EFFECT OF OPERATING VARIABLE PARAMETERS ON

CHARACTERISTICS OF EXTRUDED WHEAT FLOUR

ADEKOYA, OLUWATAMILORE HENRY

JULY, 2023

EFFECT OF OPERATING VARIABLE PARAMETERS ON

CHARACTERISTICS OF EXTRUDED WHEAT FLOUR

A FINAL YEAR RESEARCH PROJECT

BY

ADEKOYA, OLUWATAMILORE HNERY

(18CF023931)

PRESENTED TO

THE DEPARTMENT OF CHEMICAL ENGINEERING

IN PARTIAL FULFILMENT OF THE REQUIREMENTS FOR THE AWARD OF

THE DEGREE OF BACHELOR OF ENGINEERING (B.Eng.) IN CHEMICAL

ENGINEERING, COVENANT UNIVERSITY, OTA

JULY, 2023

CERTIFICATION

I, Oluwatamilore Henry Adekoya, hereby declare that the contained report on " Effect of

Extruder Screw Speed, Feed Moisture Content and Extrusion Temperature on

Characteristics of Extruded Wheat Flour" was researched, and the results analyzed,

under the supervision of Professor James A. Omoleye and approved, having satisfied the

partial requirements for the award of Bachelor of Engineering in Chemical Engineering

(B.Eng.), Covenant University, Ota.

Oluwatamilore H. Adekoya

Signature and Date

(Project Student)

Professor James A. Omoleye

Signature and Date

(Project Supervisor)

Professor Vincent E. Efeovbokhan

Signature and Date

(Head of Department)

ii

DEDICATION

I express my gratitude to God for His divine favor, peace, and guidance during my entire

five-year journey at Covenant University, which culminated in the successful completion

of this research project. Furthermore, I would like to dedicate this project report to my

parents, Mr. Olatunji Adekoya and Mrs. Kemi Adekoya, as well as my sisters, Toluwani

Adekoya, Timileyin Adekoya and Teniola Adekoya, for their constant and unwavering

support.

iii

ACKNOWLEDGEMENT

First and foremost, I would like to acknowledge my God for His divine guidance and

unwavering support throughout my academic journey.

I want to express my deep appreciation to our Chancellor, Bishop David O. Oyedepo, for

being an exceptional agent of change, and the visionary behind the concept that gave birth

to this unique institution. I would like to extend my gratitude to the Vice-Chancellor,

Professor Abiodun H. Adebayo, for his remarkable efforts in promoting research and

fostering an environment of academic excellence at this university. I would like to

acknowledge the Dean of Student Affairs, Mrs. Sola Coker, for her invaluable

contributions in creating a conducive environment for students to flourish in their

academic pursuits.

I want to express my heartfelt appreciation to my supervisor, Professor James A. Omoleye,

for his invaluable aid, encouragement, and mentorship throughout this project. I would

also like to extend my thanks to every lecturer in the Department of Chemical Engineering

for imparting the necessary theoretical knowledge, and to all the technologists who

provided assistance, contributing to the success of this research project.

I am immensely grateful to the Jim Ovia Foundation Leadership Scholarship and the

Africa-America Institute for their financial support, which has made it possible for me to

attend Covenant University. Without their generosity, this opportunity would not have

been possible. I would also like to acknowledge Dr. Ada Peters, Mrs. Omidiora, Mr. Isaac,

Mr. Samson, and other members of the international office for creating memorable

experiences during my time at Covenant University.

I would like to acknowledge my project partners, Amadi and Tosin, for their valuable

contributions to this research work. Additionally, I am grateful to my friends in CU, Jubilee

estate and Eyita for their unwavering support and encouragement. Finally, I want to

express my deepest appreciation to my parents, Mr. Olatunji Adekoya and Mrs. Kemi

Adekoya, as well as my sisters, Toluwani Adekoya, Timileyin Adekoya, and Teniola

Adekoya, for their constant love, encouragement, and unwavering support throughout my

academic journey.

iv

ABSTRACT

Food extrusion using a single screw extruder is an economical method of food processing

that offers great versatility, allowing for the processing of various food products and the

utilization of food waste. This study investigates the impact of extrusion parameters,

namely extrusion temperature (40-60°C), screw speed (60-80 rpm), and feed moisture

content (27-33% wb), on the characteristics of extruded wheat flour. Central composite

design was employed to design the experiment and analyze the data using Minitab

statistical software. The study examined the effects of these parameters on extrusion rate,

bulk density, water absorption index (WAI), water solubility index (WSI) and, softening

time in different temperatures of water of extruded wheat flour. The findings revealed that

screw speed positively affected extrusion rate, bulk density and WSI but negatively

affected softening time and WAI of extrudate wheat flour. Extrusion temperature

positively affected extrusion rate and WAI but had a negative effect on the bulk density,

WSI and softening time. Feed moisture content had a positive effect on extrusion rate,

WAI and softening time but negatively affected bulk density and WSI of extrudate

product. The response variables fell within the following ranges: extrusion rate of 1.342.79 g/s, bulk density of 0.667-0.989 g/cm3, WAI of 2.121-4.142 g/g, WSI of 5.84-20.22%,

and softening time of 6.34-8.33 minutes, 4.14-5.20 minutes, and 2.90-3.52 minutes at

60°C, 80°C, and 90°C water temperature, respectively, for the extruded wheat flour.

Notably, the optimized values of extrusion parameters were found to be the combination

consisting of 60°C extrusion temperature, 80 rpm screw speed, and 30.48% (wb) feed

moisture content resulted in higher water absorption index and extrusion rate along with

lower bulk density, softening time, and WSI for the extruded product.

