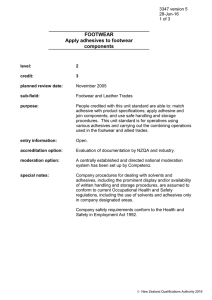

Communication www.advhealthmat.de A Highly Stretchable, Real-Time Self-Healable Hydrogel Adhesive Matrix for Tissue Patches and Flexible Electronics Jun Luo, Jiaojiao Yang, Xiaoran Zheng, Xiang Ke, Yantao Chen, Hong Tan, and Jianshu Li* natural and synthetic components, has been developed to accommodate various requirements.[2] Ideal bioadhesives should incorporate good biocompatibility, high efficacy in a humid and/or underwater environment, stable mechanical strength, while also being easy to use and store.[3] In this context, current bioadhesives have partially reached their potential; however, simultaneous implementation of all of the functions mentioned above is still a significant challenge.[4] Additionally, current clinical applications of bioadhesives assert more claims. For instance, achieving adhesion to areas with large deformations, such as skin, the bladder, heart, and penis, is particularly challenging for bioadhesives because the ductility of these organs changes the adhesion area.[3d] Moreover, soft and stretchable electronic adhesives are also highly attractive for application in wearable and implantable devices.[4a] Furthermore, adhesives with spontaneous self-healing capability have attracted significant attention because many materials are easily damaged in daily life, i.e., without external stimuli.[5] Therefore, the interest in bioadhesives is growing, and the possibilities encourage researchers to seek novel materials that aim to meet the standards for nextgeneration bioadhesives. Bombyx mori silk fibroin (SF), i.e., a natural protein fiber, exhibits significant potential for biomedical applications because of its impressive biocompatibility and tunable biodegradability.[6] Many forms of SF-based biomaterials, including electrospinning nanofibers, sponges, and hydrogels, have been developed by using an SF solution and exploiting the transition of the SF chain conformation from amorphous states to intermolecular β-sheets within a period of hours to months.[6b,7] However, the formed hydrophobic β-sheets may yield SF materials without adhesive ability and/or stretchability.[6a,8] An alternative method is the inhibition of the formation of β-sheets in the SF, which can produce materials with flexibility and stretchability,[9] e.g., a calcium-modified plasticizing SF substrate with high stretchability (>400%) was fabricated by the addition of calcium chloride and ambient hydration, and has been further investigated to develop a highly stretchable (>100%) electrode.[9a] Additionally, developing SF-based adhesives that are, e.g., convenient for synthesis, injection, and safety, The development of biocompatible self-healable hydrogel adhesives for skin or wet, stretchable surfaces in air or under water is highly desirable for various biomedical applications ranging from skin patches to bioelectronics. However, it has been proven to be very challenging because most existing hydrogel adhesives are cytotoxic, or poorly adhere to dynamic or stretchable surfaces in wet environments. In this study, multifunctional hydrogel adhesives derived from silk fibroin (SF) and tannic acid (TA) are effectively constructed with high extensibility (i.e., up to 32 000%), real-time self-healing capability, underwater adhesivity, watersealing ability, biocompatibility, and antibiotic properties. According to allatom molecular dynamics simulation studies, the properties of the hydrogel adhesives, especially high extensibility, are mainly attributed to the hydrogen bonds between TA and the SF chains in water, and water and TA molecules can result in loose assemblies with fewer β-sheets, and more random coils in the SF. Conductivity can also be easily introduced to the adhesive matrix and adjusted when the strain of the adhesives occurs. Considering that it has multiple functions and can be efficiently prepared, the proposed hydrogel adhesives have the potential for future medical applications, such as tissue adhesives and integrated bioelectronics. Bioadhesives are commonly used in clinical operations, such as tissue adhesive, hemostatic agents, and tissue sealants.[1] A variety of available bioadhesives, i.e., those based on Dr. J. Luo, X. Zheng, X. Ke, Prof. H. Tan, Prof. J. Li College of Polymer Science and Engineering State Key Laboratory of Polymer Materials Engineering Sichuan University Chengdu 610065, P. R. China E-mail: jianshu_li@scu.edu.cn Dr. J. Yang State Key Laboratory of Oral Diseases West China Hospital of Stomatology Sichuan University Chengdu 610041, P. R. China Prof. Y. Chen Shenzhen Key Laboratory of Functional Polymer College of Chemistry and Environmental Engineering Shenzhen University Shenzhen 518060, P. R. China The ORCID identification number(s) for the author(s) of this article can be found under https://doi.org/10.1002/adhm.201901423. DOI: 10.1002/adhm.201901423 Adv. Healthcare Mater. 