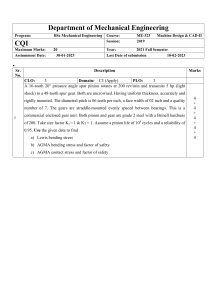

AGMA 908-B m Ob87575 000302b b y 4 m -. AGMA 908-B89 (Revision of AGMA 226.01) April 1989 AMERICAN GEAR MANUFACTURERS ASSOCIATION ~~ D Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur, Helical and Herringbone Gear Teeth AGMA INFORMATION SHEET (This Information Sheet is not an AGMA Standard) --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT A G M A 908-B W Ob87575 0003027 580 W INFORMATION SHEET Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur, Helical and Herringbone Gear Teeth AGMA 908-B89 (Revision of AGMA 226.01 1984) [Tables or other self-supporting sections may be quoted or extracted in their entirety. Credit line should read: Extracted from AGMA Standard 9084389, INFORMATION SHEET, Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur, Helical and Herringbone Gear Teeth, with the permission of the publisher, American Gear Manufacturers Association, 1500 King Street, Suite 201, Alexandria, Virginia 22314.1 AGMA standards are subject to constant improvement, revision or withdrawal as dictated by experience. Any person who refers to any AGMA Technical Publication should determine that it is the latest information available from the Association on the subject. Suggestions for the improvement of this Standard will be welcome. They should be sent to the American Gear Manufacturers Association, 1500 King Street, Suite 201, Alexandria, Virginia 223 14. ABSTRACT This Information Sheet gives the equations for calculating the pitting resistance geometry factor, I, for external and internal spur and helical gears, and the bending strength geometry factor, J , for external spur and helical gears that are generated by rack-type tools (hobs, rack cutters or generating grinding wheels) or pinion-type tools (shaper cutters). The Information Sheet also includes charts which provide geometry factors, Z and J , for a range of typical gear sets and tooth forms. Copyright O, 1989 American Gear Manufacturers Assocation 1500 King Street, Suite 201 Alexandria, Virginia 223 14 April, 1989 ISBN: 1-55589-525-5 AGMA ii --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 908-B89 A G M A 908-B m Ob87575 0003028 417 m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth FOREWORD 1 [The foreword, footnotes, and appendices are provided for informational purposes only and should not be construed as part of American Gear Manufacturers Association Information Sheet 908-B89, Geometry Factors f o r Determining the Pitting Resistance and Bending Strength of Spur, Helical and Herringbone Gear Teeth.] This Information Sheet, AGMA 908-B89, was prepared to assist designers making preliminary design studies, and to present data that might prove useful for those designers without access to computer programs. The tables for geometry factors contained in this Information Sheet do not cover all tooth forms, pressure angles, and pinion and gear modifications, and are not applicable to all gear designs. However, information is also contained for determining geometry factors for other conditions and applications. It is hoped that sufficient geometry factor data is included to be of help to the majority of gear designers. Geometry factors for strength were first published in Information Sheet AGMA 225.01, March, 1959, Strength of Spur, Helical, Herringbone and Bevel Gear Teeth. Additional geometry factors were later published in Standards AGMA 220.02, AGMA 221.02, AGMA 222.02, and AGMA 223.01. AGMA Technical Paper 229.07, October, 1963, Spur and Helical Gear Geometry Factors, contained many geometry factors not previously published. Due to the number of requests for this paper, it was decided to publish the data in the form of an Information Sheet which became AGMA 226.01, Geometry Factors for Determining the Strength of Spur, Helical, Herringbone and Bevel Gear Teeth. ) AGMA 218.01, AGMA Standard for Rating the Pitting Resistance and Bending Strength of Spur and Helical Involute Gear Teeth, was published with the methods for determining the geometry factors. When AGMA 218.01 was revised as ANWAGMA 2001-B88, the calculation procedures for Geometry Factors, I and J , were transferred to this revision of the Geometry Factor Information Sheet. The values of I and J factors obtained using the methods of this Information sheet are the same as those of AGMA 218.01. The calculation procedure for I was simplified, but the end result is mathematically identical. Also, the calculation of J was modified to include shaper cutters and an equation was added for the addendum modification coefficient, x , previously undefined and all too often misunderstood. Appendices have been added to document the historical derivation of both I and J . Because an analytical method for calculating the Bending Strength Geometry Factor, J , is now available, the layout procedure for establishing J has been eliminated from this document. All references to geometry factors for bevel gears have been removed. This information is now available in AGMA 2003-A86, Rating the Pitting Resistance and Bending Strength of Generated Straight Bevel, ZEROL Bevel and Spiral Bevel Gear Teeth. The first draft of this Information Sheet, AGMA 908-B89, was presented to the Gear Rating Committee in August, 1987. It was approved by the AGMA Gear Rating Committee on February 24, 1989, after several revisions. It was approved for publication by the AGMA Technical Division Executive Committee on April 2 1,19 89. I AGMA iii 908-B89 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT AGHA 908-B W Ob87575 0003029 3 5 3 W Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth PERSO JNEL of the AGMA Committee for Gear Rating Chairman: J. Bentley (Peerless-Winsmith) Vice Chairman: O. LaBath (Cincinnati Gear ) ACTIVE MEMBERS M. Antosiewicz (Falk) J. D. Black (General Motors/AGT) E. J. Bodensieck (Bodensieck Engineering) W. A. Bradley (AGMA) R. Calvert (Morgan Construction) A. S . Cohen (Engranes y Maquinaria) J. DeMarais (Bison Gear) R. Donoho (Clark Equipment) R. J. Drago (Boeing) D. W. Dudley (Honorary Member) R. Errichello (Academic Member) H. Hagan (Nuttall Gear) N. Hulse (General Electric) H. Johnson (Browning Co.) X. D. Kemp (Kymmene-Stromberg Santasalo) J. C. Leming (Arrow Gear) (Deceased) L. Lloyd (Lufkin Industries) J. Maddock (Consultant) D. McCarthy (Dorris) D. R. McVittie (Gear Works - Seattle) M. W. Neesley (Westech) J. A. Nelson (General Electric) W. P. Pizzichil (Philadelphia Gear) J. W. Polder (Maag/NNI Netherlands) E. E. Shipley (Mechanical Technology) W. L. Shoulders (Reliance Electric) (Deceased) F. A. Thoma (Honorary Member) C. C. Wang (Consultant) R. Wasilewski (Arrow Gear) D. L. Manet (Falk) T. J. Maluri (Gleason) B. W.McCoy (Marathon Le Tourneau) D.Moser (Nuttall Gear) B. L. Mumford (Alten Foundry) W. Q. Nageli (MAAG) B. C. Newcomb (Chicago Gear - D. O. James) G. E. Olson (Cleveland Gear) J. R. Partridge (Lufkin Industries) A. E. Phillips (Emerson Electric/Brawning) B. D. Pyeatt (Amarillo Gear) T. Riley (NWL Control System) G. R. Schwartz (Dresser) A. Seireg (Academic Member) E. R. Sewall (Sewall Gear) L. J. Smith (Invincible Gear) M. Tanaka (Nippon Gear) H.J. Trapp (Klingelnberg) T. Urabe (Tsubakimoto Chain) D. A. Wagner (General Motors/AGT) R. E. Weider (Clark Equipment) L. E. Wilcox (Gleason) H. Winter (Academic Member) J. Worek (IMO Delaval) J. Amendola (MAAG/Artec) K. Beckman (Lufkin) E. R. Braun (Eaton) D. L. Borden (Consultant) A. Brusse (Hamilton) G. Buziuk (Brad-Foote) J. Cianci (General Electric) D. M. Connor (Cummins Engine) J. T. Cook (Dresser) E. Danowski (Sumitomo Heavy Industries) R. DiRusso (Kaman) A. B. Dodd (NAVSEA System Command) L. L. Haas (SPEC0 Division) F. M. Hager (Cummins Engine) A. C. Hayes (DACA) W. H. Heller (Peerless-Winsmith) G. Henriot (Engrenages et Reducteurs) R. W. Hercus (F. W. Hercus) M. Hirt (Renk) W. H.Jogwick (Union Carbide) T. Kameyama (Seiki-Kogyosho) D. L. King (Terre11 Gear) P. Losekamp (Xtek) K. Mariager (F. L. Smidth) AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS iv Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 908-B 89 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- ASSOCIATE MEMBERS Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth Table of Contents Section Title 1. Scope 1.1 1.2 1.3 1.4 1.5 Page Pitting Resistance Geometry Factor. I ................................. Bending Strength Geometry Factor. J ................................. Tables .......................................................... Exceptions ....................................................... Bending Stress in Internal Gears ..................................... 1 1 1 1 1 2 . Definitions and Symbols 2.1 Definitions ....................................................... 2.2 Symbols ......................................................... . Basic Gear Geometry 3.1 3.2 3.3 3.4 3.5 Contact Ratios .................................................... Minimum Length of the Lines of Contact ............................. Load Sharing Ratio, m N ......................................... Operating Helix Angle, qr ......................................... Operating Normal Pressure Angle, +nr .............................. 6 6 6 6 6 4 . Pitting Resistance Geometry Factor. I 4.1 4.2 4.3 4.4 5 . 6 . Pitting Resistance Geometry Factor Calculation ......................... 7 Operating Pitch Diameter of Pinion. d ................................ 7 Radii of Curvature of Profiles at Stress Calculation Point . . . . . . . . . . . . . . . . . 7 Helical Overlap Factor. C ,,, ......................................... 7 Bending Strength Geometry Factor. J 5.1 Virtual Spur Gear ................................................. 5.2 Pressure Angle at the Load Application Point .......................... 5.3 Generating Rack Shift Coefficient .................................... 5.4 Load Angle and Load Radius ....................................... 5.5 Tool Geometry .................................................. 5.6 Generating Pressure Angle ......................................... 5.7 Algorithm for Determining the Critical Point .......................... 5.8 Iteration Convergence ............................................. 5.9 Radius of Curvature of Root Fillet ................................... ............................................. 5.10 Helical Factor. Ch 5.11 Stress Correction Factor. Kf ....................................... 5.12 Helix Angle Factor. KQ ........................................ 5.13 Tooth Form Factor. Y ............................................ 8 8 9 9 10 12 13 14 15 15 16 16 16 Determining Addendum Modification Coefficients 6.1 6.2 6.3 6.4 Generating Rack Shift Coefficients .................................. Sum of the Addendum Modification Coefficients for Zero Backlash . . . . . . . Tooth Thinning for Backlash ...................................... Addendum Modification Coefficients ................................ AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 16 16 17 17 908-B 89 V Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- 3 2 2 AGflA 908-B Ob87575 0003031 T O 1 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Table of Contents (cont) Section Title Page 7. Geometry Factor Tables Using the Tables ................................................. Whole Depth .................................................... Outside Diameter ................................................ Type of Gearing ................................................. Center Distance .................................................. Tooth Thickness Backlash Allowance ................................ Undercutting Top Land Cutter Geometry Axial Contact Ratio ............................................... 7.1 7-2 7.3 7.4 7.5 7.6 7.7 7.8 7.9 7.10 Bibliography 17 18 18 18 18 18 19 19 19 19 .................................................... ...................................................... ................................................. . . ................................................................ 53 Appendices .... ........... 55 61 Appendix D Appendix E Original Derivation of AGMA Geometry Factor for Pitting Resistance. I ANWAGMA 2001-B88 Pitting Resistance Formula Derivation Explanation of the AGMA Gear Tooth Strength Rating Derivation For External Gears ............................................... Selection of Shaper Cutter Geometry ................................ Derivation of Helical Overlap Factor. C,,, ............................. Appendix F High Transverse Contact Ratio Gears ................................ 73 Appendix A Appendix B Appendix C 65 69 71 Tables Table 2-1 Table 5-1 Tables Symbols Used in Equations ......................................... 2 Limiting Variation in Action for Steel Spur Gears for Load Sharing . . . . . . . . 8 I and J FACTORS ............................................... 20 Figures .......................... 5 ....................................... 9 10 11 12 12 12 13 13 14 15 15 Fig 3-1 Transverse Plane View of The Line of Action Fig Fig Fig Fig Fig Fig Fig Fig Fig Fig Fig Load Angle and Load Radius Pressure Angle Where Tooth Comes to Point .......................... Shaper Cutter with Protuberance .................................... Involute Drawn Through Point "S" Pressure Angle Where Cutter Tooth Comes to a Point .................. Angle to Center. S. of Tool Tip Radius (Effective Cutter) ............... Critical Point of Maximum Bending Stress ............................ Shaper Cutter Generation .......................................... Iteration Function Oblique Contact Line ............................................. Helical Factor. Ch ............................................... 5-1 5-2 5-3 5-4 5-5 5-6 5-7 5-8 5-9 5-10 5-11 Fig 7-1 .................................. ................................................ Undercutting Criteria ............................................. .'t.... . . Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 908-B8 9 vi AGMA .4 . . . 19 "I Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT A G M A 908-B m Ob87575 0003032 948 m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth 1. Scope thickness due to protuberance below the active profile is handled correctly by this method. The procedures in this Information Sheet describe the methods for determining Geometry Factors for Pitting Resistance, I, and Bending Strength, J . These values are then used in conjunction with the rating procedures described in AGMA 200 1-B88, Fundamental Rating Factors and Calculation Methods for Involute Spur and Helical Gear Teeth, for evaluating various spur and helical gear designs produced using a generating process. (7) The root profiles are stepped or irregular. The J factor calculation uses the stress correction factors developed by Dolan and Broghamer[11. These factors may not be valid for root forms which are not smooth curves. For root profiles which are stepped or irregular, other stress correction factors may be more appropriate. (8) Where root fillets of the gear teeth are produced by a process other than generating. (9) The helix angle at the standard (reference) diameter* is greater than 50 degrees. 1.1 Pitting Resistance Geometry Factor, I. A mathematical procedure is described to determine the Geometry Factor, I, for internal and external gear sets of spur, conventional helical and low axial contact ratio, LACR, helical designs. In addition to these exceptions, the following conditions are assumed: (a) The friction effect on the direction of force is neglected. (b) The fillet radius is assumed smooth (it is actually a series of scallops). 1.2 Bending Strength Geometry Factor, J . A mathematical procedure is described to determine the Geometry Factor, J, for external gear sets of spur, conventional helical and low axial contact ratio, LACR, helical design. The procedure is valid for generated root fillets, which are produced by both rack and pinion type tools. 1.5 Bending Stress in Internal Gears. The Lewis method [2] is an accepted method for calculating the bending stress in external gears, but there has been much research [3] which shows that Lewis’ method is not appropriate for internal gears. The Lewis method models the gear tooth as a cantilever beam and is most accurate when applied to slender beams (external gear teeth with low pressure angles), and inaccurate for short, stubby beams (internal gear teeth which are wide at their base). Most industrial internal gears have thin rims, where if bending failure occurs, the fatigue crack runs radially through the rim rather than across the root of the tooth. Because of their thin rims, internal gears have ring-bending stresses which influence both the magnitude and the location of the maximum bending stress. Since the boundary conditions strongly influence the ring-bending stresses, the method by which the internal gear is constrained must be considered. Also, the time history of the bending stress at a particular point on the internal gear is important because the stresses alternate from tension to compression. Because the bending stresses in internal gears are influenced by so many variables, no simplified model for calculating the bending stress in internal gears can be offered at this time. 1.3 Tables. Several tables of precalculated Geometry Factors, I and J, are provided for various combinations of gearsets and tooth forms. 1.4 Exceptions. The formulas of this Information Sheet are not valid when any of the following conditions exist: (1) Spur gears with transverse contact ratio less than one, mp < 1.0. (2) Spur or helical gears with transverse contact ratio equal to or greater than two, m p 2 2.0. Additional information on high transverse contact ratio gears is provided in Appendix F. (3) Interference exists between the tips of teeth and root fillets. (4) The teeth are pointed. ( 5 ) Backlash is zero. (6) Undercut exists in an area above the theoretical start of active profile. The effect of this undercut is to move the highest point of single tooth contact, negating the assumption of this calculation method. However, the reduction in tooth root [ 3 Numbers in brackets refer to the bibliography. * Refer to AGMA 112.05 for further discussion of standard (reference) diameters. AGMA 1 908-B 89 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT A G M A 908-B m Ob87575 0003033 884 m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth 2. Definitions and Symbols resistance and bending strength formulas are shown in Table 2-1. NOTE: The symbols, definitions and terminology used in this Standard may differ from other AGMA standards. The user should not assume that familiar symbols can be used without a careful study of these definitions. Units of measure are not shown in Table 2-1 because the equations are in terms of unity normal module or unity normal diametral pitch. 