) Divide Column C by Column B to obtain Column A. area: symbol m2 The SI unit of AREA is the SQUARE METRE. Square Inches Square Feet Square Yards Acre Hectare (ha) DeNsiTY: symbol kg/m3 lb/in3 The SI unit of DENSITY is the lb/ft3 kilogram per cubic metre. lb/yd3 eNerGY: symbol J C To Obtain 645.16 0.929 0.836 4047 10000 mm m2 m2 m2 m2 27.68 16.02 0.5933 t/m3 kg/m3 kg/m3 1.eleCTriCal eNerGY kilowatt hour (kW.h) The SI unit of ENERGY is the 2.HeaT eNerGY JOULE. British thermal unit (Btu) Btu/gal 1 J = 1 N.m Btu/ft3 A joule is the energy expended or the work done when a force of one newton moves the point of application a distance of one metre in the direction of that force. B By a multiply remarks 3.6 1.055 0.2321 37.26 MJ kJ kJ/L †† kJ/m3 3.meCHaNiCal eNerGY foot poundal (ft.pdl) inch pound-force (in.lbf) foot pound-force (ft.lbf) foot ton force (ft.tonf) Metre kilogram force (m.kgf) The SI unit of FORCE (kg.m/ Poundal (pdl) s2) has been given the special name – NEWTON. Pound-force (lbf) The newton is the force ton-force (tonf) which when applied to a body having a mass of *kilogram-force (kgf) one kilogram, causes an acceleration of one metre *also known as kilopond (kp) per second in the direction of application of the force. pounds-force per inch .04214 0.1130 1.356 3.037 9.807 J J J kJ J N 4.448 N 9.964 kN 9.807 N N/m 14.59 N/m 32.69 kN/m 25.4 0.3048 0.9144 20.12 1609 1.609 millimetres (mm) metres (m) metres (m) metres (m) metres (m) kilometres (km) ounce pound slug ton (2240 lb) short ton (2000 lb) ton (2240 lb) 28.35 0.4536 14.59 1016.05 907.2 1.016 grams (g) kilograms (kg) kg kg kg tonne (t) pounds per foot (lb/ft) pounds per yard (lb/yd) 1.488 0.4961 kg/m kg/m pounds-force per foot ton/ft inches leNGTH: symbol m feet yards The SI unit of LENGTH is the chain METRE. mile mile The SI unit of MASS is the KILOGRAM. 0.1383 175.1 lbf/in The SI unit is NEWTON PER lbf/ft METRE: symbol N/m ton-force per foot mass: symbol kg PressUre: symbol Pa The SI unit of PRESSURE or stress is the NEWTON PER SQUARE METRE which has been given the name PASCAL. 1 N/m2 = 1Pa = 0.000145lbf/in2 A pascal is the pressure or stress which arises when a force of one newton is applied uniformly over an area of one square metre. 6.895 kPa 6.895 MPa 47.88 Pa kgf/cm2 98.07 kPa 100 kPa bar Vertical column (head) of water. (H20 at 20oC) metres of water 9.79 kPa 2.984 kPa torr (vacuum) 0.1333 kPa 1mm Hg. (mercury) 0.1333 kPa 1in. Hg. (mercury) 3.386 kPa atmosphere (atm) 101.325 kPa 0.133 Pa 0.04214 N.m 0.1130 1.152 N.m kgf.cm 1.356 13.83 N.m kgf.cm 3.037 kN.m 9.807 0.09807 N.m N.m 0.3048 0.00508 0.4470 1.609 m/s m/s m/s km/h 16387 0.02832 0.7646 1 000 000 0.001 0.004546 mm3 m3 m3 mm3 m3 m3 28.41 568.3 1.137 4.546 3.785 1.000 4.536 millilitre (ml) millilitre (ml) litre (L) †† litre (L) †† litre (L) †† kilogram (kg) kilogram (kg) m3/s feet of water Poundal-foot pdl.ft pound-force inch lbf.inch The SI unit of TORQUE is lbf.inch the NEWTON METRE. The pound-force feet newton metre is the work lbf.ft done when a force of one lbf.ft newton moves the point of application a distance of one