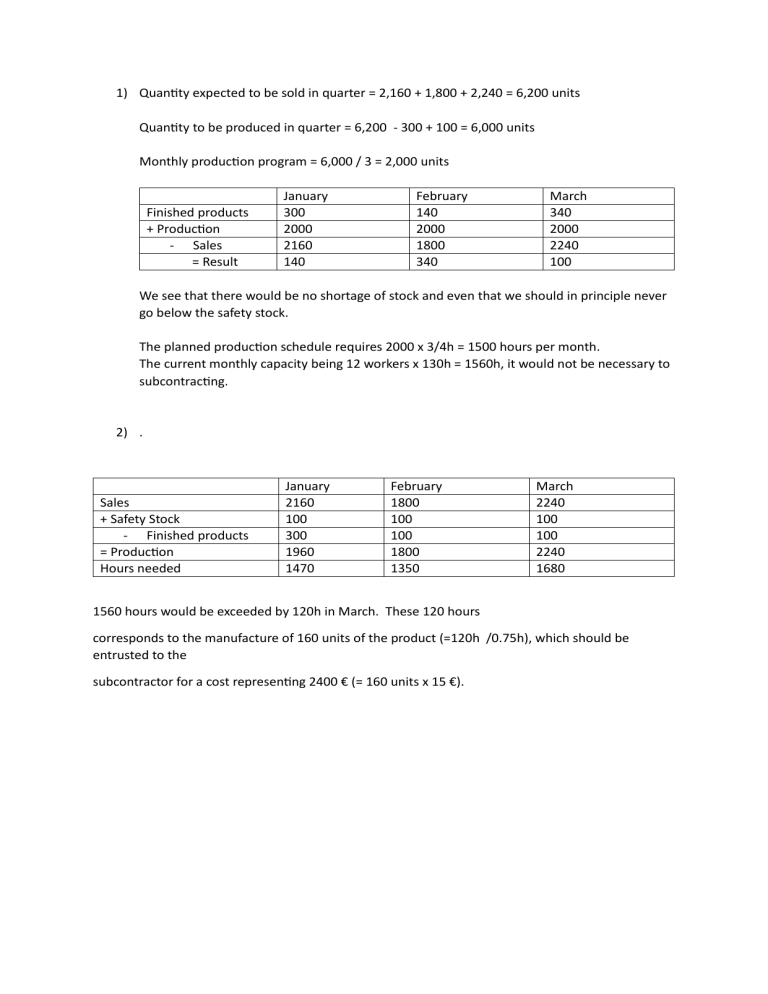

1) Quantity expected to be sold in quarter = 2,160 + 1,800 + 2,240 = 6,200 units Quantity to be produced in quarter = 6,200 - 300 + 100 = 6,000 units Monthly production program = 6,000 / 3 = 2,000 units Finished products + Production - Sales = Result January 300 2000 2160 140 February 140 2000 1800 340 March 340 2000 2240 100 We see that there would be no shortage of stock and even that we should in principle never go below the safety stock. The planned production schedule requires 2000 x 3/4h = 1500 hours per month. The current monthly capacity being 12 workers x 130h = 1560h, it would not be necessary to subcontracting. 2) . Sales + Safety Stock - Finished products = Production Hours needed January 2160 100 300 1960 1470 February 1800 100 100 1800 1350 March 2240 100 100 2240 1680 1560 hours would be exceeded by 120h in March. These 120 hours corresponds to the manufacture of 160 units of the product (=120h /0.75h), which should be entrusted to the subcontractor for a cost representing 2400 € (= 160 units x 15 €).