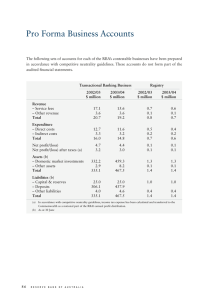

Int. J. Production Economics 162 (2015) 174–191 Contents lists available at ScienceDirect Int. J. Production Economics journal homepage: www.elsevier.com/locate/ijpe Cooperative quality investment in outsourcing Jingxian Chen a,b,n, Liang Liang a, Feng Yang a a b School of Management, University of Science and Technology of China, Hefei 230026, China School of Business, Nantong University, 9 Seyuan Road, Jiangsu, Nantong 226019, China art ic l e i nf o a b s t r a c t Article history: Received 10 April 2014 Accepted 21 January 2015 Available online 7 February 2015 This paper highlights the importance of having a cooperative quality investment (CQI) strategy and proposes a simple proportional investment sharing schedule in the outsourcing of a supply chain, which consists of a contract manufacturer (CM, the supplier) and two competitive original equipment manufacturers (OEMs, the buyers), the demands of which are sensitive to both price and product quality. A three-stage dynamic game-theoretic framework is applied to describe decisions of every entity. Specifically, we analyze three possible decision structures for the quality choice: the CM optimally sets the product quality, and two OEMs cooperatively or noncooperatively set the product quality. By the backward induction approach, we obtain the analytical equilibrium solutions for each decision scenario. We determine that the CM's share of quality investment expenses is sufficiently large, and the CQI strategy will be beneficial to quality enhancement regardless of who sets the product quality level. With respect to the equilibrium payoffs (profits), this study shows that the CM always prefers to have complete control of the quality choice when there is implementation of the CQI strategy, while the OEMs are always hurt by this strategy, except when they cooperate on the quality decision with a rather large CM share. In addition, the whole supply chain's profit can be improved by practicing the CQI strategy. Furthermore, we explicitly propose the conditions for realizing this improvement. & 2015 Elsevier B.V. All rights reserved. Keywords: Supply chain Outsourcing Cooperation Competition Quality improvement Game theory 1. Introduction In the early 1990s, such business gurus as Peter Drucker and Tom Peters challenged companies to “do what you do best and outsource the rest” (Vitasek and Manrodt, 2012). Thereafter, many business leaders took this advice and a rapid increase in outsourcing could be found in the late 1990s and the first decade of the twenty-first century. Currently, outsourcing is a pervasive feature of a supply chain and has contributed significantly to the growth of the global economy. Firms in different industries increasingly consider outsourcing to be a strategic option to reduce the cost, improve the quality, increase productivity, and enhance core competencies (Xiao et al., 2014). A new report has stated that Pacific Rim Countries accounted for 46.6% of the total United States manufactured imports and China accounted for 54.7% (approximately 25.5% of the total manufactured imports) of the United States manufactured imports from Pacific Rim Countries in 2012 (Morrison, 2013). Many business practices have verified the advantages of having a supply chain outsourcing strategy; for example, Nike has used outsourced providers to help them dominate the footwear market, capturing and building a 47% market share (Vitasek and Manrodt, 2012). However, some argue that more reliance on outside suppliers is likely to lead to a loss of overall market performance due to issues such as the loss of long term of research and development (R&D) competitiveness, incompatible strategy goals, long lead-times, less control on the quality, higher transaction costs, poor delivery reliability, and the loss of in-production capability (Gilley and Rasheed, 2000; Xiao et al., 2014). As a well-known downside of outsourcing, low control on the supplier's (i.e., contract manufacturer, CM) quality could cause the supplier to have no incentive with respect to the quality investment, which ultimately incurs poor product quality. Therefore, the customer manufacturer (i.e., the original equipment manufacturer, OEM) should define some incentive mechanisms for improving the product quality to enhance the competitiveness in the terminal consumption market. How to encourage the CM to improve the quality in n Corresponding author at: School of Business, Nantong University, 9 Seyuan Road, Jiangsu, Nantong 226019, China. Tel. þ 86 13962967110; fax þ 86 513 85012561. E-mail addresses: jxchenms@vip.163.com (J. Chen), lliang@ustc.edu.cn (L. Liang), fengyang@ustc.edu.cn (F. Yang). http://dx.doi.org/10.1016/j.ijpe.2015.01.019 0925-5273/& 2015 Elsevier B.V. All rights reserved. J. Chen et al. / Int. J. Production Economics 162 (2015) 174–191 175 outsourcing? This question is an interesting but challenging topic that is a management focus. In practice, strengthening quality inspection is always used to implement quality control on the supplier's quality. Although a more rigorous quality standard would be beneficial to the OEM for enhancing the quality competence in the end market, it could deeply hurt the CM and even disrupt the supply chain due to the pressure of a standard implementation. For example, one factory of the giant CM Hon Hai Limited (also known as Foxconn Technology Group) in the Chinese mainland underwent a large-scale strike that was triggered by the instruction to strengthen quality inspections for iPhone 5, which was given by the OEM customer Apple Inc. (Elmer-DeWitt, 2012). Some procurement and supply chain managers suggest that the OEM should pay for the CM's quality improvement (Tencent Technology, 2012). With consideration of this advice, this paper will propose a simple vertical quality cooperation schedule for encouraging quality improvement and exploring its effects on quality choice and supply chain performance. Cooperative quality investment (CQI) is not a novel definition in the literature: Banker et al. (1998) have studied the impact of quality cooperation on product quality. Moreover, as these authors cited in their paper, the Big Three automakers practice this cooperation in battery technology for electric vehicles (Section 3, page 1185). The cooperation discussed in their study is between two enterprises that are at the same echelon of the supply chain, i.e., a horizontal cooperation. However, this paper will focus on vertical quality cooperation strategies and aim to provide insights by studying the interactions among the players in supply chain outsourcing. To the best of our knowledge, this type of quality cooperation strategy has received little attention in the extant literatures. However, it is commonly observed in practice such as Toyota Motor Co., Ltd. beginning to cooperate with its supplier for improving the product quality since 1970 (Toyota, 2012). A recent study considered a cooperative R&D strategy in supply chain and analyzed the members' cooperative behavior under three common options: an R&D cartel, a research joint venture, and a research joint venture cartel (Ge et al., 2014). In contrast to Ge et al.'s concentration on cooperation in a supply chain with one supplier and one manufacturer, we consider CQI in the outsourcing of a supply chain that consists of a CM and two competing OEMs. In addition, we consider two OEMs that compete both on price and on product quality. For example, Nokia and Apple competitively sell cell phones that have different prices and quality levels at the same end consumer market in the Chinese mainland, while most of their cell phones are assembled by a common CM Foxconn Limited (Luk, 2013). In this study, we employ the game-theoretic approach to model the CQI strategy in supply chain outsourcing and use the backward induction technique to derive equilibrium solutions of quality, prices and profits for each member. In our model framework, we propose a simple proportional sharing schedule for quality investment, i.e., each OEM will share partial quality investment expenses for compensating CM's quality expenditure. Thus, the following question can naturally arise: who controls the quality choice? Each supply chain member has a different profit function with regard to the quality, which could yield different optimal quality levels and in turn affect quality investment expenses and profits. Thus, the power configuration of the quality decision plays an important role in our model. Enlightened by the famous “Manufacturer Stackelberg” and “Retailer Stackelberg” models proposed by Choi (1991), we consider two types of channel power structures: The CM has complete control on the quality decision vs. the OEMs have complete control on the quality decision. In addition, observing the downstream firms in a supply chain, such as retailers cooperating on product differentiation to relax price competition (Banker et al., 1998; Tsay and Agrawal, 2000; Xiao et al., 2014), we investigate the OEMs cooperating and not cooperating on quality decisions separately in the latter case. We find that if the CM is willing to share a sufficiently large investment fraction, then the CQI strategy will be beneficial to quality enhancement regardless of who sets the product quality level. With the respect to the equilibrium payoffs (profits), this study shows that the CM always prefers to have complete control over the quality choice with the implementation of the CQI strategy, while the OEMs are always hurt by vertical quality cooperation except that they cooperate on the quality decision when there is a rather large CM share. In addition, the whole supply chain profit can be improved by practicing the CQI strategy. Furthermore, we explicitly propose the conditions for realizing this improvement. In other words, we show that implementing the CQI strategy could be valuable for the supply chain. The reminder of this paper is organized as follows. Section 2 briefly reviews the related literature, and Section 3 details our key assumptions and notations. In Sections 4 and 5, we investigate three decision models of the quality choice: the CM optimally sets the product quality and the OEMs cooperate or do not cooperate on the quality decision. Section 6 discusses the effects of the CQI strategy on quality improvement and equilibrium profits as well as supply chain performance. Concluding remarks and future directions are presented in Section 7. All of the proofs are deferred to the appendix for clarity of exposition. 