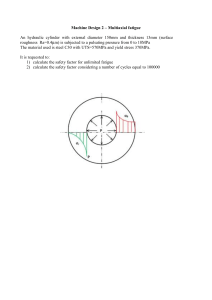

OMMI, 2008, Volume 5, Issue 1, May www.ommi.co.uk HRSG optimisation for cycling duty based on Euro Norm EN 12952-3 Ir. Pascal Fontaine1 and Ir. Jean-François Galopin2 1 Marketing Manager CMI Energy Av Greiner 1, 4100 Seraing BELGIUM. 2 Design Manager CMI Energy Av Greiner 1, 4100 Seraing BELGIUM. pascal.fontaine@cmigroupe.com jean-francois.galopin@cmigroupe.com Mr Pascal Fontaine. In 1990, Mr Pascal Fontaine graduated as professional Engineer in Power Generation from the University of Liège in Belgium. Within CMI Energy, he gained his experience on HRSG design and management, where he occupied the following positions: Process Engineer for 4 years, Technical Project Manager for 5 years, Proposal Manager for 4 years, and currently Marketing Manager for CMI Energy. Mr Fontaine is the author of several papers and international publications on both Horizontal and Vertical HRSG technologies and HRSG cycling related issues. Abstract Nowadays, most of the combined cycle power plants are working on day/night and weekday/weekend cycling. The onset of deregulation and consequent merchant power have brought combined cycle plants to supply electrical power to the grid as and when needed with minimum notice. Combined cycles are also often forced to run on partial loads. Even units which were originally designed for base load are all eventually forced to cycle as new more efficient power plants are built. As generally recognised nowadays, the cycling criterion is to be integral part of the HRSG design. In this paper, the HRSG fatigue analysis using the European Norm EN 12952-3 will be discussed. This paper will present how the European Norm can be used to assess HRSG cumulative damage and how the HRSG cyclic life time can be optimised. Key Words. European Norm EN 12952-3, HRSG, Fatigue 1. Introduction Nowadays, most of the combined cycle power plants are working on day/night and weekday/weekend cycling. The onset of deregulation and consequent merchant power have brought combined cycle plants to supply electrical power to the grid as and when needed with minimum notice. Combined cycles are also often forced to run on partial loads. Even units which were originally designed for base load are all eventually forced to cycle as new more efficient power plants are built. As generally recognised nowadays, the cycling criterion is to be integral part of the HRSG design. In this paper, the HRSG fatigue analysis using the European Norm EN 12952-3 will be discussed. This paper will present how the European Norm can be used to assess HRSG cumulative damage and how the HRSG cyclic life time can be optimised. The theory is first reviewed as a base to explain how Euro Norm can be used for cyclic optimisation. In complement to construction code (i.e ASME), this paper will explain how the boiler cyclic life can be optimised with progressive pressure start-up ramp 1 OMMI, 2008, Volume 5, Issue 1, May www.ommi.co.uk rates reducing the overall start-up time. This paper focuses on fatigue and we will not discuss here the interaction mechanisms between fatigue and creep on hot superheater. 2. Stress over component thickness There are mainly two kinds of stress inside component wall: the mechanical stress originated from internal pressure, and the thermal stress originated from thermal expansion. During startup, those stresses are in opposite directions, while they are in the same directions during shutdown. Eventually, these stresses combine together into Von Mises stresses (Fig. 1). Thermal stress sth is: - fonction of transient f(t) only - proportionnal to delta T?over e - compression during start-up - traction stress during stoppage Insulated Q ext = 0 sth = sp + sth Ma in co mp on e nt dia me ter D sTotal Internal Pressure, Temperature = fonction (time) sp sp ~= Thickness e (up to 6 inch for HP drum) e e Pression * Diameter 2*e sTotal Stress Mechanical stress sp is: - proportionnal to pressure P - proportionnal to diameter D - nearly constant over thickness - always a traction stress Fig. 1 Mechanical and thermal stress over component wall thickness during transients 3. Stress cycle during a cold start-up A cold start-up, meaning from sub-cooled water, is special compared to a hot start because the inner shell is heated up while the internal pressure is atmospheric and constant. That induces compression thermal stress which is not yet counter-balanced