2.1 Definitions. The terms used, wherever applicable, conform to the following standards: ANSI Y10.3-1968, Letter Symbols for Quantities Used in Mechanics of Solids AGMA 112.05 Gear Nomenclature (Geometry) Terms, Definitions, Symbols, and Abbreviations AGMA 600.01 Metric Usage 2.2 Symbols. The symbols used in the pitting Symbols Bn C Cl,C2’ ’ 6‘ ‘n 1 ‘n 4’ ‘n 6 ‘h Ç a.. cJI Da i9Da2 d F H hF I J J1 Js Kf KJI L min M mF MG mN mn mP n ni “2 AGMA Terms normal operating circular backlash standard center distance distances along line of action (Fig 3-1) distances along line of action of virtual spur gear helical factor operating center distance helical overlap factor addendum diameter, pinion and gear pinion operating pitch diameter effective face width parameter for stress correction factor nominal tool addendum height of Lewis parabola pitting resistance geometry factor bending strength geometry factor adjusted geometry factor geometry factor from table stress correction factor helix angle factor parameter for stress correction factor minimum length of contact lines parameter for stress correction factor axial contact ratio gear ratio load sharing ratio normal module transverse contact ratio virtual tooth number virtual tooth number of tool pinion tooth number gear tooth number 2 908-B89 ,+ Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Where First Used Eq 6.7 Eq 6.4 Eq 3.11-3.16 Eq 5.15-5.17 Eq 5.69 Eq 3.7 Eq 4.1 Eq 7.1-7.2 Eq 4.1 Eq 3.20 Eq 5.72 Eq 5.36 Eq 5.62 Eq 4.1 Eq 5.1 Eq 7.6 Eq 7.6 Eq 5.1 Eq 5.77 Eq 5.72 Eq 3.21 Eq 5.72 Eq 3.20 Eq 3.1 Eq 3.24 Eq 7.9M Eq 3.18 Eq 5.2 Eq 5.29 Eq 3.1 Eq 3.1 * ’& Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Table 2-1 Symbols Used in Equations A G H A 908-B = Ob87575 0003034 7 5 0 = Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth Table 2-1 (cont) Symbols Used in Equations Symbols na nC nr ‘nd pb PN PX R2 Rbli Rb2 Rbc RC %i R o l , R02 Roc ‘ n ) ‘n2 r; ‘no G O ‘i* ‘na, ‘na2 rn b ‘nb2 %bo nL ‘ SF ’n ’ n i , ‘n2 ‘na ‘no sns X xl’ x2 X g xO x g l *x g 2 Y Y Y’ Z AGMA Terms Where First Used fractional part of mF tool tooth number fractional part of m P normal diametral pitch transverse base pitch normal base pitch axial pitch standard pitch radii, pinion and gear base radii, pinion and gear base radius of tool standard pitch radius of tool mean radius of pinion addendum radii, pinion and gear, internal and external outside radius of tool reference pitch radii of virtual spur gear generating pitch radius of virtual spur gear reference pitch radius of virtual tool generating pitch radius of virtual tool radius to center “S” of tool tip radius virtual outside radii virtual base radii virtual base radii of tool virtual load radius tooth thickness at critical section reference normal circular tooth thickness reference normal circular tooth thickness, pinion and gear tooth thickness at outside diameter reference normal circular tooth thickness of tool standard tooth thickness, thinned for backlash stock allowance per side of tooth addendum modification coefficient at zero backlash addendum modification coefficient, pinion and gear generating rack shift coefficient addendum modification coefficient of tool generating rack shift coefficient, pinion and gear tooth form factor iteration function derivative of iteration function active length of line of action 3 908-B89 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Eq 3.22 Eq 5.29 Eq 3.22 Eq 7 . 5 Eq 3.8 Eq 3.9 Eq 3.19 Eq 3.2-3.3 Eq 3.5-3.6 Eq 5.34 Eq 5.33 Eq 4 . 3 Eq 3 . 1 2 , 3.15 Eq 5.36 Eq 5 . 3 , 5.12 Eq 5.51 Eq 5.30 Eq 5.52 Eq 5.39 Eq 5 . 5 , 5.14 Eq 5.4, 5.13 Eq 5.31 Eq 5.28 Eq 5.72 Eq 5.20 Eq 6.1-6.2 Eq 7 . 9 Eq 5.35 Eq 7 . 6 Eq 5.37 Eq 5.19 Eq 6.5 Eq 5.19 Eq 5.35 Eq 6.1-6.2 Eq 5 . 1 Eq 5.63 Eq 5.64 Eq 3.17 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT A G H A 908-B Ob87575 0003035 657 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth Table 2-1 (cont) Symbols Used in Equations Symbols ßn Asn 80 8ao ?n nF en ‘no KFiKS ns 1i.no En E nF p 1 * p2 Pmí, P m 2 Pa0 PF PF Q Qn Q; QnL +nP Qnpo Qnr Qnns Qnw Qr Jr % Jrr o Terms Where First Used angle of surface, normal iteration angle angle between tangent to fillet and tooth center line amount gear tooth is thinned for backlash amount of protuberance, tool amount of effective protuberance, tool ordinate of gear fillet curve ordinate of critical point “F” angular displacement of gear angular displacement of tool distance from pitch point to points “F” and “S” angle to center “S” of tool tip radius auxiliary angle locating point “S” abscissa of gear fillet curve abscissa of critical point “F” radii of curvature of profiles at point of contact stress calculation radii of curvature of profile at mean radius tool tip radius radius of curvature of fillet curve minimum radius of curvature of fillet curve standard transverse pressure angle standard normal pressure angle generating pressure angle load angle pressure angle at radius where gear tooth is pointed pressure angle at radius where tool tooth is pointed operating normal pressure angle pressure angle at point “S” on tool pressure angle at load application point operating transverse pressure angle standard helix angle base helix angle operating helix angle angle of inclination of helical contact line Eq Eq Eq Eq Eq Eq 5.53 5.65 5.59 5.19 5.38 5.38 Fig 5-8 Eq 5.61 Eq 5.57 Eq 5.56 Eq 5.54, 5.55 Eq 5.47 Eq 5.53 Fig 5-8 Eq 5.60 Eq 4.1 Eq Eq Eq Eq Eq Eq Eq Eq Eq Eq Eq Eq Eq Eq Eq Eq Eq Eq 4.8 5.39 5.66 5.68 3.4 3.4 5.48 5.22 5.22 5.43 3.28 5.40 5.10 3.7 3.2 3.10 3.27 5.70 SUBSCRIPTS o tool 1 pinion 2 gear n normal or virtual spur gear r operating or running - absence of a subscript indicates transverse 90 8-B89 AGMA --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT A G M A 908-6 W 0687575 000303b 593 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth 3. Basic Gear Geometry The following equations apply to spur and helical gears where spur gearing is a particular case with zero helix angle. Where double signs are used (e.&, t ) ,the upper sign applies to external gears and the lower sign applies to internal gears. The equations are derived in terms of unity normal module (mn = 1.0) or unity normal diametral pitch and are valid for any consistent set of units. All angles are given in terms of radians, unless otherwise specified. where Cr = operating center distance Transverse base pitch, p b Pb = IT nl Normal base pitch, p N p N = 7T cos +n Base helix angle, Qb The following variables must be made dimensionless by dividing with the normal module, m,, or multiplying with the normal diametral pitch, P n d , (See AGMA 112.05 for definitions of mn or Pnd ). The variables to be adjusted are Cr , F , Ro 1, Ro 2, Roc Rc, ha0 80 Pa,* and AS,. Qb = cos-’ (Eq 3.9) (%) PN (Eq 3.10) Figure 3-1 is a view of the line of action in the transverse plane. The lengths, c1 through c6, are derived from Fig 3-1. See 1.4 item ( 6 ) . referencing exceptions regarding gear tooth undercut. y Gear ratio, mG / n I --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- n2 mG = nl where n 2 = gear tooth number \ = pinion tooth number Standard (reference) pitch radius, R where Q = standard helix angle Standard (reference) pitch radius, R R2 = R 1 m G Standard transverse pressure angle, + where +n = standard normal pressure angle* Pinion base radius, R b l Rbl = R i COS + (Eq 3.5) Gear base radius, Rb2 Fig 3-1 Transverse Plane View of The Line of Action R b 2 = R b l mG Operating transverse pressure angle, +r * For a complete discussion, see 9.01 of AGMA 112.05 Gear Nomenclature (Geometry) Terms, Definitions, Symbols, and Abbreviations AGMA I Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 9 O 8-B 89 5 > Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT Ob87575 0003037 q 2 T A G H A 908-B Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth where F Sixth distance along line of action, c6 c6 = C, sin 9, (Eq 3.11) = effective face width at mn = 1.0 For spur gears, m F = 0.0 First distance along line of action, C1 3.2 Minimum Length of the Lines of Contact. C1 = 2 [C6-(Ro2- Rbz)0*5] where Ro2 (Eq 3.12) For spur gears with m < 2.0 the minimum P length of contact lines, Lmin, is: = addendum radius of gear, for =F L,in internal or external gears (Eq 3.21) For helical gears, two cases must be considered: Third distance along line of action, C3 Case I, for nu 5 1 - n, (Eq 3.13) (Eq 3.22) Fourth distance along line of action, Cq Case II, for na > 1 - nr (Eq 3.14) - m p F - (1 - n a )(i - n r ) Lmin - Fifth distance along line of action, C5 where nr (Eq 3.15) where Example : for a contact ratio, m of 1.4, then n, = 0.4 P’ Second distance along line of action, C2 (Eq 3.16) 3.3 Load Sharing Ratio, mN Active length of line of contact, Z For helical gears: (Eq 3.17) Distance C2 locates the lowest point of single tooth contact (LPSTC) and distance C4 locates the highest point of single tooth contact (HPSTC) , where C,, Rol and RO2 are values for mn = 1.0. mN = For spur gears with m < 2.0, P L, = F, therefore: m N = 1.0 Axial pitch, p x = L PX sin JI F - (Eq 3.19) 3.5 Operating Normal Pressure Angle, +nr (Eq 3.20) +nr = si<’ (COSQb sin +r 1 6 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS (Eq 3.26) (Eq 3.27) PX AGMA (Eq 3.25) 3.4 Operating Helix Angle, Qr Axial contact ratio, mF mF= (Eq 3.21) gives For LACR helicals, ( m F I. l.O), load sharing is accomodated by CQ, therefore: (Eq 3.18) pb (Eq 3.24) m N = 1.0 Transverse contact ratio, mp “P = F min 3.1 Contact Ratios. L (Eq 3.23) = fractional part of m P = fractional part of mF nu Ro 1 = addendum radius of pinion z = cg - c l cos @b PX Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT (Eq 3.28) 908-B89 m A G M A 908-B Ob87575 0003038 3bb m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth 4. Pitting Resistance Geometry Factor, I = addendum radius, gear, internal or Ro2 external The pitting resistance geometry factor, I , is a dimensionless number. It takes into account the effects of: (1) radii of curvature (2) load sharing (3) normal component of the transmitted load 4.1 Pitting Resistance Calculation. Radius of curvature of the pinion profile at the point of contact stress calculation, pl .L (Eq 4.4) where Rbl Geometry Factor = base radius, pinion Radius of curvature of the gear profile at the point of contact stress calculation, p 2 where = sixth distance along line of action C6 (see Eq 3.11) where +,. = operating transverse pressure angle C,,, = helical overlap factor (See 4.4 and Appendix E) d = pinion operating pitch diameter rnN = load sharing ratio p = radius of curvature of pinion profile at point of contact stress calculation 4.3.2 Spur and Low Axial Contact Ratio Helical Gears. For spurs and LACR helicals (mF 5 1.0) the radii of curvature are calculated at the LPSTC 0% P 1 = c2 4.6) where = second distance along line of action C2 (see Eq 3.16) = radius of curvature of gear profile at p2 point of contact stress calculation 4.4 Helical Overlap Factor, CQ* 4.2 Operating Pitch Diameter of Pinion, d. For LACR helical gears (rnF 5 1.0) ' ) r br d = "G!: where mG 1 C Jr = gear ratio = [- rn l F(l- prn1prn2z )]Oa5 P ~ P ~ P N (Eq 4.8) where Radii of Curvature of Profiles a t Stress Calculation Point 4.3 Z = active length of line of action pN = normal base pitch 4.3.1 Conventional Helical Gears. For conventional helical gears (mF > 1.0) the radii of curvature are calculated at the mean radius or middle of the working profile of the pinion where: Radius of curvature of the pinion profile at the mean radius of the pinion, prnl Mean radius of pinion, Rrnl Radius of curvature of the gear profile at the mean radius of the gear, prn2 . r 1 (Eq 4.10) where Rol * For spurs and conventional helicals c+ = = addendum radius, pinion 1.0 (Eq 4.11) See Appendix E for derviation of C zlr ' 9 08-B 89 7 AGMA --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT A G f l A 908-6 0687575 0003039 2 T 2 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth 5. Bending Strength Geometry Factor, J (Eq 5.4) The bending strength geometry factor, J , is a dimensionless number. It takes into account the effects of: (1) shape of the tooth (2) worst load position (3) stress concentration (4) load sharing between oblique lines of contact in helical gears Both tangential (bending) and radial (compressive) components of the tooth load are included. This analysis applies to external gears only. The J factor calculation procedure must be repeated for both the pinion and the gear using the appropriate dimensions for each. J = Virtual outside radius, rna rna = rn Kf mN (Eq 5 . 5 ) n = nl (Eq 5-61 rn = R i (Eq 5.7) 'nb = R b l (Eq 5-81 'na = (Eq 5.9) 5.2 Pressure Angle a t the Load Application Point. Spur gears develop the most critical stress when load is applied at the highest point of the tooth where a single pair of teeth is carrying all of the load. Spur gears having variations that prevent two pairs of teeth from sharing the load may be stressed most heavily when the load is applied at the tip. Table 5-1 has been used in previous standards to establish the variation in base pitch between the gear and pinion, which determines whether or not load sharing exists in steel spur gears. Values in excess of those shown in Table 5-1 require the use of tip loading. Kf M N C,,, - R1 For spur gears, the actual geometry is used y cJr - where Y + Ro = tooth form factor (See 5.13) = helical overlap factor (See 4.4) = stress correction factor (See 5.11) = load sharing ratio (See 3.3) Table 5-1 Limiting Variation in Action for Steel Spur Gears for Load Sharing (Variation in Normal Base Pitch) It is recognized that an anomaly exists when calculating the J factor for LACR gears where the value obtained may be greater than a conventional helical gear. For this reason, it is recommended that the J factor be calculated for both the LACR condition and as a conventional helical gear, using a value for F which is slightly greater than p x . The resulting conservative value should be used unless otherwise justified. Number Of Pinion Teeth 15 Maximum Allowable Variation in inches (mm),When Teeth Share Load Load per Inch of Face (per mm of face) 500 lb 1000 lb 2000 lb 4000 lb 8000 lb (90 N) (175 N) (350 N) (700 N) (1400 N) 0.0004 0.0007 0.0014 0.0024 (0.01) (0.02) (0.04) (0.06) 0.0042 (0.11) 5 . 1 Virtual Spur Gear. The following analysis is based on the work of Errichello [4] [5] [6]. 20 Helical gears are considered to be virtual spur gears with the following virtual geometry: 0.0003 0.0006 0.0011 0.0020 0.0036 (0.01) (0.02) (0.03) (0.05) (0.09) 25 0.0002 0.0005 0.0009 0.0017 0.0030 (0.01) (0.01) (0.02) (0.04) (0.08) Virtual tooth number, n For helical gears and spur gears that are analyzed where the load is applied at the tip of the tooth, the pressure angle at load application point, +nw,is given by: Standard (reference) pitch radius of virtual spur gear, rn r - -n n - 2 (Eq 5.10) Virtual base radius, rnb AGMA 8 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 908-B89 A G M A 908-B W Ob87575 0003040 T L 4 W Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth For spur gears, where the highest bending stress occurs when the load is at the highest point of single tooth contact (HPSTC) , the pressure angle is given by: As, x c4 -- rnb tan+ nW (Eq 5.11) Equation 5.11 may also be used for LACR helical gears, but distance C4 must be based on the virtual spur gear. The following equations are developed from analogy with Eqs 3.3, 3.6, 3.11, 3.12, 3.14, 5.5 and 5.11. Standard (reference) pitch radius of virtual spur gear, rn2 - ‘n2 (Eq 5.12) ‘n m G Virtual base radius, 5 b 2 -- ‘nb2 (Eq 5.13) -- ‘na2 ‘n2 + + A S, - rr I2 2 tan +n sn = normal circular tooth thickness measured on the Standard (reference) pitch cylinder sn = IT +2 2 x tan +n g defines the load angle, +nL, and the load radius, rnL‘ The load is shown applied at an arbitrary point “W” , such that: - inv +nP = pressure angle at radius where gear tooth is pointed. see Fig 5-2 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- First distance along line of action, Cn 1, of virtual spur gear 2 = [Cná- (‘na2-‘$2 )O’”] (Eq 5 . l 6 ) Fourth distance along line of action,Cn4, of virtual spur gear ‘n4 = ‘ni PN (Eq 5.17) + The pressure angle at load application point, +nw = Cn 4 - (Eq 5.18) ‘nb 5.3 Generating Rack Shift Coefficient. The generating rack shift coefficient, xg , applies to the completely finished teeth. It includes the rack shift for addendum modification plus the rack shift for thinning the gear teeth to obtain backlash: = xg x - Asn 2 tan +n (Eq 5.19) where x = addendum modification coefficient at zero backlash AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS (Eq 5.22) where Sixth distance along line of action, C n 6 , of virtual spur gear cn 6 = ( ‘nb 2 + ‘nb Itan +nr (Eq 5.15) cn1 (Eq 5.21) 5.4 Load Angle and Load Radius. Figure 5-1 (Eq 5.14) R02 - R2 (Eq 5.20) where 9, ga2 Virtual outside radius, S, +nL = tan r$nW mG ‘nb = = amount gear tooth is thinned for backlash Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT A G H A 908-B W Oh87575 000304L 950 W Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth equal a large number such as nc = 10 000. When exact cutter dimensions are not known, refer to Appendix D. Helical gears are considered to be generated by a virtual shaper cutter with the following virtual geometry: V i a l tooth number of tool, no nc no = CO9 where nc Jr (Eq 5.29) = tool tooth number Standard (reference) pitch radius of virtual tool, ‘no rn0 = 2 (Eq 5.30) Virtual base radii of tool, rnbo --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- ‘nbo -- ‘no cos 4n (Eq 5.31) For spur gears, the actual cutter geometry is used Fig 5-2 Pressure Angle Where Tooth Come&to Point inv+ = inv+, nP but ‘ “ ~ 9= ~ tan+n 2rn = sn + zn - (Eq 5.23) 9, n + +n- n ‘no = Rc (Eq 5.33) where Rc = standard pitch radius of tool ‘nbo = Rbc (Eq 5.25) where +sny = tanQnw- tan4, (Eq 5.32) (Eq 5.24) inv+ = tan+n - 4n (Eq 5.26) nP Substituting this value in Eq 5.22 gives: +nL no = n c (Eq 5.27) Equation 5.27 gives the load angle for any load position specified by tan 4nnw. From Fig 5-1, the virtual load radius, rnL, is: (Eq 5.28) 5.5 Tool Geometry. The following analysis is based on pinion type generating tools commonly referred to as shaper cutters. However, the method applies equally well to rack-type generating tools by letting the tooth number of the tool Rbc = base radius of tool Figure 5-3 shows a shaper cutter with protuberance,öO. A tool without protuberance is a particular case for which 8, = O. The center of the tip radius, point “S”, is located by radius r and angle &/2. The nominal tool addendum is h,, . The reference addendum related to the virtual radius, rno , is hu0 + x0, where Xo is the addendum modification coefficient corresponding to the present sharpening condition of the cutter. The addendum modification coefficient of the tool, x0, relates the actual normal circular tooth thickness of the tool, sno, to the nominal value of m / 2 . If sno is known from measurements of the tool, x0 may be calculated from: io 9O 8-B8 9 AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS (Eq 5.34) Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT Ob87575 0003042 897 A G M A 908-B a Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth where Roc (Eq 5.35) = outside radius of tool where sno, u s , Roc, and Rcare values for where S no = reference normal circular tooth mn = 1.0. thickness of tool Finishing hobs usually have sno=rr12 in which case xo = O. A pre-grind hob which has teeth thinner than 1712 to provide stock allowance for grinding usually has a tooth thickness of: NOTE: xo is positive when sno> IT/^ (corresponding to a new shaper cutter), or negative when sno < rr12 (corresponding to a used shaper cutter). Near the mid-life of the cutter, its tooth thickness equals ~ r / 2 and xo = 0.0. r sno -- r - 2 - 2u, (Eq 5.37) where = stock allowance per side of the gear us tooth Since us is removed during grinding, the basic rack corresponding to the finished gear teeth is used for the analysis; Le., let sno = 7 ~ 1 2and reduce the amount of protuberance: xo = o suo = so - us cos 4Jn (Eq 5.38) where Tr “O suo = amount of effective protuberance, 8, tool = amount of protuberance, tool from Fig 5-3 . ‘no where r S radius gs, &TOOL SPACE Fig 5-3 Shaper Cutter with Protuberance +ns The nominal tool addendum is defined as the addendum where the normal circular tooth thickness of the tool equals the nominal value of ~ 1 2 . If the outside radius of the tool is known from measurements, the nominal tool addendum, hu0 , may be calculated from: Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS (Eq 5.39) Figure 5-4 shows an involute drawn through point “S”. The pressure angle at point “S” on tool, is: @TOOL TOOTH AGMA pa0 = tool tip radius Pau Rc- x 0 - = radius to center “S” of tool tip no bao= Roc- t huo t xo = cos -1 (--)nbo no inv+ns = tan 4~~~ - (Eq 5.40) ,+ (Eq 5.41) The reference circular tooth thickness of the cutter is: ‘no - 7T 2 + 2 x 0 tan+, (Eq 5.42) In Fig 5-5, 4Jnpo is the pressure angle where the cutter tooth comes to a point. It is given by: (Eq 5.36) 90 8-B 8 9 11 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- r,So = = O687575 A G M A 908-B 00030Ll3 7 2 3 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth - = inv +n+ ,no inv+ nP0 2rno but: inv+n ‘no = tan +n - +n (Eq 5.44) - (Eq 5.45) - no inv+ = tan +n nP0 from Fig 5-6 -= (Eq 5.43) - +n +-‘no inv+npo - inv+ns + (800- pa0 ) rnbo 2 where A, (Eq 5.46) n0 (Eq 5.47) = angle to center “S” of tool tip radius inv Fig 5-5 Pressure Angle Where Cutter Tooth Comes to a Point 5.6 Generating Pressure Angle. The generating pressure angle, 4; , depends on the virtual center distance between the cutter and the gear which is determined by xg and Xo. The generating pressure angle, 4; , is obtained from: inv+i = + 2(x + xo )tan+n 8 n + no (Eq 5.48) Fig 5-6 Angle to Center, S, of Tool Tip Radius (Effective Cutter) 9O 8-B89 AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Fig 5-4 Involute Drawn Through Point “S” Ob87575 0003044 bbT A L M A 908-B Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth Arc involute may be solved by iteration.