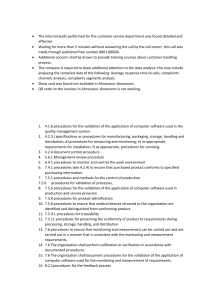

Mandatory documents in ISO 13485:2016 1. 4.1.6 procedures for the validation of the application of computer software used in the quality management system 2. 4.2.3 ) specifications or procedures for manufacturing, packaging, storage, handling and distribution; d) procedures for measuring and monitoring; e) as appropriate, requirements for installation; f) as appropriate, procedures for servicing. 3. 4.2.4 document control procedure 4. 5.6.1 Management review procedure 5. 6.4.1 procedures to monitor and control the work environment 6. 7.4.1 procedures (see 4.2.4) to ensure that purchased product conforms to specified purchasing information. 7. 7.5.1 procedures and methods for the control of production 7.5.6 procedures for validation of processes, 8. 7.5.6 procedures for the validation of the application of computer software used in production and service provision 9. 7.5.8 procedures for product identification 10. 7.5.8 procedures to ensure that medical devices returned to the organization are identified and distinguished from conforming product. 11. 7.5.9.1 procedures for traceability 12. 7.5.11 procedures for preserving the conformity of product to requirements during processing, storage, handling, and distribution 13. 7.6 procedures to ensure that monitoring and measurement can be carried out and are carried out in a manner that is consistent with the monitoring and measurement requirements. 14. 7.6 The organization shall perform calibration or verification in accordance with documented procedures. 15. 7.6 The organization shall document procedures for the validation of the application of computer software used for the monitoring and measurement of requirements. 16. 8.2.1procedures for the feedback process 17. 8.2.2 procedures for timely complaint handling in accordance with applicable regulatory requirements. 18. 8.2.3 procedures for providing notification to the appropriate regulatory authorities. 19. 8.2.4 procedure to describe the responsibilities and requirements for planning and conducting audits and recording and reporting audit results. 20. 8.2.6 This shall be carried out at applicable stages of the product realization process in accordance with the planned and documented arrangements and documented procedures. 21. 8.3.1 procedure to define the controls and related responsibilities and authorities for the identification, documentation, segregation, evaluation and disposition of nonconforming product. 22. 8.3.3 procedures for issuing advisory notices in accordance with applicable regulatory requirements 23. 8.4 procedures to determine, collect and analyse appropriate data to demonstrate the suitability, adequacy and effectiveness of the quality management system. 24. 8.5.2 procedure for corrective actions 25. 8.5.3 procedure for preventive actions