2020, 1901423 1901423 (1 of 9) © 2020 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.advancedsciencenews.com www.advhealthmat.de which are highly desired for biomedical purposes, remains to be a challenge.[10] Specifically, tannic acid (TA), which is a natural polyphenol compound with rich ester bonds and polyphenol groups, intrinsically exhibits biological properties of tissue adhesion,[11] antioxidant capability, and antibiosis.[12] It has demonstrated the potential to be a universal binder to induce gelation of some biomacromolecules, as the biomacromolecules tend to form complex amorphous structures owing to the strong noncovalent interactions between TA and the biomacromolecules.[13] An SF- and TA-based hydrogel bioadhesive has been developed recently via a facile method with wet adhesion property and instant hemostatic ability under both wet and dynamic biological environments, rapid sealing of severely bleeding tissues, excellent biocompatibility and biodegradability as well as effective antibacterial protection.[14] Here, based on the SF hydrogel that is cross-linked by TA (hereafter referred to as FT hydrogel adhesives) via the intermolecular interactions between SF and TA (Figure 1a), we investigate the system with many excellent advantages of highly extensible, real-time self-healable, water-sealing, shapeable, and antibiotic for tissue adhesives. All-atom molecular dynamics (AAMD) simulation studies are performed to study the hydrogel adhesives, especially the highly extensibility. Furthermore, we evaluate the potential of the adhesive as a matrix by loading conductive materials to obtain hybrid materials with conductive performance. FT hydrogel adhesives were spontaneously formed by mixing an aqueous SF solution (10 wt% in distilled water) and aqueous TA solution (10 wt% in phosphate-buffered saline (PBS), pH 3.5) with different volume ratios (Figure S1 in the Supporting Information). The resultant hydrogels were thoroughly washed with deionized water and labeled as FT-6/4, FT-5/5, FT-4/6, FT-3/7, and FT-2/8, respectively, corresponding to the SF-to-TA ratio of the 6/4, 5/5, 4/6, 3/7, and 2/8 mixtures. The colors of these hydrogel adhesives changed from yellow to tan as the TA content increased (Figure 1b). The fabrication process can also be carried out by using a twin-barreled syringe (Figure 1c). Owing to the reversibility of a hydrogen bond (hereafter referred to as an Hbond) between amide groups of SF and polyphenol groups of TA, the developed chutty-like FT hydrogel adhesives demonstrated self-healing properties (e.g., as shown in Figure 1d, the instantaneous conjoining of cut pieces of the FT-4/6 sample). The adhesives are soft but compact owing to their compact structure; thus, these adhesives can be molded to form various free-standing shapes, such as spheres, cubes, cylinders, and triangles (Figure 1e). The FT hydrogel adhesives are waterproof and can prevent water leakage (Figure 1f). A bursting pressure test was also performed to evaluate the water sealing strength quantitatively. According to the results of the bursting pressure test presented in Figure S2 in the Supporting Information, the bursting pressure of FT hydrogel adhesives increased with increasing TA content. The adhesives can be stretched into long fibers by subjecting them to plastic deformation. It is notable that all groups have high extensibility (Video S1, Supporting Information), such as Group FT-6/4 demonstrated high extension ratio of 32 000% from 5.5 mm to around 1760 mm in length (Figure 1g); this was determined by measuring the length before and after stretching the hydrogel by hand. This ratio is much higher than that for other previously Adv. Healthcare Mater. 2020, 1901423 reported SF materials.[9a,15] The rearrangement and/or reconfiguration of SF structures can be facilitated by the gluing action of the TA molecules between the SF molecules, which might be the cause of the observed high extensibility.[11] Considering the trade-off between the mechanical properties and extensibility, it should be noted that when the ratio is lower than 2/8, the prepared FT hydrogel adhesives exhibit poor ductility because too many TA molecules which cause the crosslinks between SF and TA are excessive; conversely, when the ratio is higher than 6/4, the prepared FT hydrogel adhesives have poor adhesive ability because less TA corresponds to few polyphenol groups. A cryo-scanning electron microscopy (cryo-SEM) image of Group FT-6/4 shows a porous structure (Figure 1h), which is typical for hydrogels.