by any tensile stress from pressurization. As soon as pressure starts to increase, mechanical tension stress will release thermal stress as they are in opposite directions. Therefore, the largest amplitude of this stress cycle will occur during such a cold start-up, which is the most severe condition. In addition, the internal protective magnetite layer could crack during the early stage of start-up. This ferrous oxide Fe3O4 is created naturally under pressure at drum normal operating condition. The Euro Norm allows an empirical stress range of -600 N/mm² and +200 N/mm². As this magnetite layer is formed under pressure, it is already under compression strain at cold conditions, and therefore, subject to overpass the lower limit during a cold start-up (Fig. 2). 2 OMMI, 2008, Volume 5, Issue 1, May (N/mm? www.ommi.co.uk Inner shell surface circonferentiel stress Forbidden zone according to Euro Norm 12952 + 200 MaxsT sTnom MaxsT P, sp - 600 Overall material fatigue range: MinsT T sTOTAL =sth+ sp Time sth MinsT START-UP Forbidden zone according to Euro Norm 12952 (internal magnetite layer protection) STOPPAGE Fig. 2 Schematic approach of the cycling stress range over drum thickness for a cold start-up During the subsequent pressure increase, the drum shell is heated from the inside by boiling water and the heat is transmitted from inside to outside generating a temperature profile. A significant temperature difference between inner and outer shell surfaces builds up. The outer shell surface temperature lags behind the inner one. This temperature profile over the drum thickness is constant and slides up (Fig. 3). This shifting temperature profile has roughly a quadratic shape versus wall thickness, and so is the induced thermal stress profile. Once pressure is stabilized at the normal operating condition, this temperature profile will vanish, so will thermal stress, and only this mechanical stress will remain in the equipment wall. During shutdown, the same opposite phenomenon occurs with reversed temperature profile between external and internal surfaces on drum shells. This complete cycling stress, including start-up and shutdown, shall be considered for component fatigue analysis. Regardless of the stress transients, the ASME code considers the permanent operating conditions on creep for thickness calculation. 3 OMMI, 2008, Volume 5, Issue 1, May www.ommi.co.uk F in a l te m p e ra tu re u n ifo rm o v e r th ic k n e s s T In te rn a l w a ll s th t1 t2 T e m p e ra tu re p ro file is s lid in g E x te rn a l w a ll t3 t4 t5 T e m p e ra tu re p ro file is b u ild in g T im e P ro file s o f te m p e ra tu re a n d th e rm a l s tre s s In te rn a l w a ll E x te rn a l w a ll D ru m w a ll th ic k n e s s T e m p e ra tu re p ro file b u ild in g T e m p e ra tu re p ro file slid in g T e m p e ra tu re p ro file v a n ish in g T im e Fig. 3 Schematic evolution of stress and temperature on internal/external walls during start-up 4. Impact of component thickness Temperature difference between inner and outer walls is roughly proportional to the square of the drum thickness, and so is also the thermal stress. This is why thin walls are so beneficial in terms of cycling fatigue. For instance, it is generally considered that the thickness of a superheater outlet header made of P91 material can be reduced by a factor of 2 compared to the same header made in P22 material. Consequently, the induced thermal stress would be reduced by a factor of 4 for such P91 header compared to P22 header (Fig. 4). Thincomponent sth Temperature/ thermal stressprofiles Thickcomponent 4 DT°' 1 DT° e If e' =2e, thensth' =4sth Time e' =2e Fig. 4 Illustration of thermal stress which is proportional to square of component thickness 4 OMMI, 2008, Volume 5, Issue 1, May www.ommi.co.uk 5. Material fatigue induced by cycling stress This start-up/shutdown cycle represents one simplified stress range. The allowable number of cycle is calculated with the Euro Norm EN 12952-3 (Fig. 5). In practice, cold, warm and hot cycle stress numbers are considered as per plant cyclic service informed by the specification. Other stress cycles can also be accounted, such as partial cycle when the first unit is started on a 2-2-1 arrangement, or even Low Cycle Fatigue (LCF) due to attemperation in operation. Then, the Miner’s rule is used to account each of those fractions of cumulative fatigue damage. Application