v

TABLE OF CONTENT

CERTIFICATION

ii

DEDICATION

iii

ACKNOWLEDGEMENT

iv

ABSTRACT

v

LIST OF TABLES

ix

LIST OF FIGURES

x

LIST OF PLATES

xi

CHAPTER ONE INTRODUCTION

1

1.1 Background of Study

1

1.2 Statement of Problem

2

1.3 Aim and Objectives of the Study

4

1.3.1 Aim of the study

4

1.3.2 Objectives of the study

4

1.4 Justification of Study

5

1.5 Scope of Study

5

CHAPTER TWO LITERATURE REVIEW

2.1 Wheat Flour

7

7

2.1.1 Factors that cause variation in wheat flour

7

2.1.2 Processing of wheat

9

2.1.3 Advantages of wheat flour

10

2.1.4 Industrial application of wheat

12

2.2 Overview of Extrusion Technology

14

2.2.1 Screw extruders

14

2.2.2 History of screw extruders

14

2.2.3 Components of the extruder

15

2.2.4 Types of extrusion

20

2.3 Food Extrusion

27

2.3.1 Instrumentation for extrusion processing

vi

28

2.3.2 Measuring and controlling fundamental variables

28

2.3.3 Measurement of extrudate product variables

32

2.4 Effects of Extrusion Parameters on Extrudate variables

35

2.4.1 Bulk density

35

2.4.2 Expansion

36

2.4.3 Hardness

37

2.4.4 Water adsorption index (WAI) and water solubility index (WSI)

38

2.5 Optimization of Food Extrusion Process

39

2.5.1 Optimization using response surface

41

2.5.2 Composite design (CCD)

41

2.5.3 Box-Behnken design (BBD)

42

2.6 Review of Past Works

43

CHAPTER THREE METHODOLOGY

44

3.1 Materials

44

3.2 Equipment and Apparatus

44

3.2.1 Equipment

44

3.2.2 Apparatus

47

3.3 Procedure

47

3.3.1 Changes to the existing single screw extruder

47

3.3.2 Design of experiment

47

3.3.3 Extrusion process

48

3.3.4 Bulk density test

49

3.3.5 Water adsorption index (WAI) and water solubility index (WSI)

50

3.3.6 Softening time

50

3.3.7 Response models and optimization

50

3.4 Precaution Taken

50

CHAPTER FOUR RESULTS AND DISCUSSION

4.1 Results

52

52

4.1.1 Results on extrusion rate

54

4.1.2 Results on bulk density

56

4.1.3 Results on water adsorption index

58

vii

4.1.4 Results on water solubility index

60

4.1.5 Results on softening time at different temperature

62

4.2 Discussion of Results

69

4.2.1 Extrusion rate

69

4.2.2 Bulk density

71

4.2.3 Water adsorption index

72

4.2.4 Water solubility index

73

4.2.5 Softening time at different temperature

74

CHAPTER FIVE CONCLUSION AND RECOMMENDATIONS

77

5.1 Conclusion

77

5.2 Contribution to Knowledge

78

5.3 Recommendation

78

REFERENCES

79

APPENDICES

84

Appendix A: Extrusion Process

84

Appendix B: Bulk Density Test

85

Appendix C: Water Adsorption Index Test

86

Appendix D: Water Solubility Index Test

87

viii

LIST OF TABLES

TABLE

3.1

Design of experiment

TITLE

PAGE

49

4.1

Values of multi-level independent variables

52

4.3

Regression coefficients for independent variables and product responses

54

4.4

Regression coefficients for independent variables for extrusion rate

54

4.5

Regression coefficients for independent variables for bulk density

56

4.6

Regression coefficients for independent variables for WAI

58

4.7

Regression coefficients for independent variables for WSI

60

4.8

Regression coefficients for independent variables for softening time at 60℃ 62

4.9

Regression coefficients for independent variables for softening time at 80℃ 64

4.10

Regression coefficients for Independent variables for softening time at 90℃ 66

4.11

Optimized extrusion parameters

67

4.12

Optimized response variables

68

4.13

Quadratic models developed for each response variables

68

A-1

Extrusion Process Raw Data

84

B-1

Bulk density test raw data

85

C-1

Water adsorption index raw data

86

D-1

Water solubility index raw data

87

ix

LIST OF FIGURES

FIGURE

TITLE

2.1

Schematics of an extruder with major parts

PAGE

16

2.3

Schematic diagram of metal extrusion process

22

2.4

Direct extrusion

22

2.5

Indirect extrusion

23

2.6

Hydrostatic extrusion

24

2.7

Lateral extrusion

24

2.8

Three types of impact extrusion

25

2.9

Blow film extrusion

26

2.10

Simple food extrusion process

28

4.1

Surface plot of extrusion rate vs moisture content, screw speed

55

4.2

Surface plot of extrusion rate vs moisture content, extrusion temperature

55

4.3

Pareto chart of standardized effects for extrusion rate

55

4.4

Surface plot of bulk density vs moisture content, screw speed

56

4.5

Surface plot of bulk density vs moisture content, extrusion temperature

57

4.6

Pareto chart of standardized effects for bulk density

57

4.7

Surface plot of WAI vs moisture content, extrusion temperature

58

4.8

Surface plot of WAI vs screw speed, extrusion temperature

59

4.9

Pareto chart of standardized effects for WAI

59

4.10

Surface plot of WSI vs moisture content, screw speed

60

4.11

Surface plot of WSI vs moisture content, extrusion temperature

61

4.12

Pareto chart of standardized effects for WSI

61

4.13

Surface plot of softening time at 60℃ vs moisture content, screw speed

62

4.14

Surface plot of softening time at 60℃ vs moisture content, temperature

63

4.15

Pareto chart of standardized effects softening time at 60℃

63

4.16

Surface plot of softening time at 80℃ vs moisture content, screw speed

64

4.17

Surface plot of softening time at 80℃ vs moisture content, temperature

65

4.18

Pareto chart of standardized effects softening time at 80℃

65

4.19

Surface plot of softening time at 90℃ vs moisture content, screw speed

66

4.20

Surface plot of softening time at 90℃ vs moisture content, screw speed

67

4.21

Pareto chart of standardized effects softening time at 90℃

67

x

LIST OF PLATES

PLATE

3.1

TITLE

Wheat flour

3.2

Centrifuge

45

3.3

Weighing balance

45

3.4

Single screw extruder

45

3.5

Measuring cylinder

46

3.6

Spatula

46

3.7

Mortar and pestle

46

xi

PAGE

44

CHAPTER ONE

INTRODUCTION

1.1 Background of Study

Extrusion cooking is a continuous process in which materials, typically food products or

plastics, are converted to fluid and forced through a small opening or die to form specific

shapes. This process occurs by action of high temperatures, pressures, and shear stresses.

Extrusion is a flexible and effective procedure that uses high-temperature, short-time (HTST) thermal processes. From a range of basic ingredients, such as grains, extrusion process

can produce a variety of ready to eat meals such as cereal or pasta. The quality and texture

of extrusion-produced goods are also consistent (Choton, Gupta, Bandral, Anjum, &

Choudary, 2020).

The food sector has a variety of issues that extrusion cooking addresses. Extrusion

technique eliminates waste by creating products with an extended shelf life, which

eliminates the need for refrigeration or preservatives. As a result of the process's ability to

regulate process factors like temperature and pressure, the end product's quality is

consistent and reproducible. Finally, compared to other methods of producing food, the

process' overall manufacturing cost is substantially cheaper since it is highly automated,

uses less manpower, and enables continuous production (Egal, 2019).

Extrusion cooking involves forcing food materials through a heated barrel that contains a

screw or other mechanical device that pushes the mixture while applying pressure and heat

concurrently. An extruder is a machine employed in the process of extrusion. Its

fundamental parts consist of a barrel, either a single or twin screw, heating and cooling

jackets, a die, a hooper, and controls for regulating screw speed and temperature. There

are two classifications of extruders: single screw and twin-screw (Sobowale, Adebo, &

Adebiyi, 2018).

To make wheat suitable for human consumption, it is processed into a fine powder known

as wheat flour. Depending on its gluten content, wheat can be classified as “soft” with low

gluten levels, or “hard” with high gluten concentrations. The extrusion process for wheat

flour entails mixing it with water to create a paste, which is then extruded through a

machine to produce various products like breakfast cereals, snacks, pasta, and pet food.

While the extrusion process is inherently a simple technological procedure, its regulation

becomes challenging due to the significant impact of various process factors. The quality

and uniformity of the extruded product are ultimately impacted by extrusion variables,

1

which have a substantial influence on the extrusion process. For instance, if the

temperature is too low, the material could not flow well and could cause blockages, which

would result in waste. A weak and brittle extrudate may arise from under-extrusion and

poor layer adhesion if the speed is too high. A die that is too big can result in poor

resolution and detail, while a die that is too tiny might result in longer extrusion rates and

perhaps not producing enough material.

Extrusion variables can be classified into two categories: independent and dependent.

Independent factors, such as feed moisture content, screw speed, and extrusion

temperature, can be controlled or adjusted. On the other hand, dependent variables, such

as extrudate qualities (texture, color, water absorption index, water solubility index, and

bulk density), as well as extrudate attributes (viscosity, flow rate, and system pressure),

are influenced by changes in the independent variables. (Ruiz-Gutiérrez, SánchezMadrigal, & Quintero-Ramos, 2018).

Understanding how to modify these factors can aid in extrusion process optimization,

leading to improved extrudate quality, quicker extrusion times, and reduced material and

energy waste. Additionally, knowing how these factors interact might make it simpler to

detect and fix problems when they occur by aiding in troubleshooting. Because it enables

the extrusion process to be optimized, understanding how extruder variables impact

extrusion is crucial.

