principles-of-composite-material-mechanics-fourth-edition-hardcovernbsped-1498720692-9781498720694

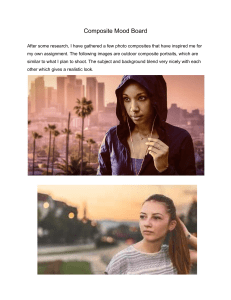

advertisement

PRINCIPLES OF

COMPOSITE

MATERIAL

MECHANICS

FOURTH EDITION

MECHANICAL ENGINEERING

A Series of Textbooks and Reference Books

Founding Editor

L. L. Faulkner

Columbus Division, Battelle Memorial Institute

and Department of Mechanical Engineering

The Ohio State University

Columbus, Ohio

RECENTLY PUBLISHED TITLES

Principles of Composite Material Mechanics, Fourth Edition

Ronald F. Gibson

Steam Generators and Waste Heat Boilers: For Process and Plant Engineers

V. Ganapathy

Maintenance, Replacement, and Reliability: Theory and Applications, Second Edition

Andrew K.S. Jardine and Albert H.C. Tsang

Heat Exchanger Design Handbook, Second Edition,

Kuppan Thulukkanam

Vehicle Dynamics, Stability, and Control, Second Edition,

Dean Karnopp

HVAC Water Chillers and Cooling Towers: Fundamentals, Application,

and Operation, Second Edition,

Herbert W. Stanford III

Ultrasonics: Fundamentals, Technologies, and Applications, Third Edition,

Dale Ensminger and Leonard J. Bond

Mechanical Tolerance Stackup and Analysis, Second Edition,

Bryan R. Fischer

Asset Management Excellence,

John D. Campbell, Andrew K. S. Jardine, and Joel McGlynn

Solid Fuels Combustion and Gasiication: Modeling, Simulation, and Equipment

Operations, Second Edition, Third Edition,

Marcio L. de Souza-Santos

Mechanical Vibration Analysis, Uncertainties, and Control, Third Edition,

Haym Benaroya and Mark L. Nagurka

Principles of Biomechanics,

Ronald L. Huston

Practical Stress Analysis in Engineering Design, Third Edition,

Ronald L. Huston and Harold Josephs

PRINCIPLES OF

COMPOSITE

MATERIAL

MECHANICS

FOURTH EDITION

Ronald F. Gibson

Boca Raton London New York

CRC Press is an imprint of the

Taylor & Francis Group, an informa business

CRC Press

Taylor & Francis Group

6000 Broken Sound Parkway NW, Suite 300

Boca Raton, FL 33487-2742

© 2016 by Taylor & Francis Group, LLC

CRC Press is an imprint of Taylor & Francis Group, an Informa business

No claim to original U.S. Government works

Version Date: 20151215

International Standard Book Number-13: 978-1-4987-2072-4 (eBook - PDF)

This book contains information obtained from authentic and highly regarded sources. Reasonable

efforts have been made to publish reliable data and information, but the author and publisher cannot

assume responsibility for the validity of all materials or the consequences of their use. The authors and

publishers have attempted to trace the copyright holders of all material reproduced in this publication

and apologize to copyright holders if permission to publish in this form has not been obtained. If any

copyright material has not been acknowledged please write and let us know so we may rectify in any

future reprint.

Except as permitted under U.S. Copyright Law, no part of this book may be reprinted, reproduced,

transmitted, or utilized in any form by any electronic, mechanical, or other means, now known or

hereafter invented, including photocopying, microfilming, and recording, or in any information storage or retrieval system, without written permission from the publishers.

For permission to photocopy or use material electronically from this work, please access www.copyright.com (http://www.copyright.com/) or contact the Copyright Clearance Center, Inc. (CCC), 222

Rosewood Drive, Danvers, MA 01923, 978-750-8400. CCC is a not-for-profit organization that provides licenses and registration for a variety of users. For organizations that have been granted a photocopy license by the CCC, a separate system of payment has been arranged.

Trademark Notice: Product or corporate names may be trademarks or registered trademarks, and are

used only for identification and explanation without intent to infringe.

Visit the Taylor & Francis Web site at

http://www.taylorandfrancis.com

and the CRC Press Web site at

http://www.crcpress.com

To my wonderful family, Maryanne, Tracy, Tola, Sophie, and Aidan,

and the memory of my parents, Jim and Lora Gibson

Contents

Preface to the First Edition................................................................................. xiii

Preface to the Second Edition ........................................................................... xvii

Preface to the Third Edition .............................................................................. xix

Preface to This Edition ....................................................................................... xxi

Author ................................................................................................................. xxiii

1. Introduction .....................................................................................................1

1.1 Basic Concepts ....................................................................................... 1

1.2 Constituent Materials for Composites ...............................................5

1.2.1 Reinforcement Materials including

Nanoreinforcements .............................................................10

1.2.2 Matrix and Filler Materials................................................... 12

1.3 Structural Applications of Composites ............................................ 18

1.4 Multifunctional Applications of Composites.................................. 28

1.5 Fabrication Processes .......................................................................... 31

1.6 Elements of Mechanical Behavior of Composites ..........................42

1.7 Review of Basic Mechanics of Materials Equations .......................44

References ....................................................................................................... 55

2. Lamina Stress–Strain Relationships ........................................................ 57

2.1 Introduction ......................................................................................... 57

2.2 Effective Moduli in Stress–Strain Relationships ............................ 58

2.3 Symmetry in Stress–Strain Relationships ....................................... 62

2.4 Orthotropic and Isotropic Engineering Constants ........................ 69

2.5 Specially Orthotropic Lamina........................................................... 73

2.6 Generally Orthotropic Lamina ......................................................... 78

References ....................................................................................................... 94

3. Effective Moduli of a Continuous Fiber-Reinforced Lamina ............. 95

3.1 Introduction ......................................................................................... 95

3.2 Elementary Mechanics of Materials Models ................................. 104

3.2.1 Longitudinal Modulus ........................................................ 106

3.2.2 Transverse Modulus ............................................................ 110

3.2.3 Shear Modulus and Poisson’s Ratio .................................. 112

3.3 Improved Mechanics of Materials Models .................................... 120

3.4 Elasticity Models ............................................................................... 124

3.4.1 Finite Difference Models..................................................... 126

3.4.2 Finite Element Models......................................................... 129

vii

viii

Contents

3.4.3 Closed-Form and Variational Models ............................... 133

3.5 Semiempirical Models ...................................................................... 134

References ..................................................................................................... 140

4. Strength of a Continuous Fiber-Reinforced Lamina .......................... 143

4.1 Introduction ....................................................................................... 143

4.2 Multiaxial Strength Criteria ............................................................ 146

4.2.1 Maximum Stress Criterion ................................................. 147

4.2.2 Maximum Strain Criterion ................................................. 151

4.2.3 Quadratic Interaction Criteria ............................................ 153

4.3 Micromechanics Models for Lamina Strength ............................. 167

4.3.1 Longitudinal Strength......................................................... 168

4.3.2 Transverse Strength ............................................................. 176

4.3.3 In-Plane Shear Strength ...................................................... 180

4.3.4 Multiaxial Strength.............................................................. 181

References ..................................................................................................... 186

5. Analysis of Lamina Hygrothermal Behavior ....................................... 191

5.1 Introduction ....................................................................................... 191

5.2 Hygrothermal Degradation of Properties ..................................... 193

5.3 Lamina Stress–Strain Relationships including

Hygrothermal Effects ....................................................................... 208

5.4 Micromechanics Models for Hygrothermal Properties .............. 217

References ..................................................................................................... 228