of the norm shows that a cold start is up to 20 more damaging than a warm start, and that the stress range resulting from a hot start is typically below the fatigue limit and not contributing to the total fatigue damage (except for the damaging quenching issue, see §7). The fatigue damage is very sensitive to stress range because of its logarithmic nature (see the double logarithmic scale of Fig. 5). A small variation in stress amplitude impacts largely the corresponding number of cycles, even more so for small amplitude 2fa of warm start-ups. Fatigue calculation does not fix exactly the line between a crack and a nocrack initiation, but it is rather a statistical probability of crack occurrence under Na, fa conditions, eventually representing a percentage of risk of failure. The sensitivity and probabilistic nature of fatigue results in an uncertainty in fatigue lifetime analysis. Robust modeling by finite element can reduce the other uncertainties which come from simplified stress ranges and boundaries. Fig. 5 Wöhler curve from EN 12952-3 showing material fatigue for symmetric stress range (amplitude fa) versus allowable number of cycles Na for various material tensile strength Rm. 5. Allowable temperature ramp rates for start-up and shutdown ASME I considers continuous operation at design conditions, but it does not mandate assessment for fatigue analysis. European boiler manufacturer perform this analysis using the European Norm 12952-3 to calculate the acceptable pressure/ time gradients. The European Norm 12952-3 derives largely from the German code TRD 301, which was commonly used 5 OMMI, 2008, Volume 5, Issue 1, May www.ommi.co.uk previously for cyclic assessment. Whereas the HRSG is designed according to ASME, it is checked, in addition, for fatigue analysis using Euro Norm. Input data are basically the components diameter, material, thickness and operating pressure and temperature. Two methods can be applied, either the number of cycles is calculated for given start-up and shutdown rates, or those allowable rates are calculated for a given number of cycles. An interesting feature is the ramp rate variation versus operating pressure (Fig. 6): as pressure increases, the allowable pressure ramp rate also increases. In practice, EN fatigue analysis is applied to the thick HP drum wall as well as to outlet headers of reheater and HP superheater. Fig. 6 Example of results from TRD301 (European Norm 12952-3) for determination of acceptable temperature gradients on an HP drum 90mm thick in SA302B up to 110 bar A. As explained above, a cold start is the most stressful event in terms of fatigue effect, inasmuch as it includes the largest cycle range. Unless required otherwise by a specification, the number of cold start-ups considered for design by CMI is 2000 over a 20-year design lifetime. By applying the norm for an extended number of cold start-ups, we calculate negative temperature gradients (Fig. 7). This is of course impossible, and it shall be interpreted as a statistical fact that material would have no more strength reserve to perform such extended number of start-ups, meaning that such cumulative cycling damage has exhausted the component fatigue lifetime. 6 OMMI, 2008, Volume 5, Issue 1, May www.ommi.co.uk Fig. 7 Euro Norm results showing temperature gradient versus number of cold start-ups 7. Euro Norm 12952 improvements compared to former TRD 301 code TRD 301 was generally looked upon as the reference for pressure vessels cycling analysis. However, when compared to finite element (FE) analysis, this code revealed itself to be rather conservative. For instance, TRD considered empirical stress concentration factor around nozzles which were proven to be high by FE, as cautions are taken in construction to avoid sharp edges on those openings. Also, the feedwater nozzle on drums is always equipped with an internal thermal sleeve to accommodate the induced thermal shock without undue stress occurrence when cold feedwater is first admitted into a warm drum. The main improvement of the Euro Norm compared to the former TRD 301 for cyclic analysis is on this determination of stress concentration factors, as finite element analysis can be used (Fig. 8). Fig. 8 Finite Element nozzle analysis for stress concentration calculation In order to fully apprehend all changes between EN 12952-3 and TRD 301, an overall survey of the two codes was conducted by CMI on