[5] Let the first trial value for be: From Fig 5-8 the auxiliary angle locating point “ S ” , p n o , is: ;+ +;i= (3 inv ;+ 0.33 (Eq 5.49) ) This trial value is successively improved upon using: where a, = angle of surface normal a 5.6.1 Generating Pitch Radii. The generating pitch radius of virtual spur gear, r l , is: (Eq 5.51) The generating pitch radius of virtual tool, il 5; , is: (Eq 5.52) 5.7 Algorithm for Determining the Critical Point. Figure 5-7 shows the critical point of maximum bending stress located at the intersection of the Lewis parabola and the gear tooth fillet. To locate this point, we consider the relative motion between the shaper cutter and the generated gear tooth. Figure 5-8 shows the shaper cutter generating an arbitrary point “F” on the gear tooth fillet. From the law of conjugate gear tooth action, point “F” lies on a line which extends from the generating pitch point “ P ” through the center of the tool tip radius, point “ S ” . The fillet coordinates are best expressed by selecting the angle a, as the independent parameter. Then for a n = n / 2 , generating starts at the lowest point on the fillet and proceeds up the fillet as a n is diminished corresponding to clockwise rotation of the tool and counter-clockwise rotation of the gear. I . VERTEX GEAR TOOTH CENTERLINE Fig 5-7 Critical Point of Maximum Bending Stress AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Fig 5-8 Shaper Cutter Generation 13 908-B89 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- .CRITICAL POINT 0687575 00030V5 5Tb W A G M A 908-B Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth Distance from pitch point to point “S”, K S , is: = height of Lewis parabola hF Differentiating Eq 5.63 gives: The distance from pitch point to point “F”, K F , is: K F = K S - Pa, (Eq 5.55) K F and K S are vectors and may be positive or negative. The angular displacement of tool, II eno, is: r sin a,, (Eq 5.56) n en = (Eq 5.57) en, where = angular displacement of gear e, (Eq 5.58) --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- The slope of the line tangent to the fillet at point ”F” is: ß,= an -8, (Eq 5.59) where = angle between tangent to fillet and ß, tooth center line The coordinates of critical point “F” are: sin en + KF cos ß n (Eq 5.60) The ordinate of critical point “ F ” , qnF q n F = r i cos9, + KF sinß, = derivative of iteration function Assuming an initial approximation for a!, = 7~14, it is successively improved upon by using Newton’s Method of iteration. L (Eq 5.65) an1 = a n - y’ On each iteration, a n is set equal to ani and Eq 5.53 through Eq 5.65 are iterated until [y[in Eq 5.63 is a negligible tolerance. 5.8 Iteration Convergence. Equation 5.63, expressing the function y = f ( a! n ) , is plotted in Fig 5-9 for a typical case. By selecting an=n/4as the initial approximation, rapid convergence to the proper root is obtained, usually within 3 to 5 iterations. This choice for the initial value prevents convergence to the incorrect root which exists closer to a = O. This incorrect root corresponds to the case where the Lewis parabola is inverted, opening upward rather than downward. 15 , The abscissa of critical point “ F ” , gnF En, = r; (Eq 5.64) where y’ The gear rotation angle is: 1 (Eq 5.61) 10 Let Y = f(a!n) (Eq 5.62) 5 For point “F” to be on the Lewis parabola, the following equation must be satisfied: O hF y = rnL- nF = 2hF tanß, where y - knF = O (Eq 5.63) -5 = iteration function I I O ml4 Fig 5-9 Iteration Function 9O 8-B 89 AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS an I nt2 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT A G M A 908-B Ob87575 000304b 432 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth 5.9 Radius of Curvature of Root Fillet. The radius of curvature of the fillet curve, at any point defined by a n is given by: Pk, --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- KS addendum beyond the loaded portion (see Fig 5-10) (Eq 5.66) = r" no -T' no (Eq 5.67) The J factor uses the minimum radius of curvature which occurs at the point where the fillet curve is tangent to the root circle, where a = n / 2 and pno = O. NOTE: Full Buttressing Exists When 5 2 One Addendum Fig 5-10 Oblique Contact Line For Spur and LACR Helical Gears(mF 5 1.0), a unity value is used, Subsituting, the minimum radius of curvature of fillet curve, pF, is: Ch = 1.0 (Eq 5.69) For conventional Helical Gears, when mF > 1.0 c - 1 h- 5.10 Helical Factor, Ch. The helical factor, C h , is the ratio of the root bending moment produced by tip loading to the root bending moment produced by the same intensity of loading applied along the oblique helical contact line. It is based on the work of Wellauer and Seireg [7]. (Eq 5.70) o .5 where w = angle of inclination of helical contact line in degrees w If the worst condition of load occurs where full buttressing exists, the value of Ch may be increased by 10 percent. Full buttressing exists when the face of the tooth extends at least one = tan-1 (tan+ sin+n) Equation 5.70 is valid for (Eq 5.71) + < 50'. Ch values can be taken from Fig 5-11 2.0 = 30' 1.8 = 22O P O .CI 1.6 = 15' o 9 L 1.2 1 .o Helix Angle, $ Fig 5-11 Helical Factor, AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS ch 15 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 90 8-B 8 9 A G M A 908-B Ob87575 0003047 379 m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth The helical factor, C h , is based on the work of Wellauer and Seireg [7]. 6. Determining Addendum Modification Coefficients 5.11 Stress Correction Factor, Kf. The stress correction factor, KI, includes the effects of stress concentration and load location, based on the work of Dolan and Broghamer [i]. It is given by: In order to use Section 5, x1 and x2 must be determined. If these values are not known, this Section provides a method for determining them. (Eq 5.72) 6.1 Generating Rack Shift Coefficients. If the normal circular tooth thicknesses are known, the generating rack shift coefficients are found from Eqs 6.1 and 6.2. where sF = tooth thickness at critical section = 2EnF x - 51-? gl - 2 tan+n hF = minimum radius of curvature of fillet curve = height of Lewis parabola H = 0.331 - 0.436+n (Eq 5.74) L = 0.324 - 0.492& = 0.261 t 0.545+n (Eq 5.75) M exg P 22tan - T c$~ = x 82 + - x 81 (Eq 6.3) where X gl (Eq 5.76) X 82 where +n ) (Eq 5.73) xg2 = pF 0% 6.1) = standard normal pressure angle = generating rack shift coefficient, pinion = generating rack shift coefficient, gear Exg = sum of generating rack shift coefficients Note: In order to calculate an accurate value for Kf , the significant decimal places in Eq 5.74 through 5.76 are necessary. The resulting values of H, L and M may be rounded to two decimal places. 5.12 Helix Angle Factor, KJ,. The helix angle factor, KJ,, depends on the type of gear. For Spur and LACR Helical Gears(mF <_ l.O), a unity value is used, KJ,= 1.0 For Conventional Helical Gears, when mF > 1.0 KJ, = Snl = reference normal circular tooth thickness, pinion (see Eq 5.21) Sn2 = reference normal circular tooth thickness, gear (see Eq 5.21) 6.2 Sum of Addendum Modification Coefficients for Zero Backlash. Although the amount of tooth thinning applied to each gear may be unknown, the sum of the addendum modification coefficients for the gear pair, ex, can be established. c (inv 4,. - inv +) ex = tan + (Eq 5.77) ex = x2 f 5.13 Tooth Form Factor, Y. The tooth form factor, Y, is calculated by: C = R 2 f Ri COS$,. COS$ x1 (Eq 6.5) 0% 6-61 where x = addendum modification coefficient, pinion x2 = addendum modification coefficient, gear AGMA 908-B89 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT AGMA 908-El 0687575 0003048 205 = Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth C = standard center distance criteria listed in 7.1 through 7.10 were used in calculating the table values. R 1 = standard pitch radius, pinion The following paragraphs and equations use dimensionless numbers to describe the gear geometry. To make actual measurements dimensionless, they are converted to ratios by multiplying them by diametral pitch, dividing them by module, or comparing them to a IT (3.1416) circular pitch at the standard pitch diameter. Any consistent system of units can be used for this conversion, see Section 3. R2 = standard pitch radius, gear 6.3 Tooth Thinning for Backlash. It is usually impossible to determine the ratio As, / A sn2 that was used for existing gears. The following analysis is based on common practice where Asnl = Asn2, in which case: 7.1 Using the Tables. Each table of I and J values was generated for a specific tool form (basic rack) defined by whole depth factor, normal pressure (profile) angle and tool edge (tip) radius. Each tool form was used to generate 66 tables of values: Asnl= Asn2= where B, = normal operating circular backlash C, = operating center distance For spur gears: Loaded at Tip x1 = x p = o x1 = 0.25, xz = -0.25 X I = 0.50, xp = -0.50 A ~n1= tooth thinning for backlash, pinion tooth thinning for backlash, gear A s2= Loaded at HPSTC x1 = x2 = o x1 = 0.25, xp = -0.25 x1 = 0.50, xp = -0.50 6.4 Addendum Modification Coefficients. The addendum modification coefficients, xi and x2, can be established from Eq 6.9 and 6.10. x 2 = xg2 2 "n2 2 tan Qn For helical gears: 10 degree standard helix angle x1 = xp = o X I = 0.25, xp = -0.25 x1 = 0.50, xp = -0.50 (Eq 6.10) 15 degree standard helix angle x1 = x p = o x1 = 0.25, x p = -0.25 x1 = 0.50, xp = -0.50 7. Geometry Factor Tables The following tables provide the Geometry Factor for Pitting Resistance, I , and the Geometry Factor for Bending Strength, J , for a range of typical pairs of gears. The tables were prepared by computer, programmed in accordance with Section 5. The values were rounded to two significant figures. The tables cover various combinations of helix angle, pressure angle, whole depth, tool edge radius, tooth load point and addendum modification. The Tables do not cover all tooth forms, pressure angles, and pinion or gear modifications, and are not applicable to all gear designs. In addition to the basic geometry, the AGMA 20 degree standard helix angle x1 = xp = o x1 = 0.25, x2 = -0.25 x1 = 0.50, x2 = -0.50 25 degree standard helix angle x1 = xp = o x1 = 0.25, x p = -0.25 x1 = 0.50, x2 = -0.50 30 degree standard helix angle x1 = x p = o x1 = 0.25, xp = -0.25 XI = 0.50, xp = -0.50 17 908-B89 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT A G H A 908-B œ Ob87575 0003049 1 4 1 œ Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth To obtain values for I and J , enter the table for the appropriate whole depth factor tool, helix angle, loading condition and addendum modification factor and select values for the numbers of pinion and gear teeth. If the exact values for your gearset are not listed, the calculation method of Section 5 is recommended. Interpolation is not recommended. c = -n l +n2 2cos where C x1+x2 = 7.3 Outside Diameter. The tabulated values are calculated for gears having an outside diameter (addendum diameter) equal to (in terms of mn = 1.0): 3 +2 cos (1 + x2) cos* * x = addendum modification coefficient, pinion x2 = addendum modification coefficient, gear A sn = 0.024 - = 0.024 pnd If the gears being evaluated have different minimum tooth thicknesses, the Bending Strength Geometry Factor, J, can be approximated using Eq 7.6. The Pitting Resistance Geometry Factor, I , is unaffected by variations in tooth thickness. where Ji =(%J nl n2 Jr = pinion tooth number Dai = pinion addendum diameter J1 = adjusted geometry -jctor Da2 = gear addendum diameter Js = geometry factor from table = gear tooth number JS = standard helix angle, degrees where snl = adjusted circular tooth thickness 7.4 Type of Gearing. The tables apply to external gears only. An analytical method for determining the Bending Strength Geometry Factor, J , for internal gears is beyond the scope of this Standard. Sns = standard tooth thickness, thinned per Eq 7.5 Example: From the table at the top of page 32 for 20' pressure angle spur gears, loaded at the highest point of single tooth contact, the J factor for a 21 tooth pinion operating with a 35 tooth gear is found to be 0.34. The table is based on a circular tooth thickness of: 7.5 Center Distance. The tables apply to gearsets that operate on a standard center distance. This center distance is the tight mesh center distance for gears not yet thinned for backlash. See 7.6. 18 AGMA .'. Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 9 O 8-B 89 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- + Xi) (Eq 7-41 7.6 Tooth Thickness Backlash Allowance. The values in the tables are calculated based on a backlash allowance. The circular tooth thicknesses for the pinion and the gear are each thinned by an amount, A S n , shown in Eq 7.5. or 1 normal module. The actual generated depths are slightly greater due to tooth thinning for backlash. (1 o where 7.2 Whole Depth. Whole depth is expressed in the Tables as a "whole depth factor", the whole depth of a basic rack for 1 normal diametral pitch +2 = standard center distance. For this center distance the sum of the addendum modification coefficients is zero (See 5.3 for definitions), A "U" in the tables indicates a gear tooth combination which should be avoided due to undercutting. A "T" in the tables indicates a gear tooth combination which should be avoided due to pointed pinion teeth. = * A G M A 908-B = Ob87575 0003050 963 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth -IT_ 7.9 Cutter Geometry. The hob geometry used in the calculation of I and J is as follows: = 3’1416 - - 0.024 = 1.547 2 (from Sections 7 and 7.3) 0.024 2 For a 10 normal diametral pitch gear or pinion, the equivalent circular tooth thickness would be: -1.547 10 - 0.155 (Eq 7.7) A 6.5% reduction in tooth thickness reduces J by 12%. 7.7 Undercutting. The tables do not include geometry factors when an undercutting condition exists in either of the two gears. This condition can be evaluated using Eq 7.8 and Fig 7-1 where the generating rack shift coefficient, x g , must be equal to or greater than the expression in Eq 7.8. gmin = where hao h -p ao ao = 10 O00 ‘no = 1.5708 xo = 0.0 ¿io = 0.0 where nc If a value for J for a 0.010 inch thinner pinion, having a circular thickness of 0.155 - 0.010 = 0.145 inch is required, the approximate value is: X nC = tool tooth number ‘no = reference normal circular tooth xo = addendum modification coefficient Bo of tool = amount of protuberance thickness of tool Hl -DATUM - - - _PITCH _ LINE n sin2+ (1-sin+)-n 2 n (Eq 7.8) = nominal tool addendum r = A = tool tip radius = pinion or gear tooth number n 7.8 Top Land. The tables do not include geometry factors when either the pinion or gear tooth top land is less than the value expressed in Eq 7.9. %a min 2 / Fig 7-1 Undercutting Criteria 0.3 %d 7.10 Axial Contact Ratio. The I and J factors for helical gears are calculated using an axial contact ratio, m F ,equal to 2.0. When the axial contact ratio is other than 2.0, the resulting values for I and J may be reduced by as much as 10%. (Eq 7.9M) where = tooth thickness at outside diameter, in (mm) AGMA 19 908-B89 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- I * - Sna min ? 0 . 