6. Analysis of a Discontinuously Reinforced Lamina ............................ 231

6.1 Introduction ....................................................................................... 231

6.2 Aligned Discontinuous Fibers ........................................................ 232

6.2.1 Stress and Strength Analysis ............................................. 233

6.2.2 Modulus Analysis ................................................................ 239

6.3 Off-Axis-Aligned Discontinuous Fibers ........................................ 249

6.3.1 Stress and Strength Analysis ............................................. 249

6.3.2 Modulus Analysis ................................................................ 251

6.4 Randomly Oriented Discontinuous Fibers ................................... 260

6.4.1 Stress and Strength Analysis ............................................. 261

6.4.2 Modulus Analysis ................................................................ 262

6.5 Nanoibers and Nanotubes.............................................................. 271

6.5.1 Stress and Strength Analysis ............................................. 274

6.5.2 Modulus Analysis ................................................................ 275

6.6 Particulates ......................................................................................... 279

6.6.1 Stress and Strength Analysis ............................................. 280

6.6.2 Modulus Analysis ................................................................ 282

6.7 Hybrid Multiscale Reinforcements.................................................284

References ..................................................................................................... 294

Contents

ix

7. Analysis of Laminates ............................................................................... 299

7.1 Introduction ....................................................................................... 299

7.2 Theory of Laminated Beams ...........................................................300

7.2.1 Flexural Stresses and Delections ......................................300

7.2.2 Shear Stresses and Delections ..........................................305

7.3 Theory of Laminated Plates with Coupling.................................. 317

7.4 Stiffness Characteristics of Selected Laminate

Conigurations..............................................................................324

7.4.1 Specially Orthotropic Laminates....................................... 325

7.4.2 Generally Orthotropic Laminates ..................................... 325

7.4.3 Symmetric Laminates ......................................................... 326

7.4.4 Antisymmetric Laminates.................................................. 327

7.4.5 Quasi-Isotropic Laminates ................................................. 327

7.5 Derivation and Use of Laminate Compliances ............................. 335

7.5.1 Inversion of Laminate Force–Deformation Equations ...... 335

7.5.2 Determination of Lamina Stresses and Strains............... 337

7.5.3 Determination of Laminate Engineering Constants ...... 338

7.5.4 Comparison of Measured and Predicted

Compliances .....................................................................341

7.6 Hygrothermal Effects in Laminates ............................................... 350

7.6.1 Hygrothermal Degradation of Laminates........................ 350

7.6.2 Hygrothermal Stresses in Laminates................................ 350

7.6.3 Laminate Hygrothermal Expansion Coeficients ........... 353

7.7 Interlaminar Stresses ........................................................................354

7.8 Laminate Strength Analysis ............................................................ 360

7.8.1 First Ply Failure and Subsequent Ply Failures Due

to In-Plane Stresses .............................................................. 360

7.8.2 Delamination Due to Interlaminar Stresses .................... 363

7.9 Delection and Buckling of Laminates .......................................... 383

7.9.1 Analysis of Small Transverse Delections ........................384

7.9.2 Buckling Analysis ................................................................ 390

7.10 Selection of Laminate Designs ........................................................ 394

7.11 Application of Laminate Analysis to Composite Structures ...... 401

7.11.1 Composite Sandwich Structures ....................................... 401

7.11.2 Composite Grid Structures .................................................404

References ..................................................................................................... 417

8. Analysis of Viscoelastic and Dynamic Behavior ................................. 421

8.1 Introduction ....................................................................................... 421

8.2 Linear Viscoelastic Behavior of Composites .................................425

8.2.1 Boltzmann Superposition Integrals for Creep

and Relaxation ...................................................................... 428

8.2.2 Differential Equations and Spring–Dashpot Models ........ 432

8.2.3 Quasielastic Analysis ..........................................................442

Contents

x

8.2.4

Sinusoidal Oscillations and Complex Modulus

Notation.................................................................................445

8.2.5 Elastic–Viscoelastic Correspondence Principle ............... 449

8.2.6 Temperature and Aging Effects ......................................... 455

8.3 Dynamic Behavior of Composites .................................................. 474

8.3.1 Longitudinal Wave Propagation and Vibrations

in Specially Orthotropic Composite Bars ......................... 475

8.3.2 Flexural Vibration of Composite Beams ........................... 481

8.3.3 Transverse Vibration of Laminated Plates .......................485

8.3.4 Analysis of Damping in Composites ................................ 492

8.4 Nanoenhancement of Viscoelastic and Dynamic Properties......... 502

References ..................................................................................................... 514

9. Analysis of Fracture ................................................................................... 519

9.1 Introduction ....................................................................................... 519

9.2 Fracture Mechanics Analyses of Through-Thickness Cracks .........519

9.2.1 Stress Intensity Factor Approach....................................... 522

9.2.2 Strain Energy Release Rate Approach .............................. 526

9.2.3 Virtual Crack Closure Technique ...................................... 530

9.3 Stress Fracture Criteria for Through-Thickness Notches............ 536

9.4 Interlaminar Fracture .......................................................................543

9.5 Nanoenhancement of Fracture Toughness ................................... 555

References ..................................................................................................... 562

10. Mechanical Testing of Composites and Their Constituents ............. 569

10.1 Introduction ....................................................................................... 569

10.2 Measurement of Constituent Material Properties........................ 570

10.2.1 Fiber Tests ............................................................................. 570

10.2.2 Neat Resin Matrix Tests ...................................................... 573

10.2.3 Constituent Volume Fraction Measurement .................... 576

10.3 Measurement of Basic Composite Properties ............................... 578

10.3.1 Tensile Tests .......................................................................... 578

10.3.2 Compressive Tests................................................................ 582

10.3.3 Shear Tests............................................................................. 585

10.3.4 Flexure Tests ......................................................................... 594

10.3.5 Interlaminar Fracture Tests ................................................ 595

10.3.6 Fiber/Matrix Interface Tests ............................................... 599

10.3.7 Open-Hole and Filled-Hole Tests ...................................... 601

10.3.8 Bearing Tests......................................................................... 602

10.3.9 Pull-Through Tests...............................................................604

10.4 Measurement of Viscoelastic and Dynamic Properties .............. 613

10.4.1 Creep Tests ............................................................................ 613

10.4.2 Vibration Tests ...................................................................... 617

Contents

xi

10.5 Measurement of Hygrothermal Properties ................................... 624

10.5.1 Glass Transition Temperature Tests .................................. 625

10.5.2 Thermal Expansion Tests.................................................... 625

10.5.3 Moisture Absorption Tests ................................................. 626

References .....................................................................................................630

11. Answers to Selected Problems ................................................................. 639

Appendix A: Matrix Concepts and Operations ........................................... 641

Appendix B: Stress Equilibrium Equations ................................................. 651

Appendix C: Strain–Displacement Equations ............................................. 655

Preface to the First Edition

Composite materials is truly an interdisciplinary subject, and the number

of students taking courses in this area is steadily increasing. Books on the

subject tend to emphasize either the mechanics or the materials science

aspects of composites. Principles of Composite Material Mechanics is mechanics

oriented. Composite materials technology is new enough for many working

engineers who have had no training in this area, and so, a textbook in composite material mechanics should be useful not only for the education of new

engineers, but also for the continuing education of practicing engineers and

for reference. The high level of interest in composite materials, the interdisciplinary nature of the subject, the need to reeducate practicing engineers, and

the need for a new composite mechanics textbook at the introductory level

all led to my decision to write this book.

