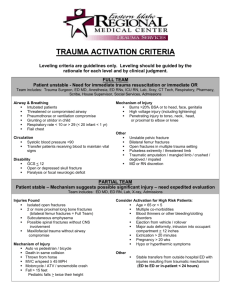

Injury, Int. J. Care Injured 47S7 (2016) S20–S24 Contents lists available at ScienceDirect Injury j o u r n a l h o m e p a g e : w w w. e l s e v i e r . c o m / l o c at e / I n j u r y Biomechanical testing to evaluate the cut-through resistance of intramedullary nails for the proximal humerus Maximilian Wanzla,*, Peter Foehrb, Ulrich Schreiberc, Rainer H. Burgkartb, Andreas Lenicha a Department of Orthopaedic Sports Surgery, Klinikum rechts der Isar, Technische Universität München, Munich, Germany Department of Orthopaedics and Sportsorthopaedics, Klinikum rechts der Isar, Technische Universität München, Munich, Germany University of Applied Science Munich, Munich, Germany b c K E Y W O R D S A B S T R A C T proximal humerus fracture Intramedullary nailing for stabilization of proximal humeral fractures is well-established. Complications as part of a cut-through, such as backing out of locking screws, loss of reduction, and perforation of the screws into the glenoid, are equally well-known. The test bench presented in this study enables testing of the cut-through behavior of multiple intramedullary implants on a simulated osteoporotic three-part fracture configuration with three different loading circumstances (A, B and C). In situation A, the glenohumeral dynamic force with progressive loadings entered at an angle of 15° to the humeral shaft. In situation B the force entered at an angle of 35° and in situation C the angle measured 55°. Three different types of nails were tested: the Targon PH with the optimal proximal screw length (T) and with all four proximal screws shortened (Tshort), the Synthes MultiLoc PHN with (S5) and without (S4) the additional calcar screw and, lastly, the PolyAxNail PH, a polyaxial intramedullary nail, in a neutral screw configuration (PAN) and a version with diametrically opposed crossed first and fourth locking screws (PAN10). Significant differences in the three cases were found with the evaluation of the failure load, which represents the cut-through resistance. Case A: Tshort (245.4 ± 18.7 N) – S4 (346.8 ± 18.0 N) (adjusted p = 0.002); Tshort (245.4 ± 18.7 N) – S5 (368.5 ± 12.0 N) (adjusted p = <0.001); Tshort (245.4 ± 18.7 N) – T (323.5 ± 38.2 N) ( p = 0.004); Case B: no significant differences between the study groups (adjusted significance). Case C: PAN (412.5 ± 16.0 N) – S5 (471.5 ± 21.5 N) (adjusted p = 0.007); T (414.0 ± 33.5 N) – S5 (471.5 ± 21.5 N) (adjusted p = 0.008). The optimal screw length has a strong influence on the failure load. Choosing proximal screws that are too short, produces a negative impact on the cut-through resistance. The additional calcar screw of the MultiLoc PHN and the polyaxiality of the PolyAxNail showed a positive effect with regard to the failure load reached. © 2016 Elsevier Ltd. All rights reserved. intramedullary nailing biomechanical testing cut-through Introduction Fractures of the proximal humerus are the third most common fractures found in the elderly population [1]. According to CourtBrown et al. [2], the average age of patients is approximately 66 years, with a higher percentage of afflicted women than men. The authors report an increasing incidence with higher age. Additionally, an increase in incidence over the last decades is reported [3,4]. Osteoporosis seems to be a strong risk factor for fractures of the proximal humerus [5]. Stable fractures with little or no dislocation can be treated conservatively. Unstable and displaced fractures on the other hand, represent a clear indication for operative intervention [6]. Tepass et al. [7] recommend * Corresponding author at: Maximilian Wanzl. Tel: +49 17632542895. E-mail address: m.wanzl@t-online.de (M. Wanzl). 