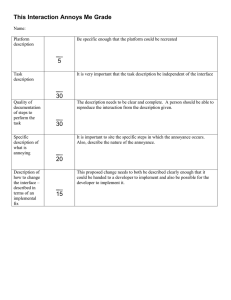

A Study on the Sound Quality Evaluation Model of Mechanical Air-Cleaners Jeong-Guon Ih1 e-mail: j.g.ih@kaist.ac.kr Su-Won Jang Cheol-Ho Jeong2 Department of Mechanical Engineering, Center for Noise and Vibration Control 共NoViC兲, KAIST, Daejeon 305-701, Korea Youn-Young Jeung Tech. Center, Woongjin Coway Co., Ltd., Seoul 151-818, Korea In operating the air-cleaner for a long time, people in a quiet enclosed space expect low sound at low operational levels for a routine cleaning of air. However, in the condition of high operational levels of the cleaner, a powerful yet nonannoying sound is desired, which is connected to a feeling of an immediate cleaning of pollutants. In this context, it is important to evaluate and design the air-cleaner noise to satisfy such contradictory expectations from the customers. In this study, a model for evaluating the sound quality of air-cleaners of mechanical type was developed based on objective and subjective analyses. Sound signals from various aircleaners were recorded and they were edited by increasing or decreasing the loudness at three wide specific-loudness bands: 20–400 Hz (0–3.8 barks), 400–1250 Hz (3.8–10 barks), and 1.25– 12.5 kHz bands (10–22.8 barks). Subjective tests using the edited sounds were conducted by the semantic differential method (SDM) and the method of successive intervals (MSI). SDM tests for seven adjective pairs were conducted to find the relation between subjective feeling and frequency bands. Two major feelings, performance and annoyance, were factored out from the principal component analysis. We found that the performance feeling was related to both low and high frequency bands, whereas the annoyance feeling was related to high frequency bands. MSI tests using the seven scales were conducted to derive the sound quality index to express the severity of each perceptive descriptor. Annoyance and performance indices of air-cleaners were modeled from the subjective responses of the juries and the measured sound quality metrics: loudness, sharpness, roughness, and fluctuation strength. The multiple regression method was employed to generate sound quality evaluation models. Using the developed indices, sound quality of the measured data was evaluated and compared with the subjective data. The difference between predicted and tested scores was less than 0.5 points. 关DOI: 10.1115/1.3085889兴 1 Corresponding author. Present address: Department of Electrical Engineering, Technical University of Denmark, DK-2800 Kgs. Lyngby, Denmark. Contributed by the Technical Committee on Vibration and Sound of ASME for publication in the JOURNAL OF VIBRATION AND ACOUSTICS. Manuscript received January 20, 2008; final manuscript received October 23, 2008; published online April 21, 2009. Assoc. Editor: Stephen A Hambric. Paper presented at the 2007 ASME International Mechanical Engineering Congress 共IMECE2007兲, Seattle, WA, November 10–16, 2007. 2 Journal of Vibration and Acoustics 1 Introduction Air cleaners, having capacities for enclosed spaces of 25– 50 m2, are usually operated in quiet rooms for a long time in the vicinity of people. For example, they operate for a whole day or during working hours at homes or offices. Because the air pollution levels are ever increasing in urban areas, the air-cleaner quickly becomes an essential appliance for small offices and homes. During the normal purification operation, the machine operational levels are low and people in the room usually expect a calm and quiet, or even not audible, sound. When the air-cleaner detects pollutants, the machine automatically changes its operation to a preset level depending on the extent of the pollution. At high operational levels, contrastingly, a powerful and wellcleaning yet nonannoying and more undisturbing sound is desired, where the auditory feeling is connected to an immediate and effective cleaning of pollutants. Considering the viewpoint of such contradictory expectations and the demands of the customers, sound quality should be investigated for the evaluation and design of emitted noise. Usually, the fan noise is the main source of noise in the mechanical-type cleaner using high efficiency