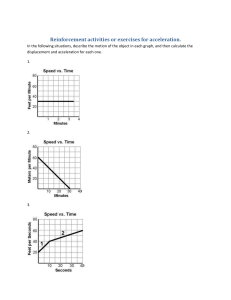

A. Spring Helical extension springs appear to be similar to compression springs, having a series of coils wrapped into a cylindrical form. However, in extension springs, the coils either touch or are closely spaced under the no-load condition. Then as the external tensile load is applied, the coils separate. The drawbar spring incorporates a standard helical compression spring with two looped wire devices inserted through the inside of the spring. With such a design, a tensile force can be exerted by pulling on the loops while still placing the spring in compression. A torsion spring, as the name implies, is used to exert a torque as the spring is deflected by rotation about its axis. Leaf springs are made from one or more flat strips of brass, bronze, steel, or other materials loaded as cantilevers or simple beams. They can provide a push or a pull force as they are deflected from their free condition. A Belleville spring has the shape of a shallow, conical disk with a central hole. It is sometimes called a Belleville washer because its appearance is similar to that of a flat washer. A very high spring rate or spring force can be developed in a small axial space with such springs Garter springs are coiled wires formed into a continuous ring shape so that they exert a radial force around the periphery of the object to which they are applied. Constant-force springs take the form of a coiled strip. The force required to pull the strip off the coil is virtually constant over a long length of pull. The magnitude of the force is dependent on the width, thickness, and radius of curvature of the coil and on the elastic modulus of the spring material. Power springs, sometimes called motor or clock springs, are made from flat spring steel stock, wound into a spiral shape. A torque is exerted by the spring as it tends to unwrap the spiral. v. B. Simple Stresses i. ii. iii. iv. Tensile Stress is the ratio of a stretching force acting on a material to the cross-sectional area of that material. It is the force per unit area that is putting an object in tension. Compressive Stress - Compressive means the material is under compression and that there are forces acting on it trying to compress the material. Bearing stress is the contact pressure between the separate bodies. It differs from compressive stress, as it is an internal stress caused by compressive forces. Shear Stress - A type of stress that acts coplanar with cross section of material. vi. Bending/Flexure Stress is the internal resistance generated within a component when an external bending moment or force is applied. Torsional Stress is a form of shear stress experienced by a body when a twisting force is applied. C. Thin-Walled Cylinder i. ii. iii. ii. Tangential Stress (Circumferential Stress) Longitudinal Stress Spherical Cylinders iii. D. Kinematics i. ii. iii. iv. v. vi. vii. viii. MECHANICS – deals with the relations among force, matter, and motion. KINEMATICS – the part of mechanics concerned with describing motion. MOTION – is a continuous change of position. VELOCITY - The velocity of a body is a vector quantity that describes both how fast it is moving and the direction in which it is headed. The magnitude of a velocity is sometimes called speed. ACCELERATION - The acceleration of a body is the rate at which its velocity is changing. - Acceleration is the second derivative of displacement. AVERAGE ACCELERATION - The average acceleration of the particle as it moves from a point to another is defined as the ratio of the change in velocity to the elapsed time. INSTANTANEOUS ACCELERATION - The instantaneous acceleration of a body is its acceleration at some one instant of time or at some one point of its path. Projectile motion is the motion of an object thrown or projected into the air, subject to only the acceleration of gravity. The object is called a projectile, and its path is called its trajectory. E. Newton’s Law of Motion i. FIRST LAW OF MOTION A body at rest will remain at rest, and a body in motion will continue to move with constant velocity if there is no force acting on it. ii. SECOND LAW OF MOTION If a net force F acts on an object of mass m, the object will have acceleration a. iii. THIRD LAW OF MOTION To every action there opposed and equal reaction. iv. is always CENTRIPETAL FORCE is a net force that acts on an object to keep it moving along a circular path. v. ROTATION F. Oscillation and Simple Harmonic Motion i. Oscillation is defined as the process of repeating variations of any quantity or measure about its equilibrium value in time. iv. v. vi. vii. viii. ix. Vibration is used to describe the mechanical oscillations of an object. A particle being vibrated means it oscillate between two points about its central point. Sine wave is a perfect example of oscillation. Here the wave moves between two points about a central value. Amplitude (A) is the height or the maximum distance that the oscillation takes place Period (T) is the time taken to complete one complete cycle Frequency (F) is the number of complete cycles that occur in a second. Frequency is the reciprocal of the time period. Restoring Force - when an elastic object such as a spring is stretched or compressed, a restoring force appears that tries to return the object to its normal length. Hooke's Law - the restoring force Fr is proportional to the displacement x provided the elastic limit is not exceeded. Simple Harmonic Motion is periodic motion that occurs when the restoring force on a body displaced from an equilibrium position is proportional to the displacement and in the opposite direction.