0020-1383 / © 2016 Elsevier Ltd. All rights reserved. plates and intramedullary nails, followed by fracture prosthesis for the majority of surgical procedures. While the prosthetic restoration is mainly used for luxation fractures, multi segment fractures, and fractures with a head-split component, for two- to four-part fractures, both plates and nailing systems are being used [8]. The use of intramedullary nailing for stabilization of proximal humeral fractures has been expanded with good results through more sophisticated locking methods [9–12]. Implant associated complications, attributed to the cut-through phenomenon, however, continue to pose a challenge. These include complications like backing out or cutting out of locking screws, loss of reduction, and perforation of the screw into the glenoid [11–15]. Recent biomechanical studies have broached these complications, however, there are only few studies which cover the testing and evaluation of different intramedullary implants and their cut-through behavior [16–18]. The selected load cases usually correspond to in-vivo and in-vitro studies of the biomechanics of the shoulder [19–22]. M. Wanzl et al. / Injury, Int. J. Care Injured 47S7 (2016) S20–S24 A dynamic fatigue test determines the cut-through behavior in terms of the failure load of three different intramedullary implants fixating a three-segment fracture. Unlike the aforementioned studies, which simulated only a singular load case with a fixed glenohumeral force application, the herein study considers an abduction movement divided into three separate load cases (Cases A, B and C). This corresponds to a postoperative abduction, starting from the neutral position (Case C) and reaching an abduction of 90° (Case A). By using an artificial bone in connection with a standardized three-segment fracture, this study can be easily reproduced. The three intramedullary implants are used to investigate the following questions: The Targon PH (Proximal Humerus Nail, Aesculap, Tuttlingen, Germany) is used to determine the impact of short screw lengths while the Synthes MultiLoc PHN (Proximal Humerus Nail, Synthes, Oberdorf, Switzerland) is used to test an additional ascending calcar screw. The impact of a polyaxial locking mechanism is tested using the PolyAxNail PH (OT Medizintechnik, Munich, Germany). Materials and methods Three different standard proximal humeral nails were examined for their cut-through behavior based on the failure load under a dynamic sinusoidal force with progressive loadings. The artificial bone model for the proximal part was a polyurethane foam with a density of ρ = 80 kg/m3 (Puren GmbH, Überlingen, Germany) and the model for the distal part was a rigid polyamide shaft. The cut-through is defined in the displacement of the humeral head in the direction of the force vector and therefore describes the movement of the proximal screws into the glenohumeral joint. The dimensions of a human humerus were derived from CT-Data and transferred into the artificial bone model. A three-segment fracture was simulated for the humeral head and the greater tuberosity, whereas the fragments had no cortical bone layer and a large fracture gap without medial support. The implantation position of each implant was detected based on virtual implantations of all study groups on the segmented humerus [23]. The optimal screw length of each proximal screw was measured with the tip of the screw 3 mm from the articular surface. This virtual implantation was done in accordance with the manufacturers OR manually. The position of the intramedullary nail, as well as the position of the screws, was then transferred to the test specimen. The intramedullary nails were subsequently placed into the test specimen with a standardized implantation jig. The following three intramedullary nails were tested: Targon PH (Aesculap, Tuttlingen, Germany) in a version with an optimal screw length for the four proximal locking screws and in a short version with 8 mm shortened screws; the MultiLoc PHN (Synthes, Oberdorf, Switzerland) in two versions with four proximal locking screws and an additional ascending calcar screw; and lastly, PolyAxNail PH (Polyaxial Proximal Humerus Nail, OT Medizintechnik, Munich, Germany) in a version with the four proximal screws in neutral screw positions at an angle of 90° to the longitudinal axis of the nail and in a version with the first and fourth proximal screw mirrorinverted 10° horizontally. This resulted in six study groups (Figure 1): T = Targon PH, Tshort = Targon PH with 8 mm shortened screws, S4 = MultiLoc PHN four proximal screws, S5 = MultiLoc PHN four proximal screws and an additional calcar screw, PAN = PolyAxNail PH neutral screw position, PAN10 = PolyAxNail PH with entanglement. Three biomechanical situations of glenohumeral force entry with A (15°), B (35°) and C (55°) were defined, according to studies by Bergmann et al. [19,20]. Accordingly, situation A (15°) corresponds to an arm abduction of approximately 90°, situation B (35°) corresponds to an abduction of about 45° and situation C (55°) corresponds to a neutral arm position. With the exception of Tshort tested only in 15° (A), the implants were tested in the study groups in all three cases, with a minimum number of n = 5 experiments. For each experiment, a new biomechanical test specimen was used. The artificial bone specimens S21 Fig. 1. Intramedullary nails and their tested screw configurations: T = Targon PH; Tshort = Targon PH with 8 mm shortened screws; S4 = MultiLoc PHN with four proximal screws; S5 = MultiLoc PHN with four proximal screws and an additional calcar screw; PAN = PolyAxNail PH neutral screw positon; PAN10 = PolyAxNail PH with entanglement; *1 calcar screw (S5). were exposed to a cyclic sinusoidal force with progressive loading stages using the uniaxial dynamic test system Zwick HC10 (Zwick/Roell GmbH, Ulm, Germany) (Figures 2 and 3). After a linear displacement controlled ramp-up to a maximum load of 50 N, a sinusoidal force controlled loading phase was applied, starting at mid-load value of 50 N with an amplitude of 10% and a frequency of 5 Hz. Every 250 cycles the step-by-step increase of the force’s mean value was increased by 10 N. Once a mean force value of 200 N was reached, the step-by-step increase was reduced to 5 N. The cut off criterion was set at a transversal dislocation of the humeral head of 5 mm or the achievement of a mean force value of 500 N. The axial force was measured using a 2 kN load cell of the type 1010 AF 2KN (Huppert GmbH, Herrenberg, Germany). Using the machine configuration software testXpert R (Zwick/Roell GmbH, Ulm, Germany) the axial load [N] and the dislocation [mm] were detected for every tenth cycle. The statistical analysis of the failure load was performed with SPSS Statistics 22.0/23.0 (IBM, Armonk, United States). The normal distribution was calculated using the Kolmogorov-Smirnov or the ShapiroWilk test and the normal distribution charts. The Kruskal-Wallis test with a subsequent pairwise 2-sided test was used to examine differences within the three biomechanical cases and the study Fig. 2. Test set up: (*1) load cell; (*2) X-Y-Mz-Compensator; (*3) piston with ball joint; (*4) artificial osteoporotic humeral head segment; (*5) humeral shaft in fixation unit; (*6) digital photo camera; (α) 35° glenohumeral load (Case B). S22 M. Wanzl et al. / Injury, Int. J. Care Injured 47S7 (2016) S20–S24 Fig. 5. Distribution of failure load Case B (35°). The Kolmogorov-Smirnov test showed a normal distribution of the failure load over all study groups. Statistical analysis of the failure load shows significant differences between the study groups for the biomechanical situations A and C. The highest average failure load over all three cases was observed for the MulitLoc S5 with the additional calcar screw (Case A: 368.5 ± 12 N; Case B: 421.3 ± 13.4 N; Case C: 471.5 ± 21.5 N) (Figures 