3 m n sna n Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT A G H A 908-B Obi37575 000305L 8 T T Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth I AND J FACTORS FOR:’ 14.5 DEG. PRESSURE ANGLE DEG. HELIXANGLE TOOL EDGE RADIUS EQUAL ADDENDUM ( x 1= x = O) 2.157 WHOLE DEPTH FACTOR 0.024 TOOTH THINNING FOR BACKLASH LOADED AT TIP 0.0 0.157 GEAR TEETH 14 12 17 P G u u u u u u u u u PINION TEETH 21 26 P G P G P G u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u P G u u u 35 P 55 G P G P 135 G 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J 0.061 0.18 0.074 0.18 0.19 0.096 0.18 0.20 0.18 0.061 0.19 0.19 0.088 0.19 0.20 0.061 0.20 0.20 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. DEG. PRESSURE ANGLE DEG. HELIX ANGLE O. 157 TOOL EDGE RADIUS 25 PERCENT LONG ADDENDUM PINION (x I 14.5 0.0 2.157 WHOLE DEPTH FACTOR 0.024 TOOTH THINNING FOR BACKLASH LOADED AT TIP = 0.25) 25 PERCENT SHORT ADDENDUM GEAR ( x 2 = - 0.25) GEAR TEETH 14 12 17 PINION TEETH 21 26 P G P G P G u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u P G P G u u u u u u u u u u u u 35 P 55 G P G 12 I J 14 I J P --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- i AND J FACTORS FOR:’ 135 G 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J 0.060 0.20 0.16 0.071 0.20 0.17 0.087 0.20 0.18 0.111 0.20 0.19 0.059 0.20 0.17 O. 077 0.20 0.18 0.106 0.20 0.19 0.060 0.20 0.18 O. 092 0.20 0.19 0.060 0.20 0.19 1 The letter “U” indicates a gear tooth combination which produces a n undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 20 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 9 08-B 89 m A G H A 908-B Ob87575 0003052 73b D Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth ) I AND J FACTORS FOR:’ 2.157 WHOLE DEPTH FACTOR DEG. PRESSURE ANGLE 0.024 TOOTH THINNING FOR BACKLASH DEG. HELIX ANGLE LOADED AT TIP TOOL EDGE RADIUS 50 PERCENT LONG ADDENDUM PINION ( x = O. 50) 14.5 0.0 0.157 50 PERCENT SHORT ADDENDUM GEAR ( x 2 = - 0.50) PINION TEETH GEAR TEETH 14 12 21 17 P G u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u P G P G u u u u u u u u u u u u P 26 G P 55 35 G P G P 135 G P G 12 I J 14 I c I I ~ I J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J 0.056 0.21 0.12 0.067 0.21 0.13 0.081 0.21 0.15 o. 100 0.21 0.17 O. 127 0.21 0.19 0.056 0.21 0.13 0.071 0.21 0.15 0.091 0.21 0.17 0.123 0.21 0.19 0.056 0.21 0.15 0.078 0.21 0.17 0.114 0.21 0.19 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- I 0.057 0.21 0.17 0.096 0.21 0.19 0.060 0.21 0.19 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. I AND J FACTORS FOR:’ DEG. PRESSURE ANGLE DEG. HELIX ANGLE TOOL EDGE RADIUS EQUAL ADDENDUM ( x 1 = x = O) WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT HIGHEST POINT OF SINGLE TOOTH CONTACT 14.5 0.0 O. 157 2.157 0.024 PINION TEETH GEAR TEETH I 12 I J 14 I J 14 12 17 P G u u u u u u u u u 21 G G u u u u u u u u J u u u u u u u u u u u u u u - u u u u u u u u u u u u u u u u U u u u u u u t r u u u u 35 P G G 26 P P P P 55 G P 135 G P G 17 I J 21 I J 26 I J 1 ,, I 35 I J 55 I J 135 I J f 0.061 0.29 0.29 0.074 0.30 0.31 0.096 0.31 0.34 0.061 0.33 0.33 0.088 0.35 0.35 0.061 0.38 0.38 I t I 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 21 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 908-B89 A G U A 908-B Ob87575 0003053 6 7 2 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth I AND J FACTORS FOR:’ 14.5 DEG. PRESSURE ANGLE 0.0 DEG. HELIX ANGLE 0.157 TOOL EDGE RADIUS 25 PERCENT LONG ADDENDUM PINION (x 25 PERCENT SHORT ADDENDUM GEAR WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT HIGHEST POINT OF SINGLE TOOTH CONTACT = 0.25) 2.157 0.024 ( ~ 2= - 0.25) ~ PINION TEETH --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- GEAR TEETH 12 I J 14 I 12 14 P G u u 17 P G 21 P G 26 P G J u u u u 17 I J u u u u u u 21 I J u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u 26 I J 35 I J 55 I J 135 I J P 35 G 0.060 0.32 0.22 0.071 0.32 0.24 0.087 0.33 0.27 0.111 0.35 0.29 P 55 G 0.059 0.34 0.24 0.077 0.35 0.27 O. 106 0.36 0.30 P 135 G 0.060 0.37 0.29 0.092 0.39 0.32 P G 0.060 0.41 0.35 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. I AND J FACTORS FOR:l 14.5 DEG. PRESSURE ANGLE 2.157 WHOLE DEPTH FACTOR 0.0 DEG. HELIX ANGLE 0.024 TOOTH THINNING FOR BACKLASH O. 157 TOOL EDGE RADIUS LOADED AT HIGHEST POINT OF SINGLE TOOTH CONTACT 50 PERCENT LONG ADDENDUM PINION (x = 0.50) 50 PERCENT SHORT ADDENDUM GEAR ~~ (x, = - 0.50) ~ ~ PINION TEETH GEAR TEETH 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J 12 17 14 P G P G u u u u u u u u u u u u 21 P G u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u P 26 G 0.056 0.35 0.15 0.067 0.36 0.17 0.081 0.36 0.19 0.100 0.37 0.22 O. 127 0.38 0.26 P 35 G 0.056 0.37 0.17 0.071 0.37 0.20 0.091 0.38 0.23 O. 123 0.39 0.26 P 55 G 0.056 0.38 0.20 0.078 0.39 0.24 0.114 0.40 0.27 P 135 G O . 057 0.41 0.25 0.096 0.42 0.29 P G 0.060 0.43 0.32 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 9 O 8-B 89 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT m A G H A 908-B m Ob87575 0003054 509 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth I AND J FACTORS FOR:’ DEG. PRESSURE ANGLE DEG. HELIX ANGLE TOOL EDGE RADIUS EQUAL ADDENDUM ( x 1 = x = O ) WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP 14.5 10.0 0.157 GEAR TEETH 12 I J 14 I J 17 I J 21 I J 26 I J --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- ) 2.157 0.024 PINION TEETH 14 12 17 21 G u u u u u u u u u u u u u u u G u u u u u u u u u G u u u u u u u u u u u u u u u u u G u u u u u u u u u u u u u u u u u u u 35 P P G 26 P P P 35 I J 55 I J 135 I J P 55 G 0.122 0.43 0.43 0.1ss 0.45 0.46 0.212 0.47 0.50 P 135 G 0.132 0.48 0.48 0.197 0.50 0.52 P G O. 145 0.55 0.55 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. ) I AND J FACTORS FOR:’ 14.5 DEG. PRESSURE ANGLE 10.0 DEG. HELIX ANGLE 0.157 TOOL EDGE RADIUS 25 PERCENT LONG ADDENDUM PINION ( x 25 PERCENT SHORT ADDENDUM GEAR WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP = 0.25) 2.157 0.024 (x2 = - 0.25) PINION TEETH GEAR TEETH 12 14 P G 17 P G 21 P G 26 P G P 3s G P 135 55 G P G P G 12 I J u u 14 I J 17 I u u u u J u u u u u u 21 I J 26 I u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u O. 107 0.43 0.34 0.137 0.44 0.38 0.181 0.45 0.41 u u u u u u u u 0.47 J 35 I J 55 I J 135 I J ) 0.250 0.46 0.117 0.46 0.39 0.159 0.47 0.43 0.233 0.49 0.47 0.129 0.50 0.45 0.206 0.52 0.49 O. 144 0.56 0.53 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 9 08-B 89 23 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT m A G H A 908-B m Ob87575 0003055 445 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- I AND J FACTORS FOR:? DEG. PRESSURE ANGLE 10.0 DEG. HELIX ANGLE O. 157 TOOL EDGE RADIUS 50 PERCENT LONG ADDENDUM PINION (xl 14.5 50 PERCENT SHORT ADDENDUM GEAR GEAR TEETH 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP = 0.50) 2.157 0.024 (x2 = - 0.50) PINION TEETH 12 P G u w u w u u u u u u u w u u u u u u u u u u u w u u u P G u u u 21 17 14 P G P 0.054 0.42 0.20 0.085 0.42 0.24 0.117 0.43 0.27 0.160 0.43 0.30 0.218 0.44 0.34 O. 300 0.45 0.39 26 P G 0.071 0.44 0.25 0.101 0.44 0.28 O . 141 0.45 0.31 O. 198 0.46 0.35 0.282 0.46 0.40 55 35 G 0.086 0.46 0.29 0.124 0.46 0.32 0.179 0.47 0.37 0.264 0.48 0.42 P G 0.102 0.48 0.34 0.154 0.49 0.38 O. 242 0.50 0.44 P 135 G o. 120 0.51 0.41 O. 208 0.52 0.46 P G O. 141 0.56 0.51 1 The letter ?U?indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. I AND J FACTORS FOR:? DEG. PRESSURE ANGLE DEG. HELIX ANGLE TOOL EDGE RADIUS EQUAL ADDENDUM ( x 1= x = O) WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP 14.5 15.0 0.157 2.157 0.024 PINION TEETH GEAR TEETH 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J 17 14 12 P G 26 21 P G P G 55 35 P G P G u u u u w u w u w u u u u u w u u u u u u u u u w u w u u u w u u u u u u u u u u u u u u u u u u u u u u u u u u u u u P G O. 124 0.43 0.43 0.156 0.45 0.46 0.214 0.47 0.50 P 135 G 0.133 0.48 0.48 O. 198 0.50 0.52 P G O. 146 0.54 0.54 1 The letter ?U? indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 24 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 908-B89 A G M A 908-B W Ob87575 000305b 381 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth i AND J FACTORS FOR:’ ) 14.5 DEG. PRESSURE ANGLE 15.0 DEG. HELIXANGLE 0.157 TOOL EDGE RADIUS 25 PERCENT LONG ADDENDUM PINION (x 25 PERCENT SHORT ADDENDUM GEAR WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP = 0.25) 2.157 0.024 (x2 = - 0.25) PINION TEETH GEAR TEETH 17 14 12 P G u u u u u u u u u J 55 I J G u u u u u u U u u u u u u u u u u G u u u u u u u u u u u u u u L u u u u u u u u G u u J u 17 I J 21 I 26 21 P P P P 35 G P 55 G P 135 G P G 12 I J 14 I J 26 I J 35 I 135 I J T 0.109 0.43 0.35 0.138 0.44 0.38 0.182 0.45 0.41 0.250 0.47 0.46 0.118 0.46 0.39 0.161 0.47 0.43 0.233 0.49 0.47 0.130 0.50 0.45 O. 206 0.52 0.49 0.145 0.55 0.53 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. D I AND J FACTORS FOR:’ DEG. PRESSURE ANGLE 15.0 DEG. HELIX ANGLE O. 157 TOOL EDGE RADIUS 50 PERCENT LONG ADDENDUM PINION ( x 14.5 50 PERCENT SHORT ADDENDUM GEAR WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP = 0.50) 2.157 O. 024 (x2 = - 0.50) PINION TEETH G u u u u u u u J 26 I J 35 I u u u u u u u u J 55 I J u u u u u u u u J 14 I J 17 I J 21 I 135 I J P G u u u u u u 21 17 P 12 I ) 14 12 u P G 0.059 0.42 0.21 0.090 0.43 0.25 o. 121 0.43 0.27 0.162 0.44 0.31 0.219 0.44 0.35 0.299 0.45 0.39 P 26 G P 0.075 0.44 0.26 0.104 0.45 0.28 0.144 0.45 0.32 0.199 0.46 0.36 0.281 0.47 0.40 55 35 G 0.089 0.46 0.29 0.126 0.46 0.33 0.180 0.47 0.37 0.264 0.48 0.42 P G 0.105 0.48 0.35 0.156 0.49 0.39 O. 242 0.50 0.44 P G P 135 G o. 122 0.51 0.41 O. 209 0.52 0.46 O. 142 0.56 0.51 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- GEAR TEETH 1 The letter “U” indicates a gear tooth combination which produces a n undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 25 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 90 8-B 89 m AGMA 908-B Ob87575 0003057 218 m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth I AND J FACTORS FOR:’ 14.5 DEG. PRESSURE ANGLE 20.0 DËG. HELIXANGLE O. 157 TOOL EDGE RADIUS EQUAL ADDENDUM (x 1= x = O) WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP 2.157 0.024 PINION TEETH --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- GEAR TEETH 14 12 21 17 P G u u u u u u u u u P G u u u u u u u u u u u u u u u u P G u u u 26 P G u u u u u u u u u u u u u u u 35 P G u u u u u u u u u u u u u u u u u P 55 G P 135 G P G 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J o. 125 0.43 0.43 0.158 0.44 0.45 0.215 0.46 0.49 0.134 0.47 0.47 0.199 0.49 0.50 O. 146 0.53 0.53 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. I AND J FACTORS FOR:’ 14.5 DEG. PRESSURE ANGLE 20.0 DEG. HELIX ANGLE 0.157 TOOL EDGE RADIUS 25 PERCENT LONG ADDENDUM PINION WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP (Y 25 PERCENT SHORT ADDENDUM GEAR (x2 = 2.157 0.024 = 0.25) - 0.25) PINION TEETH GEAR TEETH 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I J 14 12 P G u u u P G P G u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u 135 I J 21 17 P 26 G O. 104 0.40 0.32 0.126 0.41 0.34 0.156 0.42 0.37 0.198 0.43 0.40 0.262 0.44 0.43 P 35 G 0.111 0.43 0.35 O. 140 0.43 0.38 0.183 0.44 0.41 0.250 0.46 0.44 P 55 G 0.120 0.45 0.39 O. 162 0.46 0.42 0.234 0.48 0.46 P 135 G 0.131 0.49 0.44 0.207 0.50 0.48 P G 0.145 0.53 0.51 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 26 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 9 O 8-B 8 9 = Ob87575 A G H A 908-B 0003058 154 = Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth I AND J FACTORS FOR:’ 14.5 DEG. PRESSURE ANGLE 20.0 DEG. HELIX ANGLE 0.157 TOOL EDGE RADIUS 50 PERCENT LONG ADDENDUM PINION ( x 1 50 PERCENT SHORT ADDENDUM GEAR WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP = 0.50) 2.157 0.024 (x2 = - 0.50) PINION TEETH GEAR TEETH 14 12 P G u u u u u u u u u u u u u u u u u u u J u u u u 135 I J u u u u 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I P G u u u P 26 21 17 G P 0.065 0.41 0.22 0.095 0.42 0.25 0.125 0.42 0.28 0.166 0.43 0.31 0.220 0.43 0.34 0.297 0.44 0.38 P G 0.081 0.43 0.26 0.109 0.43 0.29 0.147 0.44 0.32 0.201 0.45 0.35 0.280 0.45 0.40 35 G 0.094 0.45 0.30 0.130 0.45 0.33 0.182 0.46 0.37 0.264 0.47 0.41 P 55 G 0.108 0.47 0.34 0.158 0.47 0.38 0.242 0.48 0.43 P 135 G O. 124 0.50 0.41 0.209 0.50 0.45 P G 0.143 0.54 0.49 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. I AND J FACTORS FOR:’ 14.5 25.0 O. 157 EQUAL DEG. PRESSURE ANGLE DEG. HELIX ANGLE TOOL EDGE RADIUS ADDENDUM ( X 1= x = O ) WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP 2.157 0.024 ~~~ PINION TEETH GEAR TEETH 12 14 P G u u u u u u u u u 21 P G u u u u u u u u u u u u u u u u P G u u u J 21 I J 12 I J 14 I J 17 I 17 G u u u u u u u u u u u u u u u u u u u u u u u u P 26 I J 35 I J 55 I J 135 I J 1 35 26 P G 0.121 0.38 0.38 O. 142 0.39 0.40 O. 174 0.40 0.42 0.225 0.42 0.45 P 55 G O. 127 0.41 0.41 O. 160 0.42 0.43 0.218 0.44 0.46 P 135 G 0.135 0.45 0.45 0.201 0.47 0.48 P G O. 147 0.50 0.50 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. AGMA 27 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 908-B89 Ob87575 0003059 090 A G M A 908-B Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth I AND J FACTORS FOR:’ 14.5 DEG. PRESSURE ANGLE 25.0 DEG. HELIX ANGLE 0.157 TOOL EDGE RADIUS 25 PERCENT LONG ADDENDUM PINION ( x 25 PERCENT SHORT ADDENDUM GEAR WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP = 0.25) 2.157 0.024 (x2 = - 0.25) PINION TEETH GEAR TEETH 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J 12 14 P G u u u 17 P G u u u u u u u u u 21 P G u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u P 26 G 0.108 0.39 0.31 0.129 0.40 0.33 0.158 0.40 0.36 0.200 0.41 0.38 0.262 0.42 0.41 P 35 G 0.115 0.41 0.34 0.143 0.42 0.36 0.185 0.43 0.39 0.250 0.44 0.42 P 55 G O. 123 0.43 0.38 O. 164 0.44 0.40 0.234 0.45 0.44 P 135 G O. 133 0.46 0.42 0.208 0.47 0.46 P G 0.146 0.50 0.48 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. Z AND J FACTORS FOR:‘ 14.5 DEG. PRESSURE ANGLE 25.0 DEG. HELIX ANGLE 0.157 TOOL EDGE RADIUS 50 PERCENT LONG ADDENDUM PINION ( x 50 PERCENT SHORT ADDENDUM GEAR WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP = O. SO) 2.1.57 0.024 (x2 = - 0.50) PINION TEETH GEAR TEETH 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J 12 17 14 P G u u u u u u u u u u u u u u u u P G 0.057 0.38 0.19 O. 086 0.39 0.22 O. 117 0.39 0.24 O. 148 0.39 0.27 0.188 0.40 0.29 0.240 0.40 0.32 0.311 0.41 0.36 P 26 21 G 0.073 0.40 0.23 o. 102 0.40 0.25 O. 131 0.40 0.28 O. 170 0.41 0.30 0.222 0.41 0.33 0.295 0.42 0.37 P G 0.087 0.41 0.26 0.114 0.42 0.29 0.151 0.42 0.31 0.203 0.42 0.34 0.279 0.43 0.38 P 35 G 0,099 0.43 0.29 0.134 0.43 0.32 0.185 0.44 0.35 0.263 0.44 0.39 P 55 G 0.112 0.45 0.34 0.161 0.45 0.37 0.242 0.46 0.41 P 135 G 0.127 0.47 0.39 0.210 0.48 0.43 P G --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- I 0.144 0.51 0.47 1 The letter “U” indicates a gear tooth combination which produces a n undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 28 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 9 08-B 89 A G H A 908-B Ob87575 O003060 802 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth 1 I AND J FACTORS FOR:’ 2.157 WHOLE DEPTH FACTOR 0.024 TOOTH THINNING FOR BACKLASH LOADED AT TIP 14.5 DEG. PRESSURE ANGLE 30.0 DEG. HELIX ANGLE 0.157 TOOL EDGBRADIUS EQUAL ADDENDUM ( x 1= x = O ) GEAR TEETH 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J 12 14 P G u u u 17 P G u u u u u u u u u PINION TEETH 21 26 P G P G P G u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u O. 123 0.36 0.36 O. 145 0.37 0.37 O. 177 0.38 0.39 O. 227 0.39 0.42 35 P 55 G O. 129 0.38 0.38 0.163 0.39 0.40 0.220 0.41 0.43 P G 0.137 0.41 0.41 o. 202 0.43 0.44 P 135 G O. 148 0.46 0.46 1 The letter “U” indicates a gear tooth combination which produces a n undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. 1 I AND J FACTORS FOR:’ 14.5 DEG. PRESSURE ANGLE 2.157 WHOLE DEPTH FACTOR 30.0 DEG. HELIX ANGLE 0.024 TOOTH THINNING FOR BACKLASH 0.157 TOOL EDGE RADIUS LOADED AT TIP 25 PERCENT LONG ADDENDUM PINION ( x = 0.25) 25 PERCENT SHORT ADDENDUM GEAR GEAR TEETH 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J ) 14 12 P G u u u ( x =~- 0.25) 17 P G u u u u u u u u u u u u u u u u u u u u u u u u u u u P G 0.105 0.35 0.27 0.126 0.35 0.29 O. 147 0.36 0.31 0.176 0.36 0.33 0.216 0.37 0.35 0.272 0.38 0.38 PINION TEETH 21 26 P G P G 0.112 0.37 0.30 0.133 0.37 0.32 0.161 0.38 0.34 0.201 0.38 0.36 0.261 0.39 0.39 0.118 0.38 0.33 O. 146 0.39 0.34 0.187 0.40 0.37 0.250 0.41 0.39 55 35 P G 0.126 0.36 0.166 0.41 0.38 0.235 0.42 0.41 P G P 135 G 0.40 0.13.5 0.43 0.39 0.209 0.44 0.42 0.147 0.46 0.45 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. AGMA 29 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 908-B89 Ob87575 00030bL 7q9 A G M A 908-B Geometry Factors for Determining the Pitting Resistance and Bending Slrenglh of Spur and Helical Gear Teeth I AND J FACTORS FOR: 2.157 WHOLE DEPTH FACTOR 14.5 DEG. PRESSURE ANGLE .O24 TOOTH THINNING FOR BACKLASH 30.0 DEG. HELIX ANGLE LOADED AT TIP 0.157 TOOL EDGE RADIUS 50 PERCENT LONG ADDENDUM PINION ( x = 0.50) 50 PERCENT SHORT ADDENDUM GEAR (x2 = - 0.50) PINION TEETH GEAR TEETH 12 I 14 17 21 26 35 J I J I J I J I J I J 55 I J 135 I J 14 12 P G 0.055 0.35 0.17 0.078 0.35 0.19 0.107 0.35 0.21 O. 138 0.36 0.24 O. 168 0.36 0.25 0.206 0.36 0.28 0.256 0.37 0.30 0.320 0.37 0.33 P 21 17 G 0.068 0.36 0.20 0.095 0.36 0.22 o. 125 0.37 0.24 O. 154 0.37 0.26 0.191 0.37 0.28 0.241 0.38 0.31 0.307 0.38 0.33 P P G 0.082 0.37 0.23 0.110 0.37 0.25 O. 137 0.38 0.27 O. 174 0.38 0.29 0.223 0.39 0.32 0.292 0.39 0.35 35 26 G P 0.095 0.38 0.26 0.120 0.39 0.28 O. 156 0.39 0.30 o. 205 0.40 0.33 0.277 0.40 0.36 G P 55 G P 135 G P G o. 105 0.40 0.29 O. 139 0.40 0.31 O. 187 0.40 0.34 0.262 0.41 0.37 0.117 0.41 0.32 O. 164 0.42 0.35 0.242 0.42 0.38 0.130 0.43 0.37 0.211 0.44 0.40 O. 145 0.46 0.43 I AND J FACTORS FOR:' WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP 2.250 0.024 DEG. PRESSURE ANGLE DEG. HELIX ANGLE TOOL EDGE RADIUS EQUAL ADDENDUM ( x 1= x = O) 20.0 0.0 0.250 PINION TEETH GEAR TEETH 17 14 12 G u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u G u u u u u u u u u G u u u P 35 26 21 P P P G P G P 55 G P 135 G P G 12 I J 14 I --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J 0.078 0.24 0.24 0.084 0.24 0.25 0.091 0.24 0.26 o. 102 0.24 0.28 O. 118 0.24 0.29 0.079 0.25 0.25 0.088 0.25 0.26 0.101 0.25 0.28 0.121 0.25 0.29 0.080 0.26 0.26 0.095 0.26 0.28 0.120 0.26 0.29 O. 080 0.28 0.28 0.112 0.28 0.29 O. 080 0.29 0.29 1 The letter "U" indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 30 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 9 O 8-B 8 9 m A G H A 908-B Ob87575 00030b2 b85 m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth r AND J FACTORS FOR:’ 20.0 DEG. PRESSURE ANGLE 0.0 DEG. HELIXANGLE 0.250 TOOL EDGE RADIUS 25 PERCENT LONG ADDENDUM PINION (X 25 PERCENT SHORT ADDENDUM GEAR (x2 = GEAR TEETH 12 G u u u u u u u u u u u u u u u 0.080 0.27 0.19 0.087 0.27 0.21 0.094 0.27 0.22 u u u u 0.27 u u u u 0.27 u u u u 0.27 J u u 14 I J 17 I u 21 26 35 55 135 P - 0.25) PINION TEETH 21 26 G P G P P G J I J I J I J I J I J = 0.25) 17 14 P 12 I WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP 2.250 0.024 G 0.080 0.27 0.21 0.088 0.27 0.22 0.098 0.27 0.24 0.113 0.27 0.26 O. 103 0.24 0.115 0.26 0.131 0.080 0.28 0.22 0.092 0.28 0.24 O. 108 0.28 0.26 0.134 0.28 0.27 0.133 0.28 0.28 0.28 55 35 P G 0.080 0.28 0.24 0.099 0.28 0.26 0.129 0.28 0.28 P G 0.080 0.29 0.26 0.116 0.29 0.28 P 135 G 0.080 0.28 0.30 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. I AND J FACTORS FOR:’ 20.0 DEG. PRESSURE ANGLE 0.0 DEG. HELIX ANGLE 0.250 TOOL EDGE RADIUS 50 PERCENT LONG ADDENDUM PINION ( x 2.250 0.024 50 PERCENT SHORT ADDENDUM GEAR = - O . 50) (X WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP = O. 50) PINION TEETH GEAR TEETH 12 14 P G T T T T T T T T T T T T T T T T P 17 G P 21 G P 26 G P 35 G P 55 G P 135 G P G 12 I J 35 I J 55 I J 135 I J 0.080 0.30 0.12 0.088 0.30 0.15 0.097 0.30 0.17 o. 105 0.30 0.19 0.116 0.30 0.21 0.130 0.30 0.24 O. 148 0.30 0.27 0.080 0.30 0.15 0.090 0.30 0.17 0.099 0.30 0.19 0.111 0.30 0.21 O . 127 0.30 0.24 O. 149 0.30 0.27 0.080 0.31 0.17 0.090 0.31 0.19 O. 103 0.31 0.21 o. 122 0.31 0.24 O . 148 0.31 0.27 0.080 0.19 0.094 0.31 0.21 0.114 0.31 0.24 O. 145 0.31 0.27 0.31 0.080 0.30 0.21 0.101 0.30 0.24 O . 