The objective of this research is to investigate how independent extrusion variables

(temperature, moisture content, and screw speed) impact dependent variables (extrusion

rate, bulk density, water adsorption index, water solubility index, and softening time in

60°C, 80°C, and 90°C water). By analyzing these relationships, the study aims to

contribute to the optimization of wheat flour extrusion processes.

1.2 Statement of Problem

The global population is projected to reach 9.9 billion by the year 2050 (IISD's SDG

Knowledge Hub, 2020). As the population expands, the demand for food also increases,

leading to a surge in waste and byproducts. Currently, approximately 1.6 billion tons of

food, valued at $1.2 trillion, are lost or wasted annually, accounting for one-third of the

total food production. Unfortunately, this problem is anticipated to exacerbate in the

coming decades, with food waste projected to rise to 2.1 billion tons by 2030, amounting

to $1.5 trillion in losses – a one-third increase in just a decade (Detisch, 2018), because of

the problems with trash management and dumping, the buildup of these industrial

2

wastes has a detrimental effect on the ecosystem (Debomitra, Richter, Pichmony, Bon-Jae,

& Ganjyal, 2021).

The food-processing industry generates substantial quantities of solid and liquid waste

during manufacturing, preparation, and consumption. This results in the loss of valuable

biomass and essential nutrients, while also contributing to escalating disposal problems

and potential pollution concerns. Such wastes are a significant cause of environmental

damage, leading to the loss of aesthetic value, the production of unpleasant odors, and

smoke pollution from improper burning. India, being the world's second-largest producer

of fruits and vegetables, wastes around 18% of its produce, amounting to a value of $7

billion (Khedkar & Singh, 2018). If not adequately managed, the sheer volume of food

waste can overwhelm disposal facilities, they could be harmful to health of persons, serve

as a haven for disease-carrying vectors. When it rains, dumping waste into water bodies,

could clog drainage systems and result in flooding, which could result in the loss of lives

and property. In addition, waste from the food processing industry is frequently rich in

organic matter. They decay anaerobically if disposed of improperly, producing methane,

a very potent greenhouse gas. Methane has a far larger potential for global warming than

carbon dioxide and contributes to climate change (Betz, Buchli, Göbel, & Müller, 2015).

The United Nations has identified food waste disposal as a worldwide issue as it accounts

for roughly 8% of GHG emissions. The environmental issues associated with disposing of

food waste have gotten worse over time and hence stimulated the need for proper

management of food waste (Kaur, Rani, & Yogalakshmi, 2020).

Food extrusion involves feeding raw ingredients through an extruder at specific

temperatures, pressures, and shear forces to form a cooked, structured product with the

necessary texture and functional qualities. Today, food extrusion is frequently used for

food processing for a variety of reasons, including its adaptability, which enables it to

process various food products, as well as its comparatively cheap operating costs and

minimum energy usage (Cotacallapa-Sucapuca, et al., 2021). Food extrusion technology

also provides a means to valorise food wastes by utilizing vegetables and fruits in form of

pomace, a solid remains of fruit after pressing for juice and a source of dietary fiber. This

technology uses nutritious fruit waste to colour cereals and ready-to-eat snacks, offering

consumers looking to make healthier decisions an enticing substitute. Including fruits and

vegetables in extruded products is a practical way to cut down on food waste and improve

the nutritional value of the final product (Offiah, Kontogiorgos, & Falade, 2018).

3

Waste generation is a necessary part of life; it cannot be prevented, but it can be managed.

There are several waste management techniques that can help minimize waste and one of

such technique is to domesticate technologies, such as food extrusion, that allow for

reduced waste production. These technologies are typically domesticated by process

optimization. Process optimization is examining and modifying numerous elements of a

process, such as equipment and parameters, to obtain a desired result more effectively with

minimal consumed resources and at a minimal cost. Process optimization plays a crucial

role in waste management by reducing waste generation, improving efficiency, and

minimizing resource consumption.

By understanding the impact of screw speed, extruder temperature and feed moisture

content on extrudate characteristics such as bulk density, water adsorption index, water

solubility index, softening time, and compressive force required to break the extrudate,

food producers can identify the optimal combination of settings that yield the desired

product quality. This knowledge contributes to domestication of food extrusion technology

thus minimizing waste and maximizing revenue and effectiveness.

1.3 Aim and Objectives of the Study

1.3.1 Aim of the study

The objective of this project is to examine how temperature, screw speed, and feed

moisture content influence the extrusion rate, bulk density, water adsorption index, water

solubility index, and softening time of extruded wheat flour in water at temperatures of

60°C, 80°C, and 90°C.

1.3.2 Objectives of the study

The specific objectives of the study are to:

I.

Use Composite design on Minitab statistical software (Version 20.3) to design the

extrusion experiment;

II.

III.

Extrude wheat flour using a single screw extruder;

Examine the influence of independent variables (extrusion temperature, moisture

content and extruder screw speed) on dependent variables (bulk density, water

adsorption index, water solubility index, and softening time);

IV.

Use response surface models to determine the effect of extrusion temperature,

moisture content and extruder screw speed on each dependent variable and,

4

V.

Determine the optimized combination of independent process variables that yield

the best dependent variables.

1.4 Justification of Study

Chemical engineers have a strong background in process engineering, which makes them

adept at analyzing and optimizing various parameters in food processing. This study

investigates the effects of extrusion temperature, feed moisture content, and extruder screw

speed on bulk density, softening times, and water adsorption index amongst other

physicochemical properties of extrudate products. By systematically studying and

manipulating these variables, one can identify the optimal conditions that lead to desired

product characteristics. This optimization process can help improve production efficiency,

reduce energy consumption, and minimize waste generation, thus contributing to

domesticating food extrusion technology. By encouraging food extrusion, this study will

contribute to SDG 3 - Good Health and Well-being since extrusion cooking is used in

valorizing agricultural wastes, SDG 8 - Decent Work and Economic Growth by creating

job opportunities in the food industry, and SDG 13 – Climate Action by reducing methane

emissions from landfills.

In addition, domesticating food extrusion contributes to SDG 9: Industry, Innovation, and

Infrastructure and SDG 12: Responsible Consumption and Production, which promotes

sustainable resource use and waste reduction. This study also contributes to SDG 2 - zero

hunger by production of cheap nutritious food products, especially in developing countries

where food insecurity is prevalent. The efficiency of food production and processing can

be improved by optimizing food extrusion procedures. Optimized extrusion techniques can

help to increase food availability, decrease food loss and waste, and promote food security

by maximizing the use of raw materials, and lowering waste creation.

1.5 Scope of Study

All the aspects to be addressed in this study are mentioned below;

1. Wheat flour as extrusion feedstock

2. A review of existing literature on effect of extrusion parameters on wheat flour and

other related crop to assess the current date and identify the gaps.

3. Examine the influence of independent variables on extrudate characteristics

5

4. Statistical analysis of on extrusion rate, bulk density, water adsorption index, water

solubility index, and softening time in different temperatures of water of extruded

wheat flour.

5. Development and optimization of response surface models that give a relation

between the extrusion parameters and response variables

6

CHAPTER TWO

LITERATURE REVIEW

2.1 Wheat Flour

Wheat flour is a finely ground product made from ground wheat grains. It is greatly applied

in various food applications. Wheat flour is made up of starch, proteins, fats and small

amounts of vitamins and minerals. Starch makes up majority of the grain's composition.

There are numerous types of wheat flour, and the variances are as a result of the types of

wheat grain, the components of wheat grain employed, how the wheat was processed, and

any additives added to the flour (Rattray, 2023). Approximately 600 million tonnes of

wheat are produced worldwide each year, making it one of the most significant grains.

About 70% of wheat is utilized in food production. Processing wheat requires milling,

which is crucial. Flour manufactured from wheat is used to make goods including bread,

cakes, cereal, macaroni, and noodles.