4–6; Table 1). The distribution of the failure load shows a highly significant difference between the study groups ( p < 0.001) for situation A (15°). The pairwise comparisons deliver the following results: There is a significant increase of the average failure load between Tshort - S4* (adjusted p = 0.002) by 101.4 N and Tshort - S5** (adjusted p < 0.001) by 123.1 N. For all other combinations, no significant differences were observed. Looking separately at the mating T (323.5 ± 38.2 N) – Tshort (245.4 ± 18.7 N) reaching a difference of 78.1 N, extracted from the multiple comparison with the other implants a significance ( p = 0.004) was observed between T - Tshort***. The mating S4 (346.8 ± 18.0 N) – S5 (368.5 ± 12.0 N) shows a difference of 21.7 N and PAN (289.0 ± 34.4 N) – PAN10 (307.5 ± 38.1 N) had a difference of 18.5 N. (Figure 4; Table 1) The pairwise comparisons for situation B (35°) do not show significant differences between the study groups. The results for the average failure load of the different mating are: S4 (403.7 ± 26.0 N) – S5 (421.3 ± 13.4 N) with a difference of 17.6 N and PAN (380.7 ± 44.9 N) – PAN10 (378.7 ± 26.0 N) with a difference of 2 N. The Targon PH has reached an average failure load of 376.1 ± 11.2 N (Figure 5; Table 1). Fig. 4. Distribution of failure load Case A (15°). Fig. 6. Distribution of failure load Case C (55°). Fig. 3. Test set up (close-up) three-part fracture with fracture gap: (*1) piston with ball joint; (*2) artificial osteoporotic humeral head segment; (*3) artificial osteoporotic tuberculum majus segment; (*4) intramedullary nail; (*5) humeral shaft in fixation unit groups contained therein. The p-value was specified as an adjusted p-value due to multiple comparisons. The level of significance used across all tests had a value of 0.05. Results M. Wanzl et al. / Injury, Int. J. Care Injured 47S7 (2016) S20–S24 S23 Table 1. Failure load of each study group (Case A, B and C) Case A (15°) T Tshort S4 S5 PAN PAN 10 Case B (35°) Case C (55°) AV [N] SD [N] AV [N] SD [N] AV [N] SD [N] 323.5 245.4 346.8 368.5 289.0 307.5 38.2 18.7 18.0 12.0 34.4 38.1 376.1 – 403.7 421.3 380.7 378.7 11.2 – 26.0 13.4 44.9 26.0 414.0 – 444.0 471.5 412.5 442.9 33.5 – 22.0 21.5 16.0 9.2 The distribution of the failure load of situation C (55°) shows a significant difference for the study groups ( p = 0.004). Adjusted significant differences arise between the groups in pairwise comparison. The mating PAN - S5* (adjusted p = 0.007) shows an increase of the failure load by 59.0 N and the mating T - S5** (adjusted p = 0.008) an increase by 57.5 N. For all other combinations of situation C (55°) no statistically significant differences were observed. The results for the average failure load of the mating are: S4 (444.0 ± 22.0 N) – S5 (471.5 ± 21.5 N) with a difference of 27.5 N and PAN (412.5 ± 16.0 N) – PAN10 (442.9 ± 9.2 N) with a difference of 30.4 N (Figure 6; Table 1). Discussion Intramedullary nailing of the fractured proximal humerus has reached a large indication spectrum and is being used successfully [10,11,15,24–29]. Complications in terms of cut-through, however, still remain a major problem. Our presented method, therefore, tests the cut-through behavior of different intramedullary nails under postoperative and physiological load application. The defined situations A, B and C cover a whole abduction cycle from a neutral arm position to a maximum abduction of 90°. Whereas situation A (15°) corresponds to an arm abduction of approximately 90°, situation B (35°) corresponds to an abduction of about 45° and situation C (55°) corresponds to a neutral arm position. A homogenous artificial bone model was used to achieve the best possible quantitative comparison of the resulting load stages between the test groups. This resulted in a maximum standard deviation of 44.9 N. No major differences could be seen in the