Chapters 1 through 7 form the basis of a one-semester senior/graduatelevel course in mechanical engineering, which I have taught for the last 15

years. Chapters 8 through 10, along with selected papers from technical journals and student research projects/presentations, form the basis of a second

one-semester course, which is taken only by graduate students, and which I

have taught for the last 4 years. The book could also be the basis for a twoquarter sequence by omitting some topics. The prerequisites for the course

are knowledge of mechanics of materials, introduction to materials engineering, and ordinary differential equations, and the previous exposure to

linear algebra is highly desirable. For some of the graduate-level material,

earlier courses in advanced mechanics of materials, elasticity, and partial

differential equations are recommended, but not required.

Some of the basic elements of composite mechanics covered in this book

have not changed since the irst books on the subject were published in the

1960s and 1970s, and, where possible, I have tried to use the accepted terminology and nomenclature. For example, the coverage of stress–strain relationships and transformation of properties for anisotropic materials in Chapter

2 and the classical lamination theory in Chapter 7 is consistent with that of

the previous textbooks such as the Primer on Composite Materials by Ashton,

Halpin, and Petit, and Mechanics of Composite Materials by Jones. However,

rather than beginning the study of laminates by jumping directly into classical lamination theory, I have concluded that a better pedagogical approach

is to irst introduce the basic laminate concepts by using the simpler theory

of laminated beams in pure lexure. Also, I believe that the concept of an

effective modulus of an equivalent homogeneous material, which had previously been covered only in advanced books such as Mechanics of Composite

Materials by Christensen, is essential for the proper development of heterogeneous composite micromechanics. Thus, effective modulus–concepts are

xiii

xiv

Preface to the First Edition

emphasized from their introduction in Chapter 2 to their use in the analysis

of viscoelastic and dynamic behavior in Chapter 8.

Although many basic concepts have been presented in the earlier textbooks, numerous new developments in composite mechanics over the last

two decades have made it increasingly necessary to supplement these books

with my own notes. Thus, I have an added coverage of important topics

such as hygrothermal effects in Chapter 5, discontinuous iber composites in

Chapter 6, viscoelastic behavior and dynamic behavior in Chapter 8, fracture

in Chapter 9, and mechanical testing in Chapter 10. The coverage of experimental mechanics of composites has been expanded to include summaries

of the most important ASTM standard test methods, many of which did not

exist when the early mechanics of composites books were published. A variety of example problems and homework problems, a number of them related

to practical composite structures, are also included.

The contents of this book represent the cumulative effects of more than 25

years of interactions with colleagues and students, and I would be remiss

if I did not mention at least some of them. My fascination with composites

began in 1965 with my irst engineering position in what is now a part of Oak

Ridge National Laboratory in Tennessee, where I was involved in the design

and development of a high-speed rotating equipment. At that time, I realized that the advantages of using composites in a rotating equipment are

numerous, as is the case in many other applications. My experiences working with Dean Waters and other colleagues in the mechanical development

group in Oak Ridge have had a strong inluence on my later career decision

to emphasize composites research and education. My doctoral research on

vibration-damping characteristics of composites with Robert Plunkett at the

University of Minnesota further cemented my desire to continue working in

the composites area and ultimately led to my career in university teaching

and research.

After beginning my academic career at Iowa State University in 1975, I

began a long and productive association with C.T. Sun, and later had the

pleasure of spending a 1-year leave working with C.T. and his colleagues

Robert Sierakowski and Shive Chaturvedi at the University of Florida. I owe

much of my understanding of composite mechanics to interactions with

them. The notes leading to this book were developed by teaching composite mechanics courses at Iowa State University, the University of Idaho, the

University of Florida, Michigan State University, and Wayne State University

(WSU), and I am indebted to the students who took my classes and helped

me to “debug” these notes over the years. Most recently, my students at WSU

have been particularly effective at inding the inevitable errors in my notes.

Interaction with my graduate students over the years has immeasurably

contributed to my understanding of composite mechanics, and the work of

several of those students has been referred to in this book. I am particularly

indebted to Stalin Suarez, Lyle Deobald, Raju Mantena, and Jimmy Hwang,

all former graduate students at the University of Idaho.

Preface to the First Edition

xv

Serious work on this book actually began during a sabbatical leave at

Michigan State University in 1987, and I am indebted to Larry Drzal and

his colleagues for our many stimulating discussions during that year.

Particularly important was the interaction with Cornelius Horgan, with

whom I team taught a course on advanced mechanics of composites. Most

recently, my collaboration with John Sullivan and his colleagues of the Ford

Scientiic Research Laboratory has proved to be very rewarding, and I am

indebted to John for his careful review of the book and helpful comments.

I am grateful to Carl Johnson, also of the Ford Scientiic Research Laboratory,

for his encouragement and support and for providing several of the igures

in Chapter 1. The strong support of WSU, which made it possible to establish

the Advanced Composites Research Laboratory there in 1989, is gratefully

acknowledged. The support and encouragement of my department chairman, Ken Kline, has been particularly important. Generous support for my

composites research from numerous funding agencies over the years has

also helped to make this book possible. Grants from the Air Force Ofice

of Scientiic Research, the National Science Foundation, the Army Research

Ofice, the Boeing Company, and the Ford Motor Company have been particularly important.

McGraw-Hill and I would like to thank the following reviewers for their many

helpful comments and suggestions: Charles W. Bert, University of Oklahoma;

Olivier A. Bauchau, Rensselaer Polytechnic Institute; Shive Chaturvedi,

Ohio State University; Vincent Choo, New Mexico State University; John M.

Kennedy, Clemson University; Vikram K. Kinra, Texas A & M University; C.T.

Sun, University of Florida; and Steven W. Yurgartis, Clarkson University.

Finally, my wife and best friend, Maryanne, has been my strongest supporter as I labored on this project, and there is no way that I could have done

it without her love, encouragement, patience, and understanding.

Ronald F. Gibson

Preface to the Second Edition

There have been many developments in mechanics of composite materials

since the irst edition of this book was published. Accordingly, the second

edition has new sections on recent applications of composite mechanics to

nanocomposites, composite grid structures, and composite sandwich structures. To strengthen the emphasis on the basic principles of mechanics,

I have added a review of the basic mechanics of materials equations in the

introduction, and appendices covering the derivations of stress equilibrium

equations and strain–displacement relations from elasticity theory. Coverage

of micromechanics in Chapter 3 has been revised to include more detailed

discussions of elasticity and inite-element models. Chapter 4 on strength

analysis has been updated to include results from the World Wide Failure

Exercise. Chapter 8 has been improved by adding a phenomenological

approach to understanding the linear viscoelastic behavior of composites.

Chapter 9 on fracture has been updated to include coverage of the initeelement implementation of the virtual crack closure technique. Chapter 10

on testing of composites and their constituents has been extensively updated

to include coverage of both new and revised ASTM standard test methods.

Finally, more example problems and homework problems have been added

to most chapters, and new references have been cited throughout.

As with the irst edition, I am indebted to many colleagues, graduate students, and sponsors. I am grateful to WSU for providing a nurturing environment for my teaching and research, and for granting me sabbatical leave,

which were essential to the completion of this project. My graduate students

have been particularly helpful in identifying the inevitable errors in the irst

edition, and their thesis research indings have enabled me to add important new dimensions in the second edition. And as with the irst edition,

my wife and best friend, Maryanne, has continued to be my strongest supporter, and I will be forever grateful for her love, encouragement, patience,

and understanding.