2.1.1 Factors that cause variation in wheat flour

2.1.1.1 Variance based on wheat grain

Wheat grain is either classified as soft or hard depending on their gluten content. If the

gluten content is high, wheat grains are referred to as hard and soft if gluten content is low.

Gluten is a type of protein that accounts for the elastic qualities of wheat flour. The more

gluten a wheat has, the simpler it is for the flour to develop a strong structure that can

capture yeast waste gases during kneading and successfully rise during baking. A flour

with less gluten has a lighter, less chewy texture, like those used in cakes. Flour's gluten

content will vary depending on where it was milled and how the wheat crop grows. Hard

red wheat, soft red wheat, durum wheat, and white wheat are the four principal wheat kinds

farmed worldwide. Flour with a high gluten level is made from hard red wheat, whereas

flour with a low gluten content is made from soft red wheat. Semolina flour made from

durum is processed and mostly used to make macaroni pasta. Of all the wheat flours that

are produced in large quantities, semolina flour has the most gluten. Low gluten flour is

made from white wheat (Chu, 2014).

Hard wheat is used to make bread flour and high gluten flour. While bread flour has an

average gluten content of 11.5%, high gluten flour has an average gluten content of 13%.

The difference between the two types of flour is that some high gluten flours have had

their starch percentage reduced, raising the gluten concentration to 14%. Usually, these

flours are used to make bread. High gluten flour is only used for highly elastic breads like

7

bagels and pizza. Soft wheat is used to make cake flour, which has a low (8–10%) gluten

level. This flour may also be used to make delicate cakes. To make all-purpose flour, hard

and soft wheat grains are combined. The range of gluten content of the all-purpose flour is

9–12%. This flour may be used to produce both bread and cakes, making it the most

adaptable. However, compared to using bread or cake flour, your breads won't be as chewy

and your cakes won't be as soft. Pastry flour is a blend of hard and soft wheat flours, with

a focus on soft. The typical gluten concentration is 9–10%. Pastry flour can be used to

make pie crusts.

2.1.1.2 Variance based on part of wheat grain included

Wheat grain is made up of three parts; endosperm, germ and bran. Endosperm makes up a

significant portion of wheat flour. It is the biggest portion of the wheat kernel, accounting

for 83% of the weight of the kernel, and it provides the majority of the nutrients for the

growing wheat plant. The endosperm of the wheat is ground into a fine powder when it is

milled into flour, and this powder serves as the foundation for white or refined wheat flour.

The majority of the protein (gliadin and glutenin) and carbohydrates (mainly starch) are

found in the endosperm. Compared to the bran and germ parts of the wheat kernel, the

endosperm of wheat includes trace amounts of lipids, fibre, vitamins, and iron in addition

to carbohydrates and proteins (Senay, 2020).

When producing refined white flour, the germ and bran of the wheat kernel are two parts

that are frequently removed. They are nevertheless preserved in whole wheat flour,

producing a more nutrient- and fiber-rich final product. The wheat kernel's embryo, or

germ, is a nutrient-rich component, it makes up about 14% of the kernel’s weight. It is a

tiny, oval-shaped structure that is situated near the kernel's base. Essential fatty acids,

vitamins, minerals (including zinc and iron), and phytonutrients are all present in the germ.

It is a strong source of protein and is high in unsaturated fats. Whole wheat flour contains

the germ, which imparts a nutty flavour, healthy natural oils, and essential nutrients. The

wetness and softness of baked foods can be enhanced by the lipids in the germ. However,

compared to refined white flour, the fat content of whole wheat flour may also make it

more prone to spoiling.

The bran is the wheat kernel's outer covering of defence, it makes up 2.5% of the kernel’s

weight. It is a fibrous component rich in dietary fibre, antioxidants, and many vitamins and

minerals, including vitamin B6 and folate, selenium, manganese, and phosphorus. Whole

wheat goods benefit from the texture and flavour of the bran, which gives them a somewhat

rougher texture and nutty flavour. The bran's fibre facilitates digestion and offers a number

8

of health advantages, including encouraging bowel regularity, managing blood sugar

levels, and maintaining heart health.

2.1.2 Processing of wheat

The broad range of procedures used to turn harvested wheat grains into a variety of wheatbased goods, such as flour, bran, and wheat germ, is referred to as "wheat processing." It

includes a number of procedures and methods that turn unprocessed wheat into finished

goods fit for human consumption or further industrial uses. The procedure is long and

difficult. After preparation, the wheat undergoes grading, inspection, and weighing.

Subsequently, the grains are sorted based on their weight, size, and shape. The steps

involved in wheat processing are given below (UDAWAT, 2020):

1. Harvesting: Harvesting mature wheat plants marks the start of the wheat milling

process. Combination harvesters are often used to chop and gather the wheat stalks

during the harvesting process.

2. Cleaning: After being harvested, wheat is cleaned to get rid of debris like dirt,

rocks, and other contaminants.

3. Conditioning: For the best milling qualities, the moisture level of the wheat is

adjusted by conditioning and tempering. The wheat is steeped in water at this point

to make the bran removal process simple. To guarantee that the grain's moisture

level is consistent throughout, conditioning is done before milling. During the

milling process, the moisture aids in keeping the bran from breaking.

4. Milling: The milling process starts by sending the conditioned wheat through a

series of rolls which rotate at different velocity. The rotating action of the rolls

cause the wheat grain to open causing the endosperm to be separated from the bran.

The method of using rolls to form wheat flour is known as roller milling. Other

milling methods such as stone milling, hammer milling, or impact milling can also

be used to separate endosperm from the bran. The bran and other outer layers of

the grains separate from the endosperm as they are crushed. The bran is the fibrous

outer layer that protects the wheat kernel. It has nutrients like minerals and dietary

fiber. The endosperm particles are smaller and lighter than the separated bran

particles.

5. Sifting and separation: Following milling, the flour is sieved or sifted to get rid of

any impurities and divide it into several classes or particle sizes. The crushed grains

go through sieves and screens that assist separating the bran from the finer

9

endosperm particles. The bran, being larger and coarser, is separated from the finer

flour particles by size and density. Air currents and gravity are frequently used to

facilitate this separation process.

6. Blending: In this case, ingredients are combined to create various flours. For

instance, whole wheat flour (crushed endosperm) is created by mixing white flour

with wheat bran.

7. Fortification and enrichment: Flour may occasionally go through fortification or

enrichment, which involves reintroducing specific components, including vitamins

and minerals, to the flour to improve its nutritional value. This process is frequently

used when using refined white flour.

8. Distribution and packaging: The processed wheat products, such as flour,

semolina, bran, and wheat germ, are distributed and packed in the proper containers

or bags. The products are better shielded from physical harm, pests, and moisture

thanks to packaging materials.

2.1.3 Advantages of wheat flour

Wheat is an essential part of the diets of billions of people worldwide. Therefore, it's

important to not undervalue the nutritional importance of wheat proteins, especially in less

developed countries where people may consume a large amount of bread, noodles, and

other wheat-based foods like bulgur and couscous on a regular basis. Wheat supplies

around 20% of the total dietary calories and about 55% of the carbohydrate content. Its

composition includes notable levels of vitamins (such thiamine and vitamin-B) and

minerals (including zinc and iron), as well as 78.10% carbs, 14.70% protein, 2.10% fat,

and 2.10% minerals (Kumar, 2011).

2.1.3.1 Benefits of Carbohydrate

Carbohydrates can be categorized in various ways, and one such classification is

determined by the number of simple sugar units present in the carbohydrate molecule.

Monosaccharides are single-unit sugars, while disaccharides are sugars with two units.

Galactose, fructose, and glucose are examples of monosaccharaides. However, lactose and

sucrose are examples of disaccharides. Simple carbohydrates typically refer to

carbohydrates with one or two simple sugar molecules. On the other hand, complex

carbohydrates encompass long-chain compounds, such as glycogen and fibers. (The

Nutrition Source, 2019).