[16] In addition, a porous structure can be observed in the SEM images of freeze-dried FT hydrogel adhesives (Figure S3, Supporting Information). The orientation of the arrangement of silk nanofibers can also be identified in the cryo-SEM image of Group FT-6/4 after stretching (Figure 1h inset), indicating that the hydrogel adhesive is a complex of silk nanofibers (Figure S4, Supporting Information) that are dynamically cross-linked by TA via the Hbonds between the SF amide groups and TA polyphenol groups. Interestingly, FT hydrogel adhesives prepared with different SF-to-TA ratios had a very similar water content, i.e., approximately 30% (Figure S5, Supporting Information), which is lower than that of other silk-based hydrogels,[6a] and is the reason for the high mechanical strength of FT hydrogel adhesives. The FT hydrogel adhesives were examined over a frequency range of 0.1–10 Hz under isothermal conditions (22 ± 1 °C) (Figure 1i), and both storage and loss modulus values (>1 MPa) were found to be higher than that for most SF-based hydrogels.[15] All hydrogel adhesives were liquefied at a shear stain above 4%, as indicated by the following result: storage modulus < loss modulus (Figure S6, Supporting Information). These self-healing and shear-thinning properties make it feasible to inject the materials through a needle to perform minimally invasive injections or catheter deliveries, as their initial mechanical strength can be completely recovered after injection.[17] The molecular structure of the SF in the FT hydrogel adhesives is mainly controlled by the crosslinker, TA, and water.[13] To better understand the mechanism responsible for the high extensibility of SF, AAMD simulations were performed (Figure 2). The mechanical strength of SF is mainly dictated by the crystalline domain, whereas the stretchability is determined by the amorphous domain.[9a,18] Therefore, we simulated the amorphous domain to explore how water and TA molecules influence the stretchability of SF. In this study, only two extreme conditions, i.e., in vacuum (fully dehydrated) and in water (fully hydrated), were simulated. Accordingly, the following four simulations were conducted: self-assembly of silk chains I) in vacuum, II) in water, III) in vacuum with TA, and IV) in water with TA. In Case III, TA molecules were randomly inserted into the initial structure of the SF, and the weight fraction of TA was 37%, corresponding to Group FT-6/4 in our experiments. Details of the model and simulation methods are provided in the Supporting Information. Our simulations show that water and/or TA molecules influenced the secondary structure of silk protein, thus enabling 1901423 (2 of 9) © 2020 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.advancedsciencenews.com www.advhealthmat.de Figure 1. a) Schematic of the FT hydrogel adhesive formation. b) Color of FT hydrogel adhesives according to the SF/TA ratio. c) Preparation of FT hydrogel adhesives by mixing an SF solution and a TA solution in a twin-barreled syringe, and efficiently ejecting from the static mixer. d) Self-healing property of the FT hydrogel adhesive. The initial sample was cut into two pieces and then brought together again; the self-healing process instantaneously yielded a recovered adhesive (Group FT-4/6 is given as an example). e) FT hydrogel adhesive molds; they can be molded into various shapes (Group FT-5/5 is given as an example) and support their own weight. f) Waterproof property of FT hydrogel adhesives: they can patch the balloon and instantly seal out water to create a flexible and watertight barrier (Group FT-2/8 is given as an example). g) High extensibility of FT hydrogel adhesives: a Group FT-6/4 sample was stretched up to 32 000%. h) Microstructure of FT hydrogel adhesives: cryo-SEM images of a Group FT-6/4 sample before and after (insert) manual stretching. i) Rheological behavior of FT hydrogel adhesives; the modulus of Groups FT-2/8, FT-4/6, and FT-6/4 are shown for different frequencies. high extensibility. When silk chains assembled in vacuum (i.e., Case I in Figure 2a), approximately 26%, 45%, and 23% of protein residues (Figure 2e) are in the form of β-sheets, coils, Adv. Healthcare Mater. 2020, 1901423 and turns, respectively. As an expanded structure for proteins, β-sheets facilitate close packing of silk chains, thus excessively increasing the density (Figure 2f) and mechanical strength.