particulate air 共HEPA兲 filters. Fan noise is unavoidable due to the circulation of air; however, different from the air-conditioning system, direct contact of the air stream with room occupants is not required in the design. Owing to this feature, the designer has an opportunity to modify the air-cleaner structure, mainly for the inlet and outlet designs or the operational conditions of the fan. Because there has been no sound quality model for the total perception of air-cleaner sound, as far as to the authors’ knowledge, it was imperative to find the relation between subjective feelings and physical nature of the air-cleaner sounds. Three wide specific-loudness bands were classified as representative sound bands based on the noise characteristics of air-cleaners: 20–400 Hz 共0–3.8 barks兲, 400– 1250 Hz 共3.8–10 barks兲, and 1.25–12.5 kHz bands 共10–22.8 barks兲. Two kinds of subjective tests using the edited sounds were conducted by the semantic differential method 共SDM兲 关1,2兴 and the method of successive intervals 共MSI兲 关3兴. SDM tests for seven adjective pairs describing the feeling to the air-cleaner sound were conducted to find the relation between subjective feeling and frequency bands. Because we had many test data, the popular paired comparison method 共PCM兲 关4兴 was not easy to use. In practicing the MSI test, many sound samples edited from various operational and artificial conditions are tested for a given question. In this case, a score should be marked to each sound within a given scale, and then the average of the repeated tests yields a result comparable to the PCM. Two major feelings were factored out from the principal component analysis. Two indices, which were derived for evaluating the two major feelings, were validated through the other test set. A design guideline for air-cleaner sound is suggested. 2 Analysis of Air Cleaner Sound The noise spectrum was measured in an anechoic chamber, for which the measurement method complies with the Korean Standard, KS C 9314 关5兴. The radiated pressures in the frontal direction and upward direction were chosen as the data for preparing the jury tests. This is because the frontal direction is the usual direction of hearing the air-cleaner sound in daily life and the sound pressure level 共SPL兲 is the loudest in the upward direction due to the outlet location of typical compact air-cleaners. From the A-weighted noise spectrum 关6兴 in Fig. 1, one can find that the loudest frequency ranges are 200–300 Hz and 400–700 Hz. The measurement was made at the center of an anechoic chamber 共cutoff frequency= 110 Hz兲. The low frequency range at 200– 300 Hz is related to the radiation from the frontal panel and cover plate, as well as the exhaust port. The noise from the rotation of fan and motor dominated the frequency range in 400–700 Hz. Sound power level 共PWL兲 was measured according to ISO 3745 关7兴 in a semi-anechoic chamber. Measured sound power levels are Copyright © 2009 by ASME JUNE 2009, Vol. 131 / 034502-1 Downloaded 05 May 2009 to 192.38.67.112. Redistribution subject to ASME license or copyright; see http://www.asme.org/terms/Terms_Use.cfm 40 Level 1 Level 2 Level 3 Level 4 Level 5 Background noise SPL (dBA) 30 20 10 0 Increasing operation level -10 100 1000 Frequency (Hz) Fig. 1 A-weighted noise spectrum „SPL… measured in the frontal direction for varying operation levels. The curve with the lowest level depicts the background noise in the anechoic chamber. shown in Fig. 2. The intensity level is quite high at the opening between the frontal cover and the main body at 200 Hz band. Beyond 630 Hz band, the sound intensity from the outlet part is predominant, as shown in Fig. 3共b兲. According to the measurement, the entire frequency range is divided into three sections: the 50 45 PWL (dBA) 40 35 30 25 20 15 10 5 100 160 250 400 630 1000160025004000630010000 1/3 octave band center freq. (Hz) Fig. 2 A-weighted sound power level „PWL… of an air-cleaner varying the operation level: „— 䉳 —… background noise, „—䊏—… level 1, „—쎲—… level 2, „—䉱—… level 3, „—䉲—… level 4, and „—⽧—… level 5 low frequency range below 400 Hz 共3.8 barks兲, where the structure borne noise due to the vibration of the frontal panel is dominant; fan and motor