2. Related literature Non-price competition is observed in many industries and is well-studied in the economics and marketing literature. As an important non-price competitive feature in the majority of industries, product (service) quality has received intensive attention. Some pioneering studies have investigated the market equilibrium and social optimum value for the product quality of a monopolist (Spence, 1975; Sheshinski, 1976; Mussa and Rosen, 1978). These basic models were extended to discuss oligopolists competing on quality with a constant or zero quality cost and a single product in studies by Dixit (1979) and Gal-Or (1983). Moorthy (1988) later employed a quadratic function to describe the quality cost and studied a noncooperative game model between two identical oligopolists whose consumers preferred a higher quality product to a lower quality product. With a similar quadratic quality cost function for a single product, Banker et al. (1998) studied the noncooperative game model between two competing manufacturers who faced a linear demand pattern and how the quality was influenced by having a competitive intensity. Other related literature on this topic includes Rhee (1996), Villas-Boas (1998), Desai (2001), and others. More recently, Yayla-Küllü et al. (2013) studied multiproduct quality competition with consideration of having a limited capacity. As a strategic issue, quality in these studies refers to both the design and conformance quality characteristics that are of interest to the customer when evaluating the product offered by the firm (see Garvin (1984) for an excellent summary of the quality definition). However, these studies did not investigate the strategic interaction among the players in the environment of a supply chain channel. Researchers in marketing and operations have pushed quality choice into the framework of a supply chain. We refer to the seminal work of Reyniers and Tapiero (1995), which highlighted the importance of strategic quality choice in a supplier–producer supply chain. Chambers et al. (2006) analyzed the impact of variable production costs on competitive behavior in a duopoly in which manufacturers 176 J. Chen et al. / Int. J. Production Economics 162 (2015) 174–191 compete on quality and price in a two-stage game. Xu (2009) investigated a joint pricing and product quality decision in a manufacturer– retailer channel, in which the manufacturer sells a product through the retailer. Xie et al. (2011a, 2011b) studied a quality investment and price decision model in a supplier–manufacturer supply chain. They considered risk-averse behavior in different supply chain channel strategies: Vertical Integration, Manufacturer's Stackelberg and Supplier's Stackelberg. They also proposed a quality decision model that had an exogenous price for the competing supply chain (Xie et al., 2011a, 2011b). Moreover, Xiao et al. (2014) examined strategic outsourcing decisions for two competing supplier–manufacturer supply chains in which the manufacturers' key components have quality improvement opportunities. In addition, a few papers started to study manufacturer quality decisions and retailer effort decisions by considering a quality and effort-induced demand pattern in a manufacturer–retailer supply chain in which the manufacturer distributed a chosen quality product through the retailer using a simple wholesale pricing contract. See Gurnani and Erkoc (2008) and Ma et al. (2013) for additional information. Another group of researchers recognized that asymmetric quality-related information such as quality level and quality cost could be vital to quality choice for supply chain players. Thus, many related contractual agreements are developed for mitigating the impact of asymmetric quality information. Examples include Baiman et al. (2000), Gurnani and Erkoc (2008), Chao et al. (2009), Guo (2009) and Kaya and Özer (2009). However, neither of these articles includes the effect of quality competition or cooperation. In addition to quality, from the perspective of non-price competition in the supply chain channel, other competitive factors, such as service and delivery time, have been studied in the literature. For example, Tsay and Agrawal (2000) developed a general price and service competition model in a distribution channel that consists of a manufacturer and two competitive retailers. Xiao and Yang (2008) extended this model into two competing supply chains and considered the effect of uncertain demand and risk attitude of the players. Boyaci and Ray (2003) studied a profit-maximizing firm that sold two substitutable products in a price-sensitive and delivery time-sensitive market. However, these articles did not consider cooperative strategic interactions among vertical players. We refer to Lu et al. (2011) for a comprehensive review of this field. This paper is closely related to Banker et al. (1998) and Kaya and Özer (2009). Banker et al. (1998) employed a two-stage game theoretic model to study price and quality decisions of two competitive manufacturers as well as quality cooperation between them. Our paper differs from their studies in that (1) we develop a three-stage game theoretic model and derive the equilibrium solutions of three different decision models; (2) we investigate both upstream and downstream firm's decisions in a two-echelon supply chain; and (3) we focus on vertical quality cooperation among the supply chain members. Kaya and Özer (2009) developed a three-stage noncooperative game for analyzing the quality risk from noncontractible product quality and private quality cost information in a CM–OEM supply chain. They did not consider competitive market and quality cooperation, which are mainly discussed in our study. 3. Problem description and notations In this paper, we consider a supply chain that consists of a CM and two competitive OEMs, who present competition on both price and product quality. In a traditional scenario, the CM makes quality decisions and takes its investment expenses and sets a simple wholesale price contract for completing the transferable payment, while the OEMs focus on the sales and pricing of its products (Kaya and Özer, 2009). However, in this paper, we propose a CQI schedule in which two OEMs share partial quality investment expenses of their own products for inducing CM's quality improvement. With respect to this cost-sharing mechanism, the following question is naturally raised: who makes the decision of determining the quality level? To describe the decision structure between the CM and two OEMs, we present a three-stage game process as shown in Fig. 1. In the noncooperative quality investment scenario, the CM determines the quality level at stage 1. However, if the members jointly share the quality investment expenses, the CM or two OEMs can determine the quality level at this stage. Then, at the following stage, the CM offers a wholesale price contract to two OEMs. After observing the preceding quality level and wholesale price, each OEM sets the retail price at the last stage. Then, the market demands are fulfilled at the determined price with the chosen quality product. In an outsourcing mode, one can expect that the OEM always has full power on the choice of the product quality, whereas this paper considers that the CM also has the opportunity of setting the quality for the manufactured products. We suggest this assumption given the fact that contract manufacturers (CMs) have grown rapidly in many industries and often achieved some degree of power over OEMs (Gray et al., 2009). For example, Kaya and Özer (2009) noted that several CMs in the pharmaceuticals industry have been undertaking research and development, creating a $30 billion drug-development and manufacturing market. Additionally, managers in business practice agree with the standpoint that allowing a CM to address formulation challenges, regulatory issues and Good Manufacturing Practices (GMPs) alleviates a large number of complexities, delays and overhead from the host of challenges that a brand faces in bringing products to the shelves in a competitive marketplace (Moloughney, 2013). These facts provide some rational explanations for the assumption that the CM optimally chooses the product quality, which has also been studied in the literature (Benjaafar et al., 2007; Kaya and Özer, 2009; Jin and Ryan, 2012). Under the common knowledge assumption, this dynamic game can be solved by using the backward induction approach. We will