136 0.30 0.27 0.080 0.24 o. 120 0.30 0.27 0.30 0.080 0.30 0.27 1 The letter “T” indicates a gear tooth combination which produces pointed teeth with a top land less than O. 3/ Pnd in one or both components and should be avoided. See Section 7. AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 31 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- J 14 I J 17 I J 21 I J 26 I 908-B89 AGHA 908-B Ob87575 00030b3 511 = Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth I AND J FACTORS FOR:’ DEG. PRESSURE ANGLE DEG. HELIX ANGLE TOOL EDGE RADIUS EQUAL ADDENDUM ( x 1= x = O ) WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT HIGHEST POINT OF SINGLE TOOTH CONTACT 20.0 0.0 0.250 2.250 0.024 PINION TEETH 14 GEAR TEETH P G 12 I J u u u J 21 I J 26 I J 35 I J 55 I J 135 I J 12 17 P G u u u u u u u u u 21 26 P G u u u u u u u u u u u u u u u u u u u u u u u u 0.078 0.33 0.33 0.084 0.33 0.35 0.091 0.34 0.37 0.102 0.34 0.40 u u u u u u 0.35 P G P 35 G P 135 55 G P G P G 14 I J 17 I 0.118 0.43 0.079 0.35 0.35 0.080 0.088 0.36 0.38 o. 101 0.37 0.41 o. 121 0.38 0.44 0.39 0.39 0.095 0.40 0.42 o. 120 0.41 0.45 0.080 0.43 0.43 0.112 0.45 0.47 0.080 0.49 0.49 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. I AND J FACTORS FOR:1 20.0 DEG. PRESSURE ANGLE 0.0 DEG. HELIX ANGLE 0.250 TOOL EDGE RADIUS 25 PERCENT LONG ADDENDUM PINION (x I 25 PERCENT SHORT ADDENDUM GEAR WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT HIGHEST POINT OF SINGLE TOOTH CONTACT 2.250 0.024 = 0.25) ( ~ =2 - 0.25) PINION TEETH 12 14 P G u u J u 17 I J 21 I 17 P G u u u u u u u J 26 I J 35 I J 55 I u u u u u u u u u u u u J u u u u u u u u 12 I J 14 I 135 I J P 21 G 0.080 0.36 0.24 o. 087 0.37 0.26 0.094 0.37 0.29 O. 103 0.37 0.32 o. 115 0.38 0.35 0.131 0.39 0.39 P 26 G P 0,080 0.39 0.27 0.088 0.39 0.29 0.098 0.40 0.32 0.113 0.40 0.36 0.134 0.41 0.40 35 G 0.080 0.41 0.30 0.092 0.41 0.33 0.108 0.42 0.36 0.133 0.43 0.41 P 55 G 0.080 0.43 0.34 0.099 0.44 0.37 O . 129 0.45 0.42 P 135 G P G --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- GEAR TEETH 0.080 0.47 0.39 O . 116 0.48 0.44 0.080 0.51 0.46 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 32 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 9O 8-B 89 m A G M A 908-8 Ob87575 00030b4 458 m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth I AND J FACTORS FOR:’ 20.0 DEG. PRESSURE ANGLE 0.0 DEG. HELIX ANGLE 0.250 TOOL EDGE RADIUS 50 PERCENT LONG ADDENDUM PINION (X WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT HIGHEST POINT OF SINGLE TOOTH CONTACT = 0.50) 50 PERCENT SHORT ADDENDUM GEAR (X2 = 2.250 0.024 - 0.50) PINION TEETH GEAR TEETH 14 12 P G T T T T T T T T T T T T T T T T P 17 G P 21 G P 26 G P 35 G P 55 G P 135 G P G 12 I J 14 I J I J I J I J I J I J I J 17 21 26 35 55 135 0.080 0.40 0.14 0.088 0.41 0.17 0.097 0.41 0.20 o. 105 0.41 0.23 0.116 0.42 0.26 0.130 0.42 0.30 O. 148 0.43 0.34 0.080 0.42 0.18 0.090 0.43 0.21 0.099 0.43 0.23 0.111 0.43 0.27 0.127 0.44 0.31 O. 149 0.44 0.35 0.080 0.44 0.21 0.090 0.45 0.24 O. 103 0.45 0.27 0.122 0.45 0.31 O. 148 0.46 0.36 0.080 0.46 0.24 0.094 0.46 0.28 0.114 0.47 0.32 0.145 0.47 0.37 0.080 0.48 0.29 0.101 0.48 0.33 0.136 0.49 0.38 0.080 0.50 0.34 0.120 0.50 0.40 0.080 0.52 0.43 1 The letter “T” indicates a gear tooth combination which produces pointed teeth with a top land less than 0.3/Pnd in one or both components and should be avoided. See Section 7. I AND J FACTORS FOR:’ DEG. PRESSURE ANGLE DEG. HELIX ANGLE TOOL EDGE RADIUS EQUAL ADDENDUM (X 1= x = O) WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP 20.0 10.0 0.250 2.250 0.024 PINION TEETH GEAR TEETH 12 14 P G u u J u 17 I J 21 I 12 I J 17 P G u u u u u u u u u 21 P G u u u u u u u u u u u u u u u u u u u u u u u u u u u u u u P 26 G P 35 G P 55 G P 135 G P G 14 I 26 35 55 135 J I J I J I J I J 0.127 0.46 0.46 0.143 0.47 0.49 O. 164 0.48 0.52 o. 195 0.49 0.55 0.241 0.50 0.60 0.131 0.49 0.49 0.153 0.50 0.53 0.186 0.52 0.56 0.237 0.53 0.61 O. 136 0.54 0.54 O. 170 0.55 0.57 0.228 0.57 0.62 O. 143 0.59 0.59 0.209 0.60 0.63 0.151 0.65 0.65 1 The letter “U” indicates a gear tooth combination which produces a n undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-3. AGMA 33 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 908-B89 m A G M A 908-B Ob87575 0003065 394 m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth I AND J FACTORS FOR:’ DEG. PRESSURE ANGLE 2.250 WHOLE DEPTH FACTOR DEG. HELIX ANGLE 0.024 TOOTH THINNING FOR BACKLASH LOADED AT TIP 0.250 TOOL EDGE RADIUS 25 PERCENT LONG ADDENDUM PINION ( x = 0.25) 20.0 10.0 25 PERCENT SHORT ADDENDUM GEAR (x, = - 0.25) PINION TEETH GEAR TEETH 12 14 P G u u u u P 17 G P 21 G P 26 G P 35 G P 55 G P 135 G P G 12 I J 14 I 17 21 26 35 55 135 J I J I J I J I J I J I J O. 109 0.30 0.46 O. 129 u u u u u u u u u u u u 0.47 0.34 O. 151 0.47 0.38 O. 172 0.48 0.41 0.200 0.48 0.44 0.236 0.49 0.49 0.286 0.50 0.54 0.116 0.49 0.35 0.137 0.50 0.38 0.157 0.50 0.42 0.185 0.51 0.45 0.223 0.52 0.50 0.276 0.53 0.55 0.122 0.52 0.39 0.142 0.53 0.42 O. 170 0.53 0.46 0.209 0.54 0.51 0.266 0.55 0.56 0.127 0.55 0.43 0.155 0.55 0.47 0.194 0.56 0.52 0.255 0.57 0.57 O. 134 0.58 0.49 O. 173 0.59 0.53 0.240 0.60 0.58 0.141 0.62 0.55 0.214 0.63 0.60 0.151 0.66 0.63 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. DEG. PRESSURE ANGLE DEG. HELIX ANGLE 0.250 TOOL EDGE RADIUS 50 PERCENT LONG ADDENDUM PINION ( x 20.0 50 PERCENT SHORT ADDENDUM GEAR (X WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP = O. 50) 2.250 0.024 10.0 ,= - O. 50) PINION TEETH GEAR TEETH 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J 12 P 14 G 0.077 0.18 0.099 0.51 0.22 0.126 0.51 0.26 0.154 0.52 0.30 0.182 0.52 0.33 0.217 0.53 0.37 0.263 0.53 0.42 0.321 0.54 0.48 P 17 G P 21 G P 26 G P 35 G P 55 G P 135 G P --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- I AND J FACTORS FOR: G 0.51 0.088 0.53 0.22 0.113 0.53 0.26 0.141 0.53 0.30 O. 168 0.54 0.34 0.203 0.54 0.38 0.248 0.55 0.43 O. 309 0.55 0.49 AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 0.099 0.55 0.27 0.125 0.55 0.31 0.151 0.55 0.35 O. 185 0.56 0.39 0.231 0.56 0.44 0.295 0.57 0.50 0.109 0.57 0.32 0.134 0.57 0.36 0.167 0.57 0.40 0.213 0.58 0.45 0.280 0.58 0.52 0.118 0.58 0.37 o. 150 0.59 0.41 O. 196 0.59 0.47 0.266 0.60 0.53 0.127 0.61 0.43 0.172 0.61 0.48 0.247 0.62 0.55 34 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 0.137 0.63 0.50 0.216 0.64 0.57 O. 149 0.67 0.61 9 O 8-B 89 m A G M A 908-B Ob87575 00030bb 220 m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth I AND J FACTORS FOR:’ WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP 2.250 0.024 DEG. PRESSURE ANGLE DEG. HELIX ANGLE TOOL EDGE RADIUS EQUAL ADDENDUM ( X 1= x = O) 20.0 15.0 0.250 I PINION TEETH GEAR TEETH 12 14 P G J u u 14 I J 17 I u 17 P G u u u u u u u u u u u u u u u u u u u u u u u P 21 G P 26 G P 35 G P 55 G P 135 G P G 12 I 21 26 35 55 135 J I J I J I J I J I J u u u u O. 124 0.43 0.43 0.139 0.44 0.46 0.154 0.45 0.49 O. 175 0.46 0.52 0.204 0.47 0.55 0.244 0.48 0.59 O. 128 0.47 0.47 0.143 0.48 0.50 0.165 0.49 0.53 0.196 0.50 0.56 0.132 0.50 0.50 0.154 0.51 0.53 0.187 0.53 0.57 0.137 0.54 0.54 0.171 0.56 0.58 0.59 0.241 0.51 0.60 0.237 0.54 0.61 0.229 0.57 0.62 0.209 0.61 0.64 O. 143 0.59 0.151 0.65 0.65 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. I AND J FACTORS FOR:’ 20.0 DEG. PRESSURE ANGLE 2.250 WHOLE DEPTH FACTOR 15.0 DEG. HELIX ANGLE 0.024 TOOTH THINNING FOR BACKLASH LOADED AT TIP 0.250 TOOL EDGE RADIUS 25 PERCENT LONG ADDENDUM PINION ( x = 0.25) 25 PERCENT SHORT ADDENDUM GEAR (X2 = - 0.25) PINION TEETH 12 I J 14 I J 17 I 21 26 35 55 135 J I J I J I J I J I J 14 12 P G u u u u u u u u u u u u u u u u P 17 G 0.111 0.47 0.32 O. 131 0.48 0.35 O. 152 0.48 0.39 O. 173 0.49 0.42 o. 200 0.50 0.45 0.236 0.50 0.49 0.285 0.51 0.54 P 21 G 0.117 0.50 0.36 O. 138 0.51 0.40 0.158 0.51 0.43 O. 186 0.52 0.46 0.223 0.53 0.50 0.275 0.54 0.55 P 26 G P 35 G P 55 G P 135 G P G O. 123 0.53 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- GEAR TEETH 0.40 O. 143 0.53 0.44 O. 171 0.54 0.47 0.209 0.55 0.51 0.265 0.56 0.56 O. 128 0.55 0.44 0.155 0.56 0.48 0.195 0.57 0.53 0.255 0.58 0.58 0.134 0.58 0.49 O. 174 0.59 0.54 0.240 0.60 0.59 O. 142 0.62 0.56 0.214 0.63 0.61 0.151 0.67 0.63 1 The letter “U” indicates a gear tooth combination which produces a n undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 35 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 908-B89 Ob87575 0 0 0 3 0 b ï L b ï AGHA 908-El Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth I AND J FACTORS FOR: 20.0 DEG. PRESSURE ANGLE 15.0 DEG. HELIX ANGLE 0.250 TOOL EDGE RADIUS 50 PERCENT LONG ADDENDUM PINION (x --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- 50 PERCENT SHORT ADDENDUM GEAR GEAR TEETH 12 I 14 17 21 26 35 55 135 J I J I J I J I J I J I J I J WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP = 0.50) 2.250 0.024 (X2 = - 0.50) PINION TEETH P 17 14 12 G 0.081 0.52 0.20 o. 102 0.52 0.23 0.128 0.52 0.27 O. 156 0.53 0.31 0.183 0.53 0.34 0.218 0.54 0.38 0.262 0.54 0.43 0.319 0.55 0.49 P G 0.091 0.53 0.24 0.116 0.54 0.28 0.143 0.54 0.31 0.169 0.55 0.35 O. 203 0.55 0.39 0.248 0.55 0.44 O. 307 0.56 0.50 P 26 21 G P 0.102 0.55 0.28 0.127 0.56 0.32 0.152 0.56 0.36 O. 186 0.57 0.40 0.231 0.57 0.45 0.294 0.58 0.51 P G 0.111 0.57 0.33 0.135 0.58 0.37 O. 168 0.58 0.41 0.213 0.59 0.46 0.279 0.59 0.52 35 G P 55 G P 135 G P G 0.119 0.59 0.38 0.151 0.60 0.42 0.196 0.60 0.48 0.265 0.61 0.54 0.128 0.61 0.44 0.173 0.62 0.49 0.246 0.62 0.55 0.138 0.64 0.51 0.216 0.65 0.58 O. 149 0.67 0.61 I AND J FACTORS FOR:’ DEG. PRESSURE ANGLE DEG. HELIX ANGLE TOOL EDGE RADIUS EQUAL ADDENDUM ( x 1= x = O) WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP 20.0 20.0 0.250 2.250 0.024 PINION TEETH GEAR TEETH 12 I J 14 I J 17 I 21 26 35 55 135 J I J I J I J I J I J 14 12 17 P G u u u u u u u u u u u u u u u u u u u u u u u u u u u P G u u u P 26 21 G 0.125 0.44 0.44 O. 140 0.45 0.46 0.156 0.45 0.49 O. 177 0.46 0.51 0.205 0.47 0.54 0.245 0.48 0.58 P P G 0.129 0.47 0.47 O. 145 0.48 0.49 0.167 0.49 0.52 0.197 0.50 0.55 0.242 0.51 0.59 35 G 0.133 0.50 0.50 o. 155 0.51 0.53 0.188 0.52 0.56 0.238 0.54 0.60 P 55 G 0.138 0.54 0.54 O. 172 0.55 0.57 0.229 0.57 0.61 P 135 G 0.144 0.58 0.58 0.209 0.60 0.62 P G 0.151 0.64 0.64 1 The letter “U”indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 36 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 908-B89 W Ob87575 00030b8 O T 3 W A G M A 908-B Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth I AND J FACTORS FOR: 2.250 WHOLE DEPTH FACTOR 20.0 DEG. PRESSURE ANGLE 0.024 TOOTH THINNING FOR BACKLASH 20.0 DEG. HELIX ANGLE LOADED AT TIP 0.250 TOOL EDGE RADIUS 25 PERCENT LONG ADDENDUM PINION (xl = 0.25) 25 PERCENT SHORT ADDENDUM GEAR (x2 = - 0.25) PINION TEETH 12 I 12 P 14 G P 17 G P 21 G P 26 G P 35 G 0.108 0.45 0.29 O. 124 0.45 0.32 0.144 0.46 0.35 0.114 0.47 0.33 O. 133 0.48 0.36 0.119 0.50 0.37 O. 165 0.47 0.39 O. 154 0.48 0.39 0.140 0.51 0.40 26 I J 0.186 0.47 0.41 0.49 0.42 0.51 35 I J 0.212 0.48 0.44 0.201 0.50 0.45 0.52 55 I J 0.246 0.48 0.48 0.236 0.50 0.49 0.223 0.52 0.50 0.209 0.54 0.51 0.56 135 I J 0.291 0.49 0.53 0.284 0.51 0.53 0.274 0.53 0.54 0.265 0.55 0.56 0.255 0.57 0.57 J 14 I J 17 I J 21 I J O. 174 0.160 0.43 55 G P 135 G P G 0.125 0.53 0.41 O. 145 0.53 O. 187 0.44 0.130 0.55 0.45 O. 172 0.46 P 0.54 O. 156 0.47 0.55 0.48 O. 135 0.58 o. 195 0.52 0.49 O. 175 0.53 O. 142 0.61 0.55 0.240 0.59 0.58 0.214 0.62 0.60 0.58 0.151 0.65 0.62 I AND J FACTORS FOR: DEG. PRESSURE ANGLE DEG. HELIX ANGLE TOOL EDGE RADIUS 50 PERCENT LONG ADDENDUM PINION ( x WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP 2.250 0.024 20.0 20.0 0.250 = O. SO) (x2 = 50 PERCENT SHORT ADDENDUM GEAR --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- GEAR TEETH - 0.50) PINION TEETH GEAR TEETH 12 I 14 17 21 26 J I J I J I J I J 35 I J 55 I J 135 I J 14 12 P G 0.086 0.52 0.21 O. 106 0.52 0.24 O. 132 0.52 0.28 0.159 0.53 0.32 0.185 0.53 0.35 0.219 0.53 0.39 0.261 0.54 0.43 O. 317 0.54 0.48 P G 0.095 0.53 0.25 o. 120 0.53 0.29 0.146 0.54 0.32 0.171 0.54 0.36 O. 204 0.54 0.39 0.248 0.55 0.44 0.305 0.55 0.49 AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 21 17 P G O. 105 0.55 0.29 O. 130 0.55 0.33 O. 155 0.56 0.37 0.187 0.56 0.40 0.231 0.56 0.45 0.292 0.57 0.50 P P 0.114 0.57 0.34 0.138 0.57 0.38 O. 170 0.57 0.41 0.214 0.58 0.46 0.278 0.58 0.52 55 35 26 G G P G P 135 G P G o. 121 0.58 0.38 O. 152 0.59 0.43 0.197 0.59 0.47 0.265 0.60 0.53 0.130 0.60 0.44 O. 173 0.61 0.49 O. 246 0.61 0.55 37 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT O. 139 O. 3 o. 1 0.216 0.63 0.57 0.150 0.66 0.60 908-B89 m AGMA 908-B Ob87575 00030b9 T 3 T m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth I AND J FACTORS FOR:’ DEG. PRESSURE ANGLE DEG. HELIX ANGLE TOOL EDGE RADIUS EQUAL ADDENDUM (x 1= x = O) WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP 20.0 25.0 0.250 2.250 0.024 PINION TEETH GEAR TEETH 12 I J 12 14 P G u u u u u u u u u u u u u u u u 14 I J 17 I J 21 I 26 35 55 135 J I J I J I J I J P 17 G O. 123 0.40 0.40 O. 137 0.41 0.43 O. 152 0.41 0.45 O. 167 0.42 0.47 0.187 0.43 0.49 0.213 0.44 0.52 0.248 0.45 0.55 P 21 G P O. 126 0.43 0.43 O. 142 0.44 0.45 0.157 0.44 0.47 0.178 0.45 0.50 0.207 0.46 0.52 O. 247 0.47 0.56 26 G P 0.130 0.46 0.46 O. 146 0.47 0.48 O. 168 0.48 0.50 0.199 0.49 0.53 0.244 0.50 0.56 35 G 0.134 0.49 0.49 0.156 0.50 0.51 0.189 0.51 0.54 0.239 0.52 0.57 P 55 G 0.138 0.52 0.52 0.173 0.53 0.55 0.230 0.54 0.58 P 135 G O. 144 0.56 0.56 0.210 0.57 0.59 P G 0.151 0.61 0.61 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. Z AND J FACTORS FOR: 20.0 DEG. PRESSURE ANGLE 25.0 DEG. HELIX ANGLE TOOL EDGE RADIUS 0.250 25 PERCENT LONG ADDENDUM PINION ( x I 25 PERCENT SHORT ADDENDUM GEAR WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP = 0.25) 2.250 0.024 (x2 = - 0.25) PINION TEETH 12 I J 14 I J 17 I 21 26 35 55 135 J I J I J I J I J I J 14 12 P G P 17 G P 21 G P 26 G P 35 G P 55 G P 135 G 0.112 0.44 0.30 0.127 0.45 0.33 O. 146 0.45 0.36 0.167 0.46 0.38 0.187 0.46 0.41 0.213 0.116 0.46 0.33 O. 135 0.47 0.36 0.156 0.47 0.39 0.176 0.48 0.41 0.202 o. 122 0.49 0.37 0.142 0.49 0.40 0.161 0.50 0.42 O. 188 O. 127 0.51 0.41 O. 146 0.51 0.43 0.173 0.131 0.53 0.44 0.158 0.47 0.44 0.246 0.48 0.44 0.236 0.50 0.45 0.224 0.52 0.46 0.210 0.53 0.47 0.196 0.55 0.48 0.175 0.47 0.47 0.289 0.49 0.48 0.282 0.51 0.48 0.273 0.53 0.49 0.264 0.54 0.50 0.254 0.56 0.51 O. 240 0.58 0.53 0.214 0.48 0.50 0.52 0.53 0.55 0.57 0.59 0.51 AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 0.51 0.52 0.53 0.54 P G O. 137 38 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 0.56 O. 143 0.57 0.151 0.62 0.59 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- GEAR TEETH 908-B89 W Ob87575 0003070 751 W A G M A 908-B Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth I AND J FACTORS FOR: 20.0 DEG. PRESSURE ANGLE 2.250 WHOLE DEPTH FACTOR 25.0 DEG. HELIX ANGLE 0.024 TOOTH THINNING FOR BACKLASH LOADED AT TIP 0.250 TOOL EDGE RADIUS 50 PERCENT LONG ADDENDUM PINION ( x = 0.50) 50 PERCENT SHORT ADDENDUM GEAR GEAR TEETH 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J 12 P 0.092 0.50 0.23 o. 112 0.50 0.25 0.136 0.51 0.29 0.162 0.51 0.32 0.187 0.51 0.35 0.219 0.52 0.38 0.260 0.52 0.42 0.313 0.52 0.47 P = - O. 50) 17 14 G (X G P G PINION TEETH 21 26 P G P G P 0,117 0.55 0.34 0.140 0.55 0.37 0.171 0.55 0.41 0.214 0.55 0.45 0.276 0.56 0.50 0.132 0.58 0.43 O. 174 0.58 0.48 0.245 0.58 0.53 35 55 G P G P 135 G o. 100 0.51 0.26 O. 124 0.52 0.29 O. 149 0.52 0.33 0.174 0.52 0.36 0.206 0.53 0.39 0.247 0.53 0.43 0.302 0.53 0.48 0.109 0.53 0.30 0.133 0.53 0.34 0.157 0.54 0.36 0.189 0.54 0.40 0.231 0.54 0.44 0.290 0.55 0.49 O. 124 0.56 0.38 0.154 0.56 0.42 O. 197 0.57 0.46 0.263 0.57 0.51 O. 140 0.60 0.49 0.216 0.60 0.55 0.150 0.62 0.57 I AND J FACTORS FOR:? 20.0 30.0 0.250 EQUAL GEAR TEETH DEG. PRESSURE ANGLE DEG. HELIX ANGLE TOOL EDGE RADIUS ADDENDUM ( x 1= x = O) 2.250 WHOLE DEPTH FACTOR 0.024 TOOTH THINNING FOR BACKLASH LOADED AT TIP 14 12 P G u u J u u 17 I J 21 I u u J u u u u u u u u u u P 17 G P G PINION TEETH 21 26 P G P G P 0.132 0.44 0.44 0.148 0.45 0.46 O. 170 0.45 0.48 0.200 0.46 0.50 0.245 0.47 0.53 0.139 0.49 0.49 0.174 0.50 0.51 0.231 0.51 0.54 35 55 G P G P 135 G 12 I J 14 I 26 I J 35 I J 55 I J 135 I J 0.125 0.39 0.39 0.139 0.39 0.41 0.154 0.40 0.43 0.169 0.41 0.44 0.189 0.41 0.46 0.215 0.42 0.49 0.250 0.43 0.51 O. 128 0.41 0.41 O. 144 0.42 0.43 0.159 0.43 0.45 0.180 0.43 0.47 0.208 0.44 0.49 0.248 0.45 0.52 0.135 0.46 0.46 0.158 0.47 0.48 0.190 0.48 0.50 0.240 0.49 0.53 0.145 0.52 0.52 0.210 0.53 0.55 0.151 0.56 0.56 1 The letter ?U? indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. AGMA 39 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 908-B89 m A G M A 908-B Ob87575 000307L 698 = Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth I AND J FACTORS FOR: 20.0 DEG. PRESSURE ANGLE 30.0 DEG. HELIX ANGLE 0.250 TOOL EDGE RADIUS 25 PERCENT LONG ADDENDUM PINION ( x 25 PERCENT SHORT ADDENDUM GEAR 2.250 WHOLE DEPTH FACTOR 0.024 TOOTH THINNING FOR BACKLASH LOADED AT TIP = 0.25) (x2 = - 0.25) PINION TEETH GEAR TEETH P 12 I J 14 I 17 21 26 35 55 135 14 12 G 0.115 0.42 0.30 0.130 0.43 0.32 0.149 0.43 0.35 0.169 0.44 0.37 o. 188 0.44 0.39 0.213 0.45 0.42 0.245 0.45 0.44 0.286 0.46 0.48 J I J I J I J I J I J I J P 17 G P 21 P G 26 G P 35 G P 55 G P 135 G P G o. 119 0.44 0.33 O. 138 0.45 0.35 0.158 0.45 0.38 0.177 0.45 0.40 0.202 0.46 0.42 0.236 0.46 0.45 0.280 0.47 0.48 0.124 0.46 0.36 0.144 0.47 0.39 0.163 0.47 0.41 0.189 0.47 0.43 0.224 0.48 0.46 O. 272 0.49 0.49 O. 129 0.48 0.39 0.148 0.48 0.42 0.174 0.49 0.44 0.210 0.49 0.47 0.263 0.50 0.50 0.133 0.50 0.42 o. 159 0.50 0.45 0.196 0.51 0.48 0.253 0.51 0.51 0.138 0.52 0.46 O. 176 0.52 0.49 0.239 0.53 0.52 O. 144 0.54 0.50 0.213 0.55 0.53 0.151 0.57 0.55 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- I AND J FACTORS FOR: 20.0 DEG. PRESSURE ANGLE 30.0 DEG. HELIX ANGLE 0.250 TOOL EDGE RADIUS 50 PERCENT LONG ADDENDUM PINION (X = 0.50) 50 PERCENT SHORT ADDENDUM GEAR (X = GEAR TEETH 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP 2.250 O. 024 - O. 50) PINION TEETH 12 P 14 G 0.098 0.47 0.24 0.117 0.48 0.26 O. 141 0.48 0.29 0.166 0.48 0.32 0.190 0.48 0.34 o. 220 0.49 0.37 0.259 0.49 0.40 0.309 0.49 0.44 P 17 G 0.106 0.48 0.27 0.128 0.49 0.30 0.153 0.49 0.32 0.176 0.49 0.35 0.207 0.49 0.38 0.246 0.50 0.41 0.299 0.50 0.45 AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS P 21 G 0.114 0.50 0.30 0.137 0.50 0.33 0.160 0.50 0.36 0.190 0.51 0.39 0.231 0.51 0.42 0.287 0.51 0.46 P 26 G P o. 121 0.51 0.34 0.143 0.51 0.37 O. 173 0.52 0.40 0.214 0.52 0.43 0.274 0.52 0.47 35 G 0.127 0.52 0.37 O. 156 0.52 0.40 0.198 0.53 0.44 0.262 0.53 0.48 P 55 G 0.134 0.54 0.42 0.175 0.54 0.45 0.244 0.54 0.49 40 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT P 135 G 0.141 0.55 0.47 0.215 0.56 0.51 P G 0.150 0.57 0.53 908-B89 W 0687575 0003072 524 W A G H A 708-B Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth 1 AND J FACTORS FOR:’ DEG. PRESSURE ANGLE DEG. HELIX ANGLE TOOL EDGE RADIUS EQUAL ADDENDUM (X 1= x = O ) WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP 25.0 0.0 0.270 2.350 0.024 PINION TEETH GEAR TEETH 12 14 P G u u u u u u u u u u u u u u u u P 21 17 G P G P 26 G P 35 G P 55 G P 135 G P G 12 I J 14 I 17 21 26 35 55 135 J I J I J I J I J I J I J 0.086 0.28 0.28 0.091 0.28 0.30 0.095 0.28 0.31 o. 100 0.28 0.33 O. 106 0.28 0.34 0.113 0.28 0.36 0.123 0.28 0.38 0.090 0.30 0.30 0.096 0.30 0.31 o. 101 0.30 0.33 0.109 0.30 0.34 0.119 0.30 0.36 0.132 0.30 0.38 0.092 0.31 0.31 0.099 0.31 0.33 O. 108 0.31 0.34 0.121 0.31 0.36 0.139 0.31 0.38 0.094 0.33 0.33 O. 104 0.33 0.34 0.119 0.33 0.36 O . 