Ronald F. Gibson

xvii

Preface to the Third Edition

The goals for the third edition are to continue to present a unique blended

coverage of classical and state-of-the-art mechanics of composites technologies, while striving to incorporate the most worked-out example problems

and homework problems of any available textbook on mechanics of composite materials. A high priority has been placed on writing a textbook that

is easily understood by students. Pedagogical improvements include a total

of 81 worked-out example problems (25 of which are new for the third edition); 177 homework problems (25 of which are new); 388 igures (46 of which

are new); a new appendix on matrix concepts and operations; new coverage

of particle composites, nanocomposites, nanoenhancement of conventional

iber composites, hybrid multiscale composites; and additional coverage of

inite-element modeling and test methods. Although the book is written irst

as a textbook covering classical methods, frequent references to the current

state-of-the-art composites technology and research indings are included.

Extensive references are provided, including many current journal articles

along with classic and historical publications.

I continue to be indebted to my colleagues, graduate students, and sponsors for their encouragement and support over the years. Most recently,

my professional afiliations with WSU and the University of Nevada, Reno

(UNR) have provided the necessary positive environments for teaching and

research that made the development of this new edition possible. I have been

particularly motivated by the interactions with students in my composites

classes at WSU and UNR. As with the earlier editions of this book, my wife

and best friend, Maryanne, continues to be my most enthusiastic supporter,

and there is no way that I could have completed this project without her.

Ronald F. Gibson

xix

Preface to This Edition

My interactions with students and colleagues and my continued compositesrelated activities since the third edition was published in 2012 have motivated me to think of a number of improvements that could be made in the

fourth edition. In the previous editions, I have tried to maintain a practical

balance between the traditional classical and current state-of-the-art coverage, and previous improvements have emphasized the current state-of-theart technologies. In contrast, the fourth edition puts an increased emphasis

on pedagogy. I have kept careful notes on errors that were found in the

third edition, and those are corrected in the fourth edition. New workedout example problems and homework problems are added in most chapters.

The number of worked-out examples has been increased by about 20% to 95,

while the number of homework problems has been increased by about 12%

to 212. Rather than continuing to place all homework problems at the end of

the chapters, these problems are integrated within the chapters following

the most relevant sections, similar to the way worked-out example problems

are currently presented. With this change, it will no longer be necessary for

instructors and students to determine to which section a particular homework problem is most relevant. This is the pedagogical approach used in

many basic mechanics textbooks. One of the most frequent requests from

students has been to provide answers to selected homework problems. In my

classes, I have been providing such answers on the course website, but in the

fourth edition, I am including them in the back of the book instead.

Finally, I greatly appreciate the constructive feedback regarding the book

from my students and colleagues, along with instructors at other universities

who have adopted the book. My wife and best friend, Maryanne, continues

to be my most enthusiastic supporter, and this project would not have been

possible without her.

Ronald F. Gibson

xxi

Author

Ronald F. Gibson, PhD, is currently an adjunct professor of mechanical engineering at the University of Nevada, Reno. He earned his PhD in mechanics

from the University of Minnesota, an MS in mechanical engineering from

the University of Tennessee, and a BS in mechanical engineering from the

University of Florida. His industrial/government experience includes a position as a development engineer for Union Carbide Corporation, Nuclear

Division and a summer faculty fellowship at the NASA Langley Research

Center. He has held full-time faculty positions at Iowa State University,

The University of Idaho, and Wayne State University, as well as visiting faculty positions at Stanford University, the University of Florida, and

Michigan State University. He is an elected Fellow of the American Society of

Mechanical Engineers, the American Society for Composites, and the Society

for Advancement of Material and Process Engineering. He is a member of

the American Society for Engineering Education, the American Institute for

Aeronautics and Astronautics, and the Society for Experimental Mechanics.

He served as the president of the American Society for Composites in

2004–2005, and as the vice president during 2002–2003.

Dr. Gibson’s awards include the Hetenyi Award for Best Research Paper

of the Year from the Society for Experimental Mechanics, the College of

Engineering Outstanding Faculty Award from the University of Idaho, the

Distinguished Faculty Fellowship Award, the DeVlieg Professorship, and

the Outstanding Graduate Faculty Mentor Award from WSU. The results of

his research have been published in numerous scholarly journal articles and

presented at a variety of national and international meetings. His current

research interests include mechanical characterization of composite materials and structures, noise and vibration control with composites, design and

manufacturing of composite structures, characterization of energy-absorbing materials, multifunctional composites, and nanocomposites.

xxiii

1

Introduction

1.1 Basic Concepts

Structural materials can be divided into four basic categories: metals, polymers, ceramics, and composites. Composites, which consist of two or more

separate materials combined in a structural unit, are typically made from

various combinations of the other three materials. In the early days of modern

man-made composite materials, the constituents were typically macroscopic.

As composites technology advanced over the last few decades, the constituent materials, particularly the reinforcement materials, steadily decreased

in size. Most recently, there has been considerable interest in “nanocomposites” having nanometer-sized reinforcements such as carbon nanoparticles,

nanoibers, and nanotubes, because of the extraordinary properties of these

materials.

The relative importance of the four basic materials in a historical context

has been presented by Ashby [1], as shown schematically in Figure 1.1 that

clearly shows the steadily increasing importance of polymers, composites,

and ceramics, and the decreasing role of metals. Composites are generally

used because they have desirable properties that cannot be achieved by any

of the constituent materials acting alone. The most common example is the

ibrous composite consisting of reinforcing ibers embedded in a binder or

matrix material. Particle or lake reinforcements are also used, but they are

generally not as effective as ibers.

Although it is dificult to say with certainty when or where humans

irst learned about ibrous composites, nature provides us with numerous

examples. Wood consists mainly of ibrous cellulose in a matrix of lignin,

whereas most mammalian bone is made up of layered and oriented collagen

ibrils in a protein–calcium phosphate matrix [2]. The book of Exodus in the

Old Testament recorded what surely must be one of the irst examples of

man-made ibrous composites, the straw-reinforced clay bricks used by the

Israelites. The early natives of South America and Central America apparently used plant ibers in their pottery. These early uses of ibrous reinforcement, however, were probably based on the desire to keep the clay from

cracking during drying rather than on structural reinforcement. Much later,

1

Principles of Composite Material Mechanics

2

10,000

5000

0

1000 1500 1800

Gold Copper

Bronze

Iron

1900

1940

1990

2000

2010

2020

Glassy metals

Aluminum–lithium alloys

Cast iron

Dual phase steels

Steels

Wood

Skins

Fibers

1980

Metals

Metals

Polymers

Relative importance

1960

Alloy steels

Glues

Microalloyed steels

Development stow:

Mostly quality

control and

processing

New super alloys

Light alloys

Polymers

Conducting

Super alloys

Composites

polymers

Straw brick paper

High-temperature

Titanium

polymers

zirconium, Alloys

etc.

Stone

High-modulus Composites

Flint

polymers

Bakeline

Ceramic composites

Pottery

Polyesters Metal-matrix

Glass

Nylon

Epoxies composites

Cement

PE PMMAAcrylics Kevlar FRP

Ceramics

Refractories

Ceramics

CFRP

PC PS PP

CFRP

Portland

Fused

Tough

engineering

cement

silica Cemets Pyro, ceramics (Al2O3Si3N4 PCZ, etc.)

ceramics

10,000

Rubber

5000

0

1000 1500 1800

1900

1940

1960

1980

1990

2000

2010

2020

Year

FIGURE 1.1

Relative importance of metals, polymers, composites, and ceramics as a function of time. The

diagram is schematic and describes neither tonnage nor value. The timescale is nonlinear.

(From Ashby, M. F. 1987. Technology of the 1990s: Advanced materials and predictive design.

Philosophical Transactions of the Royal Society of London, A322, 393–407. Reproduced by permission of The Royal Society.)

humans developed structural composites such as steel-reinforced concrete,

polymers reinforced with ibers such as glass and carbon, and many other

materials.