noise dominates the midfrequency 共MF兲 noise 共400 Hz–1.25 kHz兲; the air borne noise from the outlet becomes predominant beyond 1.25 kHz 共10 barks兲, with some contribution from the motor and fan as well. Objective SQ metrics 关8兴 such as Zwicker loudness from ISO532B 共N兲, sharpness 共S兲, roughness 共R兲, and fluctuation strength 共F兲 were calculated, and the result can be seen in Fig. 4. They represent the subjective sensational quantities related to loud feeling, shrill feeling, rough feeling, and beating feeling, respectively. Although there are other SQ metrics aside from these four metrics, they were discriminated from the evaluation after the preliminary test. All SQ metrics were calculated by using the SQTEAM software in KAIST, which is a dedicated in-house program written for the SQ evaluation. Comparison of our SQ program was made with three commercial software packages, which were available in 2004. It was noted that the three commercial software packages did not always produce the same metric value. We confirmed that the algorithms implemented in our SQ platform match those in the majority of other softwares 关9兴. 3 Development of the Sound Quality Indices for Air Cleaner Noise Two kinds of subjective tests using the edited sounds were conducted by the semantic differential method and the method of successive intervals. SDM tests for seven adjective pairs were conducted to find the change of subjective feeling in terms of frequency bands. The radiated noise of one air-cleaner was measured and edited by increasing or decreasing the loudness by 30% at three wide specific-loudness bands. Seven adjective pairs are listed in Table 1. A seven-scaled test was conducted for 25 people who were educated for the hearing test. The tests were repeated three times to check the consistency of subjects. Test results reveal a correlation coefficient larger than 0.7, and then data were collected and analyzed statistically. In the statistical processing of consistent data, analysis of variance 共ANOVA兲 was applied to each evaluation item to investigate any confident difference among 28 sounds. ANOVA results show clear differences among sounds, which was checked by Tukey’s method 关10,11兴. The confidence level for each statistical processing was 95%. Two major feelings, performance and annoyance, were factored out by the principal component analysis 共PCA兲 on seven adjective pairs. Feelings of well cleaning, loudness, and roughness were grouped in factor 1 and the other feelings of abnormal, cheap, and shrill into factor 2. Factor 1 is closely related to the “well- 65 64 63 62 61 60 59 58 57 56 55 54 53 (a) (b) Fig. 3 Measured sound intensity distribution in the 1/3-octave band: „a… 200 Hz band and „b… 630 Hz band 034502-2 / Vol. 131, JUNE 2009 Transactions of the ASME Downloaded 05 May 2009 to 192.38.67.112. Redistribution subject to ASME license or copyright; see http://www.asme.org/terms/Terms_Use.cfm 1.8 S (acum) 6 N (sone) 2.0 Front Rear Left Right Top 8 4 1.6 Front Rear Left Right Top 1.4 2 (a) 1.2 1 2 3 Operational level 4 5 (b) 1 2 3 4 5 3 4 5 Operational level 0.70 Front Rear Left Right Top 0.06 Front Rear Left Right Top 0.65 F (vacil) R (asper) 0.08 0.04 0.60 0.02 0.00 (c) 1 2 3 Operational level 4 5 0.55 (d) 1 2 Operational level Fig. 4 Calculated SQ metrics: „a… N, „b… S, „c… R, and „d… F performance and annoyance, were modeled in terms of three objective SQ metrics 共N , S , F兲, because R was not influential to the feelings. It was found that if the squared term of N was included in the regression model, a better fitting model to the overall feelings 共R2 = 0.98 for both annoyance and performance兲 was obtained than the model employing only the first order loudness value: -LF 共1兲 How annoying is the sound? 