142 0.33 0.38 0.095 0.34 0.34 0.112 0.34 0.36 0.141 0.34 0.38 0.095 0.36 0.36 0.131 0.36 0.38 0.096 0.38 0.38 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. I AND J FACTORS FOR: DEG. PRESSURE ANGLE DEG. HELIX ANGLE 0.270 TOOL EDGE RADIUS 25 PERCENT LONG ADDENDUM PINION (x 25.0 0.0 25 PERCENT SHORT ADDENDUM GEAR WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP = 0.25) 2.350 0.024 (x2 = - 0.25) PINION TEETH GEAR TEETH 12 I 14 17 21 26 35 55 135 J I J I J I J I J I J I J I J 12 P 14 G 0.091 0.32 0.20 0.095 0.32 0.22 0.100 0.32 0.25 O. 106 0.32 0.27 0.111 0.32 0.29 0.118 0.32 0.31 O. 127 0.32 0.34 0.138 0.32 0.37 P 17 G 0.093 0.33 0.22 0.099 0.33 0.25 O. 106 0.33 0.27 0.112 0.33 0.29 o. 120 0.33 0.31 0.131 0.33 0.34 O. 145 0.33 0.37 AGMA P 26 21 G 0.094 0.34 0.25 o. 102 0.34 0.27 o. 109 0.34 0.29 0.119 0.34 0.31 O . 133 0.34 0.34 0.151 0.34 0.37 P G P 0.095 0.36 0.27 O. 103 0.36 0.29 0.115 0.36 0.31 0.131 0.36 0.34 0.153 0.36 0.37 35 G 0.095 0.36 0.29 0.108 0.36 0.31 O . 126 0.36 0.34 O . 153 0.36 0.37 P 55 G 0.096 0.37 0.31 0.116 0.37 0.34 0.148 0.37 0.37 135 G 0.096 0.38 0.34 0.135 0.38 0.37 P G 0.096 0.39 0.37 908-B89 41 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS P Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT m A G H A 908-B Ob87575 0003073 4b0 m Geometry Factors for Determiniig the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth I AND J FACTORS FOR:’ 25.0 DEG. PRESSURE ANGLE 0.0 DEG. HELIX ANGLE 0.270 TOOL EDGE RADIUS 50 PERCENT LONG ADDENDUM PINION ( x 50 PERCENT SHORT ADDENDUM GEAR GEAR TEETH 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J 14 12 P G T T T 2.350 WHOLE DEPTH FACTOR 0.024 TOOTH THINNING FOR BACKLASH LOADED AT TIP = O. 50) (x2 = - 0.50) 17 P G T T T T T T T T T P G T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T PINION TEETH 21 26 P G P G P 0.096 0.40 0.23 O. 106 0.40 0.25 o. 120 0.40 0.28 O. 139 0.40 0.32 O. 167 0.40 0.36 0.096 0.40 0.28 0.118 0.40 0.32 o. 155 0.40 0.36 0.096 0.40 0.25 0.110 0.40 0.28 0.131 0.40 0.32 O. 163 0.40 0.36 35 55 G P G 0.096 0.40 0.32 O. 138 0.40 0.36 P 135 G 0.096 0.40 0.36 1 The letter “T” indicates a gear tooth combination which produces pointed teeth with a top land less than 0.3/Pnd in one or both components and should be avoided. See Section 7. I AND J FACTORS FOR:’ 25.0 DEG. PRESSURE ANGLE DEG. HELIX ANGLE 0.270 TOOL EDGE RADIUS EQUAL ADDENDUM ( x 1= x = O) 2.350 WHOLE DEPTH FACTOR 0.024 TOOTH THINNING FOR BACKLASH LOADED AT HIGHEST POINT OF SINGLE TOOTH CONTACT 0.0 GEAR TEETH 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J 12 14 P G u u u u u u u u u u u u u u u u P 17 G 0.086 0.33 0.33 0.091 0.33 0.36 0.095 0.33 0.39 o. 100 0.33 0.41 O. 106 0.34 0.44 0.113 0.34 0.47 0.123 0.35 0.51 P G 0.090 0.36 0.36 0.096 0.36 0.39 o. 101 0.37 0.42 0.109 0.37 0.45 0.119 0.38 0.48 0.132 0.38 0.52 PINION TEETH 21 26 P G P G P O. 092 0.39 0.39 0.099 0.40 0.42 o. 108 0.40 0.45 o. 121 0.41 0.49 0.139 0.42 0.53 0.095 0.46 0.46 0.112 0.47 0.50 0.141 0.48 0.54 0.094 0.43 0.43 0.104 0.43 0.46 0.119 0.44 0.49 0.142 0.45 0.53 35 55 G P G 0.095 0.51 0.51 0.131 0.53 0.56 P 135 G 0.096 0.57 0.57 1 The letter “U”indicates a gear tooth combination which produces a n undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. AGMA 42 ... Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS .. 908-B89 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- ? Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT m A G M A 908-B Ob87575 000307Y 3T7 m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth ’ I AND J FACTORS FOR: 25.0 DEG. PRESSURE ANGLE 0.0 DEG. HELIX ANGLE 0.270 TOOL EDGE RADIUS 25 PERCENT LONG ADDENDUM PINION (x 25 PERCENT SHORT ADDENDUM GEAR WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT HIGHEST POINT OF SINGLE TOOTH CONTACT = 0.25) 2.350 0.024 (x2 = - 0.25) PINION TEETH GEAR TEETH 12 I 14 17 21 26 35 55 135 I J I J I J I J I J I J I J I J 12 P 14 G P 17 G P 21 G P 26 G P 35 G P 55 G P 135 G 0.091 0.38 0.22 0.095 0.38 0.25 o. 100 0.38 0.29 O. 106 0.38 0.32 0.111 0.39 0.35 0.118 0.39 0.38 O. 127 0.39 0.42 0.093 0.40 0.25 0.099 0.40 0.29 0.106 0.41 0.32 o. 112 0.41 0.35 0.120 0.41 0.39 O. 131 0.42 0.43 0.094 0.43 0.29 o. 102 0.43 0.33 o. 109 0.44 0.36 0.119 0.44 0.39 0.133 0.44 0.44 0.095 0.46 0.33 0.103 0.46 0.36 0.115 0.47 0.40 0.131 0.47 0.44 0.095 0.48 0.37 0.108 0.49 0.41 0.126 0.49 0.45 0.096 0.51 0.41 0.116 0.52 0.46 0.096 0.55 0.47 0.138 0.40 0.47 0.145 0.42 0.48 0.151 0.45 0.49 0.153 0.48 0.49 0.153 0.50 0.50 O . 148 0.53 0.51 0.135 0.56 0.53 P G 0.096 0.59 0.55 I AND J FACTORS FOR:’ 25.0 DEG. PRESSURE ANGLE 0.0 DEG. HELIX ANGLE 0.270 TOOL EDGE RADIUS 50 PERCENT LONG ADDENDUM PINION WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT HIGHEST POINT OF SINGLE TOOTH CONTACT = 0.50) (X 50 PERCENT SHORT ADDENDUM GEAR (x2 = 2.350 0.024 - 0.50) PINION TEETH GEAR TEETH 12 14 P G 12 I J 14 I T T J T J 21 I J 17 P G T T T T T T T T T 21 P G T T T T T T T T T T T T T T T T T T T T T T T T T P 26 G P 35 G P 55 G P 135 G P G 17 I T 0.096 0.52 0.27 O. 106 0.52 0.30 0.120 0.52 0.35 0.096 0.53 0.31 0.110 0.53 0.35 0.096 0.55 0.36 T T 0.139 0.52 0.40 0.131 0.54 0.41 0.118 0.56 0.42 T T O. 167 0.53 0.46 0.163 0.54 0.47 0.56 26 I I J 35 I J 55 I J 135 I J o. 155 0.48 0.096 0.58 0.43 O. 138 0.58 0.50 0.096 0.60 0.53 1 The letter “T” indicates a gear tooth combination which produces pointed teeth with a top land less than O. 31Pnd in one or both components and should be avoided. See Section 7. ‘ AGMA 43 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 908-B89 m 0687575 AGHA 908-8 0003075 233 m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth I AND J FACTORS FOR:' WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP 2.350 0.024 DEG. PRESSURE ANGLE DEG. HELIX ANGLE TOOL EDGE RADIUS EQUAL ADDENDUM (x 1= x = O) 25.0 10.0 0.270 PINION TEETH GEAR TEETH 12 I --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- J P G u u u u u u u u 14 I 17 21 26 35 55 135 J I J I J I J I J I J I J u u u u u u u u P G O. 129 0.47 0.47 O. 144 0.48 0.51 0.159 0.48 0.55 0.175 0.49 0.58 0.195 0.50 0.61 0.221 0.51 0.65 0.257 0.52 0.70 P G P 0.133 0.52 0.52 O. 149 0.52 0.55 0.165 0.53 0.58 0.186 0.54 0.62 0.215 0.55 0.66 0.255 0.56 0.71 P G 55 35 26 21 17 14 12 G P G P 135 G 0.136 0.56 0.56 0.152 0.57 0.59 0.175 0.57 0.63 0.206 0.58 0.67 0.251 0.139 0.60 0.60 0.162 0.61 0.64 0.195 0.62 0.68 0.246 0.143 0.64 0.64 O. 178 0.65 0.69 0.236 0.148 0.70 0.70 0.215 0.60 0.63 0.67 0.71 0.72 0.73 0.74 0.75 P G 0.154 0.76 0.76 1 The letter "U" indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. I AND J FACTORS FOR: 2.350 WHOLE DEPTH FACTOR DEG. PRESSURE ANGLE 0.024 TOOTH THINNING FOR BACKLASH DEG. HELIX ANGLE LOADED AT TIP 0.270 TOOL EDGE RADIUS 25 PERCENT LONG ADDENDUM PINION (x = 0.25) 25.0 10.0 25 PERCENT SHORT ADDENDUM GEAR (X2 = - 0.25) PINION TEETH GEAR TEETH 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J P G o. 120 0.53 0.33 O. 136 0.54 0.37 0.155 0.54 0.41 0.175 0.55 0.46 0.194 0.55 0.49 0.219 0.56 0.54 0.251 0.56 0.59 0.293 0.57 0.65 P G 0.125 0.56 0.38 0.143 0.57 0.42 0.163 0.57 0.46 O. 183 0.58 0.50 0.208 0.58 0.55 0.242 0.59 0.60 0.286 0.60 0.66 AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS P G 0.129 0.60 0.43 0.149 0.60 0.47 O. 168 0.61 0.51 0.194 0.61 0.56 0.229 0.62 0.61 0.278 0.63 0.67 P 35 26 21 17 14 12 G O. 134 0.63 0.48 0.153 0.64 0.52 0.179 0.64 0.57 0.216 0.65 0.62 0.269 0.66 0.68 P G O. 137 0.66 0.53 0.164 0.67 0.57 0.201 0.67 0.63 0.259 0.68 0.69 P 55 G O. 142 0.69 0.59 0.180 0.70 0.64 0.244 0.71 0.71 44 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT P 135 G 0.147 0.73 O. 0.218 0.74 0.72 P G 0.154 0.78 0.74 9 0 8-B 8 9 Ob87575 0 0 0 3 0 7 b L 7 T A G I A 908-B m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth Z AND J FACTORS FOR:’ 1 25.0 DEG. PRESSURE ANGLE 10.0 DEG. HELIX ANGLE 0.270 TOOL EDGE RADIUS 50 PERCENT LONG ADDENDUM PINION (X 50 PERCENT SHORT ADDENDUM GEAR (X GEAR TEETH 12 14 2 = 17 P G T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T P G T T T T T T T T T P G 12 I J 14 I T T J T 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J 2.350 WHOLE DEPTH FACTOR 0.024 TOOTH THINNING FOR BACKLASH LOADED AT TIP = O. 50) - O. 50) PINION TEETH 21 26 P G P G P 0.126 0.69 0.40 0.148 0.69 0.44 0.178 0.70 0.50 0.220 0.70 0.56 0.280 0.70 0.64 O. 138 0.73 0.52 O. 180 0.74 0.S9 0.249 0.74 0.67 0.132 0.71 0.45 0.161 0.71 0.51 0.203 0.72 0.57 0.267 0.72 0.65 35 55 G P 135 G O. 145 0.76 0.61 0.220 0.76 0.69 P G O. 153 0.79 0.72 1 The letter “T” indicates a gear tooth combination which produces pointed teeth with a top land less than 0.3/Pnd in one or both components and should be avoided. See Section 7. I AND J FACTORS FOR:’ 25.0 15.0 0.270 EQUAL I GEAR TEETH 12 I J 14 I J 17 I J 21 I J 26 I J DEG. PRESSURE ANGLE DEG. HELIX ANGLE TOOL EDGE RADIUS ADDENDUM ( x 1= x = O) 14 12 P G u u u u u u u u u u u u u u u u 35 I J 55 I J 135 I J 1 2.350 WHOLE DEPTH FACTOR 0.024 TOOTH THINNING FOR BACKLASH LOADED AT TIP P 17 G 0.130 0.49 0.49 O. 144 0.50 0.53 0.160 0.50 0.56 0.175 0.51 0.59 0.195 0.52 0.63 o. 222 0.52 0.67 0.257 0.53 0.72 P G 0.133 0.53 0.53 O. 149 0.54 0.57 0.165 0.55 0.60 0.186 0.55 0.64 0.215 0.56 0.68 0.255 0.57 0.72 PINION TEETH 21 26 P G P G P 0.137 0.58 0.58 O. 153 0.58 0.61 0.175 0.59 0.64 0.206 0.60 0.68 0.251 0.61 0.73 0.143 0.66 0.66 0.178 0.67 0.70 0.236 0.68 0.75 O. 140 0.61 0.61 0.163 0.62 0.65 0.195 0.63 0.69 0.246 0.64 0.74 35 55 G P G O. 148 0.71 0.71 0.214 0.72 0.76 P 135 G 0.154 0.78 0.78 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- 1 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 45 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 90 8-B 89 M Ob87575 0003077 OOb M A G M A 908-B Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth I AND J FACTORS FOR: 25.0 DEG. PRESSURE ANGLE 15.0 DEG. HELIX ANGLE 0.270 TOOL EDGE RADIUS 25 PERCENT LONG ADDENDUM PINION ( x 25 PERCENT SHORT ADDENDUM GEAR 12 P 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 J J 135 I J 0.122 0.55 0.35 O. 137 0.56 0.39 O. 155 0.56 0.43 0.175 0.57 0.48 0.195 0.57 0.51 0.219 0.57 0.55 0.251 0.58 0.61 0.292 0.59 0.66 G P ( ~ =2 - 0.25) 17 14 GEAR TEETH 2.350 WHOLE DEPTH FACTOR 0.024 TOOTH THINNING FOR BACKLASH LOADED AT TIP = 0.25) G 0.126 0.58 0.39 0.144 0.59 0.44 0.164 0.59 0.48 O. 183 0.60 0.52 0.208 0.60 0.56 0.241 0.61 0.61 0.285 0.62 0.67 P G 0.130 0.62 0.45 O. 149 0.62 0.49 0.169 0.63 0.53 0.195 0.63 0.57 0.229 0.64 0.62 O. 277 0.64 0.68 PINION TEETH 26 21 P G P G P 0.134 0.65 0.50 0.153 0.65 0.54 O. 179 0.66 0.58 0.215 0.66 0.63 0.268 0.67 0.70 0.142 0.71 0.60 0.180 0.71 0.66 0.244 0.72 0.72 0.138 0.68 0.55 0.164 0.68 0.59 0.201 0.69 0.64 0.258 0.70 0.71 35 55 G P G 0.147 0.75 0.67 0.218 0.75 0.74 P 135 G 0.153 0.79 0.76 I AND J FACTORS FOR:' 25.0 DEG. PRESSURE ANGLE 15.0 DEG. HELIX ANGLE 0.270 TOOL EDGE RADIUS 50 PERCENT LONG ADDENDUM PINION ( x 50 PERCENT SHORT ADDENDUM GEAR GEAR TEETH --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J 12 14 P G T T T T 2.350 WHOLE DEPTH FACTOR 0.024 TOOTH THINNING FOR BACKLASH LOADED AT TIP = O. 50) ( ~ =2 - 0.50) 17 P G T T T T T T P G PINION TEETH 21 26 P G P G P 0.127 0.71 0.42 O. 149 0.71 0.46 O. 179 0.71 0.52 0.220 0.72 0.58 0.279 0.72 0.65 0.138 0.75 0.54 0.180 0.75 0.60 0.249 0.75 0.68 35 55 G P G P 135 G o. 121 0.69 0.36 O. 144 T T T T T T T T T T T T T T T T T T T T 0.69 0.41 0.166 0.69 0.45 0.196 0.69 0.50 0.236 0.70 0.57 0.292 0.70 0.64 0.133 0.73 0.47 0.162 0.73 0.53 0.203 0.73 0.59 0.266 0.74 0.67 O. 145 0.77 0.62 0.219 0.78 0.70 0.152 0.80 0.73 i The letter "T" indicates a gear tooth combination which produces pointed teeth with a top land less than 0.3/Pnd in one or both components and should be avoided. See Section 7. AGMA . Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 908-B89 46 p-w : - ','i - Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT D Ob87575 0003078 T 4 2 D A G M A 908-B Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth I AND J FACTORS FOR: DEG. PRESSURE ANGLE DEG. HELIX ANGLE TOOL EDGE RADIUS EQUAL ADDENDUM ( x 1= x = O ) 25.0 20.0 0.270 WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP 2.350 0.024 PINION TEETH GEAR TEETH 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J 12 P 14 G 0.128 0.47 0.47 0.140 0.47 0.50 0.154 0.48 0.53 0.169 0.48 0.56 0.184 0.49 0.59 0.202 0.49 0.62 0.227 0.50 0.66 0.258 0.51 0.70 P 17 G 0.131 0.50 0.50 O. 145 0.51 0.54 0.161 0.51 0.57 O. 176 0.52 0.60 0.196 0.53 0.63 0.222 0.53 0.67 0.257 0.54 0.71 P 21 G P 0.134 0.54 0.54 o. 150 0.55 0.58 O. 166 0.55 0.60 0.187 0.56 0.64 0.215 0.57 0.67 0.255 0.58 0.72 26 G 0.137 0.58 0.58 0.153 0.59 0.61 O. 176 0.60 0.64 0.206 0.60 0.68 0.251 0.62 0.72 P 35 G P 55 G P 135 G P G O. 140 0.62 0.62 O. 163 0.62 0.65 0.196 0.63 0.69 0.246 0.65 0.73 0.144 0.66 0.66 O. 178 0.67 0.70 0.236 0.68 0.74 0.148 0.71 0.71 0.214 0.72 0.75 O. 53 0.76 0.76 I AND J FACTORS FOR: 25.0 DEG. PRESSURE ANGLE 20.0 DEG. HELIX ANGLE 0.270 TOOL EDGE RADIUS 25 PERCENT LONG ADDENDUM PINION ( x 25 PERCENT SHORT ADDENDUM GEAR WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP = 0.25) 2.350 0.024 (x2 = - 0.25) PINION TEETH GEAR TEETH 12 I . I 14 I 17 21 26 35 55 135 J I J I J I J I J I J I J 12 P 14 G O. 123 0.56 0.37 0.138 0.56 0.40 0.156 0.57 0.45 O. 176 0.57 0.49 0.195 0.58 0.52 0.219 0.58 0.56 0.250 0.59 0.61 0.290 0.59 0.66 P 17 G O. 127 0.59 0.41 O. 145 0.59 0.45 O. 164 0.60 0.49 0.184 0.60 0.53 0.208 0.61 0.57 0.241 0.61 0.61 0.284 0.62 0.67 AGMA P 21 G 0.131 0.62 0.46 o. 150 0.62 0.50 0.169 0.63 0.54 0.195 0.63 0.58 0.229 0.64 0.62 0.276 0.65 0.68 P 26 G 0.135 0.65 0.51 0.154 0.65 0.54 0.180 0.66 0.59 0.215 0.66 0.63 0.267 0.67 0.69 P 35 G O. 138 0.67 0.55 0.164 0.68 0.59 0.201 0.69 0.64 0.257 0.69 0.70 P 55 G 0.143 0.70 0.60 o. 180 0.71 0.65 0.243 0.72 0.71 P 135 G O. 147 0.74 0.67 0.217 0.75 0.73 G 0.153 0.78 0.75 9 O 8-B89 47 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS P Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT W Ob87575 0003079 989 A L M A 908-B Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth I AND J FACTORS FOR:’ 25.0 DEG. PRESSURE ANGLE 20.0 DEG. HELIX ANGLE 0.270 TOOL EDGE RADIUS 50 PERCENT LONG ADDENDUM PINION ( x 2.350 WHOLE DEPTH FACTOR 0.024 TOOTH THINNING FOR BACKLASH LOADED AT TIP = 0.50) 50 PERCENT SHORT ADDENDUM GEAR = GEAR TEETH 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J 14 12 17 P G T T T T T T T T T T T T T T T T T T T T T T T T T T T P G T T T (X P G 0.123 0.68 0.37 O. 145 0.69 0.42 O. 167 0.69 0.46 0.197 0.69 0.51 0.236 0.70 0.57 0.290 0.70 0.64 - O. 50) PINION TEETH 21 26 P G P G P 0.129 0.70 0.43 0.150 0.71 0.47 0.179 0.71 0.52 0.219 0.71 0.58 0.277 0.72 0.65 0.139 0.74 0.54 O. 180 0.74 0.61 0.248 0.75 0.68 0.134 0.72 0.48 O. 162 0.72 0.53 0.203 0.73 0.59 0.265 0.73 0.66 35 55 G P G 0.145 0.76 0.62 0.219 0.77 0.70 P 135 G 0.152 0.79 0.72 1 The letter “T” indicates a gear tooth combination which produces pointed teeth with a top land less than 0.3/Pnd in one or both components and should be avoided. See Section 7. I AND J FACTORS FOR: 25.0 25.0 0.270 EQUAL DEG. PRESSURE ANGLE DEG. HELIX ANGLE TOOL EDGE RADIUS ADDENDUM ( x 1= x = O) 2.350 WHOLE DEPTH FACTOR 0.024 TOOTH THINNING FOR BACKLASH LOADED AT TIP 14 GEAR TEETH 12 P 12 I J 14 I J 17 I J 23 I J 26 I J 35 I J 55 I J 135 I J O. 129 0.47 0.47 0.141 0.47 0.50 0.155 0.48 0.53 0.170 0.48 0.55 0.185 0.49 0.58 0.203 0.49 0.61 0.227 0.50 0.64 0.259 0.51 0.68 G P 17 G 0.132 0.50 0.50 0.146 0.51 0.53 0.162 0.51 0.56 0.177 0.52 0.58 O. 197 0.52 0.61 0.223 0.53 0.65 0.258 0.54 0.68 AGMA P G 0.135 0.54 0.54 0.151 0.54 0.57 0.166 0.55 0.59 0.188 0.56 0.62 0.216 0.56 0.65 0.255 0.57 0.69 PINION TEETH 26 21 P G P G P O. 138 0.57 0.57 0.154 0.58 0.60 0.176 0.58 0.63 0.207 0.59 0.66 0.251 0.60 0.70 O. 144 0.64 0.64 0.178 0.65 0.67 0.235 0.66 0.71 0.141 0.60 0.60 0.163 0.61 0.63 O. 196 0.62 0.67 0.246 0.63 0.70 48 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 55 35 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT G P G 0.148 0.68 0.68 0.213 0.69 0.72 P 135 G O. 152 0.73 0.73 908-B89 A G M A 908-B Ob87575 0003080 bTO = Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth ) I AND J FACTORS FOR: 25.0 DEG. PRESSURE ANGLE 25.0 DEG. HELIX ANGLE 0.270 TOOL EDGE RADIUS 25 PERCENT LONG ADDENDUM PINION WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP (X 25 PERCENT SHORT ADDENDUM GEAR (x2 = 2.350 0.024 = 0.25) - 0.25) PINION TEETH GEAR TEETH 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J 12 P 14 G O. 125 0.55 0.38 0.139 0.56 0.41 0.157 0.56 0.45 O.177 0.57 0.48 0.195 0.57 0.52 0.219 0.57 0.55 O. 249 0.58 0.59 0.288 0.59 0.64 P 17 G o. 128 0.58 0.42 0.146 0.58 0.45 0.165 0.59 0.49 O. 184 0.59 0.52 0.208 0.60 0.56 0.240 0.60 0.60 0.281 0.61 0.65 P 21 G P 0.132 0.61 0.46 o. 151 0.61 0.50 O. 170 0.61 0.53 0.195 0.62 0.57 0.228 0.62 0.61 O. 274 0.63 0.66 26 G P 0.136 0.63 0.51 0.154 0.64 0.54 0.180 0.64 0.57 0.215 0.65 0.62 0.265 0.65 0.67 35 G 0.139 0.65 0.54 0.164 0.66 0.58 0.201 0.66 0.63 0.256 0.67 0.68 P 55 G O. 143 0.68 0.59 0.180 0.69 0.64 O.242 0.69 0.69 P 135 G 0.147 0.71 0.65 0.216 0.72 0.70 P G o. 152 0.74 0.72 I AND J FACTORS FOR:’ 25.0 DEG. PRESSURE ANGLE 25.0 DEG. HELIX ANGLE 0.270 TOOL EDGE RADIUS 50 PERCENT LONG ADDENDUM PINION (x 50 PERCENT SHORT ADDENDUM GEAR WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP = O. 50) 2.350 0.024 (x2 = - 0.50) PINION TEETH GEAR TEETH 12 14 P G J T T 14 I J 17 I T T T T T T T T T T P 17 G P 21 G P 26 G P 35 G 55 G P P 135 G P G 12 I J 21 I J 26 I J 0.140 35 I J 55 I J 135 I J ) 0.119 0.65 0.33 T T T T 0.65 0.38 0.163 0.65 0.42 0.184 0.65 0.46 0.213 0.66 0.50 0.249 0.66 0.55 0.298 0.66 0.61 0.125 0.66 0.38 O. 147 0.67 0.43 O. 168 0.67 0.46 0.197 0.67 0.51 0.235 0.67 0.56 0.287 0.68 0.62 0.130 0.68 0.43 0.151 0.68 0.47 0.180 0.69 0.52 0.219 0.69 0.57 0.275 0.69 0.63 0.135 0.70 0.48 O. 163 0.70 0.53 0.203 0.70 0.58 0.263 0.70 0.64 O. 140 0.71 0.54 o. 180 0.72 0.59 0.246 0.72 0.66 0.145 0.73 0.61 0.218 0.73 0.67 0.151 0.75 0.70 1 The letter “T” indicates a gear tooth combination which produces pointed teeth with a top land less than 0.3/Pnd in one or both components and should be avoided. See Section 7. AGMA 49 908-B89 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT I m A G M A 908-B Ob87575 0003081 537 m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth I AND J FACTORS FOR: DEG. PRESSURE ANGLE DEG. HELIX ANGLE TOOL EDGE RADIUS EQUAL ADDENDUM (x 1= x 2= O) WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP 25.0 30.0 0.270 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- PINION TEETH GEAR TEETH 12 I J 14 I J 17 I 21 26 35 55 135 2.350 0.024 J I J I J I J I J I J 14 12 P G 0.130 0.46 0.46 0.142 0.47 0.49 0.156 0.47 0.51 O. 171 0.48 0.54 O. 186 0.48 0.56 0.204 0.49 0.58 0.228 0.49 0.61 0.259 0.50 0.64 P 17 G 0.133 0.49 0.49 O. 147 0.50 0.52 O. 163 0.50 0.54 0.178 0.51 0.56 0.198 0.51 0.59 0.223 0.52 0.61 0.257 0.53 0.64 P 21 G P 0.136 0.52 0.52 o. 151 0.53 0.55 0.167 0.53 0.57 0.188 0.54 0.59 0.216 