failure load of the individual implants while comparing the biomechanical situations A, B and C and the simulated abduction. The highest failure load value was reached by the Synthes MultiLoc S5 with the additional calcar screw, followed by the S4. The influence of the selection of too short proximal locking screws is examined on the basis of the Targon PH in case A (15°). Optimal screw lengths are chosen for the variant T. In the case of Tshort, all proximal screws are implanted with a distance shortened by 8 mm. The average failure load is thereby reduced by approximately 78.1 N. In the multiple pairwise comparisons, however, no statistically significant differences are found. If considering a separately examination of the influence of shortened screw length by the mating T – Tshort extracted from the context of multiple comparison, a significant difference is found ( p = 0.004). From a clinical point of view, stability problems resulting from inadequate screw lengths of selected screws that are too short seem to be obvious. As discovered by Lill et al. and Liew et al. the length and subchondral positioning of the screws have a direct and positive influence on the pull-out force [30,31]. In this context and with these test results we can additionally mention a higher cut-through resistance with the optimal subchondral screw length. Current literature reports increased medial stability by using calcar screws in the treatment of proximal humeral fractures [32–34]. Also in our test setup the study group S5 of MultiLoc PHN achieved the highest failure load values across all three biomechanical loading cases. In pairwise comparison with the variant S4 however, no significant differences can be detected. A biomechanical study of Rothstock et al. [17] provides similar results, with the S5 achieving the highest number of cycles to failure load. The authors could not show any significant differences in terms of number of cycles to failure load, using an additional calcar screw. Therefore they compared the MultiLoc PHN with two screw-in-screw in the first and second proximal screw with and without an additional calcar screw. Both versions had no third proximal screw set. Polyaxial locking methods are already used in plate osteosynthesis and provide both biomechanically and clinically comparable results [35–37]. Freely positioned screws with angle stability are considered beneficial. The tests conducted in this study also show values for the failure load of a polyaxial implant compared to those of conventional implants. Even though no statistically significant difference is found between the PAN10 with entanglement and the PAN with neutral screw position, the failure load did increase when using the crossed version PAN10. In addition to these findings, the authors conclude that the polyaxial locking could offer an additional positive influence compared to conventional implants, if bone areas with higher density and stability can be reached with a free orientation and positioning of the locking screws [31,38,39]. Conclusion Intramedullary nailing is currently successfully used for the treatment of fractured proximal humeri. In this study, a testing method was developed to investigate the cutting-through phenomena in proximal humeri with osteosynthesis. The presented model matches the typical implantation conditions: a three-segment fracture of osteoporotic bone without cortical support with a large medial non-contact fragment zone. The simulation of a physiological glenohumeral force entry is ensured through three biomechanical loading situations. No major differences with regard to the failure load and the glenohumeral force entry are noted across all implants: Targon PH, MultiLoc PHN and PolyAxNail PH. However, the choice of the screw length tends to have a strong influence on the stability of the implantbone interface. Extra screws, like