first analyze the OEMs' price decision given the CM's wholesale price and the quality level, and then we will investigate the CM's decisions given the quality level; and study the firm's quality choice last. Fig. 1. Decision events sequence of the CM–OEM supply chain. J. Chen et al. / Int. J. Production Economics 162 (2015) 174–191 177 In this article, we use the following notation: index of OEM, i, j ¼1,2 and iaj; the gross demand of OEM i; the potential market demand; the intrinsic demand share for the ith OEM with 0 o ξi o1 and ξ1 þ ξ2 ¼ 1; the demand responsiveness to OEM's retail price with β 4 0; the demand responsiveness to a competitor's retail price with γ 40; the quality responsiveness to OEM's product quality with λ 4 0; the quality responsiveness to a competitor's product quality with k 4 0; the retail price of OEM i; the quality level for the ith OEM product; the unit wholesale price for the ith OEM product; the unit production cost of the CM; the unit variable cost of the quality level; the unit quality investment for the ith OEM product; OEM i's profit; the CM's profit. i, j Di α ξi β γ λ k pi yi wi c η Φi V OEMi V CM For the above notation, yi, wi and pi are decision variables. Other variables are exogenous, which means that they are known to all supply chain members. Furthermore, we provide the following assumption: Assumption 1. The unit variable cost for the quality level is positive, i.e., η 4 0. Many articles in the literature allow η to be negative (Banker et al., 1998). However, in this paper, we assume that it cannot be negative. This assumption is possible and reasonable. For example, the Foxconn–Apple supply chain is disrupted because of increasing costs that are induced by strengthened inspections. Assumption 2. The quality investment cost function is Φi y2i =2, i.e., improving the quality has an increasing incremental cost at high levels, which yields a diminishing return on the quality expenditure. This relationship is commonly observed in the extant literature (Banker et al., 1998; El Ouardighi and Pasin, 2006; Xie et al., 2011a, 2011b). From Banker et al. (1998), we assume that each OEM's gross demand not only depends on its own price and quality level but also depends on the competitor's price and quality level. Thus, the demand function of OEM i can be written as Di ðpi ; pj ; yi ; yj Þ ¼ ξi α βpi þ γ pj þ λyi kyj ; i; j ¼ 1; 2 and i a j: ð1Þ To ensure that the demand Di for each OEM product is affected more by changes in its own price and quality than those of the competitor, we assume that the parameters satisfy the following: β 4 γ and λ 4 k: 4. CM optimally sets product quality We now begin analysis of the CQI strategy of the above supply chain. In this section, we consider that the CM has complete control on the quality decision in CQI. In this case, there are two weak OEMs (whose only decision is to set their own product's retail price and make a commitment to share partial investment expenses that are incurred by the upper supplier) and a more powerful CM, who jointly decide the product quality level and wholesale price. In addition, we consider a proportional sharing mechanism and assume that ϕi denotes the CM's quality investment share of product i, where 0 o ϕi r 1. We do not consider the case of ϕi ¼0, i.e., the CM makes quality decisions without incurring any expenses, which does not make any sense to our analysis and is also impossible in practice. According to Eq. (1), we give the CM and OEM i's profit function as V OEMi ¼ ðpi wi Þðξi α β pi þ γ pj þ λyi kyj Þ V CM ¼ ð1 ϕi ÞΦi y2i ; 2 ð2Þ 2 X ϕ Φi y2i : ½wi ðc þ ηyi Þðξi α βpi þ γ pj þ λyi kyj Þ i 2 i ¼ 1;j a i ð3Þ Define W 4β γ 2 , M 2β γ 2 , N βγ , Ri ¼ 2ξi αβ þ ξj αγ , S 2βλ kγ , T 2kβ λγ , Ri ¼ Ri cðM NÞ, S S ηM, and T T ηN. From Eqs. (2) and (3), we have the following: 2 2 Proposition 1. When the CM and two OEMs jointly share the quality investment expenses and the CM optimally sets the product quality level, if ϕ0i r ϕi r 1, then the optimal quality level yCi n is 2 yCi n ¼ 2 βf2Wϕj Φj ½SðMRi þ NRj Þ TðMRj þ NRi Þ βðS T ÞðSRi þ TRj Þg 2 2 2 2 2fβ2 ðS T Þ2 þ4W 2 ϕi ϕj Φi Φj ðM 2 N 2 Þ 2βWðϕi Φi þ ϕj Φj Þ½MðS þ T Þ 2NSTg2 : ð4Þ 178 J. Chen et al. / Int. J. Production Economics 162 (2015) 174–191 where ϕi is 0 2 ϕ0i ¼ β½MðS þ T2 Þ 2NST 2WΦi ðM 2 N2 Þ β½NðS2 þ T2 Þ 2MST þ : 2WΦi ðM 2 N 2 Þ ð5Þ All proofs are given in Appendix. In Eq. (4), the superscript Cn means that it is the optimal value of the case when CM optimally sets the product quality. The equilibrium wholesale price, retail price and profits are derived as follows: wCi n ¼ c þ ηyCi n þ pCi n ¼ wCi n þ n ¼ 2β V COEMi Wϕj Φj ½2Wϕi Φi ðMRi þ NRj Þ βTðSRj þ TRi Þ βWSϕi Φi ðSRi þ TRj Þ 2 2 2 ϕj Φj ½2WRi Φi ðM 2 N 2 Þ βðSRj þ TRi ÞðMT NSÞ βϕi Φi ðSRi þTRj ÞðMS NTÞ 2 2 2 ½βϕi Φi ðSRi þTRj ÞðMS NTÞ þβϕj Φj ðSRj þ TRi ÞðMT NSÞ 2WRi ϕi ϕj Φi Φj ðM 2 N 2 Þ2 2 2 2 2 2fβ2 ðS T Þ2 þ 4W 2 ϕi ϕj Φi Φj ðM 2 N2 Þ 2βWðϕi Φi þϕj Φj Þ½MðS þT Þ 2NSTg2 2 β2 ð1 ϕi ÞΦi f2Wϕj Φj ½SðMRi þ NRj Þ TðMRj þ NRi Þ βðS T ÞðSRi þ TRj Þg2 2 2 2 2 2fβ2 ðS T Þ2 þ 4W 2 ϕi ϕj Φi Φj ðM 2 N2 Þ 2βWðϕi Φi þϕj Φj Þ½MðS þT Þ 2NSTg2 ; 2 n ¼ V CCM 2 β2 ðS T Þ2 þ 4W 2 ϕi ϕj Φi Φj ðM 2 N 2 Þ 2βWðϕi Φi þ ϕj Φj Þ½MðS þ T Þ 2NST; 2 2 β ðS T Þ2 þ 4W 2 ϕi ϕj Φi Φj ðM 2 N2 Þ 2βWðϕi Φi þ ϕj Φj Þ½MðS þ T Þ 2NST; 2 2 2βWϕi ϕj Φi Φj ½MðRi þ Rj Þ þ 2NRi Rj β2 ½ϕi Φi ðSRi þ TRj Þ2 þ ϕj Φj ðTRi þ SRj Þ2 2 2 2 2 2β2 ðS T Þ2 þ8W 2 ϕi ϕj Φi Φj ðM 2 N 2 Þ 4βWðϕi Φi þ ϕj Φj Þ½MðS þ T Þ 2NST: To link the CQI strategy on the supply chain members' decision, we focus on the investment fraction ϕi. Because of the complexity of the completely general model, we derive insights about the effects of such a parameter in turn by setting simplifying conditions on other parameters, which is often used in the marketing and operations literatures (Tsay and Agrawal, 2000; Lu et al., 2011). Assuming that the condition of parameter ϕi in Proposition 1 is satisfied, Corollaries 1 and 2 summarize the effect of parameter ϕi on the equilibrium quality, wholesale and retail price, and profit. Corollary 1. For the case of the CM setting the product quality, when two OEMs are symmetrical in their potential market demand and quality investment margin (ξi ¼ ξj and Φi ¼ Φj ), the OEM that has the higher quality investment share has the higher quality level, wholesale and retail price. However, the profit is lower than the profit of the rival. Corollary 1 implies that two symmetrical OEMs differ in product quality, wholesale and retail price in that there is different quality investment expense sharing. With respect to quality improvement, each OEM will prefer the larger investment share, while it will make its profit smaller than its rival. Furthermore, will the CQI schedule be beneficial to the supply chain members in this case? To answer this question, we give the following results. Corollary 2. Assume ξi ¼ ξj and Φi ¼ Φj ; then, we have the following relations: (i) (ii) (iii) (iv) (v) ∂yCi n =∂ϕi o0 and ∂yCi n =∂ϕj o0; ∂pCi n =∂ϕi o 0 and ∂pCi n =∂ϕj o0; ∂wCi n =∂ϕi o 0 and ∂wCi n =∂ϕj o 0; n n ∂V COEMi =∂ϕi 40 and ∂V COEMi =∂ϕj 4 0; Cn Cn ∂V CM =∂ϕi o0 and ∂V CM =∂ϕj o0. Note that ϕi ¼ 1 denotes the case in which the CM fully takes the quality investment expenses, i.e., the noncooperative quality investment scenario. We derive the following insights from Corollary 2: When the CM optimally sets product quality, the CQI strategy always improves the product quality in such a way that it increases the equilibrium wholesale and retail price. Moreover, the higher the OEM's investment share is, the higher the quality, wholesale and retail price of its own product, and the higher the quality, wholesale and retail price of its rival's product. The CM usually benefits from the CQI strategy, while the OEM is always hurt by it. Furthermore, an increase in the investment share of one OEM causes it and its rival to have lower profits. However, the CM will be better off from increasing the investment sharing of each OEM. From these insights, we know that if a more powerful CM completely controls quality choice and hopes to improve the product quality by sharing investment expenses with two competitive OEMs, he should not charge too much for mitigating the profit loss that happens to the OEM. Furthermore, from Corollary 1, we suppose that the supply chain manager should be prudent in constructing a different investment-sharing policy among the CM and two symmetrical OEMs, especially when they are concerned about fairness, which is a behavioral characteristic that has been found by some economists (Kahneman et al., 1986; Rabin, 1993) and has been confirmed and studied in some of the marketing and operations literature (Cui et al., 2007; Loch and Wu, 2008). With respect to this point, if a supply chain manager sets a different sharing proportion coefficient (ϕi a ϕj ), the OEM that has a smaller coefficient might be concerned about J. Chen et al. / Int. J. Production Economics 162 (2015) 174–191 179 unfairness because he obtains lower profits than the other OEM, who owns less of the investment expenses sharing. Thus, he might break up the CQI strategy with the intent of punishing the unfair firm (the CM), which is definitely harmful to the quality improvement and supply chain performance. In the next section, we focus on an alternative channel power structure, i.e., the OEMs have full power on the quality setting. 