0.54 0.62 0.255 0.55 0.65 26 G 0.138 0.55 0.55 0.154 0.56 0.57 0.176 0.56 0.60 0.207 0.57 0.62 0.251 0.58 0.66 P 35 G 0.141 0.58 0.58 0.163 0.58 0.60 0.196 0.59 0.63 0.245 0.60 0.66 P 55 G O. 144 0.61 0.61 O. 178 0.62 0.64 0.234 0.62 0.67 P 135 G O. 147 0.64 0.64 0.212 0.65 0.68 P G 0.151 0.68 0.68 I AND J FACTORS FOR: DEG. PRESSURE ANGLE DEG. HELIX ANGLE 0.270 TOOL EDGE RADIUS 25 PERCENT LONG ADDENDUM PINION ( x 25.0 30.0 25 PERCENT SHORT ADDENDUM GEAR WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP = 0.25) 2.350 0.024 (x2 = - 0.25) PINION TEETH GEAR TEETH 12 I 14 17 21 26 35 J I J I J I J I J I J 55 I J 135 I J 12 P 14 G O. 127 0.54 0.38 0.141 0.54 0.41 0.159 0.54 0.44 O. 177 0.55 0.47 0.195 0.55 0.50 0.218 0.56 0.53 0.247 0.56 0.57 0.285 0.56 0.61 P 17 G 0.130 0.56 0.42 0.147 0.56 0.45 0.166 0.57 0.48 0.184 0.57 0.51 0.208 0.57 0.54 0.238 0.58 0.57 0.279 0.58 0.61 AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS P 21 G 0.133 0.58 0.46 0.152 0.58 0.49 0.170 0.59 0.51 O. 194 0.59 0.54 0.227 0.60 0.58 0.272 0.60 0.62 P 26 G 0.137 0.60 0.49 0.155 0.61 0.52 0.180 0.61 0.55 0.214 0.61 0.59 0.263 0.62 0.63 P 35 G O. 140 0.62 0.53 O. 164 0.63 0.56 0.200 0.63 0.59 0.254 0.64 0.64 P 55 G O. 143 0.64 0.57 O. 180 0.65 0.60 0.240 0.65 0.65 50 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT P 135 G O. 147 0.67 0.61 0.215 0.67 0.66 P G 0.151 0.70 0.67 9 O 8-B 8 9 A G H A 908-B m Ob87575 0003082 473 m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth 1 I AND J FACTORS FOR: 2.350 WHOLE DEPTH FACTOR DEG. PRESSURE ANGLE 0.024 TOOTH THINNING FOR BACKLASH DEG. HELIX ANGLE LOADED AT TIP TOOL EDGE RADIUS 50 PERCENT LONG ADDENDUM PINION ( x = O. 50) 25.0 30.0 0.270 ( ~ =2 - 0.50) 50 PERCENT SHORT ADDENDUM GEAR PINION TEETH GEAR TEETH P 12 I 14 17 21 26 35 55 135 I J P G P 21 G P 26 G P P 55 G P 135 G P G o. 122 0.62 0.34 O. 142 0.38 O. 164 0.62 0.42 0.185 0.62 0.45 O. 127 0.63 0.39 O. 148 0.63 0.42 0.169 0.63 0.46 0.132 0.64 0.43 0.152 0.64 0.46 0.136 0.65 0.47 0.225 0.61 0.48 0.212 0.62 0.48 O. 196 0.64 0.49 0.180 0.65 0.50 O. 163 0.66 0.51 0.67 0.259 0.62 0.52 0.247 0.63 0.53 0.233 0.64 0.54 0.218 0.65 0.55 0.202 0.66 0.56 O. 179 0.67 0.57 0.145 0.68 0.58 O. 303 0.62 0.57 0.294 0.63 0.58 0.283 0.64 0.59 0.272 0.65 0.60 0.261 0.66 0.61 0.244 0.67 0.62 0.216 0.69 0.64 0.62 STUB TOOTH (SYKES FORM DEG. PRESSURE ANGLE TRANSVERSE 30. DEG. HELIX ANGLE 0.157 TOOL EDGE RADIUS EQUAL ADDENDUM (x 1= x = O> O. 140 0.52 o. 151 0.65 0.70 ADDENDUM FACTOR WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP 0.8 1.900 0.024 20.0 GEAR TEETH PINION TEETH 12 14 P G 12 I J 14 I u u J u 17 P G u u u u u u u u u u u u u u u u u u u u u u u u u 17 I 21 26 35 55 135 b 35 G I AND J FACTORS FOR:’ --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- ) G 0.117 0.60 0.30 0.134 0.61 0.34 O. 155 0.61 0.37 O. 177 0.61 0.41 o. 198 0.61 0.44 J I J I J I J I J I J I J 17 14 12 J I J I J I J I J I J P 21 G P 35 26 P G G P 55 G P 135 G u 0.115 0.37 0.37 O. 129 0.38 0.39 O. 143 0.38 0.40 0.163 0.39 0.41 0.189 0.40 0.43 0.119 0.39 0.39 0.133 0.40 0.41 0.153 0.40 0.42 0.181 0.41 0.44 0.122 0.41 0.41 O. 143 0.42 0.43 0.173 0.43 0.44 0.127 0.43 0.43 0.158 0.44 0.45 0.132 0.46 0.46 u 0.226 0.41 0.45 0.223 0.43 0.46 0.219 0.44 0.47 0.211 0.46 0.47 0.193 0.47 0.48 P G O. 139 0.50 0.50 1 The letter “U” indicates a gear tooth combination which produces an undercut tooth form in one or both components and should be avoided. See Section 7 and Fig 7-1. AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 51 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 9 08-B89 m AGNA 908-B Ob87575 0003083 30T m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth I AND J FACTORS FOR: ADDENDUM FACTOR WHOLE DEPTH FACTOR 0.024 TOOTH THINNING FOR BACKLASH LOADED AT TIP 0.8 STUB TOOTH (SYKES FORM 1.900 20.0 DEG. PRESSURE ANGLE TRANSVERSE 30.0 DEG. HELIX ANGLE 0.157 TOOL EDGE RADIUS 25 PERCENT LONG ADDENDUM PINION ( x = 0.25) 25 PERCENT SHORT ADDENDUM GEAR (x2 = - 0.25) PINION TEETH GEAR TEETH 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J P 17 14 12 G O. 097 0.38 0.27 0.112 0.38 0.29 0.131 0.38 0.31 0.151 0.39 0.33 O. 171 0.39 0.34 0.197 P G P 21 P G 35 26 P G G P 55 G P 135 G G o. 102 0.39 0.30 o. 120 0.39 0.32 O. 140 0.40 0.33 0.160 0.40 0.35 0.186 0.108 0.41 0.32 O. 127 0.41 0.34 0.147 0.41 0.36 0.172 0.113 0.42 0.35 0.132 0.43 0.37 0.158 0.118 0.44 0.37 0.143 0.40 0.36 0.229 0.41 0.37 0.219 0.42 0.38 0.207 0.43 0.39 0.194 0.44 0.39 O. 180 0.46 0.40 0.38 0.272 0.41 0.39 0.264 0.42 0.40 0.255 0.44 0.41 0.246 0.45 0.42 0.236 0.46 0.43 0.221 0.48 0.44 0.197 0.41 0.42 0.43 0.44 0.45 0.47 0.48 0.41 P 0.41 0.42 0.43 0.124 0.44 0.40 0.130 0.160 0.45 0.47 0.138 0.50 0.49 I AND J FACTORS FOR: L L ADDENDUM FACTOR WHOLE DEPTH FACTOR TOOTH THINNING FOR BACKLASH LOADED AT TIP 0.8 1.900 0.024 STUB TOOTH SYKES FORM DEG. PRESSUR ANG E TRANSVERSE 20.0 DEG. HELIX ANGLE 30.0 0.157 TOOL EDGE RADIUS 50 PERCENT LONG ADDENDUM PINION ( X = 0.50) 50 PERCENT SHORT ADDENDUM GEAR (W 2 = - O. SO) PINION TEETH 12 I J 14 I J 17 I J 21 I J 26 I J 35 I J 55 I J 135 I J P G 0.069 0.41 0.21 0.089 0.41 0.23 O. 114 0.41 0.25 0.141 0.41 0.28 0.167 0.41 0.29 0.199 0.42 0.32 0.240 0.42 0.34 0.293 0.42 0.37 P G 0.079 0.42 0.24 0.103 0.42 0.26 O. 129 0.42 0.28 0.154 0.42 0.30 0.186 0.43 0.32 0.227 0.43 0.35 0.283 0.43 0.38 AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS P 26 21 17 14 12 G 0.090 0.43 0.27 0.114 0.43 0.29 0.138 0.43 0.31 0.170 0.43 0.33 0.212 0.44 0.36 0.270 0.44 0.39 P G P 35 G P 55 G P 135 G o. 100 0.44 0.30 o. 122 0.44 0.32 0.153 0.44 0.34 0.195 0.45 0.37 0.257 0.45 0.40 0.108 0.45 0.33 0.137 0.45 0.35 0.179 0.46 0.38 0.244 0.46 0.41 52 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 0.116 0.47 0.37 O. 158 0.47 0.39 0.226 0.47 0.43 P G --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- GEAR TEETH O. 126 0.48 0.41 0.198 0.48 0.44 0.137 0.50 0.47 908-B 89 A G M A 708-B = Ob87575 0003084 246 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth Bibliography 1 Dolan, T. J. and Broghamer, E. L., A Photoelastic Study of the Stresses in Gear Tooth Fillets, University of Illinois, Engineering Experiment Station, Bulletin No. 335, 1942 2 Lewis, W., Investigation of the Strength of Gear Teeth, Proc. of the Engineers Club, Philadelphia, PA, 1893, pp.16-23. 3 Chong, T.H., and Kubo A., Simple Stress Formulae for a Thin-Rimmed Spur Gear, parts 1, 2 and 3, ASME papers 84-DET-62, 63 and 64. 4 Errichello, R.,An Efficient Algorithm for Obtaining the Gear Strength Geometry Factor on a Programmable Calculator, AGMA Paper No. P139.03, October 198 1 5 Errichello, R., An Efficient Algorithm for Obtaining the Gear Strength Geometry Factor for Shaper Cut Gears, AGMA Paper N o . P139.05, October 1983 6 Errichello, R., Calc Program Finds Inverse of an Involute, Machine Design, Vol 51, No. 5 , March 8, 1979, p. 80 7 Wellauer, E. J., and Seireg, A., Bending Strength of Gear Teeth b y Cantilever Plate Theory, Journal of Engineering for Industry, Trans. ASME, Series B, Vol. 82, 1960, pp. 213-222 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 53 908-B 89 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT A G M A 908-B Ob87575 0003085 I182 = Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth (this page has been left blank) AGMA 54 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 9 O 8-B 8 9 A G M A 908-B W Ob87575 000308b 019 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth Appendix A Original Derivation of AGMA Geometry Factor for Pitting Resistance, I This Appendix is not part of AGMA 908-B89, INFORMATION SHEET - Geometry Factors for Determining the Pitting Resistance and Bending Strength for Spur, Helical and Herringbone Gear Teeth, but is included for informational purposes only. For helical gear teeth, at the operating pitch diameter: Al. Purpose. This Appendix provides an historical record for the original derivation of the pitting resistance geometry factor, I , based on the Hertzian theory for contact compressive stress between two contacting cylinders as first introduced in AGMA 229.06, June 1962. where A2. Derivation. The surface contact compressive stress between two contacting cylinders is: sc = where Sc 4P mb = load per linear unit of contact length b = total width of contact band where R1 = radius of curvature of body 1 R2 = radius of curvature of body 2 = normal load in transverse plane Wt = tangential load in transverse plane +t = operating transverse pressure angle @b = base helix angle L~~~ = minimum total length of lines of contact = surface contact compressive stress P WN 2 d = operating pitch diameter of pinion D = operating pitch diameter of gear E Making proper substitutions and multiplying by - 1- P1 K1 - - E1 = Cp SC ,/y F d+D2 cos+t sin+t Lmin d D F (Eq A.lO) Regrouping terms where El, E2 = modulus of elasticity for material of cylinders 1 and 2 p1, ~2 = Poisson’s ratio for material of cylinders 1 and 2 Combining Eqs A. 1 and A.2. 1 cos +t sin +t (Eq A. 1 i) but cos+t sin+t - D 2 d+ D - 55 AGMA - 908-B89 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS cos +t sin +t m G 2 mG+1 (Eq A.12) Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT m A G M A 908-B Ob87575 0003087 T55 m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth solving for P at operating diameters: letting c, cos +t sin+t mG = 2 F mN = (Eq A.21) (Eq A.13) m +1 G solving for P at mean tooth diameters: (Eq A.14) Lmin I = then = P & MN ($J (Eq A.15) R2m R i m + R2m where (Eq A.16) (Eq A.23) To adapt Eq A.16 to actual gears, AGMA added additional factors to the equation. These factors are: Ca = application factor for pitting resistance C, = dynamic factor for pitting resistance C, = size factor for pitting resistance Cm = load distribution factor for pitting resistance (Eq A.24) cx = A.25) + 5 mis always equal to Cf noting that Rlm = The Cq2 factor modifies Cx for the three face contact ratio conditions, see Fig A-1: mF = 0.0 for spur gears = surface condition factor for pitting resistance Putting these factors in Eq A.16 gives: s, (Eq A.22) c* C, dF (Eq A.17) I Equation A. 17 is the fundamental formula for pitting resistance and is identical to Eq 5.1 in AGMA 2001-B88 and Eq 5.1 in AGMA 218.01. O < mF 5 1.0 for LACR gears mF > 1.0 for conventional helical gears In rating standard 218.01, Dec., 1982, the I factor was expanded to include two new terms: C I = __c- expanded to I = mN - For spur gears and conventional helical gears: c$ = 1.0. - For low axial contact ratio gears, LACR, the C Q ~factor provides a linear interpolation of I between spur and conventional helical gears, see Fig A-2. The Cx multiplier was added to consider the criterion rating stress at the mean diameters, d, and Dm,of the meshing elements rather than at the operating diameters d and D . Its derivation follows: -iy Premise: IMCR = I s + m F ( I H - I , ) From Eq A.5 sc = cP = ‘ ( RRi 1 + R R ,2) AGMA ILAcR= geometry factor for the low axial contact ratio helical gear (Eq A.20) I, = geometry factor for the spur gear IH = geometry factor for the conventional helical gear 9 08-B8 9 56 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- ”~ Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS (Eq A.26) where (Eq A.19) dividing b y 5 and squaring: ($J Ri+ R2 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT = Ob87575 A G H A 908-B 0003088 991 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth for spur gears for conventional helicals where “N C,, CJ: I’= (Eq A.27) I, = ‘4 ‘c‘xh - ‘c “N ‘xh (Eq A.28) MN where = FIL min Cxh = Cx as determined at d, diameter “N = 1.0 = Cx as determined for LPSTC = 1.0 m F =O c$ m = 1.0 < 1.0 F - LACR GEAR SPUR GEAR >1.0 CONVENTIONAL HELICAL GEAR m F FOR CASE (2) : FACE, F‘,O F AN IMAGINARY GEAR WITH m F = 1 .O F‘ = ‘.-F 0 STRESS CALCULATION LOCATION Fig A-1 F m- Cx Determination in Plane of Action / Conventional helical gear I factor ( )’I is based on stress computed at d, Low axial contact ratio (LACR) gear I factor ( ILACR)is based on linear interpolation between Is & IH Spur gear I factor ( I , ) is based on stress computed at LPSTC I O 0.5 1.0 m F Fig A-2 Variation of I for LACR Gear AGMA 57 908-B89 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT Ob87575 0003089 8 2 8 D A G H A 908-B Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth Substituting in Eq A.31 for LACR gears c c c 2u = cCcx,C$ ILACR - (Eq A.29) mN Substituting in Eq A.26 using Eq A.27, Eq A.28 and Eq A.29: where MN C , Rearranging = 1.0 C 2 = 1-m JI = C , as determined for LPSTC = a transition factor for spurs to conventional helicals, for LACR gears C$ Dividing by Cc and CXS ( C$ = l + m cxh 'xsmN -3 I = --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- F' mN=- z R - "F = Z sin q b AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS c$ (Eq. A.39) (Eq A.33) From AGMA 908-B89, Eq 4.1 is: (Eq A.34) = + t , p1= R 1 & p2 = R2 in Eq A.40, Letting it can now be shown that: b Lmin c c cx = 1.0 z = (EqA.37) MN and the associated load sharing ratio F' ) From AGMA 2001-B88, Eq 6.1 is: mF %un= Fsin $b A3. Proof for Equivalency of I . The remainder of this appendix is a proof that the formulation for I factor given in AGMA 2001-B88 is identical to the I factor in AGMA 908-B89. (Eq A.32) For the case of M m; helical having m F = 1.0 and face = F', CXS is Cx for equivalent spur gear with contact stress computed at LPSTC. (EqA.31) F - mN= L xh NOTE: Cxh is Cx for the imaginary The equivalent face, F', of such a gear is: = (cc,, Taking the square root results in the expressiom found in 218.01. where The mN represents an imaginary conventional helical gear having a face contact ratio of 1 .o F' F + F sin q mF = I = - (EqA.35) cc 58 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT - 2 " 2 9 O 8-B 89 m A G H A 908-B Ob87575 0003090 5 4 T m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth so m cancelling 2c = c = N 2 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- cos +t = c,c, ,(;+i) RI+ R2 sin +t (Eq A.49) see Fig A-3 (Eq A.42) cancelling and letting D = mG d = cos +t- mG R1R2 mG+l d mG sin cos +t +* (Eq A.43) solve for d ( = d Fig A-3 )(L+L) 2 R1R2 sin+t(mG+l) Ri (Eq A.44) Therefore, Eq A.41 holds and it is shown that the I factor given in ANSVAGMA 2001-B88 is numerically identical to that in AGMA 908-B89. R2 note that R1 R2 R1 R2 then d = 2 R1R2 R1+R2 sin+t(mG+l) R1 R 2 (Eq A.45) = 2 ( R i + "2) (mG+1) sin +t (Eq A.46) SO d rearranging (mG+l) 2 = - R1+R 2 sin Qt (Eq A.47) but 2C = d ( m +1) G AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS (Eq A.48) 59 908-B89 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT A G H A 908-B W Ob87575 0003091 48b W Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth 908-B89 AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- (this page has been left blank) A G H A 708-B Ob87575 O003072 312 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth Appendix B ANWAGMA 2001-B88 Pitting Resistance Formula Derivation This Appendix is not part of AGMA 908-B89, INFORMATION SHEET - Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur, Helical and Herringbone Gear Teeth, but is included for informational purposes only B1. Purpose. This Appendix presents the derivation of the pitting resistance formula and the I factor as used in this Information Sheet. The I factor given here is a simplified version of that derived in Appendix A. This simplificationresults in the same numerical value of I . pending on the face contact ratio of the gearset, this point can be the mean diameter of the pinion or the lowest point of single tooth contact on the pinion. Additional rating factors are also added to the basic equation to adjust the stress due to factors peculiar to gearing. Starting with the general Hertz equation: B2. Derivation. The AGMA pitting resistance formula is based on the Hertz contact stress equation for cylinders with parallel axes. See Fig B- l . The load applied to the cylinder is the load normal to the tooth flank, and the length of contact is the minimum total length of lines of contact in the contact zone of the gear set. The radii of the cylinders are the radii of curvature of the teeth at the point of contact for the mating pair of gears. De- sc = 2w w b L --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- b .J Rr2 \ / Rr1 Fig B-1 Tooth Contact Stress Area AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 61 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT A G H A 90ô-B Ob87575 0003093 259 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth where SC W d l , d2 = maximum contact stress of parallel axis cylinders, lb/in2 Figure B-2 shows the oblique contact line between helical gear tooth profiles. It can be represented as the line of two contacting cones. The radii of curvature, pnl, pn2, of the pinion and gear teeth at any point along the contact line are perpendicular to the line of contact and the involute profiles at the point of contact. They are contained in the plane of action and are inclined at the base helix angle, qb, relative to the transverse plane. = contact load normal to the cylinders, lb b = semi-width of contact between cylinders, in L = length of contact between cylinders, in pl,p2 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- El, E2 = contact diameter of cylinders 1 and 2 = Poisson’s ratio of material in cylinders 1 and 2 = modulus of elasticity of material in cylinders 1 and 2 Fig B-2 Contacting Cones of Helical Gears (Extracted from AGMA 229.06) 62 Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 908-B89 A G H A 908-B 9 Ob87575 0003094 1 9 5 9 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth by defining Cp as: Converting the general nomenclature in Eqs B . l and B.2 to those used in AGMA 908-B89: L Also transferring the load and radii of curvature from the normal to the transverse plane where the geometry is more readily defined: transmitted load in the plane of action (normal to the tooth flank) minimum total length of lines of contact in contact zone where = transmitted tangential load at the radius of curvature normal to the profile at point of stress calculation for pinion and gear, respectively operating pitch diameter of the pinion Poisson’s ratio for pinion and gear material, respectively +t = operating transverse pressure angle qb = base helix angle p1, p2 modulus of elasticity for pinion and gear material, respectively = radii of curvature of profile in transverse plane at the point of stress calculation Eq B.3 can now be shown as: Rearranging Eqs B-1 and B-2, then using AGMA 908-B89 terms: Eq B. 12 was originally developed before calculators and computers, and it has some terms that made calculation simpler. These terms are not necessarily needed today, but data and values have been developed over the years, and changing terms could cause a great deal of confusion. The load sharing ratio, m N , and the pitting resistance geometry factor, I , are these terms. NOTE: Double signs are used in Eq B.3; Le., 2 , to generalize the equation for both external and internal gears. The upper sign applies to external gear sets and the lower sign applies to internal gear sets. AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS They are developed by multiplying Eq B.8 by fi 6 and 63 908-B89 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- W AGMA 908-B m 0 6 8 3 5 3 5 0003095 021 m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth To adapt Eq B.11 to actual gears, AGMA has added additional factors to the equation. These factors are: and then recombining terms so that mN and I can be defined as follows: F =- na Lmin (Eq B.lO) Ca = application factor for pitting resistance Cv = dynamic factor for pitting resistance C, = size factor for pitting resistance Cm = load distribution factor for pitting resistance Cf = surface condition factor for pitting resistance where F = effective face width of gear set d = operating pitch diameter of pinion C,,, = helical overlap factor Putting these factors in Eq B . l l gives: The helical overlap factor, C is added to iIr ' the equation for I to give a smooth transition between the I factors of spurs and low axial contact ratio (LACR) helicals. See Appendix E for its definition and derivation. Now Eq B.8 can be rewritten as: sc= c p p ! L Equation B. 12 is the fundamental formula for pitting resistance and is identical to Eq 5 . 