10

Carbohydrates are an essential part of our diets since they provide the body with glucose,

which is converted into energy to sustain biological processes and physical activities, such

as movement and cognitive functions. Glucose serves as the primary energy source for our

body, as different tissues, including muscles and the brain, directly utilize

monosaccharides for fuel. After monosaccharides are absorbed into the bloodstream

through the small intestine, they are transported to the cells that require them. Hormones

like insulin and glucagon play a crucial role in regulating blood sugar levels by adding or

removing glucose from the bloodstream as needed.

In addition to direct utilization, our body also indirectly utilizes glucose through glycogen,

a polysaccharide similar to starch. Glycogen is stored in the liver and muscles and acts as

an immediate reserve of energy. When needed, glycogen is converted back into glucose to

maintain stable blood sugar levels (European Food Information Council (EUFIC), 2020).

2.1.3.2 Benefits of Protein

Protein has a vital function in the formation and upkeep of all cells in our bodies. It

provides energy to our cells and fuels our overall body functions. Including protein in your

daily health routine is important for maintaining the well-being of your cells. Protein is

composed of amino acids, often referred to as building blocks, as they are linked together

in lengthy chains. It is categorized as a "macronutrient," which means that you require

significant quantities of it to sustain good health.

Protein fulfills various crucial roles in the body. It acts as a fundamental component for

the formation of bones, muscles, cartilage, and skin. Notably, a significant portion of your

hair and nails consists of protein. Additionally, protein is involved in the construction and

restoration of body tissues. It is found in the form of a protein compound within red blood

cells, facilitating the transportation of oxygen throughout the body and ensuring the supply

of necessary nutrients to all organs. Approximately half of the protein obtained from your

daily diet is utilized in producing enzymes, which aid in food digestion and the generation

of new cells and body chemicals. Moreover, protein plays a vital role in regulating

hormones, particularly during cell transformation and development in the pubescent stage

(Cooper, 2022).

11

2.3.1.3 Benefits of Minerals and Vitamins

Wheat's mineral content varies according to its kind, the makeup of the soil, the climate,

and agricultural practices, including organic farming. Important elements included in

wheat flour, such as iron, magnesium, phosphorus, and zinc, are essential to many body

processes. Red blood cell production and oxygen delivery both depend on iron.

Magnesium supports healthy neuron and energy metabolism. Phosphorus aids in cell

growth and bone health. Among its many uses, zinc supports the immune system and the

healing of wounds.

B vitamins, beneficial to the human body, can be found in wheat flour. These

vitamins include thiamin (B1), riboflavin (B2), niacin (B3), and folate (B9). The creation

of energy, proper nerve operation, and the metabolism of carbs, proteins, and fats all

depend on B vitamins. Additionally, they help healthy brain function, good vision, and

nervous system maintenance. Wheat flour also has vitamin E, an antioxidant that protects

cells from oxidative damage brought on by free radicals. In addition to promoting skin

health and blood vessel health, vitamin E helps the immune system operate (Cooper,

2022).

2.1.4 Industrial application of wheat

Wheat is a highly adaptable plant that has diverse uses across various industries. It is a

cereal grain cultivated in temperate regions and has the potential to be utilized in the

production of a wide range of food products. Additionally, wheat has applications in

industries such as paper manufacturing, breweries, and biofuel production.

2.1.4.1 In the food industry

The food sector is the main consumer of wheat, which is processed into several varieties

of flour including all-purpose, bread, cake, and semolina. Wheat flour is an essential

component of baking and is used to make bread, cakes, muffins, and other baked items.

Wheat flour contains gluten, which adds to the dough's structure and elasticity and allows

it to rise and acquire a desired texture in the baked goods. When making pasta and noodles,

particularly using durum wheat flour, wheat flour and water are mixed to create a dough

that is moulded into different pasta and noodle shapes. Gluten in wheat flour gives pasta

and noodles the necessary strength and texture for proper formation. Wheat also finds

application in the manufacturing of diverse snack foods, and it also holds significance as

12

a key ingredient in animal feed formulations. It serves as a valuable source of nutrition for

livestock, poultry, and other animals.

2.4.1.2 In the brewing industry

Wheat has a long history of being used as a primary ingredient in the manufacture of malt

and beer. Beer's flavor, body, and foam stability are all influenced by wheat malt, which

is made from malted wheat grains. It gives wheat beers a distinctive flavor and frequently

makes them smoother and hazier. Along with malted barley, wheat can be used as an

auxiliary in brewing. The flavor, texture, and appearance of the beer can be altered by

substituting wheat for a portion of the malted barley. Wheat can also be used in the brewing

process as a filtering aid. It helps clear the beer of unwanted particles and sediment by

acting as a clarifying agent or as a filter bed (Faltermaier, Waters, Becker, Arendt, & Gastl,

2014).

2.4.1.3 In the paper industry

Pulping refers to the transformation of raw materials, usually wood or other fibrous

substances, into a fibrous mass known as pulp. This pulp consists of individual fibers that

are well-suited for manufacturing paper, paperboard, and various other cellulose-based

products. The pulping process entails the mechanical or chemical breakdown of the raw

materials, enabling the separation of fibers from other constituents like lignin,

hemicellulose, and extractives. Wheat does not have significant direct applications in the

paper industry. Unlike other raw materials like wood, bamboo, or recycled paper, wheat is

not commonly used as a primary fiber source for paper production. However, wheat straw,

the byproduct of wheat harvesting, can be utilized as a potential source of fiber for

papermaking. Wheat straw pulp can be produced through a pulping process similar to

wood pulping.

Bleached wheat straw pulps offer a wide range of possibilities for producing diverse paper

and paperboard grades, such as lightweight printing paper, letterpress paper, typing paper,

writing paper, tissue and sanitary papers, and coated ivory board. This is due to their

favorable strength properties, reasonable brightness, and excellent printability. In certain

cases, a small proportion of bleached wood pulps or bamboo pulps may be blended with

wheat straw pulp to enhance pulp stock wet-web runability in paper machines. Moreover,

bleached wheat straw pulp finds application in the production of Bible paper products by

some paper factories (Fang & Shen, 2018).

13

2.2 Overview of Extrusion Technology

In the extrusion process, material is continually transported through a barrel containing

one or more screws and driven through a die (shaped aperture) by combining several

activities quickly. Extrusion process utilizes pressure, heat, mechanical shear and moisture

to plasticize materials through a die. Examples of these materials include food and

polymers. The extrusion process combines a number of unit activities, including shearing,

heating, and shaping, to produce the final products. (Debomitra, Richter, Pichmony, BonJae, & Ganjyal, 2021); (Choton, Gupta, Bandral, Anjum, & Choudary, 2020).

The extrusion process is a high-temperature-high-pressure method in which raw material

is put under shear forces. The solid substance experiences physicochemical changes and as

a result, becomes a melt. Before reaching the final state, this viscous substance undergoes

additional changes in its physicochemical properties when it exits the system. This occurs

due to difference in extrudate's system conditions such as temperature and pressure

difference. In Extrusion, the parameters are split into inputs parameters for the extrusion

system, dependent parameters for the extrusion system, and output parameters for the

products. Examples of output parameters include water adsorption index, water solubility

index and bulk density (Debomitra, Richter, Pichmony, Bon-Jae, & Ganjyal, 2021).

2.2.1 Screw extruders

Extruders play a vital role in continuous process operations within extrusion processing

technology. They serve multiple functions, such as transporting and compressing

particulate components, melting polymers, mixing, cooking polymeric materials, and

texturizing and shaping products. The two primary equipment designs used in extrusion

processing are the single screw extruder and the twin screw extruder. Each design allows

for various engineering choices, depending on the equipment manufacturer or specific

processing requirements. This significant flexibility in processing settings is what grants

the extrusion process its remarkable versatility. (Debomitra, Richter, Pichmony, Bon-Jae,

& Ganjyal, 2021).

