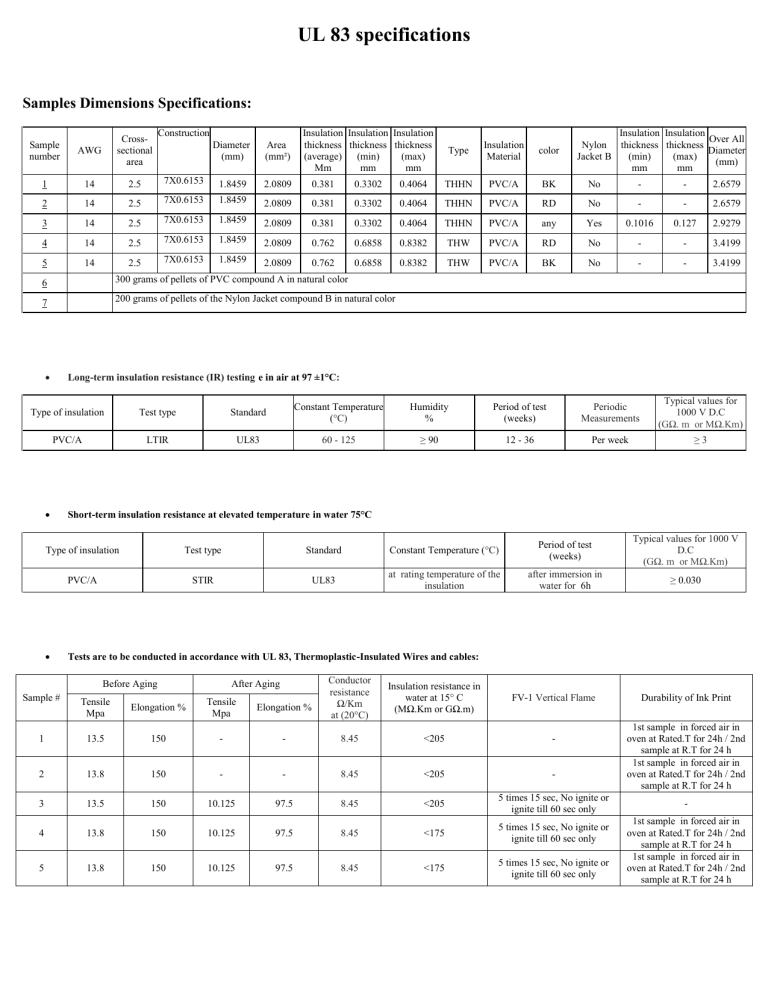

UL 83 specifications Samples Dimensions Specifications: Sample number AWG Crosssectional area 1 14 2.5 2 14 3 14 4 14 5 14 Construction Insulation Insulation Insulation thickness thickness thickness (average) (min) (max) Mm mm mm Diameter (mm) Area (mm²) 7X0.6153 1.8459 2.0809 0.381 0.3302 2.5 7X0.6153 1.8459 2.0809 0.381 2.5 7X0.6153 1.8459 2.0809 2.5 7X0.6153 1.8459 2.5 7X0.6153 1.8459 Insulation Material color 0.4064 THHN PVC/A BK No - - 2.6579 0.3302 0.4064 THHN PVC/A RD No - - 2.6579 0.381 0.3302 0.4064 THHN PVC/A any Yes 0.1016 0.127 2.9279 2.0809 0.762 0.6858 0.8382 THW PVC/A RD No - - 3.4199 2.0809 0.762 0.6858 0.8382 THW PVC/A BK No - - 3.4199 6 300 grams of pellets of PVC compound A in natural color 7 200 grams of pellets of the Nylon Jacket compound B in natural color Insulation Insulation Over All Nylon thickness thickness Diameter Jacket B (min) (max) (mm) mm mm Type Long-term insulation resistance (IR) testing e in air at 97 ±1°C: Type of insulation Test type Standard Constant Temperature (°C) Humidity % Period of test (weeks) Periodic Measurements Typical values for 1000 V D.C (GΩ. m or MΩ.Km) PVC/A LTIR UL83 60 - 125 ≥ 90 12 - 36 Per week ≥3 Short-term insulation resistance at elevated temperature in water 75°C Type of insulation Test type Standard Constant Temperature (°C) Period of test (weeks) Typical values for 1000 V D.C (GΩ. m or MΩ.Km) PVC/A STIR UL83 at rating temperature of the insulation after immersion in water for 6h ≥ 0.030 Tests are to be conducted in accordance with UL 83, Thermoplastic-Insulated Wires and cables: Before Aging Sample # Tensile Mpa 1 After Aging Conductor resistance Ω/Km at (20°C) Insulation resistance in water at 15° C (MΩ.Km or GΩ.m) FV-1 Vertical Flame Elongation % Tensile Mpa Elongation % 13.5 150 - - 8.45 <205 - 2 13.8 150 - - 8.45 <205 - 3 13.5 150 10.125 97.5 8.45 <205 5 times 15 sec, No ignite or ignite till 60 sec only 4 13.8 150 10.125 97.5 8.45 <175 5 times 15 sec, No ignite or ignite till 60 sec only 5 13.8 150 10.125 97.5 8.45 <175 5 times 15 sec, No ignite or ignite till 60 sec only Durability of Ink Print 1st sample in forced air in oven at Rated.T for 24h / 2nd sample at R.T for 24 h 1st sample in forced air in oven at Rated.T for 24h / 2nd sample at R.T for 24 h 1st sample in forced air in oven at Rated.T for 24h / 2nd sample at R.T for 24 h 1st sample in forced air in oven at Rated.T for 24h / 2nd sample at R.T for 24 h Continue tests Permittivity Sample # Flexibility 1 - 2 - immersed in water 24h at the wetrated temperature, 60°C, 75°C, or 90°C <10 immersed in water 24h at the wetrated temperature, 60°C, 75°C, or 90°C <10 at 121°C, 7d aged, 4 turns around mandrel 8mm 4 at 121°C, 7d aged, 4 turns around mandrel 8mm 5 Heat Shock Test At136°C, 7d aged, 4 turns around mandrel 8mm 3 The capacitance after