1 in ANWAGMA 2001-B88 and Eq 5.1 in AGMA 218.01. (Eq B . l l ) d FI AGMA (Eq B.12) C 9 O 8-B 89 64 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT A G M A 908-B Ob87575 0 0 0 3 0 ï b Tbô Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth Appendix C Explanation of the AGMA Gear Tooth Strength Rating Derivation For External Gears This Appendix is not part of AGMA 908-B89, INFORMATION SHEET - Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur, Helical and Herringbone Gear Teeth, but is included for informational purposes only. C1. Purpose. This Appendix explains the derivation of the AGMA strength rating formula for external gears. The formula is derived from a simplified cantilever beam theory for stress. It is based on the method of Lewis [i] where the beam is assumed to be parabolic in shape and inscribed within the gear tooth. References are sometimes made to the stress parabola which refers to the beam assumption. The formulas given are for helical gears; however, spur gears may be calculated by setting the helix angle at zero degrees so that the transverse plane equals the normal plane. Many of the variables used in this appendix are not fully derived as they are more fully explained in other sections of this information sheet. Fig C-1 Tooth Load Acting at Inscribed Parabola C2. Tooth load. To simplify the geometry of helical gear teeth in the normal plane, the concept of the virtual spur gear is used. The concept incorporated is a spur gear whose shape in the transverse plane is similar to that of a helical gear in the normal plane. The calculation of this virtual spur gear is explained in other sections. The load normal to the tooth is calculated at the working pitch diameter of the tooth. This load is then applied along the line of action (tangent to the base circle) and passing through the tip of the tooth. Figure C-1 shows a tooth with the load applied and the inscribed parabola. Certain spur gears may have this load applied at the highest point of single tooth contact. The basic bending stress equation (see Fig C-2) for a cantilever parabolic shaped beam is: 7 b - The basic compressive stress equation for this beam is: where C3. Derivation of the stress equation. The following procedure is used to derive the equations necessary for calculating the tooth form factor, Y,geometry factor, J , and corrected tensile stress, St . AGMA 6 h P1 s - Sb = bending stress, lb/in2 sc = compressive stress, Ib/in2 pl = bending load on beam, Ib pc = compressive load on beam, Ib h = height of beam, in L = length of beam, in 65 908-B89 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT A G H A 908-B Ob87575 0003097 9 T 4 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth t = tooth thickness at the critical section (tangent point of the stress parabola and the tooth root), in The compressive stress is sc = WN sin+L 'min t where +' = load angle = minimum length of lines of contact The tangential component of this load causing bending stress is 4 where ch Fig C-2 Gear Tooth as a Simple Beam The actual load applied normal to the tooth at the pitch circle is: = helical factor: A helical factor must be added to account for the oblique lines of contact in helical gears, see 5.10 and Eq 5.70, based on work of Weilauer and Seireg [2] This gives a bending stress of: --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- wt = T = 2T d Bending and compressive stresses are combined to find the maximum tensile stress. 63 O00 P n P where wN = load normal to the tooth, lb = load tangential to the tooth, lb T = torque on the pinion, lb in d = operating pitch diameter of the St' 'min "P +* Jr where si = transmitted horsepower, hp = pinion speed, rpm = operating helix angle The load, Ww is applied at the load angle, +L. Calculation of angle +L appears in other sections (see Fig C-i). The radial component of this load causing compressive stress is: Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS = maximum uncorrected tensile stress When the orginal derivations were made, calculations were done using tooth layouts and not computer calculations. The equation was therefore modified to make t h i s task easier. Layouts were done to a scale of 1 Normal Diametral Pitch (NDP) so they would be large enough to measure. Therefore, the stress equation had to be multiplied by the Normal Diametral Pitch, pd , to con- = operating normal pressure angle AGMA t (Eq C.11) pinion, in P = 66 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 908-B89 A G M A 908-B W Ob87575 0 0 0 3 0 9 8 830 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth vert these 1 NDP dimensions to actual dimensions. A load sharing ratio, mN, was defined to relate face width of the tooth to Lmin. A stress correction factor, Kf , based on photoelastic experiments of Dolan and Broghamer [ 31, was introduced to account for the radius of the tooth root. where Note the following right triangle relationships in Fig C-3. = h -t 2 therefore -6 -h t2 - 1.5 - (Eq C.13) U = wt cos l+, cos qf mN = F Lmin (Eq C.15) Kf = stress correction factor (see 5.11) pd = nominal pitch in the plane of rotation (introduced to convert J to a dimensionless value). (Eq C.12) 4u WN qs = standard helix angle F = face width Eq C.14 can be subdivided into two variables; tooth form factor, Y, and geometry factor, J , where E Tooth Ps = normal diametral pitch of layout (scale pitch), usually 1 .O in-' The Form Factor includes a term Ps which is the diametral pitch to which the layout is drawn. This term converts the values of u and t to actual values and was added to account for layouts or calculations that are done to a scale other than one NDP. Substituting Eq C.13 and letting: I SF= t , hF= h (see AGMA 908-B89 Fig 5-7) r occurs at point where trochoid meets root radius Scale pitch Ps = 1.0in-' Kq = NOTE: Shown in the Normal Plane Through the Pitch Point q COS Qs (Eq C.17) where Kq Fig C-3 Tooth Form Factor Layout With Load Sharing 1 COS = a factor which converts the pitch and load from the normal plane to the transverse plane. (see Eq C.17) Rearranging equation C.11, adding these factors and substituting, gives the following: which is identical to AGMA 908-B89, Eq 5.78 J (Eq C.14) AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS = y CJI K m f N (Eq C.19) 9 08-B 89 67 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- where A G H A 908-B 9 Ob87575 0003099 777 9 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth where J Y = tooth form factor C$ = helical overlap factor mN = load sharing ratio strength Km = load distribution factor for bending strength = dynamic factor for bending strength Ky e resulting in the final stress equation: st - wt Ka Kv pd F Ks Km J (Eq C. 21) where st The stress equation now can be written as: wt ‘d - = application factor for bending Ka The Geometry Factor, J , includes a helical overlap factor, C C is a factor used to interpolate the values for ACR gears for J, from that for spurs to conventional helicals. This factor accounts for low axial contact ratio gearing which has a face contact ratio, rn F , less than or equal to 1.0. For normal helical gears and spur gears, t h i s factor is 1.0. see 4.4. s; = = size factor for bending strength Ks = geometry factor for bending strength = corrected tensile stress Eq C.21 is the fundamental formula for bending strength and is identical to Eq 5.10 in AGMA 218.01. Eq 5.10 in ANSIIAGMA 2001-B88 is similar, but a rim thickness factor, K B , has been added. (Eq C.20) F J Rating factors are added to the equation to account for increased loads that occur in gearing: Bibliography 1 Lewis, W., Investigation of the Strength of Gear Teeth, Proc. of the Engineers Club, Philadelphia, PA, 1893, pp.16-23. 2 Wellauer, E. J., and Seireg, A., Bending Strength of Gear Teeth by Cantilever Plate Theory, Journal of Engineering for Industry, Trans. ASME, Series B, Vol. 82, 1960, pp. 213-222. 3 Dolan, T. J. and Broghamer, E. L.,A Photoelastic Study of the Stresses in Gear Tooth Fillets, University of Illinois, Engineering Experiment Station, Bulletin No. 335, 1942. AGMA 68 --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 908-B 89 A G U A 908-B = Ob87575 0003100 219 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth Appendix D Selection Of Shaper Cutter Geometry - This Appendix is not part of AGMA 908-B89, INFORMATION SHEET Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur, Helical and Herringbone Gear Teeth, but is included for informational purposes only. disk cutters have a small chamfer at the tooth tip, rather than a radius. If this is the case, the cutter should be considered sharp cornered at the inner edge of the chamfer. D2. General. This method allows a wide choice of cutter geometries to be used in generating the root trochoid form of the virtual spur gear and the J factor. For very accurate work, the exact cutter form should be used, but for most cases, the cutter form can be approximated. The method assumes that generation takes place in the normal plane. Cutters which act in the transverse plane, such as helical disc shaper cutters and some rack shaper cutters will generate root trochoid forms which are slightly different from those assumed by this method. This has a minor effect on the accuracy of the J factor. The knowledge required to convert the actual dimensions of a disk type cutter to the values necessary to determine the J factor of a specific gear is beyond the scope of this Information Sheet. Cutter manufacturers have different designs and production techniques, which affect the final tooth form and the resulting J factor. The simplified information given here is intended to provide typical values which may be used as a guide to usual practice. --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- D1. Purpose. This Appendix provides default shaper cutter data for use in calculating the bending strength geometry factor, J , when the original cutter data at the time of gear manufacture is unavailable. If the exact geometry at its worst condition is known, that geometry should be used to calculate the J factor. If the dimensions are not known, the geometry of a minimum cutter may be estimated from the following information: D3. Rack Shaped Cutters and Hobs. Rack cutters and hobs are represented as disk cutters with large numbers of teeth, such as 9999. The actual form of the cutter, in the normal plane, should be used, with all dimensions made dimensionless. To make actual measurements dimensionless, they are scaled by multiplying them by diametral pitch, dividing them by module or comparing them to a T (3.1416) circular pitch at the standard pitch diameter. Any consistent system of units can be used for this conversion. See Section 3 of AGMA 908-B89 for examples. D4.1 Number of Teeth. The maximum pitch diameter of the cutter is limited by the size of the gear shaper to 3, 4, 5 , 6 or 8 inch. This limits the number of cutter teeth as a function of the pitch. The following table is typical. Table D-1 Number of Cutter Teeth Default Values Diametral Pitch D4. Disk Shaped Cutters. Disk shaped cutters are not as standardized as hobs or other rack shaped cutters. The geometry of disk shaped cutters changes with each sharpening. Generally, the radius of the root fillet generated by these cutters decreases as they are sharpened. to 20 16 12 10 8 6 CAUTION: The tip radii and cutting depths which are commonly assumed for hobs must not be used for disk (pinion) shaped cutters without verification of the actual tool design. For example, many AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 4 3 Number of Teeth 40 32 32 30 24 18 16 15 Coarser pitches require consultation with the manufacturer. 69 908-B 89 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT A G H A 908-B m Ob87575 0003LOL 155 m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth Table D-2 Typical 20" NPA Spur Disk Cutter Proportions* - Inches Diametral Pitch, 'nd Life Number of Teeth 3 3 3 90 50 25 15 15 15 0.523 0.505 0.495 0.00 -0.08 -0.11 5.918 5.804 5.756 0.410 0.427 0.416 0.030 chamfer 0.020 chamfer 0.030 chamfer 6 6 6 90 50 10 24 24 24 0.266 0.245 0.221 0.04 -0.14 -0.34 4.430 4.365 4.297 O. 209 0.202 0.204 0.020 radius 0.010 chamfer 0.000 sharp 10 10 10 90 40 10 30 30 30 O. 140 0.158 0.01 -0.23 -0.45 3.256 3.201 3.167 O. 128 O. 123 O. 128 0.010 chamfer 0.010 chamfer 0.010 radius * 95 Tooth Addendum Tool Thickness Modification Outside Addendum 'no xO Diameter huo 0.124 Tip Radius (chamfer) The table values are actual measurements of cutters in the field and are included to illustrate the difference between different cutter manufacturers' standards and different sharpening conditions. --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- D4.2 Tooth Proportions. Table D-2, comprised of actual cutter measurements, is typical. the cutter design data. To furnish a starting point when the cutter design data is not available, approximate cutter geometry values are provided. D4.3 Tip Radius. For cutters with less than 24 teeth, assume a sharp comer. Over 24 teeth, assume a 0.1 I Gd radius. The dimensions used are those of the spur gear equivalent to the actual cutter, in the transverse plane. These dimensions are made dimensionless and are converted to virtual spur gear dimensions in the normal plane. D4.4 Tooth Thickness. See D5. D4.5 Cutter Addendum and Clearance. Assume that cutter addendum is 1.25 1 G d for full depth cutters, and 1.0 /Gd for stub depth cutters. Clearances are 0.251Gd and 0.20/ì& respectively. The approximate geometry is based on the assumption that the cutter has 18 teeth, a sharp tip radius and will reach the end of its useful life when it is sharpened to the condition where the outside diameter is equal to the standard pitch diameter plus 1.8 cutter addendums. Cutters with outside diameters larger than these will generate gears with J factors larger than or equal to the approximate cutter. D4.6 Protuberance Disk Cutters. Protuberance (pregrind and preshave) disk cutters are usually specially designed for a specific part. No default values are given here for these special cutters. Approximate minimum cutter geometry - dimensionless D5. Spur Gear Disc Shaper Cutters. If the actual cutter is at hand, the tooth thickness can be measured by the span method (see ANSIIAGMA 2002-B88 Tooth Thickness Specifications and Measurement) and the outside diameter can be measured. The tooth thickness at the standard pitch diameter, the addendum modification coefficient and the tool addendum can be calculated from involute geometry and the information in Section 5 of AGMA 908-B89. Number of teeth 18 Std. tooth thickness, transverse 1.5708 Tool Addendum 1.25 Addendum modification -0.35 Tip radius 0.0 (sharp) Depending on pressure angle, actual cutters with this geometry may not be feasible due to involute interference with the work gear. If it is possible, or if cutters with less than 18 teeth must be used, consult a cutter manufacturer for more information. D6. Helical Gear Disc Shaper Cutters. Helical disk shaper cutters cannot be measured as described above, so they must be described from AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 70 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 908-B8 9 A G M A 908-B m Ob87575 0003102 O91 m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth Appendix E Derivation of Helical Overlap Factor, C$ --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- This Appendix is not part of AGMA 908-B89, INFORMATION SHEET - Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur, Helical and Herringbone Gear Teeth, but is included for informational purposes only. I I E l . Purpose. This Appendix provides the derivation for a simplified method for calculating C as used in AGMA 908-B89. The results are 4f identical to AGMA 218.01, but the procedure eliminates the need for Cx and C,h for LACR gears. where 2 0.5 ( R m l - Rbl> (Eq E.3) Pm2' ' 6 7 Pml (Eq E.4) P1 E2. Derivation. In AGMA 218.01, the helical overlap factor for LACR helical gears is: 2 Pm1' = c2 (Eq E.5) P2 = ' 6 7 P 1 (Eq E 4 Substituting Eq E.2 into Eq E . l together with Eq E.7 and Eq E.8 gives the new expression for c4f m The term, C,h / C, , is the ratio of the radii of curvature at the mean diameter of the pinion to the radii of curvature at the LPSTC. i.e.; X = -F px - 'N - ' x sin b (Eq E.8) P1 P2 AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 71 9O 8-B 89 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT A G M A 908-B m Ob87575 0003103 T28 m Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur and Helical Gear Teeth --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- (this page has been left blank) 1 AGMA Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS 72 Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT 908-B89 AGHA 908-B Geometry Factors for De- Ob87575 0003L04 964 the pittinl Resistance and Bending Strength of Spur and Helical Gear Teeth Appendir F High Transverse Contact Ratio Gears This Appendix is not part of AGNA 908-B89, INFORMATION SHEET - Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur, Helical and Herringbone Gear Teeth, but is included for informational purposes only. This Appendix provides a reference for accommodating load distribution in a pair of high contact ratio gears. two pairs of teeth in contact at the highest point of F2. High transverse contact ratio gears. When the transverse contact ratio is greater than or equal to 2.0, the load disuibution between the Studies have been done on the subject of high transverse contact ratio, HTCR gears. See, for instance, the reference paper of Ekholy [i]. Purpose. double tooth contact becomes indeterminate, depending on tooth accuracy and stiffness. --`,```,,`,``,,,,`,`,`,,,,,`,``-`-`,,`,,`,`,,`--- F1. Bibliography 1. Ekholy, A. H . , Tooth Load Sharing in High-Contact Ratio Spur Gears, ASME paper 84-DET-65. 908-BS9 Copyright American Gear Manufacturers Association Provided by IHS under license with AGMA No reproduction or networking permitted without license from IHS Licensee=Electric Boat/9993263100 Not for Resale, 06/07/2005 09:58:05 MDT