2.2.2 History of screw extruders

Since the 19th century, both single screw and intermeshing co-rotating twin screw

extruders have been in existence. The first single screw extruder for soap production was

described in a US patent granted to Sturges in 1871, while Gray developed a single screw

extruder for gutta-percha preparation and wire coating in 1879. The rubber industry was

14

among the early adopters of screw extrusion equipment for continuous rubber

compounding. Though there were no major industrial applications from 1880 to 1930,

significant mechanical engineering advancements improved the designs of single screw

extruders. Coignet received the first patent for a twin-screw extruder in 1869, known as a

malaxator, which processed synthetic stone paste. The intermeshing co-rotating twin screw

extruder design saw notable improvements in the late 1930s, with Colombo introducing

an innovative design produced by the Italian company Lavorazione Materie Plastiche in

1939. These machines gained wide usage in the polymer sector between 1940 and 1956.

The advent of thermoplastics in the 1930s accelerated the development of extrusion

processing technology. A significant step in automated extrusion technology came with

Paul Troester's creation of an electrically heated, air-cooled single screw extruder with

automated temperature control and variable screw speed in Germany in 1939.

As the polymer industry expanded and polymer compositions became more complex,

single screw extruders demonstrated limitations in properly mixing, compounding, and

pumping polymer melts with specific properties. In response to the plastics producers'

request after World War II, twin screw extrusion technology was adopted, greatly

enhancing the process.

Between 1940 and 1960, with global plastics production increasing from 300,000 to 12

million metric tonnes annually, screw extruders played a crucial role in the remarkable rise

of the polymer processing industry, including plastics and rubber manufacturing. The

sector's growth allowed for flexible and efficient processing at a competitive cost-toperformance ratio, fully realizing the processing potential of extrusion technology.

Today, extrusion technology finds application not only in the polymer processing industry

but also in the food processing industry, as it is one of the most cost-effective methods

available. (Bouvier & Campanella, 2014).

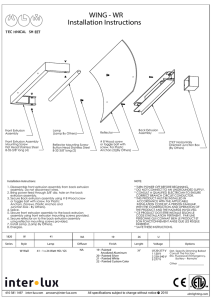

2.2.3 Components of the extruder

A schematic of an extruder's components is represented below in figure 2.1. It comprises

mostly of a barrel that extends from the hopper at the back of the extruder, through which

polymer is fed, to the die at the front of the extruder. The extruder's moving component,

the screw, is made to blend, compact, and transport the polymer as it transforms into a

viscous melt from solid granules. A motor driving a gear reducer powers the screw's

rotation within the barrel. The spinning screw is the extruder's main component. The axial

distance between one flight's edge and the equivalent edge on the following flight is known

15

as the pitch, and it is the thread of an extruder screw. The helix angle and pitch are related

terms that describe how coarse the thread is. The single screw extruder is currently the

most popular and adaptable extruder. Extruders are often identified by their barrel lengths,

which are expressed as the length-to-diameter ratio, L/D, and their bore diameters, D. For

laboratory equipment, diameters range from about 1 in. to around 8 in. for specialized

manufacturing equipment. Commercial extruders typically have L/D ratios between 20/1

and 34/1.

Figure 2.1: Schematics of an extruder with major parts

Source: (Bouvier & Campanella, 2014).

I.

Screw

The screw is the most essential part of the extruder, it is sometimes regarded to as

the heart of the extruder. The screw is a long, threaded shaft that rotates inside the

barrel. The material is pushed forward by the screw, which also mixes and

homogenizes the molten material once it has melted due to friction and heat

produced by the screw's rotation and heat from the heater bands. The feed portion,

the transition section, and the metering section are the three primary parts of the

screw. Each of these sections have a different channel depth

Feeding section: The material will be transported and melted in this portion. The

material travel from the hopper to the melting zone because of the feed

section's long flight depth and its decreasing channel depth throughout its length.

Transition section: By progressively lowering the flight depth and raising the

channel depth, the transition section aids in further melting and blending the

16

material. In order to prepare the material for final shape in the metering section and

to achieve a homogeneous melt, this part to compact the loosely packed feed and

remove air pockets in the process. It causes the resin to melt and condense into a

continuous flow of molten material. A major source of energy for melting the resin

is the frictional force created between the resin, the barrel wall, and the moving

screw. The transition section is also called the compression section

Metering section: The extrusion rate and pressure are precisely controlled by the

metering section. The material flows towards the die with a continuous flow and

pressure buildup thanks to its short flight depth and constant channel depth. A

constant flow rate is made guaranteed by the metering or pump section, which also

creates the pressure required to push the polymer melt through the remainder of the

extruder and out through the die.

II.

Barrel

The barrel is typically a cylindrical component of the extruder. In the barrel,

material to be extruded is melted, mixed, and transported. The raw material is often

heated using electric heaters or heating elements to melt it and keep it molten.

High-strength steel or other durable materials that can endure the high temperatures

and pressures are required for construction of the extruder's barrel. The material is

melted, mixed, and transported inside a cylindrical container called a barrel. The

raw material is often heated using electric heaters or heating elements to melt it

and keep it molten. High-strength steel or other durable materials that can endure

the high temperatures and pressures are required for construction of the

extruder's barrel. It is precisely machined to guarantee a uniformly smooth inner

surface. Heating components, such as electric heater bands are wrapped around the

barrel's outside. The heat from these heaters is essential to melt the material within

the extruder. In order to produce the best processing conditions for the particular

material being extruded, the barrel's temperature is carefully regulated.

III.

Heater bands

Heater bands are electric heating elements wrapped around the barrel using clamps

so as to ensure proper conduction of heat from the bands to the barrel. They supply

the heat required to melt the substance inside the barrel. To keep the best processing

conditions, the temperature of the heater bands may be accurately regulated. Heater

bands' major function is to keep the barrel at the ideal temperature so that the

17

material may be processed. Controlled heat is applied to the material as it passes

through the barrel, causing it to melt and become viscous for extrusion.

Stainless steel or ceramic are frequently used to make heater bands because they

can withstand high temperatures. They are made to securely round the extruder's

barrel and disperse heat uniformly along its length.

Electric heating components, such as resistance wires, are located inside the heater

bands and produce heat when an electrical current flows through them. The heating

components are placed precisely and created to heat the barrel's surface

uniformly. Temperature controller, used to monitor and control the barrel's

temperature, operate the heater bands. Based on the material being extruded, these

controllers enable operators to establish and maintain exact temperature required

for extrusion. Temperature sensors mounted on or inside the barrel provide

feedback that allows the heater bands' heat output to be changed to maintain the

required temperature.

IV.

Thermocouple

The thermocouple is the extruder’s temperature controller. It is used to monitor and

control the barrel's temperature, operate the heater bands. The thermocouple

provides real-time temperature feedback to ensure that the extrusion process

operates within the desired temperature range for the specific material being

extruded. Temperature sensors mounted on or inside the barrel provide feedback

that allows the heater bands' heat output to be changed to maintain the required

temperature.

Typically, a thermocouple is constructed from two distinct kinds of metal wires

that are linked at one end to create a junction. The barrel's internal position where

the temperature has to be monitored is where this connection is situated. The

opposite ends of the wires are attached to a temperature measurement equipment.

The thermoelectric effect, which is the phenomenon of creating an electric voltage

when there is a temperature gradient between the junction and the other end of the

wires, serves as the foundation for the operation of a thermocouple. It is possible

to measure this voltage in order to estimate the temperature because it is directly

proportional to the temperature differential.

V.