immersion for 14 d shall not be more than 10 percent higher than the capacitance after 24 h immersion. The capacitance after immersion for 14 d shall not be more than 10 percent higher than the capacitance after 24 h immersion. - immersed in water 24h at the wetrated temperature, 60°C, 75°C, or 90°C <10 immersed in water 24h at the wetrated temperature, 60°C, 75°C, or 90°C <10 The capacitance after immersion for 14 d shall not be more than 10 percent higher than the capacitance after 24 h immersion. The capacitance after immersion for 14 d shall not be more than 10 percent higher than the capacitance after 24 h immersion. - conditioning in an air-circulating oven for 1 h to a temperature of 121 ±1°C / 4 turns around mandrel 3mm conditioning in an air-circulating oven for 1 h to a temperature of 121 ±1°C / 4 turns around mandrel 3mm conditioning in an air-circulating oven for 1 h to a temperature of 121 ±1°C / 4 turns around mandrel 3mm Continue tests Cold Bend Test Abrasion Impact Resistance Crush Resistance - - - - - - - - 800 cycle with force 3.3 KN steel weight that impacts with an energy of 2.7 J (2 ft-lbs) upon the insulation and nylon jacket (if present) 1000N crushing conductor / same as tensile test properties - - - - - - After conditioning at a temperature of −25 ±1°C, (−40 ±1°C optional) for 4 h (4 turns around mandrel 8mm in rate; 4turn/s) After conditioning at a temperature of −25 ±1°C, (−40 ±1°C optional) for 4 h (4 turns around mandrel 8mm in rate; 4turn/s) After conditioning at a temperature of −25 ±1°C, (−40 ±1°C optional) for 4 h (4 turns around mandrel 8mm in rate; 4turn/s) Capacitance Chemical Tests. Sample 6 Infrared Spectroscopy (IR Scan) Sample 7 Determination of the Ash Content Elemental Analysis <1% Chemical analysis of hazardous substances Infrared Spectroscopy (IR Scan) THERMOGRAVIMETRIC ANALYSIS – TGA DIFFERENTIAL SCANNING CALORIMETRY – DSC PVC, Char yield 5-15%(Td) 150-250°C hazardous materials % such as (PCBs) hazardous materials % such as (PCBs) Nylon Jackets, Char yield: 10-25% (Td) 250-350°C Tg Temperature Dielectric AC Voltage Withstand in Water UL 83, Clause 5.23 Water preparation Test setup Immerse the specimen in a tank of water, ensuring that the water level is at least 2 inches (50 mm) above the highest point of the insulation. Connect the conductor of the specimen to one electrode of the test apparatus and the water tank to the other electrode. water with a temperature of 25°C ± 3°C in Tank Voltage Application Duration Specified, gradually 500V/s One Minute Summarizing the test voltages for common insulation types and conductor sizes: Insulation Type Conductor Size (AWG) Test Voltage (V) PVC 18-16 1500 PVC 14-10 2000 PVC 8-4 2500 PVC 2-0 3000 XLPE 18-16 1200 XLPE 14-10 1500 XLPE 8-4 2000 XLPE 2-0 2500 EPR 18-16 1000 EPR 14-10 1200 EPR 8-4 1500 EPR 2-0 2000 Criteria Pass/Fail OK