5. OEMs optimally set product quality In this case, there is a weak CM (whose only decision is to set the wholesale price) and two powerful OEMs, who decide the product quality and retail price. For the outsourcing in the supply chain, this circumstance is commonly observed in practice such as when the giant contract manufacturer Hon Hai charges a unit price to Nokia and Apple for assembling mobile phones, while the two OEMs decide their own product's quality and retail price for the competitive selling of cell phones in the Chinese Mainland area (Luk, 2013). Moreover, this channel decision structure is closely related to the “Retailer Stackelberg game” in theory, which is often studied by the marketing and operations scholars (Choi, 1991, 1996; Ma et al., 2013). Therefore, it is reasonable to consider this type of channel structure in our study. With respect to the decision events sequence in this section, we consider that two competitive OEMs optimally set the product quality in stage 1 (Fig. 1). The other two decision stages are the same as in the previous case. Additionally, we consider two types of decision structure for the first quality decision stage: centralized and decentralized quality decisions. For the centralized case, two OEMs jointly decide their product's quality level, whereas in the decentralized case, they simultaneously choose the quality level to maximize their own profit. 5.1. Centralized quality decision In this case, two OEMs cooperatively set the product quality level at the first stage, i.e., yi and yj are set jointly to maximize V OEMi þ V OEMj . From Eqs. (A6) and (A7), we rewrite OEM i's profit function as V OEMi ¼ β 4W 2 ðRi þ Syi Tyj Þ2 ð1 ϕi ÞΦi y2i : 2 ð6Þ Proposition 2. When the CM and two OEMs jointly share quality investment expenses and the two OEMs cooperatively set the product quality 00 n level, if 0 r ϕi r ϕi , then the optimal quality level yCO is i 2 n yCO ¼ i 2 β½2W 2 ð1 ϕj ÞΦj ðSRi TRj Þ βðS T ÞðSRi þTRj Þ 2 2 2 2 2 00 2 2 2 β½βðS T Þ 2W ð1 ϕi ÞΦi ðS þT Þ 2W ð1 ϕj ÞΦj ½βðS þ T Þ 2W 2 ð1 ϕi ÞΦi : where ϕi 2 ð7Þ is ϕ00 i ¼ 1β ðS þ TÞ2 2W 2 Φi : ð8Þ In Eq. (7), the superscript COn means the optimal value of the case of two OEMs cooperatively setting the product quality level. The equilibrium wholesale price, retail price and profits can be derived by some algebraic computation (see Table 1 for details). 5.2. Decentralized quality decision In this case, two OEMs noncooperatively set the product quality level at the first stage, i.e., yi is set to maximize V OEMi . From Eq. (6), we derive the following: Proposition 3. When the CM and two OEMs jointly share quality investment expenses and two OEMs noncooperatively set the product quality 000 n is level, if 0 r ϕi r ϕi , then the optimal quality level yNO i n yNO ¼ i βS½2W 2 Ri ð1 ϕj ÞΦj βSðSRi þTRj Þ 2 2 000 is 2 2 βS ðS T Þ þ 4W 4 ð1 ϕi Þð1 ϕj ÞΦi Φj 2βW 2 S ½ð1 ϕi ÞΦi þ ð1 ϕj ÞΦj : where ϕi ϕ000 ¼ 1 i βSðS þTÞ : 2W 2 Φi ð9Þ ð10Þ In Eq. (9), the superscript NOn means the optimal value of the case of two OEMs noncooperatively setting the product quality level. The equilibrium wholesale price, retail price and profits can be derived by some algebraic computation (see Table 1 for details). 5.3. Results To examine the effects of the CQI strategy on the supply chain's decision and performance when the product quality is chosen by the cooperative and noncooperative OEMs, we next begin the analysis of the equilibrium strategy and the payoffs (profits) of the above two decision scenarios. 180 Table 1 The equilibrium wholesale, retail price and profit for the case of OEMs set product quality. Cooperative OEMs n n ¼ c þ ηyCO þ wCO i i 2W 4 ð1 ϕi Þð1 ϕj ÞΦi Φj ðMRi þ TRj Þ βW 2 ½ð1 ϕi ÞΦi ðSRi þ TRj ÞðMS þ NTÞ þ ð1 ϕj ÞΦj ðSRj þ TRi ÞðNS þ MTÞ 2 2 2 2 2 2 ðM 2 N 2 Þfβ½βðS T Þ2 2W 2 ð1 ϕi ÞΦi ðS þ T Þ 2W 2 ð1 ϕj ÞΦj ½βðS þ T Þ 2W 2 ð1 ϕi ÞΦi g 3 n n ¼ wCO þ pCO i i 2W Ri ð1 ϕi Þð1 ϕj ÞΦi Φj βW½ð1 ϕi ÞΦi SðSRi þ TRj Þ þ ð1 ϕj ÞΦj TðTRi þ SRj Þ 2 2 2 2 2 2 β½βðS T Þ2 2W 2 ð1 ϕi ÞΦi ðS þ T Þ 2W 2 ð1 ϕj ÞΦj ½βðS þ T Þ 2W 2 ð1 ϕi ÞΦi 2 n V CO OEMi ¼ 2 2βfβWð1 ϕi ÞΦi SðSRi þ TRj Þ Wð1 ϕj ÞΦj ½βTðSRj þ TRi Þ 2W 2 Ri ð1 ϕi ÞΦi g2 β2 ð1 ϕi ÞΦi ½βðS T ÞðSRi þ TRj Þ 2W 2 ð1 ϕj ÞΦj ðSRi TRj Þ2 2 2 2 2 2 2 2 2β2 W½βðS T Þ 2W 2 ð1 ϕi ÞΦi ðS þ T Þ 2W 2 ð1 ϕj ÞΦj ½βðS þ T Þ 2W 2 ð1 ϕi ÞΦi 2 2 2 2 2 β fϕj Φj ½βðS T ÞðTRi þ SRj Þ þ 2ð1 ϕi ÞΦi W 2 ðSRi TRj Þ2 þ ϕi Φi ½βðS T ÞðSRi þ TRj Þ 2ð1 ϕj ÞΦj W 2 ðSRi TRj Þ2 g 2 n V CO CM ¼ 2 2 2 2 2 2 2 2fβ½βðS T Þ 2W 2 ð1 ϕi ÞΦi ðS þ T Þ 2W 2 ð1 ϕj ÞΦj ½βðS þ T Þ 2W 2 ð1 ϕi ÞΦi g2 βW fβWð1 ϕi ÞΦi TðSRi þ TRj Þ þ Wð1 ϕj ÞΦj ½βSðTRi þ SRj Þ 2W 2 Rj ð1 ϕi ÞΦi gfβð1 ϕi ÞΦi ðSRi þ TRj ÞðMT þ NSÞ þ ð1 ϕj ÞΦj ½βðTRi þ SRj ÞðMS þ NTÞ 2W 2 ð1 ϕi ÞΦi ðMRj þ NRi Þg 2 þ 2 2 2 2 2 βW fβWð1 ϕi ÞΦi SðSRi þ TRj Þþ Wð1 ϕj ÞΦj ½βTðTRi þ SRj Þ 2W Ri ð1 ϕi ÞΦi gfβð1 ϕi ÞΦi ðSRi þ TRj ÞðMS þ NTÞþ ð1 ϕj ÞΦj ½βðTRi þ SRj ÞðMT þ NSÞ 2W 2 ð1 ϕi ÞΦi ðMRi þ NRj Þg 2 2 2 2 2 2 ðM 2 N 2 Þfβ½βðS T Þ2 2W 2 ð1 ϕi ÞΦi ðS þ T Þ 2W 2 ð1 ϕj ÞΦj ½βðS þ T Þ 2W 2 ð1 ϕi ÞΦi g2 Noncooperative OEMs n n ¼ c þ ηyNO þ wNO i i W 2 f ð1 ϕi ÞΦi βMSðSRi þ TRj Þ ð1 ϕj ÞΦj ½βNSðSRi þ TRj Þ 2W 2 ð1 ϕi ÞΦi ðMRi þ NRj Þg 2 2 2 2 ðM 2 N 2 ÞfβS ðS T Þ þ 4W 4 ð1 ϕi Þð1 ϕj ÞΦi Φj 2βW 2 S ½ð1 ϕi ÞΦi þ ð1 ϕj ÞΦj g 2 n n ¼ wNO þ pNO i i Wð1 ϕi ÞΦi ½2W Ri ð1 ϕj ÞΦj βSðSRi þ TRj Þ 2 2 2 2 βS ðS T Þ þ 4W 4 ð1 ϕi Þð1 ϕj ÞΦi Φj 2βW 2 S ½ð1 ϕi ÞΦi þ ð1 ϕj ÞΦj 2 2 n V NO OEMi ¼ n V NO CM ¼ βð1 ϕi ÞΦi ½2W ð1 ϕi ÞΦi βS ½βSðSRi þ TRj Þ 2W 2 Ri ð1 ϕj ÞΦj 2 2 2 2 2 2fβS ðS T Þ þ 4W 4 ð1 ϕi Þð1 ϕj ÞΦi Φj 2βW 2 S ½ð1 ϕi ÞΦi þ ð1 ϕj ÞΦj g2 2 2 2 β S fϕj Φj ½βSðSRj þ TRi Þ 2W Rj ð1 ϕi ÞΦi þ ϕi Φi ½βSðSRi þ TRj Þ 2W 2 Ri ð1 ϕj ÞΦj 2 g 2 þ 2 2 2fβS ðS T Þþ 4W 4 ð1 ϕi Þð1 ϕj ÞΦi Φj 2βW 2 S ½ð1 ϕi ÞΦi þ ð1 ϕj ÞΦj g2 βW 3 ð1 ϕi ÞΦi ½βSðSRi þ TRj Þ 2W 2 Ri ð1 ϕj ÞΦj fβMSð1 ϕi ÞΦi ðSRi þ TRj Þ þ ð1 ϕj ÞΦj ½βNSðSRi þ TRj Þ 2W 2 ð1 ϕi ÞΦi ðMRi þ NRj Þg 2 2 2 2 ðM 2 N 2 ÞfβS ðS T Þ þ 4W 4 ð1 ϕi Þð1 ϕj ÞΦi Φj 2βW 2 S ½ð1 ϕi ÞΦi þ ð1 ϕj ÞΦj g2 3 þ 2 2 2 βW ð1 ϕj ÞΦj ½βSðSRj þ TRi Þ 2W Rj ð1 ϕi ÞΦi fβMSð1 ϕi ÞΦi ðSRj þ TRi Þ þ ð1 ϕi ÞΦi ½βNSðSRi þ TRj Þ 2W 2 ð1 ϕj ÞΦj ðMRj þ NRi Þg 2 2 2 2 ðM 2 N 2 ÞfβS ðS T Þ þ 4W 4 ð1 ϕi Þð1 ϕj ÞΦi Φj 2βW 2 S ½ð1 ϕi ÞΦi þ ð1 ϕj ÞΦj g2 J. Chen et al. / Int. J. Production Economics 162 (2015) 174–191 þ 2 2 ðM 2 N 2 Þfβ½βðS T Þ2 2W 2 ð1 ϕi ÞΦi ðS þ T Þ 2W 2 ð1 ϕj ÞΦj ½βðS þ T Þ 2W 2 ð1 ϕi ÞΦi g2 2 J. Chen et al. / Int. J. Production Economics 162 (2015) 174–191 181 From Eqs. (6) and (7) and Table 1, we have the following (we assume that the conditions of parameter ϕi (i ¼ 1; 2) in Propositions 2 and 3 are satisfied in each Corollary): Corollary 3. For the case of two OEMs setting the product quality, whether the OEMs are cooperative or not, if they are symmetrical in terms of the potential market demand and quality investment margin (ξi ¼ ξj and Φi ¼ Φj ), the OEM with the higher quality investment share has the lower quality level, wholesale price, retail price and profit. Corollary 4. Assume that ξi ¼ ξj and Φi ¼ Φj ; then, we have the following relations: n n n n (i) ∂yCO =∂ϕi 4 0, ∂yNO =∂ϕi 4 0, ∂yCO =∂ϕj o0 and ∂yNO =∂ϕj o0; i i i i n NOn COn NOn (ii) ∂pCO =∂ ϕ 40, ∂p =∂ ϕ 4 0, ∂p =∂ ϕ o 0 and ∂p =∂ϕj o 0; i i j i i i i n NOn COn NOn (iii) ∂V CO OEMi =∂ϕi 4 0, ∂V OEMi =∂ϕi 4 0, ∂V OEMi =∂ϕj o 0 and ∂V OEMi =∂ϕj o 0. Regardless of whether two OEMs cooperatively set the product quality level or not, Corollaries 3 and 4 imply that each OEM definitely prefers the lesser amount of quality investment share. Corollary 3 means that with a relatively large investment share, the OEM's product quality will be lower than that of the rival, which in turn decreases the equilibrium retail price and finally decreases the optimal profit. Furthermore, Corollary 4 states that a single OEM's optimal product quality, retail price and profit increase in the CM's investment share of its own product but decrease in the CM's investment share of its competitor's product. The above corollaries show a counterintuitive but interesting result that the OEM with the larger investment share would obtain a lower product quality than its rival OEM. Note that both OEMs have the equivalent unit quality investment and potential demand in the above results; a larger quality share implies that the OEM would require more cost than its rival while having no advantage with respect to potential demand. Under this circumstance, the OEM would lower the product quality level for decreasing its quality-related cost and simultaneously reducing the price for obtaining a competitive advantage in the market. However, the CM's behaviors with respect to the asymmetric OEM investment share show some uncertainties (see the following corollary for details). Corollary 5. For the case of a cooperative quality decision, when ξi ¼ ξj and Φi ¼ Φj , the equilibrium wholesale price satisfies the following (ϕ is defined by Eq. (A10) in Appendix): n n n n (i) If β=γ o λ=k, then ∂wCO =∂ϕi 4 0; ∂wCO =∂ϕj 4 0 for 0 o ϕi o ϕ, ∂wCO =∂ϕj ¼ 0 for ϕi ¼ ϕ, and ∂wCO =∂ϕj o 0 for ϕ o ϕi o ϕi ; i i i i n COn (ii) If β=γ Z λ=k, then ∂wCO =∂ ϕ 4 0 and ∂w =∂ ϕ o 0. i j i i 00 Corollary 6. For the case of a noncooperative quality decision, when ξi ¼ ξj and Φi ¼ Φj , the equilibrium wholesale price satisfies the following ~ is defined by Eq. (A11) in Appendix): (ϕ ~ , ∂wNOn =∂ϕ ¼ 0 for ϕ ¼ ϕ ~ , and ∂wNOn =∂ϕ o 0 for ϕ ~ o ϕ o ϕ000 ; n n (i) If β=γ o λ=k, then ∂wNO =∂ϕi 40; ∂wNO =∂ϕj 4 0 for 0 o ϕi o ϕ j i j i i i i i i NOn NOn (ii) If β=γ Z λ=k, then ∂wi =∂ϕi 40 and ∂wi =∂ϕj o 0. Corollaries 5 and 6 state the impacts of the quality investment share on the equilibrium wholesale price of the CM. For the case of a cooperative quality decision, Corollary 5 