ton-force feet tonf.ft metre in the direction of kilogram-force that force. kgf.m 1 N.m = 1 J kgf.cm The SI unit of VELOCITY is the METRE PER SECOND. VOlUme: CaPaCiTY: symbol m3 The SI unit of VOLUME is the CUBIC METRE. NOTE: †† Capital “L” is now the legal preferred symbol for litre in Australia. ft. per second (ft/s) ft. per minute (ft/min) miles per hour miles per hour DrY: cubic inch (in3) cubic foot (ft3) cubic yard (yd3) litre (L) †† litre (L) †† gallons (lmp.) imPerial liQUiD fluid ounce pint (20 fl. oz) quart (2 pints) gallon (lmp.) gallon (US) litre (water 4oC) Imp. gallons (water 20oC) Imp. gal. per minute (gal/ min) VOlUme: raTe OF FlOW symbol m3/s Imp. gal. per minute Imp. gal. per minute The SI unit of VOLUME RATE OF FLOW is the CUBIC METRE PER SECOND. cubic ft. per minute cubic ft. per minute POWer: symbol W The SI unit of POWER is the WATT. Btu per hour (Btu/hr) horsepower (hp) ton of refrigeration 0.2931 0.7457 3.517 W kW kW sUNDrY iTems: C To Obtain kip/in2 (1000 psi) lbf/ft2 TOrQUe: symbol N.m (moment of force) VelOCiTY: symbol m/s B By lbf/in2 microns FOrCe: symbol N (NeWTON) FOrCe Per UNiT leNGTH: a multiply remarks 2 miles per gallon gallons per mile 0.0000758 0.272765 0.0758 0.000472 m3/hr litre per second (L/s) m3/s 0.472 litre per second (L/s) 1 m3 = 1 kL 0.3540 2.825 km per litre litres per km TemPeraTUre The SI unit of TEMPERATURE is the KELVIN – Symbol K For most practical purposes of temperature measurement and most calculations involving temperatures, degrees Celsius, symbol oC will be used. DeGrees FaHreNHeiT TO CelsiUs: DeGrees CelsiUs TO FaHreNHeiT: (oF – 32) x 5/9 = oC (oC x 9/5) + 32 = oF MRC Data Chart reproduced with the permission of MRC Global Australia. 154 ENG2068 © WestOne Services 2013 PIPE FABRICATION MATERIALS, DRAWING AND FABRICATION METHODS DESCRIPTION This resource covers content relating to units from the MEM training package in relation to the pipe fabrication context. It supports the units MEM09003B and MEM09211A, and partially supports MEM09217A, MEM05010C, MEM04011D, and MEM04045B. Topics include: • safety, plant and equipment • codes and standards • abbreviations and symbols • materials, systems and fittings • drawing and dimensioning • fabrication methods and processes. The book includes many technical drawings to support learning. EDITION Edition 1, 2013 TRAINING PACKAGE • METALS AND ENGINEERING COURSE / QUALIFICATION • MEM40412 Certificate IV in Engineering (Drafting) • MEM50212 Diploma of Engineering – Technical • MEM40105 Certificate IV in Engineering • MEM50105 Diploma of Engineering – Advanced Trade UNITS OF COMPETENCY This resource supports the unit: • MEM09211A Producre drawings or models for industrial piping It also partially supports: • MEM09217A Prepare plans for pipe and duct fabrication • MEM05011D Assemble fabricated components ENG2068 PIPE FABRICATION ISBN 978-1-74205-902-0 ORDERING INFORMATION: Contact WestOne Services on Tel: (08) 9229 5200 Fax: (08) 9227 8393 Email: sales@westone.wa.gov.au Orders can also be placed through the website: www.westone.wa.gov.au 9 781742 059020