[18] 1901423 (3 of 9) © 2020 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.advancedsciencenews.com www.advhealthmat.de Figure 2. Molecular simulation of the amorphous domain of SF in four different environments, i.e., in a vacuum, in water, and with and without TA molecules. a–d) Representative snapshots of silk assemblies. e) Percentages of each secondary structure. f) Densities of the resulting packed silk assemblies (excluding water molecules). g) Number of Hbonds formed among the amino acid residues of silk, and those formed between silk and TA. In contrast, other secondary structures, such as coils and turns, possess low structural regularity, and do not result in close packing, which thus allows more freedom to adjust chain conformations. The latter is beneficial for high extensibility. When silk chains are assembled in an aqueous solution (Case II in Figure 2b), approximately 21%, 52%, 20%, and 1% of the protein residues (Figure 2e) are in the form of β-sheets, coils, turns, and helices, respectively. The introduction of water molecules decreases the content of stiff β-sheets, but increases the content of random coils, thus causing the silk chains to be loosely packed. As shown in Figure 2g, the Hbond interactions within silk proteins were substantially weakened in water, and approximately 40% of the Hbonds completely broke. As noted by Chen et al.,[9a] water tends to form strong Hbonds with silk protein molecules. The number of Hbonds between water and silk was 1808 in this study, which is approximately seven times that formed within the silk proteins. Therefore, Hbonds between water and silk protein should be a crucial manner for water to break the regular secondary structure, loosen chain assemblies, and consequently increase the extensibility of SF. When silk chains are mixed with TA molecules in a vacuum (Case III in Figure 2c), the content of β-sheets (11%) was only one-half of that for Case I, but the content of coils had increased to 65%. As an active filler, the TA molecules possess many hydroxy groups, which consequently provided many opportunities for forming Hbonds with silk protein molecules (i.e., the corresponding number is 296). As a negative effect, the number of Hbonds within silk proteins was lowered to 257. However, the total amount for the silk and TA mixture Adv. Healthcare Mater. 2020, 1901423 remained to be significantly larger than that for Case I, indicating that TA could be a good choice for crosslinking silk proteins. In Case IV, TA and water molecules were also included in the simulation (Figure 2d). Among the four cases, the Case IV samples possessed the highest percentage of coils, lowest density, lowest number of Hbonds within the silk proteins, and therefore the highest water content. Notably, the number of Hbonds between the TA and silk protein molecules was higher than that within the silk proteins in Case IV. This means that these Hbond interactions induced by TA molecules cannot be easily inhibited by a water-based solvent. In summary, through Hbond interaction, both water and TA molecules were found to destroy the regular secondary structure of silk proteins, particularly the β-sheets, thus leading to loose assemblies with a higher content of random coils. Importantly, TA molecules can crosslink protein chains, even in water; this may be a primary reason for the high extensibility of SF. These results are consistent with the Fourier-transformed infrared spectroscopy and X-ray diffraction results (Figures S7 and S8, Supporting Information). The number of β-sheets in SF was found to increase with decreasing TA content for all groups. The adhesive strength and extensibility of the FT hydrogel adhesives were examined by performing lap shear measurements using a universal test machine (Figure 3a,b and Video S2, Supporting Information).[19] Fresh porcine skin tissues were selected as representative substrates, which were tested under moist conditions. The maximum detachment stress of the FT hydrogel adhesive (i.e., detachment from the tissues) was 1901423 (4 of 9) © 2020 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.advancedsciencenews.com www.advhealthmat.de Figure 3. Adhesive properties of FT hydrogel adhesives. a) Photograph of FT hydrogel adhesive, demonstrating its adhesive property (Group FT-4/6 is given as an example). b) Prepared specimen; the adhesives joined two porcine skin tissue samples fixed by using a universal test machine for lap shear testing (mean number of measurements: 3; errors bars indicate s.d.). c) Lap shear stress results for different FT adhesives. d) Typical lap shear stress– displacement curves for different FT adhesives. e) Repeated lap shear test results for Group FT-2/8 adhesives. f) Repeated lap shear stress results for different adhesives (mean number of measurements: 3; errors bars indicate s.d.). g) Photographs of the fresh and re-prepared adhesives gluing two porcine skin tissue samples (Group FT-6/4 is given as an example). Note that neither detachment nor cracking was observed in any of the FT hydrogel adhesive and porcine skin tissue samples, even after being distorted, immersed in water, distorted in water, and flushed with water. h) Photograph of the