a specific boiler under engineering. TRD 301 and EN 12952-3 calculation methods are similar, but some differences have been identified, mainly related to the empirical coefficients used within the formula on stresses evaluation: σ = αm . β .E d ms . p + α t . t t . ΔT 2 . ems 1 −ν mechanical stresses with : dms thermal stresses due to temperature gradients = equipment diameter 7 OMMI, 2008, Volume 5, Issue 1, May ems αm p αt ν βt Et ΔT www.ommi.co.uk = equipment mean thickness = stress concentration factor for membrane stresses = pressure = stress concentration factor for thermal stresses = Poisson’s ratio = differential linear thermal expansion coefficient = modulus of elasticity = temperature variation with respect to time Comparison of results is as follows: stress concentration factor α m stress concentration factor α t TRD 301 The 2 codes use different correlations. EN 12952-3 It seems to be more precise due to the fact that it incorporates the branch mean thickness within its formula (as opposed to TRD 301). α t is fixed to 2 or α t is evaluated with the help of the mean branch 1.5 depending on the head shape (cylindrical or spherical) diameter (dmb), the mean body diameter (dms) as well as the heat transfer coefficient h : 2 h h + 2700 ⎡ ⎤ α t = ⎢2 − .z + . (exp( −7.z ) − 1)⎥ + 0,81.z 2 h + 1700 h + 1700 ⎣ ⎦ in which : z= ⎧1000 W / m² K h=⎨ ⎩3000 W / m² K stresses calculations : TRD 301 Ck and Ct* (or equivalent parameters) are not used d mb d ms for steam for water EN 12952-3 A notch factor (Ck) is used to take into account the influence of surfaces and weld finish: σ ∗ = σ . Ck Where Ck=1 for our application A corrective factor (Ct*) is used to take into account the influence of temperature as well as the type of material (either ferritic or austenitic): σ ∗ (t ∗ ) = comparison criteria The sum of the cumulated damages shall be smaller than 50% σ∗ Ct ∗ In which : t* = 0,75 . tmax + 0,25 . tmin (the same definition is used for t* in TRD 301) The sum of the cumulated damages shall be smaller than 100% 8 OMMI, 2008, Volume 5, Issue 1, May www.ommi.co.uk As mentioned before, the critical components are the HP drum and high temperature superheater / reheater headers and/or manifolds. The hereafter results are based on detailed connection between branches (nozzles) and main body on an HP drum and an HP superheater: Drum SA 302 B 2170 122 SA 105 526.52 80 Superheater SA 335 P91 219.1 28.6 SA 213 T91 38 4 Type of start-up cold warm hot 50 1250 5000 7.97 7.97 7.97 Type of start-up cold warm hot 50 1250 5000 7.97 7.97 7.97 294.7 294.7 294.7 565 565 565 8 -1.8 0.08 7 -1.8 1.65 6.5 -1.8 4.78 17 -26.7 0.07 17 -26.7 1.87 17 -26.7 8.01 0.56 10.71 27.25 0.22 5.54 24.20 Main body Material Diameter [mm] Thickness [mm] Branch Material Diameter [mm] Thickness [mm] Number of cycles Max. operating pressure [N/mm²] Max. operating temperature [°C] ΔT at Pmin [°C/min] ΔT at Pmax [°C/min] Cumulative damage EN [%] Cumulative damage TRD301 [%] When comparing the cumulative damages, results are as follows: TRD 301 EN 12952-3 Total drum damage 38,52% 6,51% (set through nozzles),i.e. Total SHT damage 29,96% 9,95% (set on, weld root machined) Knowing that the maximum cumulated damage differ from one code to the other, TRD 301 results should be multiplied by a factor 2 to compare percentages of fatigue exhaustion. This analysis confirms that the most important improvement is on the Stress Induced Factors. Euro Norm appears to be less conservative than TRD 301, and more representative of physics. 8. Superheater quenching issue not accounted by the Euro Norm Mechanical stress is high for HP drum, whilst thermal stress is high for superheater and reheater, especially in case of water quenching. This quenching phenomenon occurs due to condensate water inside still hot superheater during initial gas purge. This quickly chills out parts of the component compared to others, and it induces low cycling fatigue cycle in the overall warm start-up cycle. Although the phenomenon is very damageable, it is very difficult 9 OMMI, 2008, Volume 5, Issue 1, May www.ommi.co.uk to account because of its empirical nature. Quenching issue is still not yet considered by Euro Norm, and a good engineering practice shall prevail for a large and multiple drainage system. 