共2兲 How do you feel about the air purifying performance of the air-cleaner? Jury tests using seven-scales were conducted for young people and repeated twice. Figure 6 shows the variation in the subjective response to 50 sound samples concerning the two viewpoints of SQ evaluation. One can find that the judgment on the performance feeling was harder than the annoyance. A stepwise regression method was employed to remove the variables having small contribution. By the stepwise regression, two air-cleaner SQ indices, Loud Quiet Shrill 共sharp兲 Rough Unpleasant Cheap 共high and inharmonic timbre兲 Well cleaning Abnormal Not shrill 共dull兲 Smooth Pleasant Expensive 共low and harmonic timbre兲 Poor-cleaning Normal Journal of Vibration and Acoustics +M F +HF +HF Sound 3 Sound 4 -HF -LF -M F Sound 2 Table 1 List of adjective pairs for the test using the SDM 共1a兲 Annoyance = − 4.53 + 1.61N − 0.08N2 + 1.79S Factor2 (annoyance) operating feeling” of the air-cleaner, whereas factor 2 is related to the “disturbing feeling” or annoyance. Factor scores after the PCA are plotted in Fig. 5, where sound numbers 共1–5兲 specify the noise samples radiated from five different air-cleaners. Increase in sound pressure, either at low frequencies 共+LF兲 or high frequencies 共+HF兲 or both, contributes to the high performance factor. This means that a loud sound gives rise to a feeling of a welloperating machine. However, one should be careful about the fact that, unfortunately, midfrequency and high frequency components amplify the annoyance factor as well. Similarly, ⫺LF, ⫺MF, and ⫺HF denote the decrease in sound in the corresponding frequency bands. Another subjective test was conducted to get the sound quality indices. We used 50 air-cleaner sounds at various operation conditions for five different commercialized models. The questions given to the subjects were as follows. -HF +M F -LF +LF -LF +LF -HF -M F +HF +M F Factor1 (Perform ance) -M F +M F Sound 1 +LF +HF +LF -M F -HF Fig. 5 Factor scores by the PCA: „䊏… sound 1, „䉱… sound 2, „⽧… sound 3, and „쎲… sound 4. Two factors are classified: performance and annoyance feelings. Each factor was in seven scales: −3 to +3. JUNE 2009, Vol. 131 / 034502-3 Downloaded 05 May 2009 to 192.38.67.112. Redistribution subject to ASME license or copyright; see http://www.asme.org/terms/Terms_Use.cfm 7 Subjective response 7 6 Annoyance 5 4 3 4 3 2 1 1 5 10 15 20 25 30 Sound number 35 40 45 50 Subjective score Predicted score 5 (a) 10 15 20 25 30 Sound number 7 Subjective response 7 6 Performance 5 2 (a) (b) 6 5 4 3 3 1 20 25 30 Sound number 35 40 45 50 50 4 1 15 45 5 2 10 40 Subjective score Predicted score 6 2 5 35 5 (b) 10 15 20 25 30 Sound number 35 40 45 50 Fig. 6 Subjective response for the second experiment. „a… Annoyance and „b… performance. „쎲… All juries and „䊏… consistent juries. Fig. 7 A comparison of tested and predicted subjective scores: „a… performance and „b… annoyance Performance = − 2.58 + 1.53N − 0.09N2 − 0.87S + 4.64F was decreased by 0.4 sone. In this case, a small gain in performance feeling was observed, but the annoyance feeling was reduced by about 1 subjective point. The edited sounds 3 and 4 were all louder than the original one. However, annoyance evaluations were equal to or less than that of sound 1 and performance values were higher than that of the original sound. This is due to the fact that the low frequency component is enhanced while the high frequency components are suppressed in the modification of sound 1. 共1b兲 Using Eq. 共1兲, the SQ of the measured data was evaluated and compared with the subjective data. Test data were not included in deriving Eq. 共1兲 and were obtained from different air-cleaners. The difference between predicted and tested scores for 50 sample sounds was found to be less than 0.5 points, as shown in Fig. 7. Instead of using the model in Eq. 共1兲, SQ indices for evaluating the air-cleaner noise could be made in terms of total loudness values at low, mid-, and high frequency ranges by stepwise regression as follows 共R2 = 0.94 for annoyance and R2 = 0.90 for performance兲: Annoyance = − 0.13 + 0.22Nlow 1.28Nmedium freq. 共2a兲 freq. Performance = 0.41 + 1.70Nlow − 0.44Nhigh freq. + freq. 1.43Nmedium freq. 共2b兲 In the derivation, each index was assumed to be proportional to the first order quantity of band loudness values, which was based on the observation of the application results of Eq. 