adhesives joining two porcine skin tissue samples after being immersed in PBS for 7 days (Group FT-3/7 is given as an example). Data were presented as mean ± standard deviation (n = 3). One-way analysis of variance (ANOVA) and post hoc Scheffe test were used to analyze the data. Welch’s robust test of equality of means and Tamhane’s post hoc test were used when homogeneity of variance could not be confirmed (using Levene’s test). The asterisks indicate the differences between groups are statistically significant (*p < 0.05, **p < 0.01, and ***p < 0.001). recorded as the adhesive strength. Figure 3c indicates that the lap shear strength gradually increased with increasing TA content. Group FT-2/8 achieved a maximum adhesive strength of 69.4 ± 5.3 kPa, which can be attributed to the existing catechol and polyphenol groups that possess a superior interfacial binding affinity to biological tissue.[11] Interestingly, there was no brittle fracture observed in any of the lap shear measurements because of the high extensibility of the FT hydrogel adhesives (Figure 3d), indicating their potential as adhesives for tissue with large deformations. Additionally, the FT hydrogel adhesives can be used to glue different types of materials (Figure S9, Supporting Information). We evaluated the adhesive strength of the FT hydrogel adhesives according to ASTM D1002 by performing lap shear measurements using metal substrates under moist conditions. As illustrated in Figure S10 in the Supporting Information, the adhesive strength also increased with increasing TA content, and the highest stress (12.0 ± 0.2 kPa) was measured in Group FT-2/8. The FT hydrogel adhesives can also be repeatedly applied to skin tissue, as the failure behavior (Figure 3e and Figure S11, Supporting Information) and adhesive strength (Figure 3f) did not significantly change during two re-attachments of the lap joints owing to the excellent self-healing property of the FT Adv. Healthcare Mater. 2020, 1901423 hydrogel adhesives. After air drying, the adhesives were stored for a long-term period (i.e., 3 months at room temperature, 22 ± 1 °C); they were able to recover their initial adhesive state after being immersed in water to allow swelling (Figure S12 and Video S3, Supporting Information), indicating a simplified method to store the adhesives. The ability of fresh and re-prepared FT-6/4 samples to adhere to tissues was further evaluated after gluing two pieces of porcine skin tissue (Figure 3g). It is shown that, after being distorted in air and water, flushed with water, and stretched, the adhesives maintained their adhesive ability. Besides, the adhesives were used to directly adhere to porcine skin tissue in water (Video S4, Supporting Information). Furthermore, the adhesives were demonstrated to maintain a connection between pieces of glued porcine skin tissue for at least 7 days in the presence of PBS (Figure 3h), indicating considerable potential for in vivo biomedical applications. Then, we examined the swelling behavior, cytotoxicity, and antibacterial properties of the FT hydrogel adhesives in vitro. The swelling behavior of the adhesive hydrogels was tracked over 7 days in PBS (pH 7.2). The mass swelling ratio of the hydrogel adhesives from all groups exhibited a slight decrease in 12 h mainly because some TA released to the surrounding environment. After that, the mass increased with time and 1901423 (5 of 9) © 2020 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.advancedsciencenews.com www.advhealthmat.de Figure 4. Biological properties of FT bioadhesives in vitro and in vivo. a) Cell viability of hDF cultured on Group FT-2/8 and FT-6/4 samples coated on titanium plates (mean number of measurements: 3; errors bars indicate s.d.). Group FT-2/8 and FT-6/4 samples were challenged with b) 105 CFU mL−1 E. coli or c) S. aureus, for 24 h (mean number of measurements: 3; errors bars indicate s.d.). Digital images of d,e) wound treatments and f,g) wounds 7 days post-operation. Corresponding h,i) Masson staining and j,k) hematoxylin-eosin staining of healed skin; magnification: 40×. Data were presented as mean ± standard deviation (n = 3). One-way ANOVA and post hoc Scheffe test were used to analyze the data. Welch’s robust test of equality of means and Tamhane’s post hoc test were used when homogeneity of variance could not be confirmed (using Levene’s test). The asterisks indicate the differences between groups are statistically significant (*p < 0.05, **p < 0.01, and ***p < 0.001). became stable after 4 days except for group FT-2/8 (Figure S13, Supporting Information). It might be due to Group FT-2/8 with the highest TA content in all groups released more TA and caused more crosslinking points lost and a loosen structure to absorb more water. FT-2/8 and FT-6/4 have the highest and the lowest TA content, respectively. The two representative groups were selected for further cytotoxicity and antibacterial property investigation. As shown in Figure 4a, the numbers of dermal fibroblasts cells in Groups FT-2/8 and FT-6/4 over the Adv. Healthcare Mater. 