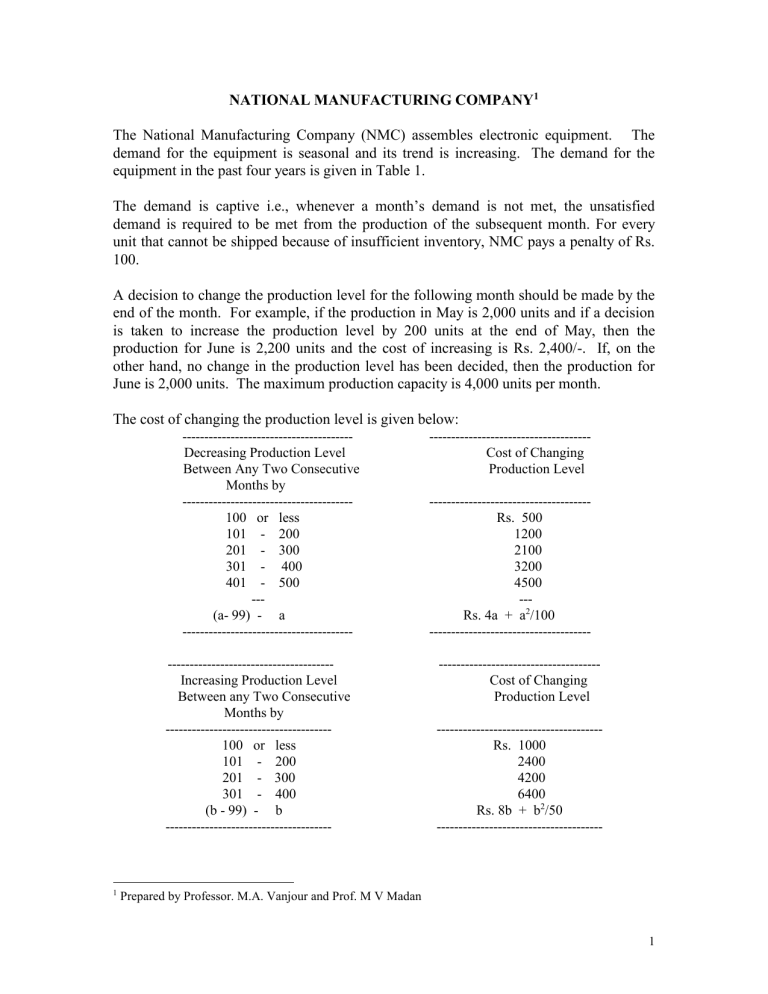

NATIONAL MANUFACTURING COMPANY1 The National Manufacturing Company (NMC) assembles electronic equipment. The demand for the equipment is seasonal and its trend is increasing. The demand for the equipment in the past four years is given in Table 1. The demand is captive i.e., whenever a month’s demand is not met, the unsatisfied demand is required to be met from the production of the subsequent month. For every unit that cannot be shipped because of insufficient inventory, NMC pays a penalty of Rs. 100. A decision to change the production level for the following month should be made by the end of the month. For example, if the production in May is 2,000 units and if a decision is taken to increase the production level by 200 units at the end of May, then the production for June is 2,200 units and the cost of increasing is Rs. 2,400/-. If, on the other hand, no change in the production level has been decided, then the production for June is 2,000 units. The maximum production capacity is 4,000 units per month. The cost of changing the production level is given below: --------------------------------------Decreasing Production Level Between Any Two Consecutive Months by --------------------------------------100 or less 101 - 200 201 - 300 301 - 400 401 - 500 --(a- 99) - a ---------------------------------------------------------------------------Increasing Production Level Between any Two Consecutive Months by -------------------------------------100 or less 101 - 200 201 - 300 301 - 400 (b - 99) - b -------------------------------------- 1 ------------------------------------Cost of Changing Production Level ------------------------------------Rs. 500 1200 2100 3200 4500 --Rs. 4a + a2/100 ------------------------------------------------------------------------Cost of Changing Production Level -------------------------------------Rs. 1000 2400 4200 6400 Rs. 8b + b2/50 -------------------------------------- Prepared by Professor. M.A. Vanjour and Prof. M V Madan 1 There will be shut down in the months of March and September. If the production level in April is different from the production level in February, then only the company will incur a cost in April for change in production level. Similarly in the months of August and October. The cost of holding equipment in inventory is Rs. 1 per month. The opening inventory at the beginning of January 1980 is 1500 units. The inventory level at the end of December 1980 should be 2500 units. This is due to a government regulation which stipulates a stock of one month demand at the end of each calendar year: Government auditors verify the stock in the first week of January. If there is a shortfall, then NMC will be compelled to place orders with contractors and pays Rs. 100 more than their factory cost (i.e., the penalty for falling short of 2500 units at the end of the year is Rs. 100 per unit). Because of this regulation NMC paid a heavy penalty in 1979. The company has decided to maintain a production of 2000 units in January 1981. Hence, when the game ends in December 1980, the cost of changing the production level in January will also be taken into account. Table - 1 Demand for the Equipment in the Past Four Years Month JANUARY FEBRUARY MARCH APRIL MAY JUNE JULY AUGUST SEPTEMBER OCTOBER NOVEMBER DECEMBER TOTAL 1976 1401 898 404 967 1081 1601 1332 1047 692 1121 1321 1729 13594 1977 1328 954 648 1101 1381 1621 1556 1162 941 1360 1809 1905 15766 1978 1696 1510 972 1192 1681 1696 1780 1578 1128 1780 1916 2521 19450 1979 2005 1607 1056 1524 1780 2305 1985 1695 1357 1981 2285 2836 22476 2