Feed throat

The raw material enters the extruder barrel through the feed throat. It offers a

regulated flow of material into the extruder and joins the hopper to the barrel. The

18

feed throat's main function is to deliver a steady and regulated flow of raw material

into the extruder barrel. Between the hopper and the barrel, it serves as a

transitional point, ensuring that the material is fed into and transported through the

extrusion system in the right manner. The design of the feed throat is influenced

by things like the kind of extruder and the properties of the substance being

extruded. The material is normally guided from the hopper and directed into the

barrel via an aperture with a funnel-like shape. The shape and dimensions of the

feed throat are optimized to promote efficient material flow and prevent bridging

or uneven feeding.

VI.

Hopper

The hopper is a big funnel-shaped container found at the top of the extruder. It

houses the raw materials that are fed into the extruder for processing, such as plastic

pellets or granules. The hopper's main function is to hold and provide the raw

material to the extruder. It delivers a stable feed rate and uninterrupted output by

supplying a regulated and continuous flow of material to the extrusion machine.

The top of the hopper is constructed with a large hole to make it simple to load the

raw material. It narrows to a smaller hole where it joins the feed throat, which

serves as the entrance to the extruder barrel. The hopper's shape and size can vary

depending on the specific requirements of the extrusion process and the

characteristics of the material being processed.

VII.

Thrust bearing

The thrust bearing's main objective is to withstand and control the axial forces

produced during the extrusion process. These forces are the consequence of the

pressure and resistance that the rotating screw must overcome as it advances the

material inside the extruder barrel. The screw's axial load is supported by the thrust

bearing, which enables the screw to revolve smoothly and keep its alignment within

the barrel. It aids in avoiding excessive wear and harm to the screw, barrel, and

gearbox, among other extruder parts. Typically, the thrust bearing is made as a

rolling-element bearing. Between the casing and the rotating portion of the

extruder, the rolling components are positioned to provide smooth rotation while

reducing wear. Ball thrust bearing and roller thrust bearing are the typical types of

thrust bearings used in extruders.

VIII.

Gear reducer

19

The gear reducer's primary function is to regulate and modify the extruder screw's

rotational speed and torque output. It provides the necessary power and torque for

plasticizing and forcing the material into the extruder barrel, enabling the

extruder to process materials efficiently. The gear reducer reduces speed by

utilizing a collection of gears in various sizes and arrangements. The ratio of the

motor speed to the speed of the extruder is known as the reduction ratio. The gear

reducer is made to improve torque while lowering speed since extruders often

need high torque and low rotating speeds. The gear reducer may employ spur

gears, helical gears, and planetary gears or a combination of these gears.

IX.

Motor

The motor's primary objective is to operate the extruder screw by converting

electrical energy into mechanical energy. It produces the rotating motion needed

to move the material within the extruder barrel and plasticize it.

Extruders can employ both AC (alternating current) and DC (direct current)

motors, among other types of motors.

2.2.4 Types of extrusion

The extrusion process involves subjecting raw materials to both high temperatures and

high pressures, causing them to undergo shear forces. This process leads to the

transformation of the solid substance into a molten state, accompanied by various

physicochemical changes. As the viscous substance moves through the system, it

experiences further alterations in its physicochemical properties before reaching its

ultimate form. These additional changes occur because of variations in temperature and

pressure within the extrudate system.

Extruded materials encompass a wide range of substances, including metals, polymers,

ceramics, concrete, modeling clay, and food items. The resulting products of the extrusion

process are commonly referred to as extrudates (Bouvier & Campanella, 2014).

2.2.4.1 Metal extrusion

Metal extrusion is a metal shaping technique that involves the application of force to push

metal or a workpiece through a die, reducing its cross-sectional area or giving it a desired

shape. This method finds extensive application in the manufacturing of pipes and steel

rods. Figure 2.1 illustrates the fundamental deformation concept of the extrusion process

and the tools utilized in extrusion, which include (1) the pressing stem, (2) the container

liner, (3) the container, (4) the dummy block, (5) the billet, (6) the extrusion, (7) the die

20

holder with the die, and (8) the die backer. The stem is a component that transmits the

main cylinder's power to the billet in the form of a column. Depending on the size of the

press, the stem must support a high pressure in order to work without bending or cracking

under high force. Before the metal billet is extruded, it is placed in a container or billet

sleeve, which has a protective lining within. It assists in preventing direct contact between

the container and the molten metal. This can lessen wear and tear brought on by the high

temperatures and pressures used in the extrusion process, which can avoid contamination

and increase the lifespan of the container. During the extrusion process, the metal billet is

held in a container. The metal billet, a cylindrical piece of metal, is positioned behind the

dummy block before the extrusion procedure starts. During the extrusion process, the

dummy block acts as a support and a barrier to stop the metal from flowing backward. A

cylindrical piece of metal known as a billet is used as the primary raw material in the

extrusion process. It is the initial substance that flows and deforms to take on the required

shape through the extrusion die. The die holder is a part that holds and supports the

extrusion die. It guarantees perfect alignment of the die throughout the extrusion process

and structural stability. The final extruded product's shape and dimensions are determined

by the extrusion die, it is made out of an aperture or hollow through which the metal flows

to take on the required profile (Guo & Yang, 2014).

Metal extrusion can be categorized into various types, depending on factors such as the

direction of extrusion flow, the force application medium, and the operating temperature.

These subdivisions include:

i.

Direct Extrusion

ii.

Indirect Extrusion

iii.

Hydrostatic Extrusion

iv.

Lateral or Vertical Extrusion

v.

Hot Extrusion

vi.

Cold Extrusion

vii.

Impact Extrusion

21

Figure 2.2: Schematic diagram of metal extrusion process

Source: (Guo & Yang, 2014)

Direct extrusion, also referred to as Forward Extrusion, starts with loading a heated

billet into a container within a press cavity, with a false block positioned behind it.

Subsequently, a mechanical or hydraulic ram forces the material through the die.

Figure 2.3: Direct extrusion

Source: (Engineering product design, 2019)

During the direct extrusion process, a portion of the extrusion load, which depends

on the billet's length, is employed to shear the inner materials away from the slowermoving peripheral region adjacent to the container wall. This action aims to

minimize friction between the billet and the wall, as the billet's surface slides along

the container wall. Frictional heat generation significantly impacts both the

extruding billet's temperature and the mechanical properties of the resulting extruded

products.When the materials tend to adhere to the container wall, the central region

22

of the billet flows more rapidly into the die than the periphery, primarily due to

friction. To mitigate this effect, molten glass or oil containing graphite particles can

be utilized as lubricants in direct extrusion. At higher temperatures, molten glass is

employed to reduce high friction, while at lower temperatures, lubricants containing

graphite powder are used to provide lubrication.

Indirect extrusion involves moving the die towards the billet inside the cavity using

a hydraulic ram located at the end of the device to force the material through the die.

Figure 2.4 illustrates this process. Due to the reduced friction on the billet caused by

the static billet container, this method requires less power. However, it becomes

challenging to control the extruded portion once it exits the die.

Figure 2.4: Indirect extrusion

Source: (Engineering product design, 2019)

Hydrostatic extrusion involves a chamber or cavity, smaller than the billet, which is

filled with hydraulic fluid to transfer force from the ram to the billet, as depicted in

figure 2.5. The pressure from the fluid applies triaxial forces, enhancing the billet's

formability. However, careful attention must be given to seal the fluid properly to

prevent leaks and minimize pressure-related issues. Despite the hydraulic fluid's

ability to reduce friction between the wall and billet, its use in the industry is limited

compared to other extrusion techniques due to the specialized equipment required,

lengthy setup process, and lower output rate.