2020, 1901423 24 h incubation time was not significantly different from that in the control group. The cytocompatibility of Groups FT-2/8 and FT-6/4 indicates the potential for further animal study. Figure 4b,c shows the results of the assay for Gram-negative and -positive bacteria models, i.e., Escherichia coli (E. coli) and Staphylococcus aureus (S. aureus), with 105 CFU mL−1, respectively. After 24 h of incubation, the Groups FT-2/8 and FT-6/4 numbers for E. coli and S. aureus with different ratios of adhesive to bacterial suspension were significantly lower than those 1901423 (6 of 9) © 2020 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.advancedsciencenews.com www.advhealthmat.de for the blank controls because of the existence of antibacterial TA in the adhesives.[12] The highest adhesive-to-bacterial suspension ratio (200 mg mL−1) in Group FT-2/8 was found to correspond to the most potent antibacterial ability to E. coli and S. aureus; this might be attributed to the sample having the highest TA concentration. The FT hydrogel adhesives are rich in TA, especially the groups with higher TA content. TA would be released from the adhesives into the surrounding environment during the antibacterial test continually. The concentration of TA in the surrounding environment increases when close to the adhesives. The high TA content makes the adhesives a poor substrate for bacteria survival. It is possible that some bacteria were absorbed in the adhesives; thus they were less in the liquid suspension to be detected. It might be the reason that not all the groups show obvious better antibiosis ability with increasing TA content. Based on the assessment of adhesion and biological ability, Group FT-2/8 with the highest TA content was chosen as the experimental group for animal wound healing. Nontreatment was selected as the control group. The in vivo adherence property of Group FT-2/8 was assessed by implementing the olivary skin incision model in mice.[4a] The healing effects observed in the nontreatment group (Figure 4d) and adhesive group (Figure 4e) were separately examined. 7 days after the skin surgery, no inflammation was found in the tissue sample of either group because of the adaption to mice (Figure 4h,i). However, the worse healing effects (Figure 4f) and more disordered structures, according to the histological evaluations of the healed skin (Figure 4j), were observed in the nonoperation group because skin defect repair was only facilitated by the migration of cells from the surrounding tissue. In the adhesive group, the adhesive (Figure 4g) nearly completely sealed the wound, and most of the aligned structures were retained in the histological evaluations of the healed skin (Figure 4k), especially the generated epidermis, which was similar to normal tissue.[4a,20] Since TA has been known to have the antibacterial ability and accelerate blood clotting, which are beneficial to wound healing.[12,21] The better healing might be due to both the covering of the wound and also the existence of TA in the adhesives. These results demonstrate the potential of FT hydrogel adhesives in noninvasive tissue reconstruction. The fabrication of an adhesive conductor with the combined features of stretchability, self-healing capability, and biocompatibility is important for the development of next-generation flexible electronics that can be applied to areas with extremely large deformation that have proven to be extremely challenging.[22] To investigate the potential of the FT hydrogel adhesives as matrices for use in bioelectronics applications, we introduced the property of conductivity to the adhesives by doping them with a type of biocompatible conductive polymer, i.e., poly(3,4ethylene dioxythiophene):poly(styrene sulfonate) (PEDOT:PSS) (Figure 5a). The hybrid adhesive was fabricated by mixing SF solution with calcium chloride (CaCl2), and TA + PEDOT:PSS solution. The resulting hybrid hydrogel (i.e., the FT-PEDOT hydrogel adhesive) is shapeable, adherent, real-time self-healable, and highly stretchable (Figure S14, Supporting Information). The real-time self-healing property of FT-PEDOT hydrogel adhesive is beneficial to the potential application in integrated Figure 5. Rapidly self-healing and stretchable FT-PEDOT hydrogel adhesive-based conductor. a) Schematic of the FT-PEDOT hydrogel adhesive formation. b) Circuit and image of FT-PEDOT hydrogel adhesive connected in series with a red LED: i) original adhesive sample, ii) completely separated adhesive sample (open circuit), and iii) adhesive sample after self-healing. c) Normalized resistance–length strain curve for the FT-PEDOT hydrogel adhesive-based sensor. d) Optical images and corresponding normalized resistance of the sensor conformally attached to a bent gloved finger. e) Durability test results for the sensor attached to a gloved finger, and variation of the normalized resistance due to repetitive finger bending. Adv. Healthcare Mater. 