means that the equilibrium wholesale price of one product increases with its CM investment share, while the impact of the other product quality investment share on the wholesale price is dependent on the relation between the relative price responsiveness β=γ and the relative quality responsiveness λ=k. We see that if β=γ is larger than λ=k, then the wholesale price of product i decreases with product j's investment share of the CM. At the same time, when β =γ is smaller than λ=k, there exists a n threshold value of the investment share of product i, which allows us to determine the comparative static result between wCO and ϕj i n COn (i a j). If ϕi is smaller than the threshold value, wCO increases with ϕ ; otherwise, if ϕ is larger than the threshold value, w increases j i i i with ϕj . Furthermore, for the case of a noncooperative quality decision, Corollary 6 shows a similar result as Corollary 5. We use Figs. 2 and 3 and Tables 2 and 3 to illustrate the above results. The default values of the parameters in all of the numerical examples in this paper are α ¼ 20, ξ1 ¼ ξ2 ¼ 0:5, β ¼ 1, γ ¼ 0.8, λ ¼ 0:8, k ¼ 0:6, η ¼ 0:2, c ¼ 0:3 and Φ ¼ 2. Fig. 2. Equilibrium wholesale price versus quality investment share coefficient when β=γ o λ=k: Cooperative OEM case. 182 J. Chen et al. / Int. J. Production Economics 162 (2015) 174–191 Fig. 3. Equilibrium wholesale price versus quality investment share coefficient when β=γ o λ=k: Noncooperative OEM case. Table 2 The effects of quality investment share on supply chain's decision of the cooperative OEM case. No. ϕ1 ϕ2 n yCO 1 n yCO 2 n wCO 1 n wCO 2 n pCO 1 n pCO 2 n V CO OEM1 n V CO OEM2 n V CO CM 1 2 3 4 5 6 7 8 9 10 0.2 0.2 0.2 0.5 0.5 0.5 0.9 0.9 0.9 0.9 0.2 0.5 0.9 0.2 0.5 0.9 0.2 0.5 0.8 0.9 0.35 0.34 0.29 0.56 0.557 0.47 3.37 3.34 3.19 2.89 0.35 0.56 3.37 0.34 0.557 3.34 0.29 0.47 1.26 2.89 25.36 25.37 25.49 25.47 25.48 25.59 27.00 26.99 26.96 26.89 25.36 25.47 27.00 25.37 25.48 27.00 25.49 25.59 26.02 26.89 29.52 29.51 29.47 29.67 29.66 29.59 31.55 31.53 31.43 31.22 29.52 29.67 31.55 29.52 29.66 31.53 29.47 29.59 30.13 31.22 17.25 17.14 15.75 17.42 17.31 15.91 19.57 19.45 18.96 17.95 17.25 17.42 19.57 17.14 17.31 19.45 15.75 15.91 16.58 17.95 208.10 208.70 208.15 208.68 209.23 208.73 208.15 208.73 210.52 210.41 Table 3 The effects of quality investment share on the supply chain's decision of the noncooperative OEM case. No. ϕ1 ϕ2 n yNO 1 n yNO 2 n wNO 1 n wNO 2 n pNO 1 n pNO 2 n V NO OEM1 n V NO OEM2 n V NO CM 1 2 3 4 5 6 7 8 9 10 11 12 0.2 0.2 0.2 0.2 0.5 0.5 0.5 0.5 0.9 0.9 0.9 0.9 0.2 0.5 0.9 0.95 0.2 0.5 0.9 0.95 0.2 0.5 0.9 0.95 0.66 0.65 0.61 0.52 1.07 1.06 0.98 0.84 6.16 6.13 5.71 4.94 0.66 1.07 6.16 15.22 0.65 1.06 6.13 15.15 0.61 0.98 5.71 14.25 25.55 25.57 25.82 26.28 25.77 25.79 26.03 26.45 28.53 28.54 28.57 28.63 25.55 25.77 28.53 33.47 25.57 25.79 28.54 33.45 25.82 26.03 28.57 33.18 29.73 29.72 29.67 29.58 30.01 30.00 29.93 29.80 33.42 33.40 33.10 32.55 29.73 30.01 33.42 39.50 29.72 30.00 33.40 39.45 29.67 29.93 33.10 38.83 17.17 16.97 14.54 10.68 17.39 17.18 14.73 10.84 33.42 33.40 17.19 12.90 17.17 17.39 33.42 24.79 16.97 17.18 33.40 24.56 14.54 14.73 17.19 38.83 210.07 210.95 195.46 46.91 210.95 211.82 196.51 49.30 195.46 196.51 186.78 61.82 From Figs. 2 and 3, we find that if the relative price responsiveness is lower than the relative quality responsiveness, the effect of CM's share of one of OEM's products on CM's rival's wholesale price is dependent on CM's quality investment share of the rival's product. However, from Tables 2 and 3 we find that if the relative price responsiveness is larger than the relative quality responsiveness, the higher the CM's share is of OEM's product, the lower the wholesale price of the rival's product. Regardless of what relation exists between the relative price responsiveness and the relative quality responsiveness, the higher the CM's share is of OEM's product, the higher the wholesale price of CM's product. In addition, we also can illustrate the other results of Corollaries 3–5 from the computational outcomes in Figs. 2 and 3 and Tables 2 and 3. Unfortunately, we cannot derive the analytical results of the effect of the quality investment share coefficient on CM's optimal profit because of the very complicated mathematical outcomes of the partial derivatives of the profit function. Therefore, we employ a numerical example to illustrate the impacts of cooperative quality investment on CM's profit. See Figs. 4 and 5 for details. From Fig. 4 and Table 2, we find that if we fix one product's share coefficient, CM's optimal profit might first increase in the other product's investment fraction and then decrease. Fig. 5 and Table 3 show a similar result for the case of noncooperative OEMs. Formally, we derive the following: Observation 1. For the case in which the OEMs optimally set the product quality, whether the two OEMs are cooperative or not, if they are symmetrical in their potential market demand and quality investment margin (ξi ¼ ξj and Φi ¼ Φj ), then CM's optimal profit might first increase and then decrease in ϕi (i¼1,2). J. Chen et al. / Int. J. Production Economics 162 (2015) 174–191 183 Fig. 4. CM's optimal profit versus quality investment share ϕ1 and ϕ2: Cooperative OEM case. Fig. 5. CM's optimal profit versus quality investment share ϕ1 and ϕ2: Noncooperative OEM case. For the case in which the OEMs set the product quality case, regardless of whether they cooperatively or noncooperatively make the quality decision, the share coefficient cannot be equivalent to 1, which corresponds to the conditions in Propositions 2 and 3. Therefore, the comparative static results, as shown in Corollaries 4–6, cannot provide any insights for explaining the values of the CQI strategy. To address the question of whether the quality cooperation will be beneficial to the supply chain members or not, we assume an equivalent investment fraction and consider two identical OEMs to analyze the effects of quality cooperation on the member's and chain's performances in the next section. In addition, we will also compare the analytical results of the above three channel structures to demonstrate which one will be better for improving the product quality and performance. 6. Impact of cooperative quality investment on performances As learned from the extant literatures, asymmetry between the OEMs creates problems when comparing decision models. Thus, in this section, we assume two identical OEMs that have the same parameter values (ξi ¼ ξj ¼ ξ, Φi ¼ Φj ¼ Φ and ϕi ¼ ϕj ¼ ϕ) to investigate the values of the CQI strategy by comparing the optimal outcomes of each decision model. With the simplified parameter structures in the decision models, we compare the equilibrium (optimal) product quality and the players' payoffs (the optimal profit of the CM and each OEM) with the traditional quality decision model shown in Section 4. For the convenience of the following comparison, we use the superscript T* to denote the optimal value of the traditional quality decision model. 6.1. Product quality To compare the optimal product quality level of each decision model, we first give the following result from Corollaries 2 and 4. n n Lemma 1. When the two OEMs are identical and ϕ r ϕ r ϕ , yCi n decreases with ϕ, while yCO and yNO are increasing in i i ϕ00 are equivalent to the right-hand side of Eqs. (5) and (8) by setting Φ ¼ Φi (i ¼ 1; 2), separately. 0 00 ϕ, where ϕ0 and Lemma 1 states the monotonicity of the optimal product quality of each decision model on parameter ϕ. From Lemma 1, we summarize our finding of the comparison results in the following Corollary. 184 J. Chen et al. / Int. J. Production Economics 162 (2015) 174–191 Table 4 Comparison results of the optimal product quality level in each decision model. No. Scenario Result 1 ϕ0 o ϕ r ϕA ϕA o ϕ r ϕB n n yCi n 4 yTi n Z yNO 4yCO i i 2 3 ϕB o ϕ r ϕC ϕC o ϕr ϕD n n yNO 4 yCi n 4 yTi n Z yCO i i 4 5 ϕD o ϕo ϕ00 n n yCi n Z yNO 4yTi n 4yCO i i n n yNO 4 yCi n Z yCO 4yTi n i i n n yNO 4 yCO 4 yCi n 4 yTi n i i Fig. 6. Equilibrium product quality versus investment share ϕ. Corollary 7. When the two OEMs are identical, if ϕA Z ϕ and ϕD r ϕ , then we have the comparison results of each optimal product quality level summarized in Table 4. 