Fibrous reinforcement is very effective because many materials are much

stronger and stiffer in iber form than they are in bulk form. It is believed

that this phenomenon was irst demonstrated scientiically in 1920 by

Grifith [3], who measured the tensile strengths of glass rods and glass ibers

of different diameters. Grifith found that as the rods and ibers got thinner,

they got stronger (see Figure 1.2 from Reference 3, as shown in Reference 4),

apparently because the smaller the diameter, the smaller the likelihood that

failure-inducing surface cracks would be generated during fabrication and

handling. By extrapolating these results, Grifith found that for very small

diameters, the iber strength approached the theoretical cohesive strength

between adjacent layers of atoms, whereas for large diameters, the iber

strength dropped to nearly the strength of bulk glass.

Results similar to those published by Grifith have been reported for a wide

variety of other materials. The reasons for the differences between iber and

bulk behavior, however, are not necessarily the same for the other materials.

For example, polymeric ibers are stronger and stiffer than bulk polymers

Introduction

3

600,000

Extrapolates to 1,600,000 psi (11,000 MN/m 2)

Tensile strength (lb/in.2)

500,000

400,000

Extrapolates to approximate

strength of bulk glass

25,000 psi (170 MN/m2)

300,000

200,000

100,000

1

1000

10 μ

20 μ

2

3

4

1000 1000 1000

Thickness of fiber (in.)

FIGURE 1.2

Grifith’s measurements of tensile strength as a function of iber thickness for glass ibers. (From

Grifith, A. A. 1920. The phenomena of rupture and low in solids. Philosophical Transactions

of the Royal Society, 221A, 163–198. Reproduced by permission of The Royal Society; Gordon,

J. E. 1976. The New Science of Strong Materials, 2nd ed. Princeton University Press, Princeton,

NJ. With permission.)

because of the highly aligned and extended polymer chains in the ibers

and the randomly oriented polymer chains in the bulk polymer. A similar

effect occurs in crystalline materials such as graphite. In addition, a single

crystal tends to have a lower dislocation density than a polycrystalline solid;

so single-crystal “whisker” materials are much stronger than the same material in polycrystalline bulk form. Whiskers typically have dimensions in the

micrometer range, and for many years, it was thought that whiskers were

the strongest and stiffest reinforcement materials available. However, it is

now believed that carbon nanotubes (CNTs), which have dimensions in the

nanometer range, are the strongest and stiffest reinforcement materials in

existence [5,6].

There can be no doubt that ibers allow us to obtain the maximum tensile

strength and stiffness of a material, but there are obvious disadvantages of

using a material in iber form. Fibers alone cannot support longitudinal compressive loads and their transverse mechanical properties are often not as

good as the corresponding longitudinal properties. Thus, ibers are generally

useless as structural materials unless they are held together in a structural

unit with a binder or matrix material and unless some transverse reinforcement is provided. Fortunately, the geometrical coniguration of ibers also

turns out to be very eficient from the point of view of interaction with the

binder or matrix. As shown in Figure 1.3 from Reference 7, the ratio of surface

area to volume for a cylindrical particle is greatest when the particle is in either

Principles of Composite Material Mechanics

l/3

4

Platelet

Area/volume ratio A/V in units of

2π

V

Fiber

20

15

10

5

0

0.01

0.1

1

10

a (log scale)

100

1000

FIGURE 1.3

Surface area-to-volume ratio A/V of a cylindrical particle of given volume plotted versus particle aspect ratio a = l/d. (From McCrum, N. G., Buckley, C. P., and Bucknall, C. B. Principles of

Polymer Engineering, 1988, New York, NY, by permission of Oxford University Press.)

platelet or iber form. For a platelet, the particle aspect ratio, that is, a = l/d (i.e.,

the length-to-diameter ratio) is very small, whereas for a iber, the aspect ratio

is very large. Thus, the iber/matrix interfacial area available for stress transfer per unit volume of iber increases with increasing iber length-to-diameter

ratio. It is also important to note that, for a iber-reinforced composite, the total

iber/matrix interfacial area will be increased if the iber diameter is decreased

while maintaining constant iber volume and iber length.

The matrix also serves to protect the ibers from external damage and

environmental attack. Transverse reinforcement is generally provided by

orienting ibers at various angles according to the stress ield in the component of interest. Filler particles are also commonly used in composites for a

variety of reasons such as weight reduction, cost reduction, lame and smoke

suppression, and prevention of ultraviolet degradation due to exposure to

sunlight.

The need for iber placement in different directions according to the particular application has led to various types of composites, as shown in Figure 1.4.

In the continuous iber composite laminate (Figure 1.4a), individual continuous iber/matrix laminae are oriented in the required directions and bonded

together to form a laminate. Although the continuous iber laminate is used

extensively, the potential for delamination, or separation of the laminae, is

still a major problem because the interlaminar strength is matrix dominated.

Woven iber composites (Figure 1.4b) do not have distinct laminae and are not

susceptible to delamination, but strength and stiffness are sacriiced because

the ibers are not as straight as in the continuous iber laminate. Chopped

iber composites may have short ibers randomly dispersed in the matrix,

Introduction

5

(a)

(b)

(c)

(d)

FIGURE 1.4

Types of iber-reinforced composites. (a) Continuous iber composite, (b) woven composite,

(c) chopped iber composite, and (d) hybrid composite.

as shown in Figure 1.4c. Chopped iber composites are used extensively in

high-volume applications due to their low manufacturing cost, but their

mechanical properties are considerably poorer than those of continuous iber

composites. Finally, hybrid composites may consist of mixed chopped and

continuous ibers, as shown in Figure 1.4d or mixed iber types such as glass

and carbon. Another common composite coniguration, the sandwich structure (Figure 1.5), consists of high-strength composite facing sheets (which

could be any of the composites shown in Figure 1.4) bonded to a lightweight

foam or honeycomb core. Sandwich structures have extremely high lexural

stiffness-to-weight ratios and are widely used in aerospace structures. The

design lexibility offered by these and other composite conigurations is obviously quite attractive to designers, and the potential exists to design not only

the structure but also the structural material itself.

1.2 Constituent Materials for Composites

Fiberglass-reinforced plastics were one of the irst structural composites.

Composites incorporating glass or other relatively low-modulus ibers

(<83 GPa [12 × 106 psi]) are used in many high-volume applications such as

Principles of Composite Material Mechanics

6

Film adhesive bonds

facings to core

High strength

composite laminate

facings

Low density

honeycomb core

FIGURE 1.5

Composite sandwich structure.

automotive vehicles because of their low cost, and are sometimes referred to

as “basic” composites. The so-called “advanced” composites made from carbon, silicon carbide, aramid polymer, boron, or other higher-modulus ibers

are used mainly in more demanding applications such as aerospace structures, where their higher cost can be justiied by improved performance.