2020, 1901423 1901423 (7 of 9) © 2020 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.advancedsciencenews.com www.advhealthmat.de bioelectronics. Since the addition of calcium can affect the structure of SF,[9a] the lap shear test was performed to the FT-PEDOT hydrogel adhesive. The lap shear stress of FT-PEDOT hydrogel adhesive was 26.2 ± 4.5 MPa, which was similar to the original FT hydrogel adhesive (28.8 ± 1.7 MPa for Group FT-5/5). It demonstrates that the FT-PEDOT hydrogel adhesive still shows good adhesion property after the addition of calcium chloride and PEDOT:PSS. The conductivity of the FT-PEDOT hydrogel adhesive was (3.17 ± 0.32) × 10−2 s m−1. After the self-healing process, the value was (3.07 ± 0.29) × 10−2 s m−1, which was similar to its original conductivity. As shown in Figure 5b, a red light-emitting diode (LED) was incorporated into a circuit with the FT-PEDOT hydrogel adhesive connected in series, and a 6 V power supplier (Figure 5b-i). The self-healing conductivity of the FT-PEDOT hydrogel adhesive was verified by dimming the LED, dividing the adhesives into two pieces (Figure 5b-ii), and observed that the LED spontaneously re-activated once the separated pieces were brought into contact (Figure 5b-iii) in the circuit. After the two adhesive pieces were brought into contact with each other, the circuit was alive as a result of the two pieces of the adhesive re-forming dynamic Hbonds at the contacted interfaces. As depicted in Figure 5c, the normalized resistance of our FT-PEDOT hydrogel adhesive-based strain sensor steadily increased to 485% as the length strain increased to 300%, indicating that the FT-PEDOT hydrogel adhesive has the potential to be used in electronic devices to accommodate large dynamic deformations. As an example, the sensor was employed to detect the flexibility of an index finger (Figure 5d). Once the finger was bent, the cross-section of the FT-PEDOT hydrogel adhesive layer began decreasing with increasing length, causing the relative resistance to increase. The resistance further increased as the bending angle increased. Furthermore, the results of the durability test performed under the condition of repetitive finger bending (≈200 times) (Figure 5e) indicate good reliability of the sensor. The FT-PEDOT hydrogel adhesive, with its high self-healing efficiency and stretchability, is very attractive as a matrix for the bio-application of healable electronic devices that can accommodate large dynamic deformations.[5a] In conclusion, we prepared SF/TA-based hydrogel adhesives with an unprecedented level of multifunctionality. The adhesives possess characteristics of high extensibility, real-time self-healing capability, pliability, injectability, antibiosis, and underwater tissue adhesiveness. Additionally, the adhesives can be stored after air drying and recovered by swelling the dried samples. The Hbonds that formed between the amide backbone of SF and the polyphenols of TA when exposed to water are responsible for the pliability of the adhesives; furthermore, the water and TA molecules lead to loose assemblies with fewer β-sheets and more random SF coils, thereby resulting in excellent extensibility of the adhesives (i.e., up to 32 000%). The adhesives can be used as a matrix to load conductive materials and obtain hybrid materials with conductive performance. They can also be extended by incorporating other additives to obtain other desired functionalities. Considering that the simple onestep preparation, which only requires an aqueous SF solution and aqueous TA solution, can be readily scaled up, the employed materials may have the potential to accommodate large deformation objects for multifunctional bio-applications such as tissue adhesives, soft electronics, and human/machine interfaces. Adv. Healthcare Mater. 2020, 1901423 Supporting Information Supporting Information is available from the Wiley Online Library or from the author. Acknowledgements The authors thank Dr. Xingyu Chen and Dr. Chunmei Ding for their valuable contributions to discussions. Financial support from the National Natural Science Foundation of China (grant nos. 51903175, 51925304, 21534008, and 51773128), and the Fundamental Research Funds for Central Universities, are gratefully acknowledged. The animal study was approved by The Animal Ethics Committee of Chengdu Dossy Experimental Animals Co., Ltd, China. Conflict of Interest The authors declare no conflict of interest. Keywords high extensibility, hydrogel adhesives, molecular dynamics simulations, self-healing, silk fibroin Received: October 7, 2019 Revised: December 29, 2019 Published online: [1] W. Zhu, Y. J. Chuah, D. A. Wang, Acta Biomater. 