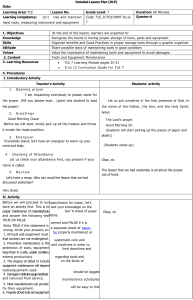

Detailed Lesson Plan (DLP) Date: Learning Area: TLE Lesson No. Learning competency: LO 1. Use and maintain hand tools, measuring instrument and equipment 1. Objectives Knowledge Skills Attitude Values 2. Content 3. Learning Resources Grade Level: 7 Code: TLE_ICTCS7/8MT-0c-d1 Duration: 60 Minutes Quarter: 4 At the end of the lesson, learners are expected to: Recognize the boons in having proper storage of tools, parts and equipment Organize benefits and Good Practices in proper storage tools through a graphic organizer Share possible ways of maintaining tools in good condition Value the importance of maintaining tools and equipment to avoid damages. Tools and Equipment Maintenance • TLE 7 Learning Module pages 25-31 • K to 12 Curriculum Guide for TLE 7 4. Procedures I. Introductory Activity Teacher’s Activity 1. Opening prayer I am requesting everybody to please stand for the prayer. Will you please lead… (point one student to lead the prayer) 2. Greetings Good Morning Class! Before we will start, kindly pick up all the trashes and throw it inside the trashcans/bins. 3. Energizer Everybody stand; let’s have an energizer to warm up your mind and body. 4. Checking of Attendance Let us check your attendance first, say present if your name is called. 5. Review Let’s have a recap. Who can recall the lesson that we had discussed yesterday? Students’ activity Let us put ourselves in the holy presence of God. In the name of the Father, the Son, and the Holy Spirit. Amen The Lord’s prayer. Good Morning Sir. (students will start picking up the pieces of paper and plastic) (Students stood up) Okay, sir. The lesson that we had yesterday is all about the proper use of tools. Very Good. II. Activity Before we will proceed to our topic/lesson for today, let’s have an activity first. This is to test your knowledge on the proper maintenance of materials/tools. Get ¼ sheet of paper and answer the following test items. TRUE OR FALSE Write TRUE if the statement is correct and FALSE if it is wrong. Write your answers on a separate sheet of paper. 1. All tools and equipment must be properly maintained so that workers are not endangered. 2. Preventive maintenance is the systematic care and protection of tools, equipment and machines in order to keep them in a safe, usable condition, limit downtime and extend productivity. 3. The degree of detail to include regarding tools and equipment maintenance will depend on the kinds of tools/equipment used. 4. Damaged or defective equipment/tools should be tagged and removed from service. 5. Most manufacturers can provide maintenance schedules for their equipment. 6. Properly stored tools and equipment will be easy to find Okay, sir. when needed and are less likely to be lost. 7. Use bins for storing small parts is a good practice on proper storage. 8. Productivity is increased because time is not lost looking for tools, parts and equipment is one of the benefits of proper storage. III. Analysis That activity would simply rear you on what will be our lesson for today. Were you able to answer it correctly? How many of you distinguish the right thing to do? (mixed answers) Okay, you don’t need to worry about it because this time I will be teaching you all about Tools and Equipment Maintenance. IV. Abstraction TOOL AND EQUIPMENT MAINTENANCE All tools and equipment must be properly maintained so that workers are not endangered. Regulations require inspections of tools, machines and equipment before use. Now, what is preventive maintenance? We must always be aware that maintenance tasks themselves are potentially hazardous and can result in injury. The successful maintenance program is: (1) Well organized and scheduled, (2) controls hazards, (3) defines operational procedures, and (4) trains key personnel. The degree of detail to include regarding tools and equipment maintenance will depend on the kinds of tools/equipment used. Some construction equipment may have very specific inspection and maintenance requirements. Electronic equipment may have different maintenance requirements. Hand tools may require only basic maintenance. Power tools should be maintained in good working order. This may be limited to ensuring that blades/bits are replaced when needed and those guards or other safety devices are operable and any damaged electrical cords/plugs are repaired or replaced. Damaged or defective equipment/tools should be tagged and removed from service. General requirements for tools and equipment maintenance include: (1) Obtaining a copy of the maintenance schedule recommended by the manufacturer (2) Ensuring that maintenance is performed as required (3) Ensuring that the person(s) performing the maintenance are competent (e.g. licensed mechanic) (4) Specifying who is responsible for overseeing equipment maintenance and where the records are kept Set up a system for removal and tagging of damaged or defective tools and equipment PROPER STORAGE OF TOOLS, PARTS, AND EQUIPMENT To ensure that tools and equipment remain in good condition and last for a long time, store them properly. Properly stored tools and equipment will be easy to find when needed and are less likely to be lost. Preventive maintenance is the systematic care and protection of tools, equipment and machines in order to keep them in a safe, usable condition limit downtime and extend productivity. Good practices include: • Parts should be properly stored and labeled. • Tools should be properly placed on the board, and labeled. Consider drawing the shapes of the tools on the board so that they always get put back in the same position. • Use bins for storing small parts • Consider making an individual (or individuals) responsible for the good maintenance of tools and parts. So what do you think the benefits of having proper storage of tools? Okay, nice idea. However, we have set here list of benefits to (Mixed answers). note for: • Tools and parts are kept in good condition and are easy to find • Costs are reduced. • Productivity is increased because time is not wasted looking for tools, parts and equipment. • Workshop staffs develop a sense of responsibility and pride in their work. V. Application GRAPHIC ORGANIZER Discuss the benefits and Good Practices in proper storage tools through graphic organizer. Write this in a ½ crosswise. Use the template below. Okay, sir. Proper Storage of Tools Good Practices Benefits VI. Assessment Answer the following right using ½ sheet of paper. TRUE OR FALSE Write TRUE if the statement is correct and FALSE if it is wrong. Write your answers on a separate sheet of paper. 1. All tools and equipment must be properly maintained so that workers are not endangered. 2. Preventive maintenance is the systematic care and protection of tools, equipment and machines in order to keep them in a safe, usable condition, limit downtime and extend productivity. 3. The degree of detail to include regarding tools and equipment maintenance will depend on the kinds of tools/equipment used. 4. Damaged or defective equipment/tools should be tagged and removed from service. 5. Most manufacturers can provide maintenance schedules Okay sir. We will do it right away. for their equipment. 6. Properly stored tools and equipment will be easy to find when needed and are less likely to be lost. 7. Use bins for storing small parts is a good practice on proper storage. 8. Productivity is increased because time is not lost looking for tools, parts and equipment is one of the benefits of proper storage. VII. Assignment To further retain the information I had given you today, study this lesson at home and prepare for an oral and a follow up quiz tomorrow. Remarks: Prepared by: DIONESIO O. CABUYAO JR. Student Teacher Checked By: ROXANE C. PAGARAN Resource Teacher School: Inayagan National High School Division: City of Naga, Cebu Okay sir, we will.