the calcar screw of the Synthes MultiLoc PHN or the use of a polyaxial locking mechanism of the PolyAxNail PH, also have a positive impact on a higher failure load. Conflict of interest The authors declare no conflict of interest. Acknowledgments We thank all contributing students involved in this project for their effort (especially to P. Kutschera and F. Franz). Special thanks to the Institute for Medical Statistics and Epidemiology (IMSE), Klinikum rechts der Isar, Technische Universität München, Munich Germany, for their statistical analyses support. S24 M. Wanzl et al. / Injury, Int. J. Care Injured 47S7 (2016) S20–S24 References [1] Court-Brown CM, Caesar B. Epidemiology of adult fractures: a review. Injury 2006;37:691–7. [2] Court-Brown CM, Garg A, McQueen MM. The epidemiology of proximal humeral fractures. Acta Orthop Scand 2001;72:365–71. [3] Palvanen M, Kannus P, Niemi S, Parkkari J. Update in the epidemiology of proximal humeral fractures. Clin Orthop Rel Res 2006;442:87–92. [4] Bahrs C, Bauer M, Blumenstock G, Eingartner C, Bahrs SD, Tepass A, et al. The complexity of proximal humeral fractures is age and gender specific. J Orthop Sci 2013;18:465–70. [5] Kelsey JL, Browner WS, Seeley DG, Nevitt MC, Cummings SR. Risk factors for fractures of the distal forearm and proximal humerus. The Study of Osteoporotic Fractures Research Group. Am J Epidemiol 1992;135:477–89. [6] Hessmann MH, Rommens PM. [Osteosynthesis techniques in proximal humeral fractures]. Chirurg 2001;72:1235–45. [7] Tepass A, Blumenstock G, Weise K, Rolauffs B, Bahrs C. Current strategies for the treatment of proximal humeral fractures: an analysis of a survey carried out at 348 hospitals in Germany, Austria, and Switzerland. J Shoulder Elbow Surg 2013;22: e8–14. [8] Loitz D, Reilmann H. Frakturen des Humeruskopfes. Der Chirurg 2001;72:1514–29. [9] Blum J, Hansen M, Rommens PM. [Angle-stable intramedullary nailing of proximal humerus fractures with the PHN (proximal humeral nail)]. Oper Orthop Traumatol 2009;21:296–311. [10] Mathews J, Lobenhoffer P. The Targon PH nail as an internal fixator for unstable fractures of the proximal humerus. Oper Orthop Traumatol 2007;19:255–75. [11] Mittlmeier TWF, Stedtfeld HW, Ewert A, Beck M, Frosch B, Gradl G, et al. Stabilization of proximal humeral fractures with an angular and sliding stable antegrade locking nail (Targon PH). J Bone Joint Surg Am 2003;85-A(Suppl 4):136–46. [12] Gradl G, Dietze A, Arndt D, Beck M, Gierer P, Borsch T, et al. Angular and sliding stable antegrade nailing (Targon PH) for the treatment of proximal humeral fractures. Arch Orthop Trauma Surg 2007;127:937–44. [13] Konrad G, Audige L, Lambert S, Hertel R, Sudkamp NP. Similar outcomes for nail versus plate fixation of three-part proximal humeral fractures. Clin Orthop Rel Res 2012;470:602–9. [14] Adedapo AO, Ikpeme JO. The results of internal fixation of three- and four-part proximal humeral fractures with the Polarus nail. Injury 2001;32:115–21. [15] Agel J, Jones CB, Sanzone AG, Camuso M, Henley MB. Treatment of proximal humeral fractures with Polarus nail fixation. J Shoulder Elbow Surg 2004;13:191–5. [16] Brianza S, Plecko M, Gueorguiev B, Windolf M, Schwieger K. Biomechanical evaluation of a new fixation technique for internal fixation of three-part proximal humerus fractures in a novel cadaveric model. Clin Biomech (Bristol, Avon) 2010;25:886–92. [17] Rothstock S, Plecko M, Kloub M, Schiuma D, Windolf M, Gueorguiev B, et al. Biomechanical evaluation of two intramedullary nailing techniques with different locking options in a three-part fracture proximal humerus model. Clin Biomech (Bristol, Avon) 2012; 27:686–91. [18] Schiuma D, Plecko M, Kloub M, Rothstock S, Windolf M, Gueorguiev B, et al. Influence of peri-implant bone quality on implant stability. Med Eng Phys 2013;35:82–7. [19] Bergmann G, Graichen F, Bender A, Kääb M, Rohlmann A, Westerhoff