0 00 In Corollary 7 and Table 4, ϕA, ϕB, ϕC and ϕD are four intersections that are defined by Eqs. (A12)–(A15) in Appendix. Corollary 7 first states that cooperative quality investment always improves the product quality when the CM has complete control (which is also shown by Corollary 2 for the nonidentical OEMs), while the same is true for the case in which the two OEMs set the product quality only if the investment fraction ϕ is sufficiently large, i.e., ϕ 4 ϕB for the noncooperative OEMs and ϕ 4 ϕD for the cooperative OEMs. Secondly, Corollary 7 also implies that, if the investment fraction ϕ is sufficiently small (i.e., ϕ o ϕA ), then letting the CM choose the product quality will be better for quality improvement. However, if the investment fraction ϕ is sufficiently large (i.e., ϕ 4 ϕB ), the decentralized quality decision by two OEMs will be better for quality improvement. Moreover, if ϕ 4 ϕD is satisfied, then regardless of whether the two OEMs cooperatively or noncooperatively set the product quality, the OEMs’ decision will yield better quality output. Another insight that is provided by Corollary 7 is that a noncooperative decision always yields better product quality than a cooperative decision for the case of OEMs having complete control of the quality. With respect to the two identical competitive firms, Banker et al. (1998) have proved that the competitive quality level will always be higher when the two firms horizontally cooperate on the quality and compete on the price under some conditions. Considering vertical quality cooperation in a two-echelon supply chain, we provide here similar and more general results without any additional conditions. Fig. 6 provides an illustration for the above insights. In general, Fig. 6 states that a relatively small share will be better for quality improvement when the CM optimally sets the quality level. However, a sufficiently large investment share for the CM will improve the product quality decision when the target quality level is established by the OEMs. 6.2. Profits We now analyze the effects of the CQI strategy on the chain member's profit. The question that we ask here is the following: What happens to the member's profit if both OEMs are willing to share partial quality investment expenses? An intuitive answer to this question is that the CM will be benefitted while the OEM will be hurt. We now investigate this intuition from comparing the profits of the above three models with the traditional model. Formally, we have the following: n n n NOn COn Tn Corollary 8. When the two OEMs are identical, if ϕ r ϕ o ϕE , then V TOEMi 4 V COEMi , V CO OEMi , V OEMi ; else if ϕE o ϕ r ϕ , then V OEMi 4 V OEMi , Cn NOn COn Tn Cn NOn Tn COn V OEMi , V OEMi ; else if ϕ ¼ ϕE , then V OEMi ¼ V OEMi 4 V OEMi , V OEMi . Here, ϕE is the unique intersection of V OEMi and V OEMi , which is shown by Eq. (A16) in the Appendix. 0 00 n n n NOn Corollary 9. When the two OEMs are identical, if ϕ A f½ϕ ; ϕB Þ [ ðϕB ; ϕD Þ [ ðϕD ; ϕ g, then V CCM 4V TCM , V CO CM , V CM ; else if ϕ ¼ ϕB , then n n Tn COn Cn COn Tn NOn V CCM ¼ V NO 4 V , V ; else if ϕ ¼ ϕ , then V ¼ V 4V , V . C CM CM CM CM CM CM CM 0 00 Because we find that most of the profit function show some uncertain analytical properties with regard to parameter ϕ, Corollaries 8 and 9 instead provide the best scenario for each chain member while not providing the whole relationship between the different profits. 2 n For example, if S 42T, then V NO increases with ϕ for ϕ 4 1 β S ðS TÞ=2ðS 2TÞW 2 Φ while decreasing in ϕ for OEMi J. Chen et al. / Int. J. Production Economics 162 (2015) 174–191 185 2 n ϕ o 1 βS ðS TÞ=2ðS 2TÞW 2 Φ; otherwise, if S o2T, then V NO OEMi decreases with ϕ. However, these uncertainties cannot prevent us from deriving managerial insights because we can summarize which decision structure is the most preferred for supply-chain members from Corollaries 8 and 9. Corollary 8 implies that if CM's share is sufficiently large such that ϕ 4 ϕE , each OEM will prefer to cooperate on the quality decision; otherwise, each OEM does not have any incentives for sharing the quality investment expenses because it cannot obtain more from the participation in the CQI strategy even when the product quality becomes improved. Together with Corollaries 7 and 8, we also find that horizontal cooperation between two competitive OEMs will be better for obtaining a profit, while a decentralized quality decision will be better for improving the product quality. Furthermore, Corollary 9 means that the CM always benefits from having complete power on the quality decision with the implementation of the CQI strategy. Corollary 9 also shows that if the two OEMs cooperate on the product quality decision and ϕ ¼ ϕB , then the CM can obtain a profit that is as high as when it optimally sets the product quality. Similarly, condition ϕ ¼ ϕD guarantees the equivalent CM profit between the cases in which the CM sets the product quality and two OEMs noncooperatively choose the quality effort. Together with Corollaries 8 and 9, we know that the CM always prefers to have complete control on the quality choice with the implementation of the CQI strategy, while the OEMs are always hurt by quality cooperation except that they cooperate on the quality decision when there is a rather large CM's share. Will the CQI strategy be beneficial to the whole supply chain? To answer this question, we provide the following findings: Corollary 10. When the two OEMs are identical, we have (i) V CSCn 4 V TSCn if and only if ϕF o ϕ o ϕ ; 0 00 n Tn (ii) V CO SC 4 V SC if and only if ϕ o ϕC o ϕ o ϕG o ϕ ; 0 00 NOn Tn (iii) V SC 4 V SC if and only if ϕ o ϕA o ϕ o ϕH o ϕ . 00 where ϕE, ϕG, and ϕH are the intersections shown by Eq. (A17)–(A19) in the Appendix. In Corollary 10, the subscript SC denotes that the whole supply chain's optimal values are represented. From Corollary 10, we know that the CQI strategy can improve the whole supply chain's profit in each channel power structure. Combining Corollaries 8–10, we find that Fig. 7. Each OEM's optimal profit versus investment share ϕ. Fig. 8. CM's optimal profit versus investment share ϕ. 186 J. Chen et al. / Int. J. Production Economics 162 (2015) 174–191 Fig. 9. Comparison results of whole supply chain's profit versus investment share ϕ. there could be some conflicts in implementing the CQI strategy in the supply chain. For example, if the CM has complete control of the 00 quality choice, the CM as well as the whole supply chain benefits from the CQI strategy for ϕF o ϕ o ϕ , whereas in this case, the two OEMs are hurt from quality cooperation. Moreover, we also find that the product quality is improved in this case from Corollary 7. Thus, at this stage whether the OEMs are willing to join with CQI or not plays a vital role in the supply chain performance. The supply chain manager can employ some efficient incentive mechanisms such as a rebate contract (Taylor and Xiao, 2009) for enhancing the incentives to the two OEMs’ participation. Similarly, when the CQI is beneficial to the OEMs and the wholesale supply chain while harmful to the CM, the supply chain manager should design some incentive mechanisms, such as a revenue-sharing contract (Cachon and Lariviere, 2005), to encourage the CM's participation in quality cooperation. To illustrate the above results, we derive Figs. 7–9. Generally speaking, from these computational results, we observe that the implementation of the CQI strategy could be valuable for each player in supply chain outsourcing as well as for the whole system. Moreover, setting an efficient quality investment share schedule plays an important role in implementing the CQI strategy with different supply chain power structures. Perhaps the negotiation game theoretic approach can be employed to address this question, but this content is beyond the scope of this paper. We would encourage researchers to devote additional attention to this issue in the future. 7. Conclusions Motivated by some supply chain quality management practices in the real world, we propose a simple proportional schedule for sharing quality investment expenses in the outsourcing of a two-echelon supply chain that consists of a CM and two competitive OEMs. Using a three-stage dynamic game theoretic framework, we describe strategic interactions of the supply chain under three different decision structures, i.e., the CM optimally sets the product quality, and the OEMs cooperate or do not cooperate on the quality decision. We derive the rather simple analytical equilibrium results and analyze the effects of sharing the coefficient on the quality improvement and the members’ profits as well as the whole supply chain profit. In each decision scenario, we compare the equilibrium variables and payoffs of the two OEMs with asymmetrical shared fractions, and we also study the comparative static properties with regard to the sharing coefficient. Furthermore, with a completely symmetrical setting, we explicitly propose the conditions for determining when the CQI strategy is beneficial to the quality and profit enhancement. These results will be helpful to effectively implement the CQI strategy in practice. This paper also provides valuable insights into the cooperative mechanism that leads to quality enhancement and the selection of supply chain channel structure for the supply chain outsourcing. There are several directions for future research. First, we derive the effects of the sharing coefficient on the product quality by the assumption of partial or complete symmetrical parameters settings. Because of the complexity of mathematical expressions of the equilibrium strategies and payoffs, the asymmetrical case is challenging and interesting. Second, this paper shows that supply-chain members might be hurt by the CQI strategy. Thus, integrating some well-known contracts (e.g., a rebate contract, a return contract, a revenue-sharing contract) into vertical quality cooperation for designing an incentives mechanism could be worth investigating. Finally, we assume that the quality investment margin of each product is common knowledge in this study. However, quality effort costs can be private information. It is interesting but challenging to investigate how the OEM designs incentive mechanisms that induce the CM to reveal its private information. Acknowledgments We would like thank the anonymous referee and the editor for their helpful suggestions and insightful comments, which have significantly improved the content and presentation of this paper. This work was supported by the National Natural Science Foundation of China (Nos. 71401082, 71110107024, 71322101, and 71301062) and the National Social Science Foundation of China (No. 10CGL025). J. Chen et al. / Int. J. Production