23

Figure 2.5: Hydrostatic extrusion

Source: (Engineering product design, 2019)

Lateral extrusion: Lateral extrusion, often referred to as sideways extrusion or cross

extrusion, forces the material to flow perpendicular to the extrusion axis. Contrary

to conventional direct extrusion, which uses axial material flow, lateral extrusion

enables the production of intricate structures with characteristics that are difficult to

achieve using other extrusion techniques.

A metal billet is inserted into a container or die assembly for lateral extrusion that

contains an aperture or cavity with the necessary cross-sectional form. The material

flows sideways and fills the cavity as a result of a force that is provided perpendicular

to the extrusion direction.

Figure 2.6: Lateral extrusion

Source: (Engineering product design, 2019)

24

Impact extrusion is an alternative method for producing extruded shapes from

metals. Unlike traditional extrusion, which requires high temperatures to soften the

material, impact extrusion uses cold metal billets. This process employs high

efficiency and pressure to extrude these billets. In a standard impact extrusion

procedure, a lubricated slug is placed in a die cavity and struck once by a punch.

The punch creates a gap between itself and the die, causing the metal to flow

around the punch. Impact extrusion works well with somewhat softer materials like

lead, aluminum, or tin. There are three main categories of impact extrusion:

forward, backward, and mixed impact extrusions, as illustrated in figure 2.7.

Figure 2.7: Three types of impact extrusion

Source: (Guo & Yang, 2014)

2.2.4.2 Polymer Extrusion

A thermoplastic substance is homogeneously melted during the high-volume production

process of plastic extrusion. Pellets, powder, or granules might be produced from this

melted substance. The melted material then exits the shaping die hole with enough

pressure.

The shape of the die hole is imprinted on the molten plastic as it exits the shaping die

through the extruder. Many different items, including pipe/tubing, window frames,

weather stripping and wire insulation may be produced using this technology. The first

step in the plastic extrusion process is to add additives to the plastic substance. Colorants

or UV inhibitors might be used as additives, depending on the needs of the production

process. The next step involved in polymer extrusion is melting the plastic in the extruder’s

barrel. The temperature of the barrel is set as the melting point of the plastic to be extruded.

The molten material is forced through a die using a rotating screw. This causes molten

plastic to take a desired shape. The procedure then proceeds to cooling after going through

the die. Several cooling rolls or a water spray might do this. The goal of cooling is to

25

prevent any modification to the shape of the extruded plastic (Wayken rapid

manufacturing, 2022).

Types of polymer extrusion are tubing extrusion, blow-film extrusion, sheet film extrusion

and over-jacketing extrusion.

Tubing extrusion: At the die section, tubing extrusion is different from typical polymer

extrusion. When working with hollow objects and tubes, such as pipes and long tubes, this

method is perfect. Additionally, it is perfect for making medical tubing and drinking

straws. In tubing extrusion, a mandrel or pin is placed within the die, after which positive

pressure is applied to the interior cavities through the pin. Manufacturers insert more than

one pin at the die's center when there are several holes required. The intended number of

holes determines how many pins are needed. Additionally, the air pressure for the pins in

this situation often comes from a distinct source, which makes it simple to change the size

of each hole.

Blow-film extrusion: Blown-film extrusion is ideal for producing products like shopping

bags. The main distinction between blown-film extrusion and conventional

polymer extrusion is the die. An upright cylinder with a circular hole that can be anything

with 3-4 meter diameter is the blown-film extrusion die. To employ the molten plastic in

this procedure, a pair of nip rollers draw it up from the die. The nip rollers are frequently

between 4-20 meters away from the die and elevated above it. The quantity of cooling

required determines the precise height of the nip roll. The wall thickness or gauge of the

film is also determined by the nip rollers' speed.

Figure 2.8: Blow film extrusion

Source: (Wayken rapid manufacturing, 2022).

Sheet film extrusion: The main need for achieving the appropriate form in this extrusion

type is a pulling and rolling operation. This involves figuring out the sheet's thickness and

26

surface roughness. The product is given the proper form and is helped to cool and

permanently solidify during the rolling process. The difference between this procedure and

blow-film extrusion is how the required form is produced.

Over-jacketing extrusion: Making insulation wires is a perfect application for this kind of

plastic extrusion. For coating wires, pressure and jacketing are the two main extrusion

plastic tools. Both tooling kinds have their applications, but which one you choose to coat

wires with will depend on how closely the plastic material must adhere to the wire.

Pressure tooling is the best option when close contact or adhesion between the wire and

the material is required. But jacketing tooling is preferable if closeness and interaction are

unnecessary. The location of the pin in relation to the die is the main distinction between

different types of tooling.

2.3 Food Extrusion

Food extrusion is employed in the food industry to create a variety of food products with

a particular form, texture, and structure. In order to create continuous, uniform forms, it

entails carefully controlling the flow of a combination of components through a die. A

variety of foods, including snacks, breakfast cereals, pasta, and pet food, are produced via

food extrusion.

Piston and ram-type extruders for processing meats and sausages were the first extruders

used in the food industry. Piston extruders have not advanced much over the years,

although they are still helpful in some applications. To switch from the previous batch

process to a continuous one, pistons were replaced in the 1930s with a single screw. The

single screws were applied to pasta manufacturing and transformed the food sector with

the speed and usefulness a screw extruder offered. Twin-screw extruders were developed

later in the 1960s. Due to the greater possibilities of a twin-screw system, food extrusion

choices diversified, resulting in a wide range of innovative cereal and snack products in

the 1980s. Extruders of the present day are incredibly versatile and functional (Gu,

Kowalski, & Ganjyal, 2017).

Extruders are well-liked because they enable the production of a number of food products,

including pre-gelatinized flours, breakfast cereals, snacks, pet foods, and pellet products,

among others, in a quick and continuous manner. It is a system that integrates several unit

processes such as mixing, kneading, cooking, shaping, and cutting all into a single piece

of equipment. Due to this, the procedure is very straightforward, highly effective, and

inexpensive in comparison to other processing techniques.

27

Food ingredients are exposed to high shear, temperature, and pressure for a brief period of

time during extrusion. As a result, the ingredients are converted inside the extruder from a

solid

powder

state

to

a

melt

state. The

melted

components

subsequently

exit the extruder through the die to form a desired shape. A sudden reduction in pressure

causes a rapid expansion and a drop in temperature in the melt as it exits the extruder,

assisting in the transformation of the melt into a cooked product. Figure 2.9 shows a

schematic of the transformation.

Figure 2.9: Simple food extrusion process

Source: (Gu, Kowalski, & Ganjyal, 2017)

2.3.1 Instrumentation for extrusion processing

The food extruder's instrumentation plays a crucial role in measuring variables related to

the process and delivering precise and timely data to the operator. This information is

essential for making informed decisions about adjusting the process. Data provided by

instrumentation can either be basic i.e. temperature, pressure and speed, or advanced i.e.

specific energy input, and intensity of mix.

In order for operators to make well-informed decisions, it is crucial for instrumentation to

have sufficient precision, and consistency. Accuracy refers to the proximity of the

measured value to the actual value, while precision pertains to the consistency of

measurements taken at different instances. Ideally, both accuracy and precision should be

high. Nevertheless, in certain situations, achieving good precision becomes more crucial

than high accuracy, especially when making comparisons over time. If it is possible to

attain precise measurements at the expense of absolute accuracy, it is often preferred

(Strahm, 2020).

2.3.2 Measuring and controlling fundamental variables

The instrumentation utilized to measure critical variables serves as the basis for controlling

the food extrusion process, whether it's achieved manually at a basic level or through

28

advanced automation. These essential variables provide valuable information to the control

system, allowing them to make informed decisions regarding process control.

2.3.2.1Temperature

One of the main goals in food extrusion cooking processes is to raise the temperature of

the raw materials to achieve cookingThis temperature elevation is necessary for starch

cooking, protein denaturation and texturization, and reaching temperatures above 100°C