P, et al. In vivo glenohumeral contact forces—measurements in the first patient 7 months postoperatively. J Biomech 2007;40:2139–49. [20] Bergmann G, Graichen F, Bender A, Rohlmann A, Halder A, Beier A, et al. In vivo glenohumeral joint loads during forward flexion and abduction. J Biomech 2011;44:1543–52. [21] Westerhoff P, Graichen F, Bender A, Halder A, Beier A, Rohlmann A, et al. In vivo measurement of shoulder joint loads during activities of daily living. J Biomech 2009;42:1840–9. [22] Poppen NK, Walker PS. Forces at the glenohumeral joint in abduction. Clin Orthop Rel Res 1978;135:165–70. [23] Harnoß TM. Morphologische 3D Analyse der anatomischen Lage von drei Marknagelmodellen zur Versorgung proximaler Humerusfrakturen. Technische Universität München. 2011. Accessible at: http://nbn-resolving.de/urn/resolver.pl?urn: nbn:de:bvb:91-diss-20110721-1081628-1-3. [24] Murray IR, Amin AK, White TO, Robinson CM. Proximal humeral fractures: current concepts in classification, treatment and outcomes. J Bone Joint Surg Br 2011;93:1–11. [25] Kloub M, Holub K, Polakova S. Nailing of three- and four-part fractures of the humeral head — long-term results. Injury 2014;45(Suppl 1):S29–37. [26] Baltov A, Mihail R, Dian E. Complications after interlocking intramedullary nailing of humeral shaft fractures. Injury 2014;45(Suppl 1):S9–15. [27] Stedtfeld HW, Biber R. Proximal third humeral shaft fractures — a fracture entity not fully characterized by conventional AO classification. Injury 2014;45(Suppl 1):S54–9. [28] Spiegelberg BG, Riley ND, Taylor GJ. Risk of injury to the axillary nerve during antegrade proximal humeral blade nail fixation - an anatomical study. Injury 2014;45:1185–9. [29] Caforio M, Maniscalco P, Colombo M, Calori GM. Long endomedullary nail in proximal third humeral shaft fractures. Injury 2016;47(Suppl 4):S64–S70. [30] Lill H. Die proximale Humerusfraktur. Berlin [u.a.]: Springer; 2014. XI, 232 S. p. [31] Liew AS, Johnson JA, Patterson SD, King GJ, Chess DG. Effect of screw placement on fixation in the humeral head. J Shoulder Elbow Surg 2000;9:423–6. [32] Gardner MJ, Weil Y, Barker JU, Kelly BT, Helfet DL, Lorich DG, et al. The importance of medial support in locked plating of proximal humerus fractures. J Orthop Trauma 2007;21:185–91. [33] Osterhoff G, Ossendorf C, Wanner GA, Simmen HP, Werner CM. The calcar screw in angular stable plate fixation of proximal humeral fractures–a case study. J Orthop Surg Res 2011;6:50. [34] Zhang L, Zheng J, Wang W, Lin G, Huang Y, Zheng J, et al. The clinical benefit of medial support screws in locking plating of proximal humerus fractures: a prospective randomized study. Int Orthop 2011;35:1655–61. [35] Zettl R, Muller T, Topp T, Lewan U, Kruger A, Kuhne C, et al. Monoaxial versus polyaxial locking systems: a biomechanical analysis of different locking systems for the fixation of proximal humeral fractures. Int Orthop 2011;35:1245–50. [36] Ockert B, Braunstein V, Kirchhoff C, Korner M, Kirchhoff S, Kehr K, et al. Monoaxial versus polyaxial screw insertion in angular stable plate fixation of proximal humeral fractures: radiographic analysis of a prospective randomized study. J Trauma 2010;69: 1545–51. [37] Voigt C, Geisler A, Hepp P, Schulz AP, Lill H. Are polyaxially locked screws advantageous in the plate osteosynthesis of proximal humeral fractures in the elderly? A prospective randomized clinical observational study. J Orthop Trauma 2011;25:596–602. [38] Hepp P, Lill H, Bail H, Korner J, Niederhagen M, Haas NP, et al. Where should implants be anchored in the humeral head? Clin Orthop Rel Res 2003;415:139–47. [39] Lill H, Hepp P, Gowin W, Oestmann JW, Korner J, Haas NP, et al. [Age- and gender-related distribution of bone mineral density and mechanical properties of the proximal humerus]. RoFo: Fortschritte auf dem Gebiete der Rontgenstrahlen und der Nuklearmedizin 2002;174:1544–50.