9. Optimisation of drum design There are 4 materials often used for drum design, namely SA 302 Gr B, SA 299, SA 516 Gr 60, SA 516 Gr 70. As one can see from their MAS curves, there is a trade off between (mainly) SA 302 Gr B and SA 299 around 100 bar as per CMI consideration, where a drum made out of SA 299 would become far too thick compared to drum made out of SA 302 Gr B. This material is generally used for HP drums in order to reduce wall thickness (Fig. 4). The two other materials are mainly used for lower pressure drums, where fatigue is not an issue (low pressure, low thickness). While performing the EuroNorm calculation with the same inputs, but with the drum thickness as a free parameter, it is interesting to note that it features an optimum in the allowable temperature gradient (Fig. 9), which can be explained as follows. Considering the temperature profile generated over the drum thickness, thermal stress on the inner shell increases roughly as the square of the wall thickness, while mechanical stress decreases proportionally according to this thickness. Therefore, during cold start-up, the inner thermal stress quickly becomes predominant, and consequently it reduces the allowable temperature gradient. Coincidentally, the calculated wall thickness according to ASME code is typically close to this optimum wall thickness calculated according EN for material fatigue. Fig. 9 Optimum HP drum wall thickness for a typical case If the main body diameter is of importance, the nozzle diameter is not to be set aside. Whilst considering a two downcomer drum, and comparing it to a 3 or 4 downcomer equivalent drum (meaning that circulation/speed criteria are conserved), calculation results below show that the drum equipped with thicker downcomers has a better fatigue resistance: Branch diameter [mm] Branch thickness [mm] Total damage as per EN 2 downcomers (base case) 641,04 95 4,95% 3 downcomers 4 downcomers 526,52 80 6,51% 475,42 75 7,24% However, this statement is not to be generalized. Indeed, when performing the same kind of calculation with header and tube connection, the opposite could be noticed. 10 OMMI, 2008, Volume 5, Issue 1, May www.ommi.co.uk 10. Welds configuration at main body to branch on drum or superheater Three design attachments are typically used in boiler industry, each using Stress Induced Factors (SIF) as specified by the Euro Norm as follows: Nozzle set through Root not machined Root machined αm = 0,9 αm theory αm = 1,6 αm theory αm = 1 αm theory Fig. 10. Various attachment configurations of nozzles on main body It is therefore important to design the welding connections as per the most appropriate way. CMI standard design is as follows: - on drums : set-through nozzle, implemented for years (with/without internal extension) - on superheater headers : set-on nozzles/branches without root weld reappropriation whenever fatigue analysis allows it, and with ground over (i.e. stubs) when required by fatigue analysis. Note that attachments connections that are using reinforcing pads cannot be calculated whilst using EN formulas directly. Then, a finite element analysis is required by Euro Norm. For HP superheater and reheater made in alloyed steel and subject to water quenching, CMI standard for tube to header welding attachments is always set-on in full strength penetration welding (Fig. 11). This design is beyond ASME minimum requirements. But, for economizer and evaporator, partial penetration welds (Fig. 12) according ASME is proven under cycling. Fig. 11 Partial penetration welding detail Fig. 12 Full penetration welding detail 11 OMMI, 2008, Volume 5, Issue 1, May www.ommi.co.uk 11. Optimisation of boiler start-up time As noted earlier (Fig. 6), the allowable temperature gradient increases as pressure is building. These calculated temperature/time gradients are converted into pressure/time gradients as those are more accessible and controllable parameters during transients. This feature is used to optimized the start-up by applying progressive pressure ramp rates (Fig. 14), which allows optimisation of the overall boiler start-up time, without consuming any extra lifetime of the boiler. Such progressive pressure gradients are always implement into the plant DCS by CMI, either via a curve of variable controlled set points applied on the HP steam turbine by-pass valve (Fig. 13), or via various HP pressure control set points during start-up. As long as the condenser is not yet ready, the boiler relies only superheater start-up vents sized ad hoc. Only the HP drum pressure needs to be controlled, and no limitations are imposed on IP and LP circuits because those are less critical items for fatigue. However, the bottle neck of the overall cold start-up time is typically on steam turbine side, rather than on boiler side. 7 6 FSR PT001A/01B PRESS GRADIENT (BAR/MIN) SETPOINT FOR POSITIVE HP DRUM 8 5 4 3 2 1 0 0 20 40 60 80 100 120 140 H P D R U M P R E S S U R E (B A R G ) F S R P T 0 0 1 A /0 1 B Fig.13 Variable HP pressure control set point during start-up Fig. 14 Start-up curve simulation based on 3 progressive start-up ramp rates, as performed by CMI for a vertical HRSG 3 pressures behind gas turbine Alstom 13E2 from a cold condition. 