共1兲. One can find that all sound components contribute to the annoyance, whereas the high frequency component has a negative effect on the performance index. Because the just noticeable differences 共JNDs兲 for the N and S are known as 7% and 5% 关8兴, respectively, the calculated JNDs of the performance and annoyance were found to be 0.4 and 0.2, respectively. Using the derived SQ indices, the sound spectrum could be modified to suggest a desirable sound from the viewpoint of SQ. Examples are shown in Fig. 8. The corresponding SQ indices were calculated and listed in Table 2. Comparing sound 1 and sound 2, overall SPL was increased by 2.5 dB, but the loudness 034502-4 / Vol. 131, JUNE 2009 40 SPL (dBA) + 0.65Nhigh freq. + 50 30 20 10 125 200 315 500 800 1.25k 2k 3.15k 1/3 octave band center freq. (Hz) 5k 8k Fig. 8 Spectra of several modified sounds: „—䊏—… sound 1 „original…, „—쎲—… sound 2 „+LF, ⴚMF, ⴚHF; ⌬L = 6 dB…, „—䉱—… sound 3 „+LF, +MF, ⴚHF; ⌬L = 4 dB…, and „—䉲—… sound 4 „+LF, ⴚHF; ⌬L = 6 dB… Transactions of the ASME Downloaded 05 May 2009 to 192.38.67.112. Redistribution subject to ASME license or copyright; see http://www.asme.org/terms/Terms_Use.cfm Table 2 Sound quality indices and sound pressure level, loudness of modified sound samples in Fig. 8 Sample No. Sound Sound Sound Sound 4 1 2 3 4 Edited frequency ranges Annoyance 共Eq. 共1a兲兲 Performance 共Eq. 共1b兲兲 SPL 共dBA兲 Loudness 共sone兲 Original +LF, ⫺MF, ⫺HF +LF, +MF, ⫺HF +LF, ⫺HF 4.3 3.4 4.3 3.8 5.4 5.6 6.4 5.9 49.0 51.5 54.5 52.5 5.9 5.5 7.3 6.2 Conclusions In this study, the SQ indices for the noise from a mechanicaltype air-cleaner were developed. To this end, the frequency range was divided into three sectors based on the noise characteristics: low frequency 共20–400 Hz兲, midfrequency 共400–1250 Hz兲, and high frequency 共beyond 1.25 kHz兲. As a result of the subjective evaluation, two principal components, performance and annoyance, were extracted as main perceptions on the air-cleaner noise. We found that the low frequency components enhance the feeling of strong performance. High frequency components can enhance the performance index but have the adverse effect of increasing the annoyance. According to the MSI test, two SQ indices, performance and annoyance, were modeled in terms of objective SQ metrics, N, S, and F. The results of this study would be useful in the noise control and psychoacoustic design of radiated sounds from an air-cleaner. Acknowledgment This work was partially supported by the BK21 Program. The authors would like to thank Woongjin Coway Co., Ltd. for their support. Nomenclature F ⫽ fluctuation strength N ⫽ loudness Journal of Vibration and Acoustics R ⫽ roughness S ⫽ sharpness References 关1兴 Engen, T., 1971, Psychophysics: Scaling Methods, 3rd ed., Holt, Rinehart, and Winston, New York. 关2兴 Ih, J.-G., Lim, D.-H., Shin, S.-H., and Park, Y., 2003, “Experimental Design and Assessment of Product Sound Quality: Application to a Vacuum Cleaner,” Noise Control Eng. J., 51, pp. 244–252. 关3兴 Bodden, M., Heinrichs, R., and Linow, A., 1998, “Sound Quality Evaluation of Interior Vehicle Noise Using an Efficient Psychoacoustic Method,” Proceedings of the Euro Noise 98, H. Fastl and J. Scheuren, eds., DEGA, Oldenberg, pp. 609–614. 关4兴 David, H. A., 1988, The Method of Paired Comparisons, 2nd ed., Oxford University, New York. 关5兴 2002, KS C 9314: Air Cleaner, Korean Standards Associations. 关6兴 Beranek, L., and Ver, I., 1992, Noise and Vibration Control Engineering: Principles and Applications, Wiley, New York. 关7兴 2003, ISO 3745: Acoustics-Determination of Sound Power Levels of Noise Sources Using Sound Pressure Precision Methods for Anechoic and Hemianechoic Rooms, International Organization for Standardization. 关8兴 Zwicker, E., and Fastl, H., 1990, Psychoacoustics: Facts and Models, Springer-Verlag, Berlin, pp. 181–236. 关9兴 Shin, S.-H., and Ih, J.-G., 2004, “A Comparison of Commercial Software for the Sound Quality Analysis,” Proceedings of the Autumn Meeting of the Acoustical Society of Korea, Acoustical Society of Korea, Seoul, pp. 215–218. 关10兴 Devore, J. L., 1995, Probability and Statistics for Engineering and the Science, 4th ed., Duxbury, Singapore. 关11兴 Shin, S.-H., Ih, J.-G., and Jeong, H., 2003, “Statistical Processing of Subjective Listening Test Data for PSQ,” Noise Control Eng. J., 51, pp. 232–238. JUNE 2009, Vol. 131 / 034502-5 Downloaded 05 May 2009 to 192.38.67.112. Redistribution subject to ASME license or copyright; see http://www.asme.org/terms/Terms_Use.cfm