The tremendous advantages of advanced ibers over glass ibers and conventional bulk materials are shown in Table 1.1, by comparing selected properties. The main advantages are higher modulus, higher strength, and lower

density. In many applications such as aerospace and automotive structures,

structural weight is very important. Depending on whether the structural

design is strength-critical or stiffness-critical, the material used should have

a high strength-to-weight ratio (or speciic strength) or a high stiffness-toweight ratio (or speciic stiffness). As shown in Figure 1.6, advanced ibers

also have signiicant advantages over conventional materials in both these

attributes, and this is the principal reason that composites will be used with

increasing frequency in aerospace structures, iber-reinforced automotive

structures, and other structures where these properties are important. When

the reinforcing ibers are combined with a matrix or binder material to form

a composite, there is obviously some reduction in the tremendously high speciic strengths and speciic moduli shown for the reinforcing ibers in Figure

1.6, but the composites still have an overwhelming advantage with respect

to these properties. Table 1.1 also shows that the ultimate strain or strain

to failure (a measure of ductility), is one attribute where reinforcing ibers

are typically not as good as conventional bulk metals and polymers, but are

still better than bulk ceramics. Many advanced ibers exhibit nearly linear

stress–strain curves to failure, and such behavior is generally considered to

4.1

4.7

4.1

3.3

3.2

9.3

3.5

4.1

86

2.8

2.4

3.1

69

200

45

114

Tensile

Modulus (GPa)

99

121

83

56

86

158

97

75

65

40

Bulk Polymers

Nylon 6/6

Polycarbonate

Polyvinylchloride

Bulk Polymer Matrix Materials

Hexply 8551-7 epoxy

Hexply 8552 epoxy

CYCOM 934 epoxy

Hexply 954-3A cyanate

Derakane 411-350 vinylester

Ultem 2300 polyetherimide

Victrex 150G

polyetheretherketone

Fortron 0214B1

polyphenylene sulide

310

1030

345

880

Bulk Metals

6061T6 Aluminum

4340 Steel

AZ80 Magnesium

6AL4V Titanium

Material

Tensile

Strength (MPa)

Selected Properties of Bulk and Fibrous Materials

TABLE 1.1

1.4

1.27

1.3

1.3

1.19

1.14

1.51

1.3

1.14

1.2

1.44

2.71

7.83

1.8

4.43

Density

(g/cm3)

61.4

78

93.1

63.8

47

75.4

104.6

74.6

65.8

54.2

27.8

114.4

131.5

191.7

198.6

Speciic

Strength

(MPa/[g/cm3])

2.9

3.2

3.6

3.1

2.8

2.8

6.2

2.7

2.5

2

2.2

25.5

25.5

25

25.7

Speciic

Modulus

(GPa/[g/cm3])

0.03

0.044

0.017

0.007

0.019

0.05

0.03

0.6

0.5

1.1

0.4

0.17

0.19

0.06

0.14

Ultimate

Strain

(Continued)

Ticona

Hexcel

Hexcel

Cytec

Hexcel

Ashland

Sabic

Victrex

Manufacturer

Introduction

7

2600a

3900a

1100a

2100a

3448

4890

4475

5670

6140

6964

3650

4550

4410

2740

4900

5880

6370

Bulk Ceramics

Alumina (Al2O3)

Silicon carbide (SiC)

Silica (SiO2)

Aluminum nitride (AlN)

Glass Fibers

E-glass

S-2 glass

PAN-Based Carbon Fibers

AS4, 12K ilaments

IM7, 12K

IM9, 12K

IM10, 12K

T-300, 12K

T-650/35, 12K

T-400H, 6K

M-40, 12K

T700S, 12K

T-800S, 24K

T-1000G, 12K

Material

Tensile

Strength (MPa)

231

276

304

303

231

248

250

392

230

294

294

72

87

375a

410a

73a

330a

Tensile

Modulus (GPa)

Selected Properties of Bulk and Fibrous Materials

TABLE 1.1 (Continued)

1.79

1.78

1.8

1.79

1.76

1.7

1.8

1.81

1.8

1.8

1.8

2.54

2.46

3.89

3.1

2.2

3.26

Density

(g/cm3)

2500

3185.4

3411.1

3890.5

2073.9

2676.4

2450.0

1513.8

2722.2

3266.7

3538.9

1357.5

1987.8

668.3

1258

500

644.2

Speciic

Strength

(MPa/[g/cm3])

129

155

168.9

169.3

131.3

145.9

138.9

216.6

127.8

163.3

163.3

28.3

35.8

96.4

132.2

33.2

101.2

Speciic

Modulus

(GPa/[g/cm3])

0.018

0.0178

0.019

0.021

0.014

0.0175

0.018

0.007

0.021

0.02

0.022

0.048

0.057

Ultimate

Strain

Hexcel

Hexcel

Hexcel

Hexcel

Cytec

Cytec

Toray

Toray

Toray

Toray

Toray

(Continued)

Owens-Corning

Owens-Corning

Accuratus

Accuratus

Accuratus

Accuratus

Manufacturer

8

Principles of Composite Material Mechanics

13,000–52,000

2700–7000

Carbon nanotubes

Carbon nanoibers

Denotes compressive property.

3900

SCS-6 silicon carbide

a

3600

320–1470

400–600

380

400

73

180

110

3430

5800

3500

Other Fibers

Boron 4.0 mil dia

124

3340

380

760

830

70

112

79

Pitch-Based Carbon Fibers

P-55S, 2K

P-100S, 2K

P-120S, 2K

Tensile

Modulus (GPa)

3620

3620

2600

1900

2100

2240

Material

Polymeric Fibers

Kevlar 29 aramid

Kevlar 49 aramid

Spectra 900/650

polyethylene

Spectra 2000/100

polyethylene

Technora aramid

Zylon-AS PBO

Dyneema SK60

polyethylene

Tensile

Strength (MPa)

Selected Properties of Bulk and Fibrous Materials

TABLE 1.1 (Continued)

1.3–1.4

1.8–2.1

3

2.54

1.39

1.54

0.97

0.97

1.44

1.44

0.97

2.0

2.13

2.13

Density

(g/cm3)

1300

1417.3

2467.6

3766.2

3608.2

3443.3

2514

2514

2680

950

985.9

1051.6

Speciic

Strength

(MPa/[g/cm3])

126.7

157.5

52.5

116.9

113.4

127.8

48.6

77.8

81.4

190

356.8

389.7

Speciic

Modulus

(GPa/[g/cm3])

0.0013

0.008

0.046

0.035

0.03

0.036

0.024

0.036

0.005

0.002

0.0042

Ultimate

Strain

Applied

sciences

Specialty

materials

Specialty

materials

Teijin

Toyobo

Toyobo

Honeywell

DuPont

DuPont

Honeywell

Cytec

Cytec

Cytec

Manufacturer

Introduction

9

Principles of Composite Material Mechanics

10

450

Specific modulus, GPa/(g/cm3)

400

P-120S fiber

350

P-100S fiber

300

250

200

P-55S fiber

IM-7 fiber IM-9 fiber

T-650/35 fiber

AS-4 fiber

Zylon-AS

Boron fiber

150

SCS-6 fiber

Bulk silicon carbide

100

Kevlar 49 fiber

Spectra 900 fiber

50

E-glass fiber

Bulk aluminum

Bulk nylon

0

0

1000

fiber

S-2 glass fiber

2000

3000

4000

Specific strength, MPa/(g/cm3)

FIGURE 1.6

Speciic modulus versus speciic strength for a variety of ibers and conventional bulk materials. The speciic value is the value of the property divided by the density.

be characteristic of brittle materials. It is important to remember, however,

that the iber strength, iber modulus, and iber ultimate strain values in

Table 1.1 are based on tensile tests with the load acting along the iber axis.

As shown later, these properties all change substantially for off-axis loading,

and applied loads are rarely aligned perfectly with the iber axis. It will be

shown later, for example, that a composite laminate can be constructed in

such a way that its overall behavior is similar to that of ductile metals, even

though the reinforcing ibers may exhibit brittle behavior.