12 OMMI, 2008, Volume 5, Issue 1, May www.ommi.co.uk 12. Conclusions It is good to be reminded that each new component avails a fatigue life time, and fatigue damage are always cumulative and cannot be reversed. Our main conclusions are as follows: 1. Compared to TRD 301, the Euro Norm 12952-3 improves methodology, but it is still conservative. To stick to reality, stress concentration factors could be determined by finite element analysis and used with the Euro Norm, as it is allowed by the code. 2. Branch to main components shall be engineered so as to minimize fatigue. This means that set-through arrangements are preferred for drums, whereas set-on are preferred for tube to headers arrangements. 3. Euro Norm shows that allowable pressure gradient varies with pressure. Then, boiler start-up time can be optimized without consuming fatigue lifetime by using progressive pressure gradients. This interesting feature, derived directly from a fatigue analysis, is used by CMI on a standard basis. 4. If possible, exact alternate stress values shall be obtained either by finite elements, or finite difference calculations, in order to have more representative results. 5. The sensitivity on allowable number of start, due to the logarithmic and probabilistic natures of fatigue, results in an inherent uncertainty in fatigue lifetime analysis. 6. The superheater water quenching, which remains the big cycling issue for hot start-up, especially for horizontal HRSGs, is not accounted by the Euro Norm. According to good engineering practice, efficient HP superheater and reheater drainage remains the key design point to overcome this quenching problem. 13. Acknowledgments A special thank to Mr Brueckner from Siemens for the useful information on the subject, as well as to Mrs Weber from CMI for her contribution for those fatigue calculations. 14. References [1] Euro Norm NBN EN 12952, Part 3, February 2002 ‘Water-tube boilers and auxiliary installations, design and calculation for pressure parts’ [2] David S. Moelling, P.E., Frank L.Berte, Ph.D.; Peter S. Jackson, P.E., Ph.D.; Tetra Engineering Group, Inc., Power Gen 2002 Brussels ‘Cycling Experience of Large Heat Recovery Steam Generators in the New England ISO Market’ [3] Dooley R.B., Todd A.K., Mc Naughton W., Paterson S.R., Pearson M., Shields K.J; 2002; EPRI, HRSGs Tube Failure [4] Leafton S.A.; Besuner P.M.; Grimsrud G.P. Aptech Engineering Services Inc; Platts Power Magazine; December 2002; ‘The real cost of cycling power plants’ [5] ABMA, Task Group on Cyclic Service, 2002 ‘Comparison of fatigue assessment techniques for heat recovery steam generators’ [6] Michael Pearson, Power, February 1997, ‘Warning: cycling HRSGs can be dangerous to your health’ 13 OMMI, 2008, Volume 5, Issue 1, May www.ommi.co.uk [7] ASME Boiler and Pressure Vessel Code Section I and Section VIII, Rules for construction of Pressure Vessels, ASME, New York , 2001 Edition , 2002 Addenda [8] Claxton K.J., Collier J.G., Ward J.A., November 1972 ‘H.T.F.S. correlations for two phase pressure drop and void fraction in tubes (H.T.F.S. design report 28). [9] Fontaine P., June 2003, ‘Cycling tolerance – Natural circulation vertical HRSGs’, ASME paper IJPGC 2003 - 40114 [10] Galopin J-F, 1996, ‘Dynamic Constraints on HRSG drum design’ [11] Robert Swanekamp, Platts Power Magazine, October 2002, ‘Users group to publish guidelines for operation, maintenance of HRSGs’ [12] TRD 301 Code, April 1979, ‘Zylinderschalen unter innerem Uberdruck’ [13] Michael Pearson, P Eng, J Michael Pearson & Associates Co Ltd. And Robert W Anderson, Florida Power Corp, Power Magazine, July/August 2000, ‘HRSGs – Questions about condensate quenching, prestart purging’. © The copyright of this paper is retained by CMI Energy, Belgium. 14