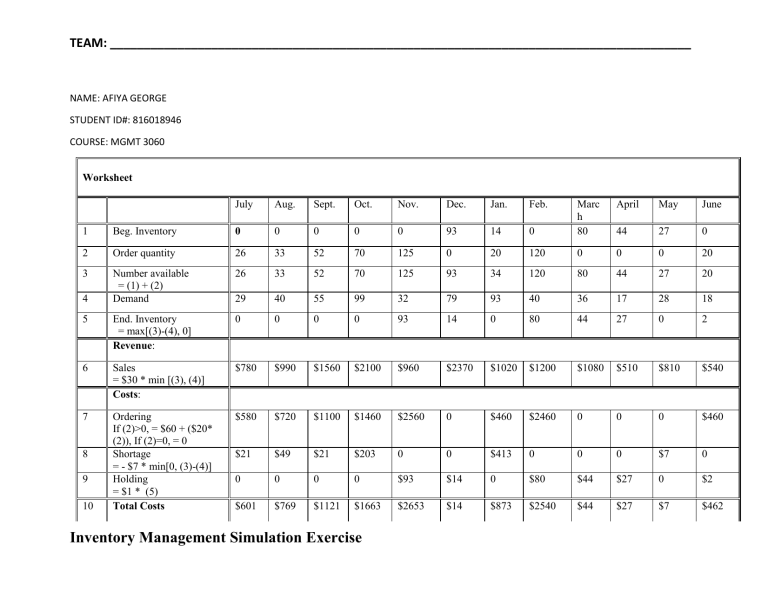

TEAM: ______________________________________________________________________________________ NAME: AFIYA GEORGE STUDENT ID#: 816018946 COURSE: MGMT 3060 Worksheet 1 Beg. Inventory 0 0 0 0 0 93 14 0 Marc h 80 2 Order quantity 26 33 52 70 125 0 20 120 0 0 0 20 3 Number available = (1) + (2) Demand 26 33 52 70 125 93 34 120 80 44 27 20 29 40 55 99 32 79 93 40 36 17 28 18 5 End. Inventory = max[(3)-(4), 0] Revenue: 0 0 0 0 93 14 0 80 44 27 0 2 6 Sales = $30 * min [(3), (4)] Costs: $780 $990 $1560 $2100 $960 $2370 $1020 $1200 $1080 $510 $810 $540 7 Ordering If (2)>0, = $60 + ($20* (2)), If (2)=0, = 0 Shortage = - $7 * min[0, (3)-(4)] Holding = $1 * (5) Total Costs $580 $720 $1100 $1460 $2560 0 $460 $2460 0 0 0 $460 $21 $49 $21 $203 0 0 $413 0 0 0 $7 0 0 0 0 0 $93 $14 0 $80 $44 $27 0 $2 $601 $769 $1121 $1663 $2653 $14 $873 $2540 $44 $27 $7 $462 4 8 9 10 July Aug. Sept. Oct. Nov. Dec. Jan. Feb. Inventory Management Simulation Exercise April May June 44 27 0 TEAM: ______________________________________________________________________________________ = (7) + (8) + (9) 11 12 Monthly Profit = (6) - (10) Annual Profit $179 $221 $179 $400 $439 $839 $437 ($1693) $2356 $147 $1276 ($417) $1939 $2086 ($1340) $746 $1036 $1782 $483 $803 $78 $2265 $3068 $3146 A specific inventory forecast is exceptionally valuable, particularly when customer demand and supply chains are shifting instantly. To accurately forecast future demand, forecasting demands for a mixture of data analysis, industry experience and customer insights. Inventory forecasting allows you to determine how much of each sort of inventory will be needed in the future. Resupply data, such as lead time, availability, and scheduling, are among the factors. The stock needed for replenishment is determined by supply and demand, inventory targets, and inventory projections. After monitoring the data given on the number of sticks sold for other new, state-of-the-art sticks from previous years, it was determined that there has been a rise in sales in both months of July and August respectively in years 1 and 2. Therefore, proven by the hysterical data, those months were expected to experience a rise in demand, which I predicted and however fell short by a few. Upon realizing the pattern of increased demand, my predictions began to rise but were met with a shock in the month of November where demand had decreased in comparison to the previous months and evidently led to holding costs. Having an excess number of sticks on hand in November, no orders were placed in December as it was expected for demand to be within the parameters of the stock on hand. After examining the market expectations of January being slow were high but there was still some uncertainty, so an order was made in moderation which did not go as expected. Demand increased by 13 sticks in January causing a major shortage cost. Moreover, during the months of January to May in the previous year’s sales increased slowly. With the rise of demand in January, a larger number of sticks were ordered in February based on the fact that shortage costs overpowered the cost of holding. The market took a complete turn compared to the previous years between February to June as demand dwindled slowly. Furthermore, when taking into consideration the months of July to October if an increased amount of sticks were order there would have been a cut down in cost. The quantity ordered for the particular months mentioned caused an increased shortage cost, it was at it’s highest in the month of October. If I had evaluated the sales given for the previous year’s effectively, I would have realized that the sales figures given Inventory Management Simulation Exercise TEAM: ______________________________________________________________________________________ have never exceeded the amount of 100 sticks in any given month. This would’ve been reflected on there being little to no holding costs in the months of November and December. With sales doubling in January year 2, it should’ve been expected that demand would be higher. If there had been a greater order quantity this year shortage costs would not have been at an all-time high in January. This may have affected the performance of the following moths as shortages lead to negative reviews which coherently affects consumer behaviour. For example, 1 customer looking to purchase a stick may have been met with the fact that the sticks are out of stock and took their dissatisfaction to the public influencing others not to purchase. Furthermore, it may have driven potential and past customer towards purchasing the stick from a competitor. The company experienced a major downturn in demand from January to June. However, on the bright side shortage costs were little to none, although shortages could’ve been used to the company’s advantage. For example, people usually fight over popular products, hoping to be first in line when they come back. One excellent method to turn a stockout into a sales opportunity is to ask clients to fill out a form to be placed on a waitlist or to provide their email address to receive an alert when the item is back in stock. Clear description of improved ordering strategy that would be implemented in the following year. Provides sound reasoning for this proposal. Moving forward a hybrid of market research and time series would be implemented in the following year to improve the order quantity. These specific strategies were chosen based on the fact that customer surveys are a crucial device for demand forecasting in market research. Targeting your audience with online surveys is now simpler than ever and survey software has significantly enhanced analysis. Market research can uncover opportunities, help with marketing campaigns, and help you better understand what your target audience needs. The surveys listed below would be used: 1. Sample surveys are used to find out more about a small sample of potential customers' purchasing habits. 2. Conduct enumeration surveys, which involve talking to as many potential clients as is feasible in order to get more information. Secondly there is time series analysis defined as a approach for predicting results over a period of time. By analysing historical inclinations, it forecasts future outcomes with the assumption that future trends would be similar to those of the past. Better inventory management is one of the main advantages of time series forecasting in supply chain management. Supply chain managers can optimize inventory levels to fulfil customer demand while lowering inventory expenses by forecasting future demand. In conclusion, with the implementation of these two strategies inventory management would become easier and more accurate. Inventory Management Simulation Exercise