1.2.1 Reinforcement Materials including Nanoreinforcements

Glass ibers consist primarily of silica (silicon dioxide) and metallic oxide

modifying elements and are generally produced by mechanical drawing of

molten glass through a small oriice. E-glass (named for its electrical properties) accounts for most of the glass iber production and is the most widely

used reinforcement for composites. The second most popular glass iber,

S-glass, has roughly 40% greater tensile strength and 20% greater modulus

of elasticity than E-glass (Table 1.1), but it is not as widely used, because of its

higher cost. S-glass actually has greater strength and elongation than many

advanced ibers, but its relatively low modulus limits its application. Glass/

epoxy and glass/polyester composites are used extensively in applications

ranging from ishing rods to storage tanks and aircraft parts.

Introduction

11

Graphite or carbon ibers are the most widely used advanced ibers, and

graphite/epoxy or carbon/epoxy composites are now used routinely in aerospace structures. Unfortunately, the names “carbon” and “graphite” are often

used interchangeably to describe ibers based on the element carbon. These

ibers are usually produced by subjecting organic precursor ibers such as

polyacrylonitrile (PAN) or rayon to a sequence of heat treatments, so that the

precursor is converted to carbon by pyrolysis. The major difference is that

graphite ibers are subjected to higher-temperature pyrolysis than carbon

ibers. The result is that carbon ibers typically are less than 95% carbon,

whereas graphite ibers are at least 99% carbon [8]. Although carbon ibers

were once prohibitively expensive, the cost has dropped signiicantly as production capacity and demand has increased. Development of new carbon

and graphite ibers continues at a rapid pace. For example, ibers based on a

pitch precursor (P-120S) with a modulus more than four times that of steel

are now available (Table 1.1). High-strength carbon ibers such as IM10 and

T-1000G, which are based on a PAN precursor, have a tensile strength more

than six times that of steel. Either high strength or high modulus is obtained

by using the appropriate heat treatment.

Advanced polymeric ibers such as Kevlar® aramid ibers by DuPont,

Spectra® polyethylene ibers by Honeywell, Technora® aramid ibers by

Teijin, and Zylon® para-phenylene benzobisoxazole (PBO) ibers by Toyobo

have extremely high speciic strengths because of their combinations of

high strength and low density. The polymeric ibers also have higher failure

strains (i.e., better ductility) than the glass or carbon ibers. The main disadvantages of the polymeric ibers are that they are generally not suitable for

use at extremely high temperatures, and some of them are also susceptible

to moisture-induced degradation. The effects of temperature and moisture

on polymers and polymer composites will be discussed in more detail in

Chapter 5.

Boron ibers are actually composites consisting of a boron coating on a

substrate of tungsten or carbon, and the diameter of boron ibers is among

the largest of all the advanced ibers, typically 0.002–0.008 in. (0.05–0.2 mm).

Boron ibers not only have much higher moduli than most carbon ibers

(Table 1.1), but they also have higher density. Boron/epoxy and boron/aluminum composites are widely used in aerospace structures where high stiffness is needed, but high cost still prevents more widespread use.

Silicon carbide (SiC) ibers are used primarily in high-temperature metal

and ceramic matrix composites because of their excellent oxidation resistance and high-temperature strength retention. At room temperature, the

strength and stiffness of SiC ibers are about the same as those of boron.

SiC whisker-reinforced metals are also receiving considerable attention as

alternatives to unreinforced metals and continuous iber-reinforced metals.

SiC whiskers are very small, typically 8–20 µin. (20–51 nm) in diameter and

about 0.0012 in. (0.03 mm) long, so that standard metal-forming processes

such as extrusion, rolling, and forging can be easily used [7].

12

Principles of Composite Material Mechanics

The ultimate reinforcement material to date is the carbon nanotube (CNT).

CNTs, which were irst observed in 1991, are two-dimensional (2D) hexagonal networks of carbon atoms (graphene sheets) that have been rolled up to

form a cage-like hollow tube having a diameter of several nanometers [5,6].

The properties for nanotubes presented in Table 1.1 are only approximate,

as nanotubes have so many different possible conigurations. For example,

they can be single walled or multiwalled, and they may occur in the form of

bundles or ropes. Carbon nanoibers have greater diameters and lengths, but

lower mechanical properties than CNTs. Nanoibers are typically less expensive than nanotubes. Both CNTs and nanoibers are discontinuous, having

rather low aspect ratios compared to conventional ibers such as glass and

carbon. Discontinuous reinforcement is discussed in Chapter 6.

Particulate reinforcements, especially nanoparticles, are increasingly used

to improve the mechanical and/or thermal properties of polymer matrix

materials in iber-reinforced composites. The longitudinal compressive

strength, transverse tensile strength, and shear strength of iber composites can be signiicantly enhanced by reinforcing the matrix with particles.

Ceramic particles and nanoparticles such as silicon dioxide (SiO2) have much

lower thermal expansion coeficients than polymer matrix materials, and

can be used to reduce undesirable thermal expansion mismatches between

iber and matrix materials in iber composites.

Hybrids consisting of mixed iber materials can be used when a single iber

material does not have all the desired properties. More complete descriptions of iber materials and their properties can be found in several composite handbooks [8–13]. Chapter 3 deals with further discussion on iber

properties, including anisotropic behavior.

1.2.2 Matrix and Filler Materials

Polymers, metals, and ceramics are all used as matrix materials in composites, depending on the particular requirements. The matrix holds the ibers

together in a structural unit and protects them from external damage, transfers and distributes the applied loads to the ibers, and, in many cases, contributes some needed property such as ductility, toughness, or electrical

insulation. A strong interface bond between the iber and matrix is obviously

desirable, and so the matrix must be capable of developing a mechanical or

chemical bond with the iber. The iber and matrix materials should also be

chemically compatible, so that undesirable reactions do not take place at the

interface. Such reactions tend to be more of a problem in high-temperature

composites. Service temperature is often the main consideration in the selection of a matrix material. Thus, the materials will be discussed below in order

of increasing temperature capability.

Polymers are unquestionably the most widely used matrix materials in

modern composites (Table 1.1). Polymers are described as being either

Introduction

13

thermosets (e.g., epoxy, polyester, and phenolic) or thermoplastics (e.g.,

polyimide [PI], polysulfone [PSU], polyetheretherketone [PEEK], and polyphenylene sulide [PPS]). On curing, thermosets form a highly cross-linked,

three-dimensional (3D) molecular network that does not melt at high temperatures. Thermoplastics, however, are based on polymer chains that do not

cross-link. As a result, thermoplastics will soften and melt at high temperatures, then harden again on cooling.

Epoxies and polyesters have been the principal polymer matrix materials for several decades, but advanced thermoplastics such as PEEK and PPS

are now receiving considerable attention for their excellent toughness and

low moisture absorption properties, their simple processing cycles, and

their higher-temperature capabilities. Aerospace grade epoxies are typically

cured at about 177°C (350°F) and are generally not used at temperatures

above 150°C (300°F), whereas advanced thermoplastics such as PPS, PI, and

PEEK have melting temperatures in the range 315–370°C (600–700°F). At this

time, it appears that polymer matrix materials for use up to 425°C (800°F) are

feasible. For higher temperatures, metal, ceramic, or carbon matrix materials

are required.

By using lightweight metals such as aluminum, titanium, and magnesium and their alloys and intermetallics such as titanium aluminide and

nickel aluminide, operating temperatures can be extended to about 1250°C

(2280°F). Other advantages of metal matrices are higher strength, stiffness,

and ductility than polymers but at the expense of higher density. Ceramic

matrix materials such as silicon carbide and silicon nitride can be used at

temperatures up to 1650°C (3000°F). Ceramics have poor tensile strength

and are notoriously brittle, however, and there is a need for much research

before these materials can be routinely used. Finally, carbon iber/carbon

matrix composites can be used at temperatures approaching 2760°C (5000°F),

but the cost of these materials is such that they are used only in a few critical aerospace applications. For further details on matrix materials and their

properties, the reader is referred to any of several handbooks [8–13].

The third constituent material of a composite, the iller material, is mixed

in with the matrix material during fabrication. Fillers are not generally used

to improve mechanical properties but, rather, are used to enhance some

other aspect of composite behavior. For example, hollow glass microspheres

are used to reduce weight, clay or mica particles are used to reduce cost,

carbon black particles are used for protection against ultraviolet radiation,

and alumina trihydrate is used for lame and smoke suppression [11]. Fillers

truly add another dimension to the design lexibility we have in composites.

EXAMPLE 1.1

Compare the total iber surface area of a group of N small-diameter

ibers with that of a single large-diameter iber having the same length

and volume.

Principles of Composite Material Mechanics

14

Solution

Assuming that the ibers are perfectly round, for a single large-diameter

iber of diameter dL, the circumferential iber surface area per unit

length is

AL = πdL

whereas the iber volume per unit length is

VL =

πdL2

4

For a single small-diameter iber of diameter dS, the corresponding circumferential surface area and volume per unit length are, respectively,

AS = πdS

and

VS =

πds2

4

For N small-diameter ibers having the same volume and length as a

single large-diameter iber,

NVS = VL

so that

N=

VL dL

=

VS dS

2

The ratio of the total surface area of N small-diameter ibers to the

surface area of a single large-diameter iber having the same volume and

length is then

2

R=

NAS NdS dL dS dL

=

=

=

dS dL dS

AL

dL

For example, if a large iber is replaced by a group of ibers having

diameters 1000 times smaller, dL = 1000 dS, and the total iber surface area

for a constant iber length and volume will increase by a factor of 1000.

It can be easily shown that the same result holds for spherical particles.

So in addition to their superior strength and stiffness, small-diameter

Introduction

15

ibers such as nanoibers have the additional advantage of signiicantly

larger iber/matrix interfacial surface area per unit volume than largerdiameter ibers.

EXAMPLE 1.2

A structural design for which the governing design criterion is limiting

the maximum working stress is sometimes referred to as a “strengthcritical design” and a structural design in which the governing design

criterion is limiting the maximum working deformation is sometimes

referred to as a “stiffness-critical design.” (a) Considering only the

mechanical properties of carbon iber-reinforced composites, which

types of carbon ibers would be the most desirable for use in strengthcritical composite designs and (b) which types of carbon ibers would be

the most desirable for use in stiffness-critical composite designs? (c) If

minimization of structural weight is an additional consideration, would

this change the answers to (a) and (b)?

Solution

a. According to Table 1.1, among the available carbon ibers, PANbased carbon ibers have the highest tensile strength values, so

they would be the most desirable for use in strength-critical

composite designs.

b. Similarly, among the available carbon ibers, pitch-based carbon ibers have the highest tensile modulus values, so they

would be the most desirable for use in stiffness-critical composite designs.

c. From Table 1.1, the PAN-based carbon ibers have the highest

speciic strength values and the pitch-based carbon ibers have

the highest speciic modulus values, so the additional consideration of structural weight would not change the answers to (a)

and (b).

EXAMPLE 1.3

A thin-walled pressure vessel of mean radius r and wall thickness t is

to contain gas at an internal pressure p. Compare the maximum internal

pressures that can be withstood by an IM10 carbon iber composite vessel and a 6061T6 aluminum vessel. Assume that both vessels have the

same radius and wall thickness, that the carbon ibers are all oriented in

the circumferential direction, and neglect the contribution of the matrix

in the composite.

Solution

From the mechanics of materials thin-walled pressure vessel theory, the

circumferential hoop stress in the vessel is given by

σ=

pr

t

Principles of Composite Material Mechanics

16

so the pressure is given by

p=

σt

r

Therefore, for the same radius and thickness, the ratio of the pressures

that can be withstood by the two vessels is given by the ratio of the tensile strengths for the two materials, as given in Table 1.1.

pIM10

6964

σ

= IM10 =

= 22.46

310

p6061T 6 σ 6061T 6

So the IM10 carbon iber vessel can withstand 22.46 times the pressure

that the 6061T6 vessel can withstand.

EXAMPLE 1.4

A cantilever beam of rectangular cross section and made of 6061T6 aluminum is to be replaced by an IM10 carbon iber composite beam having

the same length L and width b, and it must have the same tip delection

w under the same tip load P. Compare the thicknesses and weights of

the two beams, neglecting the contribution of the matrix material in the

composite.

Solution

From the mechanics of materials beam theory, the tip delection of the

cantilever beam is given by

w=

PL3

3EI

where I = bh3/12 is the area moment of inertia of the cross section about

the neutral axis or centroidal axis, b is the width, h is the thickness, and

E is the modulus of elasticity from Table 1.1. The ratio of the tip delections for the two beams having the same length, width, and load is

3

hIM10 EIM10

=1

h

6061T6 E6061T6

So the corresponding ratio of thicknesses is

hIM10 E6061T6

=

h6061T6 EIM10

1/3

69

=

303

1/3

= 0.61

and the carbon iber beam only needs to be 61% as thick as the aluminum

beam. The ratio of the weights of the two beams is given by

Introduction

17

WIM10

bhIM10 LρIM10

h ρ

1.79

= 0.403

=

= IM10 IM10 = 0.61

W6061T6 bh6061T6 Lρ6061T6 h6061T6ρ6061T 6

2.71

where W is the beam weight and ρ is the beam material density from

Table 1.1. So the carbon iber composite beam only weighs 40% as much

as the aluminum beam, but it satisies the same design criteria. These

examples demonstrate some of the advantages of composites over conventional materials without considering the matrix material. The contributions of the matrix material will be discussed in later chapters,

especially in Chapters 3 and 4.

PROBLEM 1.1

For a cylindrical particle, derive the relationship between the ratio of surface

area to volume, A/V, and the particle aspect ratio, l/d, and verify the shape of

the curve shown in Figure 1.3.

PROBLEM 1.2

Compare the total surface area of a group of N small-diameter spherical particles with that of a single large-diameter spherical particle having the same

volume.

PROBLEM 1.3

Explain qualitatively why sandwich structures (Figure 1.5) have such high

lexural stiffness-to-weight ratios. Describe the key parameters affecting the

lexural stiffness-to-weight ratio of a sandwich panel.

PROBLEM 1.4

Which of the reinforcing ibers listed in Table 1.1 would be best for use in

an orbiting space satellite antenna structure that is subjected to relatively

low stresses but has very precise dimensional stability requirements? The

answer should be based only on the properties given in Table 1.1.

PROBLEM 1.5

A support cable in a structure must be 5 m long and must withstand a tensile

load of 5 kN with a safety factor of 2.0 against tensile failure. Assuming a

solid cylindrical cross section for the cable as an approximation, (a) determine and compare the weights of cables made of 4340 steel and AS-4 carbon

ibers that meet the above requirements and (b) for an AS-4 carbon iber

cable having the same weight, length, and safety factor as the 4340 steel cable

from part (a), how much tensile load will the carbon iber cable be able to

withstand?

Principles of Composite Material Mechanics

18

ω

t

r

L

FIGURE 1.7

Simpliied model of lywheel for Problem 1.6.

PROBLEM 1.6

A lywheel for energy storage is modeled as a rotating thin-walled cylindrical ring (t ≪ r) as shown in Figure 1.7. Find the equation for the tensile

stress in the ring as a function of the mean radius, r, the rotational speed, ω,

and the mass density, ρ, of the ring, then compare the maximum peripheral