Economics 162 (2015) 174–191 187 Appendix A Proof of Proposition 1. Differentiating the profit function V OEMi (V OEMj ), which is shown by Eq. (2) with respect to pi (pj) separately, and then equating them to zero yield pni ¼ αð2β þ γ Þ þ 2β2 wi þ βγ wj þ ð2λβ kγ Þyi ð2kβ λγ Þyj 2 4β γ 2 ðA1Þ and Dni ¼ αð2β þ γ Þ þ ðγ 2 2β2 Þwi þ βγ wj þ ð2λβ kγ Þyi ð2kβ λγ Þyj : 2 4β γ 2 Since ∂2 V OEMi =∂p2i ¼ 2β and ∂2 V OEMi =∂pi ∂pj ¼ γ , V OEMi is strictly concave in pi and the reaction functions for the two OEMs intersect once because ∂2 V OEMi =∂p2i o 0 and ∂2 V OEMi =∂p2i þ ∂2 V OEMi =∂pi ∂pj j o 0. The unique pure strategy Nash equilibrium does exist (Fudenberg and Tirole, 1991), as Eq. (A1) shows. Using the above definitions in Section 3, we obtain pni ¼ wi þ 1 ðR Mwi þ Nwj þ Syi Tyj Þ W i ðA2Þ and Dni ¼ β W ðRi Mwi þNwj þ Syi Tyj Þ: ðA3Þ Substituting Eqs. (A2) and (A3) into Eq. (3) and differentiating with respect to wi and wj , respectively, then equating them to zero yield the optimal wholesale price wni (i; j ¼ 1; 2 and j ai) as wni ¼ Ri ðM NÞ þ cðM 2 N 2 Þ þ ½ðMS NTÞ þ ηðM 2 N2 Þyi ðMT NSÞyj 2ðM 2 N 2 Þ : ðA4Þ Since Hessian matrix of V CM with respect to variable wi and wj under given yi and yj is 2 3 βM 2β N 2W W 5 H ¼ 4 2β N βM : 2W W 2 Due to the conditions of M 4 N 4 0 and W 4 0, we derive that 2β M=W o 0 and H ¼ 4β ðM 2 N2 Þ=W 2 4 0. It means Hessian matrix H is negatively definite. Thus, with the given quality level yi and yj , the CM's profit function V CM is strictly concavely in ðwi ; wj Þ. The unique global optimal solutions for wholesale price can be obtained by the first order condition, as Eq. (A4) shows. Substituting wni (i ¼ 1; 2) into Eq. (A3), the demand function of OEM i is rewritten as Dni ¼ β 2W ½Ri cðM NÞ þ ðS ηMÞyi ðT ηNÞyj : ðA5Þ Recall the definition of parameters Ri , S and T, we rewrite Eqs. (A4) and (A5) as wni ¼ c þ ηyi þ Dni ¼ β 2W 1 2ðM 2 N2 Þ ðMRi þ NRj þ MSyi NTyi þ NSyj MTyj Þ; ½Ri þ Syi Tyj : ðA6Þ ðA7Þ Then we can rewrite the CM's profit function as ( ) 2 X ϕi Φi y2i 1 β ½R þ NR þ MSy NTy þ NSy MTy Þ þSy Ty ðMR V CM ¼ : i j i i j j i j 2 2 2W i 2 i ¼ 1;j a i 2ðM N Þ To verify the profit function's concavity, we calculate all leading principal minors of Hessian matrix with respect to yi and yj towards function V CM . Let Δk denote the leading principal minors of Hessian matrix of order k, then we have 2 Δ1 ¼ ∂2 V CM T Þ 2NST 2 ϕi Φi ; ¼ β ½MðS þ ∂y2i 2WðM 2 N2 Þ 188 J. Chen et al. / Int. J. Production Economics 162 (2015) 174–191 and 0 12 10 1 0 2 2 2 ∂2 V CM ∂2 V CM ∂2 V CM ∂2 V CM B T Þ 2NST T Þ 2NST T Þ 2MST A 2 2 2 B B A A ϕi Φi @β ½MðS þ ϕj Φj @β ½NðS þ Δ2 ¼ ¼ @β½MðS þ : ∂yi ∂yj ∂yj ∂yi ∂y2i ∂y2j 2WðM 2 N2 Þ 2WðM 2 N 2 Þ 2WðM 2 N 2 Þ For the strict concavity of function V CM in ðyi ; yj Þ, conditions Δ1 o 0 and Δ2 4 0 should be satisfied. Thus, we have 2 2 ϕi 4 β½MðS þ T Þ 2NST ; 2W Φi ðM 2 N2 Þ 0 ðA8Þ 0 1 0 12 2 B B B T Þ 2NST T Þ 2NST T Þ 2MST 2 2 2 C C Bϕ Φi β½MðS þ ABϕ Φj β ½MðS þ A4B A : @ i @ j @β ½NðS þ 2WðM 2 N 2 Þ 2WðM 2 N 2 Þ 2WðM 2 N 2 Þ 1 2 2 Combining Eqs. (A8) and (A9), Proposition 1 directly follows by the first order condition. ðA9Þ ⎕ Proof of Corollary 1. Let Φi ¼ Φj ¼ Φ,ξi ¼ ξj ¼ ξ, and Ri ¼ Rj ¼ R, we have yCi n yCj n ¼ 2βW ΦRðϕi ϕj ÞðS TÞðM þNÞ 2 2 2 2 2 β ðS T Þ þ4W ϕi ϕj Φ2 ðM2 N2 Þ 2βWðϕi þ ϕj ÞΦ½MðS þ T Þ 2NST: 2 2 Due to the fact that yCi n 4 0, we know that the denominator of yCi n yCj n is positive. Thus, yCi n 4 yCj n for ϕi o ϕj is obtained. Similarly, we can show other relations of the equilibrium wholesale and retail price. As to the OEM's profit, we have 2 n n V COEMi V COEMj ¼ β2 ΦðS TÞ2 R fð1 ϕj Þ½βðS þ TÞ2 2Wϕi ΦðM þ NÞ2 ð1 ϕi Þ½βðS þ TÞ2 2Wϕj ΦðM þNÞ2 g 2 2 2 2 2fβ2 ðS T Þ2 þ 4W 2 ϕi ϕj Φ2 ðM 2 N 2 Þ 2βWðϕi þ ϕj ÞΦ½MðS þ T Þ 2NSTg2 þ fβϕi ΦRðS þ TÞðMS NTÞ þ ϕj ΦR½βðS þ TÞðMT NSÞ 2ϕi ΦWðM 2 N2 Þg2 2 2 2 2 fβ2 ðS T Þ2 þ 4W 2 ϕi ϕj Φ2 ðM 2 N 2 Þ 2βWðϕi þ ϕj ÞΦ½MðS þT Þ 2NSTg2 fβϕj ΦRðS þ TÞðMS NTÞ þ ϕi ΦR½βðS þ TÞðMT NSÞ 2ϕj ΦWðM 2 N2 Þg2 2 2 2 2 fβ2 ðS T Þ2 þ 4W 2 ϕi ϕj Φ2 ðM 2 N2 Þ 2βWðϕi þ ϕj ÞΦ½MðS þ T Þ 2NSTg2 : n n Since β ðS þ TÞ2 o 2W ϕi ðϕj ÞΦðM þ NÞ and 1 Z ϕj 4 ϕi 40, the first part of V COEMi V COEMj is negative. Additionally, the second part is larger n n n n than the third part of V COEMi V COEMj because ϕi o ϕj . Thus, V COEMi o V COEMj follows. ⎕ Proof of Corollary 2. Let Φi ¼ Φj ¼ Φ, ξi ¼ ξj ¼ ξ and Ri ¼ Rj ¼ R, we have 2 2 2βW ΦðS TÞ½β ðS þ TÞ2 2W ϕj ΦðM þ NÞfβ ½MðS þ T Þ 2NST 2W ϕj ΦðM 2 N2 Þg ∂yCi n ¼ 2 2 2 2 2 2 ∂ϕi fβ ðS T Þ2 þ 4W 2 ϕ ϕ Φ ðM 2 N 2 Þ 2β Wðϕ þ ϕ ÞΦ½MðS þ T Þ 2NSTg2 i j i j and 2 2 ∂yCi n 2β W 2 ΦR½NðS þ T Þ 2MST½βðS þ TÞ2 2W ϕi ΦðM þ NÞ ¼ 2 2 2 2 2 2 ∂ϕj fβ ðS T Þ2 þ4W 2 ϕi ϕj Φ ðM 2 N2 Þ 2βWðϕi þ ϕj ÞΦ½MðS þT Þ 2NSTg2 : From OEM i's demands function shown by Eq. (A7), we know that Dni should increase with its own product quality level increasing while decrease with competing firm j's product quality level increasing (Banker et al. 1998), i.e., S 40 and T 4 0. Moreover, in order to avoid the scenario that both OEMs' demands increasing when they both reduce their quality levels by the same amount, S 4 T should be satisfied, i.e., S T 4 0. Recall that ϕj should satisfy the second order condition in Proposition 1, we can verify the relation 2 2 β½MðS þ T Þ 2 2NST o 2W ϕj ΦðM2 N 2 Þ when ϕj 4 ϕ0j . Due to the condition Δ2 4 0 and the denominator is positive of Eq. (4), we have ðS þ TÞ ϕj 4 β 2W ΦðM þ NÞ from the numerator must2 be positive. Substituting it into the numerator of ∂yCi n =∂ϕi , we can derive 2 2 βðS þ TÞ2 42W ϕj ΦðM þ NÞ when ϕj 4 β 2WðSΦþðMTÞþ NÞ. Combining it with the former relation ½MðS þ T Þ 2βNST o2W ϕj ΦðM 2 N2 Þ, we Cn Cn know that the numerator of ∂yi =∂ϕi is positive, which means ∂yi =∂ϕi o 0. Similarly, the numerator of ∂yCi n =∂ϕj can be converted to 1 n 2 2 2 2 2β W ΦR½NðS þ T Þ 2MST2 g M N 2 2 2NST if we substitute ϕi ¼ β ½MðS þ 2WT ΦÞ into it. Note that the condition ϕi 4 ϕi should be satisfied and the numerator is decreasing in ϕi . ðM 2 N 2 Þ 0 Therefore, the numerator of ∂yCi n =∂ϕj is negative, which means ∂yCi n =∂ϕj o 0. Furthermore, we can verify parts (2) and (3) of Corollary 1 by n with respect to ϕi and ϕj , separately. About OEM i's optimal profit, we the same approach. Part (5) follows by directly differentiating V CCM J. Chen et al. / Int. J. Production Economics 162 (2015) 174–191 189 use the following equivalent expression: n V COEMi ¼ ðpCi n wCi n ÞDCi n ¼ ϕj Φj ½2WRi Φi ðM2 N 2 Þ βðSRj þ TRi ÞðMT NSÞ βϕi Φi ðSRi þ TRj ÞðMS NTÞ 2 2 2 2 β2 ðS T Þ2 þ 4W 2 ϕi ϕj Φi Φj ðM2 N 2 Þ 2βWðϕi Φi þ ϕj Φj Þ½MðS þ T Þ 2NST DCi n : n By the same approach of proof of ∂yCi n =∂ϕi o 0 and ∂yCi n =∂ϕj o 0, we obtain the fact that the first item of V COEMi is decreasing in ϕi , as n n well as ϕj . Thus, ∂V COEMi =∂ϕi 4 0 and ∂V COEMi =∂ϕj 4 0 are followed by ∂DCi n =∂ϕi o 0 and ∂DCi n =∂ϕj o 0. ⎕ Proof of Proposition 2. Follows directly from the first and second order conditions, using the same approach in the proof of Proposition 1. ⎕ Proof of Proposition 3. Differentiating profit function of OEM i with respect to yi , we have ∂V OEMi βSðRi þ Syi Tyj Þ ¼ ð1 ϕi ÞΦi yi : ∂yi 2W 2 Thus, we can derive 2 ∂2 V OEMi S ¼β ð1 ϕi ÞΦi ∂y2i 2W 2 and ∂2 V OEMi βST ¼ : ∂yi ∂yj 2W 2 Since we need conditions ∂2 V OEMi =∂p2i o 0 and ∂2 V OEMi =∂p2i þ ∂2 V OEMi =∂pi ∂pj j o 0 to ensure quality selection game between two OEMs has unique pure strategy equilibrium (Fudenberg and Tirole 1991), then we have 1 ϕi 4 βSðS þ TÞ : 2W 2 Φi After setting ∂V OEMi =∂yi ¼ 0 (i ¼ 1; 2), we obtain the equilibrium product quality level as Eq. (7) shows. ⎕ Proof of Corollary 3:. Follows directly from the difference between each variable, using the same approach in the proof of Corollary 1. ⎕ Proof of Corollary 4:. Follows directly from the partial derivative expressions, using the same approach in the proof of Corollary 2. ⎕ Proof of Corollary 5:. Let Φi ¼ Φj ¼ Φ, ξi ¼ ξj ¼ ξ and Ri ¼ Rj ¼ R, we have βW 2 RðS TÞΦ½βðS þ TÞ2 2W 2 ð1 ϕj ÞΦGðϕj Þ ∂wCO i ¼ 2 2 2 2 2 4 ∂ ϕi ðM 2 N 2 Þfβ S þ ½βT 2W 2 ð1 ϕi ÞΦ½βT 2W 2 ð1 ϕj ÞΦ 2β S ½βT þ W 2 Φð2 ϕi ϕj Þg2 n and n ∂wCO βW 2 RðS TÞΦ½βðS þ TÞ2 2W 2 ð1 ϕi ÞΦgðϕi Þ i ¼ 2 2 2 2 2 4 2 2 ∂ ϕj ðM N Þfβ S þ ½βT 2W 2 ð1 ϕi ÞΦ½βT 2W 2 ð1 ϕj ÞΦ 2β S ½βT þ W 2 Φð2 ϕi ϕj Þg2 : where 3 2 2 2 Gðϕj Þ ¼ β MS þ β S ½NT þ 2ηðM 2 N 2 Þ MS½βT þ 2W 2 ð1 ϕj ÞΦ þ ½2ηM 2 NðT þ 2ηNÞ½βT 2W 2 ð1 ϕj ÞΦ and 2 3 2 2 gðϕi Þ ¼ βMS T þ β NS MT½β T 2Wð1 ϕi ÞΦ S½βNT 4ηβTðM 2 N 2 Þ þ 2NW 2 ð1 ϕi ÞΦ: From the condition in Proposition 2, we know that βðS þTÞ2 2W 2 ð1 ϕj ÞΦ o 0 and β ðS þ TÞ2 o 2W 2 ð1 ϕi ÞΦ. Note that Gðϕj Þ decreases in 1 ϕj (because of M 4 N and S 4 T) and ð1 ϕj Þ 4 βðS þ TÞ2 =2W 2 Φ. Substituting 1 ϕj ¼ βðS þ TÞ2 =2W 2 Φ into Gðϕj Þ, we have n Gðϕj Þ ¼ 2βSTðM NÞ½S þ T þ 2ηðM þ NÞ o 0. Thus, Gðϕj Þ o 0 for 1 ϕj 4 βðS þTÞ2 =2W 2 Φ, i.e., ∂wCO =∂ϕi 4 0. Similarly, we have i gðϕi Þ ¼ 2β STðM NÞ½S þ T þ 2ηðM þ NÞ 4 0 if 1 ϕi ¼ β ðS þ TÞ2 =2W 2 Φ. Note that MT Z NS (i.e., β=γ Z λ=k), then gðϕi Þ is increasing in n 1 ϕi . Thus, gðϕi Þ 4 0 for 1 ϕi 4 β ðS þ TÞ2 =2W 2 Φ, i.e., ∂wCO =∂ϕj o 0. While when MT o NS(i.e., β=γ o λ=k), we find that if 0 o ϕi r ϕ, i 00 COn COn ∂wi =∂ϕj 4 0; otherwise, if ϕ o ϕj r ϕi , ∂wi =∂ϕj o 0. Where ϕ is the unique root of the equation gðϕi Þ ¼ 0, i.e., 2 ϕ ¼ 1 βðS 2 T ÞðMT þ NSÞ þ 4ηβSTðM 2 N 2 Þ 2W 2 ΦðNS MTÞ Note that ϕ o ϕi 00 : for β=γ o λ=k, thus Corollary 5 follows. ðA10Þ ⎕ 190 J. Chen et al. / Int. J. Production Economics 162 (2015) 174–191 Proof of Corollary 6:. Follows directly from the partial derivative expressions, using the same approach in the proof of Corollary 5. In ~ can be solved as addition, the parameter ϕ ϕ~ ¼ 1 2 2 βS½NðS T Þ þ 2ηTðM 2 N 2 Þ 2W 2 ΦðNS MTÞ ðA11Þ ~ o ϕ000 for β =γ o λ=k. We also can verify the relation ϕ i ⎕ Proof of Lemma 1:. Follows directly from the partial derivative expressions. ⎕ n n and yNO 4 yCO . Let ϕA , ϕB , ϕC and ϕD denote the Proof of Corollary 7:. For the completely identical OEMs, we find that i i n Tn NOn Cn COn Tn COn Cn n intersections of yNO vs. y , y vs. y , y vs. y , and y vs. y , separately. Thus, ϕ can be solved by setting yNO ¼ yTi n , as Eq. (A12) A i i i i i i i i i shows. yCi n 4yTi n ϕA ¼ WðS TÞ SðM NÞ WðS TÞ : ðA12Þ Similarly, we derive the expressions of ϕB , ϕC and ϕD . ϕB ¼ WðS TÞ WðS TÞ þ SðM NÞ ; ðA13Þ ϕC ¼ W ðM NÞ ; W ðA14Þ ϕD ¼ W : W þðM NÞ ðA15Þ n n From Lemma 1 and the relations yCi n 4 yTi n and yNO 4yCO , we know that ϕA o ϕB and ϕC o ϕD hold. Since i i ϕB ¼ WðS TÞ WðS TÞ þ SðM NÞ o WðS TÞ SðM NÞ WðS TÞ o W ðM NÞ ¼ ϕC ; W (we drop the then we have ϕA o ϕB o ϕC o ϕD . Recall the conditions in Propositions 2 and 3, we find that ϕ is smaller than ϕ subscript i here to describe the identical case). Thus, Corollary 7 follows directly by the results showed in Lemma 1 and the relations among the parameters ϕA , ϕB , ϕC and ϕD . ⎕ 00 000 n n n COn oV TOEMi and V NO Proof of Corollary 8:. We firstly derive the relations of V COEMi OEMi o V OEMi by direct comparison of each variable's expression n showed in Table 1. Differentiating the profit function V CO with respect to ϕ , we have OEMi 2 2 n ∂V CO β R ðS TÞ2 Φ OEMi ¼ 4 0: ∂ϕ 2½βðS TÞ2 2W 2 Φð1 ϕÞ2 n Tn COn Tn COn Tn Thus, we know that if ϕ 4 ϕE , then V CO OEMi 4 V OEMi ; else if ϕ o ϕE , V OEMi oV OEMi ; else if ϕ ¼ ϕE , V OEMi ¼ V OEMi . Where ϕE can be solved by COn Tn setting V OEMi ¼ V OEMi , i.e., ϕE ¼ βðS TÞ2 þ 2ðM NÞðM N 2WÞΦ : βðS TÞ2 4W ΦðM NÞ n Furthermore, we know that V NO OEMi is decreasing in ðA16Þ n Tn ϕ when ϕ 4 ϕE and V NO OEMi ðϕ ¼ ϕE Þ o V OEMi . Thus, Corollary 8 follows. ⎕ Proof of Corollary 9:. Follows directly from the comparison results of each variable's expression, using the same approach in the proof of Corollary 8. ⎕ Proof of Corollary 10. Follows directly from the comparison results of each variable's expression, using the same approach in the proof of Corollary 8. The parameters ϕF , ϕG , and ϕH can be solved by the corresponding equations, as the following equation shows: n n n n n n V COEM1 þ V COEM2 þ V CCM ¼ V TOEM1 þ V TOEM2 þ V TCM ) ϕ ¼ ϕF ¼ β½W ðM NÞðS TÞ2 2W 2 ðM NÞΦ ðA17Þ β½ðM NÞ WðS TÞ2 2WðM NÞ½2ðM NÞ WΦ n COn COn Tn Tn Tn V CO OEM1 þ V OEM2 þ V CM ¼ V OEM1 þ V OEM2 þ V CM ) ϕ ¼ ϕC or ϕ ¼ ϕG ¼ β ½W 2 þ ðM NÞ2 ðS TÞ2 þ 2W 2 ðM NÞðM N þ WÞΦ ðA18Þ W β ðM N þWÞðS TÞ2 þ 2W 2 ðM NÞð2M 2N þWÞΦ n NOn NOn Tn Tn Tn V NO OEM1 þ V OEM2 þ V CM ¼ V OEM1 þ V OEM2 þ V CM ) ϕ ¼ ϕA or ϕ ¼ ϕH ¼ βfS½W 2 þðM NÞ2 WTðM N þ WÞgðS TÞ2 2W 2 ðM NÞ½ðM NÞðS 2TÞ þWðS TÞΦ WðS TÞ½βðM N þ WÞðS TÞ2 2WðM NÞð2M 2N þ WÞΦ Besides, we know that ϕC o ϕG and ϕA o ϕH by the direct comparison results. ⎕ ðA19Þ J. Chen et al. / Int. J. Production Economics 162 (2015) 174–191 191 References Baiman, S., Fischer, P.E., Rajan, M.V., 2000. Information, contracting, and quality costs. Manag. Sci. 46 (6), 776–789. Banker, R.D., Khosla, I., Sinha, K.K., 1998. Quality and competition. Manag. Sci. 44 (9), 1179–1192. Benjaafar, S., Elahi, E., Donohue, K.L., 2007. Outsourcing via service competition. Manag. Sci. 53 (2), 241–259. Boyaci, T., Ray, S., 2003. Product differentiation and capacity cost interaction in time and price sensitive markets. Manuf. Serv. Oper. Manag. 5 (1), 18–36. Cachon, G.P., Lariviere, M.A., 2005. Supply chain coordination with revenue-sharing contracts: strengths and limitations. Manag. Sci. 51 (1), 30–44. Chambers, C., Kouvelis, P., Semple, J., 2006. Quality-based competition, profitability, and variable costs. Manag. Sci. 52 (12), 1884–1895. Chao, G.H., Iravani, S.M., Savaskan, R.C., 2009. Quality improvement incentives and product recall cost sharing contracts. Manag. Sci. 55 (7), 1122–1138. Choi, S.C., 1991. Price competition in a channel structure with a common retailer. Mark. Sci. 10 (4), 271–296. Choi, S.C., 1996. Price competition in a duopoly common retailer channel. J. Retail. 72 (2), 117–134. Cui, T.H., Raju, J.S., Zhang, Z.J., 2007. Fairness and channel coordination. Manag. Sci. 53 (8), 1303–1314. Desai, P.S., 2001. Quality segmentation in spatial markets: when does cannibalization affect product line design? Mark. Sci. 20 (3), 265–283. Dixit, A., 1979. Quality and quantity competition. Rev. Econ. Stud. 46 (4), 587–599. El Ouardighi, F., Pasin, F., 2006. Quality improvement and goodwill accumulation in a dynamic duopoly. Eur. J. Oper. Res. 175 (2), 1021–1032. Elmer-DeWitt, P., 2012. What's really going on at Apple's iPhone 5 factory in Zhengzhou, China. Fortune, Website, ⟨http://tech.fortune.cnn.com/2012/10/07⟩. Fudenberg, D., Tirole, J., 1991. Game Theory. The MIT Press, Massachusetts. Gal-Or, E., 1983. Quality and quantity competition. Bell J. Econ. 14 (2), 590–600. Garvin, D.A., 1984. What does product quality really mean. Sloan Manag. Rev. 26 (1), 25–43. Ge, Z., Hu, Q., Xia, Y., 2014. Firms' R&D Cooperation behavior in a supply chain. Prod. Oper. Manag. 23 (4), 599–609. Gilley, K.M., Rasheed, A., 2000. Making more by doing less: an analysis of outsourcing and its effects on firm performance. J. Manag. 26 (4), 763–790. Gray, J.V., Tomlin, B., Roth, A.V., 2009. Outsourcing to a powerful contract manufacturer: the effect of learning-by-doing. Prod. Oper. Manag. 18 (5), 487–505. Guo, L., 2009. Quality disclosure formats in a distribution channel. Manag. Sci. 55 (9), 1513–1526. Gurnani, H., Erkoc, M., 2008. Supply contracts in manufacturer–retailer interactions with manufacturer‐quality and retailer effort‐induced demand. Naval Res. Logist. 55 (3), 200–217. Jin, Y., Ryan, J.K., 2012. Price and service competition in an outsourced supply chain. Prod. Oper. Manag. 21 (2), 331–344. Kahneman, D., Knetsch, J.L., Thaler, R., 1986. Fairness as a constraint on profit seeking: entitlements in the market. Am. Econ. Rev. 76 (4), 728–741. Kaya, M., Özer, Ö., 2009. Quality risk in outsourcing: noncontractible product quality and private quality cost information. Naval Res. Logist. 56 (7), 669–685. Loch, C.H., Wu, Y., 2008. Social preferences and supply chain performance: an experimental study. Manag. Sci. 54 (11), 1835–1849. Lu, J.-C., Tsao, Y.-C., Charoensiriwath, C., 2011. Competition under manufacturer service and retail price. Econ. Model. 28 (3), 1256–1264. Luk, L., 2013. As apple feels bite, Hon Hai looks to diversify. Wall Street J. May, 27. Ma, P., Wang, H., Shang, J., 2013. Supply chain channel strategies with quality and marketing effort-dependent demand. Int. J. Prod. Econ. 144 (2), 572–581. Moloughney, S., 2013. Contract manufacturing: ensuring a quality future. Website, ⟨http://www.nutraceuticalsworld.com/issues/2013-03/view_features/contract-manufac turing-ensuring-a-quality-future/⟩. Moorthy, K.S., 1988. Product and price competition in a duopoly. Mark. Sci. 7 (2), 141–168. Morrison, W.M., 2013. China-U.S. Trade Issues. CRS Report for Congress, Website, ⟨http://fpc.state.gov/documents/organization/212021.pdf⟩. Mussa, M., Rosen, S., 1978. Monopoly and product quality. J. Econ. Theory 18 (2), 301–317. Rabin, M., 1993. Incorporating fairness into game theory and economics. Am. Econ. Rev. 83 (5), 1281–1302. Reyniers, D.J., Tapiero, C.S., 1995. The delivery and control of quality in supplier–producer contracts. Manag. Sci. 41 (10), 1581–1589. Rhee, B.-D., 1996. Consumer heterogeneity and strategic quality decisions. Manag. Sci. 42 (2), 157–172. Sheshinski, E., 1976. Price, quality and quantity regulation in monopoly situations. Economica 43 (170), 127–137. Spence, A.M., 1975. Monopoly, quality, and regulation. Bell J. Econ. 6 (2), 417–429. Taylor, T.A., Xiao, W., 2009. Incentives for retailer forecasting: rebates vs. returns. Manag. Sci. 55 (10), 1654–1669. Tencent Technology, 2012. Supply chain is disrupted: crises faced on Foxconn and Apple Inc. Website, ⟨http://tech.qq.com/a/20121019/000021.htm⟩. Toyota, 2012. New initiatives for quality improvement. Toyko, Website, ⟨http://www.toyota-global.com/company/history_of_toyota/75years/text/entering_the_automotive_ business/chapter2/section1/item3.html⟩. Tsay, A.A., Agrawal, N., 2000. Channel dynamics under price and service competition. Manuf. Serv. Oper. Manag. 2 (4), 372–391. Villas-Boas, J.M., 1998. Product line design for a distribution channel. Mark. Sci. 17 (2), 156–169. Vitasek, K., Manrodt, K.B., 2012. What five great economists can tell us about outsourcing. Supply Chain Manag. Rev. 16 (4), 18–25. Xiao, T., Xia, Y., Zhang, G.P., 2014. Strategic outsourcing decisions for manufacturers competing in product quality. IIE Transactions 46 (4), 313–329. Xiao, T., Yang, D., 2008. Price and service competition of supply chains with risk-averse retailers under demand uncertainty. Int. J. Prod. Econ. 114 (1), 187–200. Xie, G., Wang, S., Lai, K., 2011a. Quality improvement in competing supply chains. Int. J. Prod. Econ. 134 (1), 262–270. Xie, G., Yue, W., Wang, S., et al., 2011b. Quality investment and price decision in a risk-averse supply chain. Eur. J. Oper. Res. 214 (2), 403–410. Xu, X., 2009. Optimal price and product quality decisions in a distribution channel. Manag. Sci. 55 (8), 1347–1352. Yayla-Küllü, H.M., Parlaktürk, A.K., Swaminathan, J.M., 2013. Multi-product quality competition: impact of resource constraints. Prod. Oper. Manag. 22 (3), 603–614.