2018, 74, 1. [2] a) G. Wang, N. Liu, M. Guo, Polymers 2018, 10, 843; b) V. Granskog, O. C. J. Andrén, Y. Cai, M. González-Granillo, L. Felländer-Tsai, H. von Holst, L.-A. Haldosen, M. Malkoch, Adv. Funct. Mater. 2015, 25, 6596; c) W. Zhu, Y. Peck, J. Iqbal, D. A. Wang, Biomaterials 2017, 147, 99. [3] a) J. Li, A. D. Celiz, J. Yang, Q. Yang, I. Wamala, W. Whyte, B. R. Seo, N. V. Vasilyev, J. J. Vlassak, Z. Suo, D. J. Mooney, Science 2017, 357, 378; b) S. O. Blacklow, J. Li, B. R. Freedman, M. Zeidi, C. Chen, D. J. Mooney, Sci. Adv. 2019, 5, eaaw3963; c) A. Assmann, A. Vegh, M. Ghasemi-Rad, S. Bagherifard, G. Cheng, E. S. Sani, G. U. RuizEsparza, I. Noshadi, A. D. Lassaletta, S. Gangadharan, A. Tamayol, A. Khademhosseini, N. Annabi, Biomaterials 2017, 140, 115; d) S. Liang, Y. Zhang, H. Wang, Z. Xu, J. Chen, R. Bao, B. Tan, Y. Cui, G. Fan, W. Wang, W. Wang, W. Liu, Adv. Mater. 2018, 30, 1704235. [4] a) B. Liu, Y. Wang, Y. Miao, X. Zhang, Z. Fan, G. Singh, X. Zhang, K. Xu, B. Li, Z. Hu, M. Xing, Biomaterials 2018, 171, 83; b) S. Rose, A. Prevoteau, P. Elziere, D. Hourdet, A. Marcellan, L. Leibler, Nature 2014, 505, 382; c) K. Azuma, M. Nishihara, H. Shimizu, Y. Itoh, O. Takashima, T. Osaki, N. Itoh, T. Imagawa, Y. Murahata, T. Tsuka, H. Izawa, S. Ifuku, S. Minami, H. Saimoto, Y. Okamoto, M. Morimoto, Biomaterials 2015, 42, 20. [5] a) M. Liao, P. Wan, J. Wen, M. Gong, X. Wu, Y. Wang, R. Shi, L. Zhang, Adv. Funct. Mater. 2017, 27, 1703852; b) A. Li, Y. Jia, S. Sun, Y. Xu, B. B. Minsky, M. A. C. Stuart, H. Cölfen, R. von Klitzing, X. Guo, ACS Appl. Mater. Interfaces 2018, 10, 10471. [6] a) C. Vepari, D. L. Kaplan, Prog. Polym. Sci. 2007, 32, 991; b) D. N. Rockwood, R. C. Preda, T. Yücel, X. Wang, M. L. Lovett, D. L. Kaplan, Nat. Protoc. 2011, 6, 1612. [7] a) U.-J. Kim, J. Park, C. Li, H.-J. Jin, R. Valluzzi, D. L. Kaplan, Biomacromolecules 2004, 5, 786; b) B.-M. Min, G. Lee, S. H. Kim, 1901423 (8 of 9) © 2020 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim www.advancedsciencenews.com [8] [9] [10] [11] [12] [13] [14] [15] www.advhealthmat.de Y. S. Nam, T. S. Lee, W. H. Park, Biomaterials 2004, 25, 1289; c) Y. Tamada, Biomacromolecules 2005, 6, 3100. S. Kapoor, S. C. Kundu, Acta Biomater. 2016, 31, 17. a) G. Chen, N. Matsuhisa, Z. Liu, D. Qi, P. Cai, Y. Jiang, C. Wan, Y. Cui, W. R. Leow, Z. Liu, S. Gong, K. Q. Zhang, Y. Cheng, X. Chen, Adv. Mater. 2018, 30, 1800129; b) G. G. Leisk, T. J. Lo, T. Yucel, Q. Lu, D. L. Kaplan, Adv. Mater. 2010, 22, 711. B. P. Partlow, C. W. Hanna, J. Rnjak-Kovacina, J. E. Moreau, M. B. Applegate, K. A. Burke, B. Marelli, A. N. Mitropoulos, F. G. Omenetto, D. L. Kaplan, Adv. Funct. Mater. 2014, 24, 4615. M. Shin, J. H. Ryu, J. P. Park, K. Kim, J. W. Yang, H. Lee, Adv. Funct. Mater. 2015, 25, 1270. N. Sahiner, S. Sagbas, M. Sahiner, C. Silan, N. Aktas, M. Turk, Int. J. Biol. Macromol. 2016, 82, 150. J. P. Van Buren, W. B. Robinson, J. Agric. Food Chem. 1969, 17, 772. S. Bai, X. Zhang, P. Cai, X. Huang, Y. Huang, R. Liu, M. Zhang, J. Song, X. Chen, H. Yang, Nanoscale Horiz. 2019, 4, 1333. L.-D. Koh, Y. Cheng, C.-P. Teng, Y.-W. Khin, X.-J. Loh, S.-Y. Tee, M. Low, E. Ye, H.-D. Yu, Y.-W. Zhang, M.-Y. Han, Prog. Polym. Sci. 2015, 46, 86. Adv. Healthcare Mater. 2020, 1901423 [16] S. Sun, L. B. Mao, Z. Lei, S. H. Yu, H. Colfen, Angew. Chem., Int. Ed. 2016, 55, 11765. [17] a) A. Parisi-Amon, W. Mulyasasmita, C. Chung, S. C. Heilshorn, Adv. Healthcare Mater. 2013, 2, 428; b) L. Shi, F. Wang, W. Zhu, Z. Xu, S. Fuchs, J. Hilborn, L. Zhu, Q. Ma, Y. Wang, X. Weng, D. A. Ossipov, Adv. Funct. Mater. 2017, 27, 1700591. [18] a) S. Keten, Z. Xu, B. Ihle, M. J. Buehler, Nat. Mater. 2010, 9, 359; b) I. Su, M. J. Buehler, Nanotechnology 2016, 27, 302001. [19] M. A. Gonzalez, J. R. Simon, A. Ghoorchian, Z. Scholl, S. Lin, M. Rubinstein, P. Marszalek, A. Chilkoti, G. P. Lopez, X. Zhao, Adv. Mater. 2017, 29, 1604743. [20] T. S. Alster, H. Bryan, C. M. Williams, Arch. Dermatol. 2001, 137, 885. [21] K.-T. Chung, T. Y. Wong, C.-I. Wei, Y.-W. Huang, Y. Lin, Crit. Rev. Food Sci. Nutr. 1998, 38, 421. [22] a) T. P. Huynh, P. Sonar, H. Haick, Adv. Mater. 2017, 29, 1604973; b) L. Zhang, Z. Liu, X. Wu, Q. Guan, S. Chen, L. Sun, Y. Guo, S. Wang, J. Song, E. M. Jeffries, C. He, F. L. Qing, X. Bao, Z. You, Adv. Mater. 2019, 31, 1901402. 1901423 (9 of 9) © 2020 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim