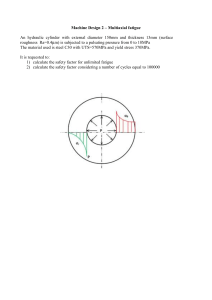

Proceedings of OMAE'05 24th International Conference on Offshore Mechanics and Arctic Engineering June 12-16, 2005, Halkidiki, Greece OMAE2005-67051 AN OVERVIEW OF THE REASSESSMENT STUDIES OF FIXED OFFSHORE PLATFORMS IN THE BAY OF CAMPECHE, MEXICO Partha Chakrabarti, Adinarayana Mukkamala, Ibrahim Abu-Odeh and Bidyut Majumdar, ZENTECH Incorporated, 8582 Katy Freeway Houston, Texas, USA, Michael Havbro Faber and Daniel Straub, Swiss Federal Institute of Technology, ETH Zürich, Juan de Dios de la O, Pemex Exploration y Producción, Mexico Abstract Pemex Exploration y Producción owns and operates several fields in the Bay of Campeche, located in the south Gulf of Mexico, for oil and gas production. Many of these fixed offshore platforms were built during the 70s and 80s and have already exceeded their design service life. In order to meet the growing demand for oil and natural gas it is necessary to extend the service life of these platforms by at least another 15 to 30 years. To meet this extended service life, thorough and systematic reassessment studies need to be conducted leading to identification of any structural weakness and possible locations of fatigue problems. To extend the fatigue life of the welded joints, inspections according to risk based inspection planning are required to be performed. In the present paper, an overview of the reassessment study procedure is outlined and pertinent results are presented for more than twenty platforms. The most important engineering considerations and various analyses involved in the study are discussed in detail. The platforms cover the categories of Drilling, Production, Gathering and Habitation. Depending on the category, Pemex specifications assign different levels of acceptable reliabilities and reserve strength ratios. The ultimate strength of the platforms is determined using a detailed model of jacket, piles and deck structures and a state-of-the-art nonlinear progressive collapse analysis technique commonly known as ‘pushover’ analysis. The structural models include local joint flexibility of the jacket joints, soil-pile interaction, geometric nonlinearity and material plasticity. They also include the information of damages and deterioration obtained from inspection reports such as dents, bents, cracks etc. The joint modeling is performed using the latest available procedures that use nonlinear load-deformation curves. Fatigue analyses are based on spectral analysis technique and include the dynamic response of the structure to wave loads. The structural models for fatigue analysis include the effects of local joint flexibility and soil-pile interaction. Results for one typical platform are presented in complete detail to facilitate the understanding of the reassessment study procedure. A typical risk based inspection planning for extending fatigue service life is also presented. Finally, the summary of results for 28 platforms is presented to appreciate the importance of the various parameters. It is hoped that this very wide database of results for platforms of different configurations can serve as a useful resource for the offshore industry in general. 1 INTRODUCTION Pemex Exploration y Producción intends to extend the service life of their fixed offshore platforms in the Cantarell field in the bay of Campeche which were installed in the 70s and 80s by 15 to 30 years in order to get more hydrocarbons from this field. These platforms were originally designed for wave, wind and current loads in association with the service loads and also for seismic conditions. Over the years there has been some deterioration such as dents and bents in members, cracks and other damages. Pemex has performed periodic inspections to assess the condition of the platform structure. In order to achieve this target systematic reassessment of the platforms is necessary to establish the present structural safety of the platforms. To extend the service life of the platforms any repair or retrofitting necessary has to be determined. Finally, an inspection philosophy and plan has to be developed, in particular for fatigue prone joints of each platform, for the remaining period of the service life. In the first phase of this effort more than twenty platforms have been assessed. The procedures for the assessment and the results are discussed in here. 1 Copyright © 2005 by ASME Reassessment of a platform involves the following analyses: • Pushover analysis for ultimate strength o for waves o for seismic • Spectral fatigue analysis for fatigue life assessment of welded joints of the jacket • Long term Weibull stress distribution at a hotspot • Risk-bases Inspection planning (RBI) The objective of the pushover strength analysis is to check the overall safety of the jacket for environmental loads. The objective of the fatigue analysis is to identify critical fatigue prone joints. The objective of the risk-based analysis for fatigue critical joints is to arrive at a rational inspection planning strategy. The salient features of the analysis will be discussed here and the results of one selected platform will be presented. Finally, the overall summary of results of the 28 platforms will be presented and discussed. 2 PLATFORM GEOMETRY & PROPERTIES The platforms are located in the Cantarell field in the Bay of Campeche. The general descriptions of the platforms are given below: Table 1 Platform Details Platform Total Service Life (years) Configuration no. of piles - dia. Framing Type 64 8-1.422m 8P-1A Nomenclature Operation Water Depth (m) C-1 Compression 44.20 C-2 Compression 46.63 44 8- 1.422m 8P-3 D-1 Drilling 39.62 67 8-1.219m 8P-2A D-2 Drilling 39.60 35 8- 1.219m 8P-2B D-3 Drilling 42.20 35 8- 1.219m 8P-6 D-4 Drilling 48.46 55 8- 1.219m 8P-5 D-5 Drilling 47.24 55 8- 1.219m 8P-5 D-6 Drilling 44.19 57 8- 1.067m 8P-1A D-7 Drilling 46.63 46 8- 1.219m 8P-6 D-8 Drilling 42.06 36 8- 1.219m 8P-2A D-9 Drilling 45.11 36 8- 1.219m 8P-1A D-10 Drilling 44.50 41 8- 1.067m 8P-1A D-11 Drilling 44.70 36 8- 1.219m 8P-1A D-12 Drilling 45.41 41 8- 1.067m 8P-1A G-1 Gathering 39.62 63 8-1.219m 8P-3 G-2 Gathering 44.19 56 8- 1.067m 8P-4 G-3 Gathering 46.63 45 8- 1.067m 8P-4 L-1 Habitation 40.40 44 8- 1.067m 8P-1B L-2 Habitation 44.65 54 8- 1.067m 8P-1B L-3 Habitation 46.94 45 8- 1.067m 8P-1B P-1 Production 48.30 65 4-1.372m 4P-1 P-2 Production 44.20 55 8- 1.219m 8P-5 P-3 Production 46.63 46 8- 1.219m 8P-1A P-4 Production 44.50 55 8- 1.219m 8P-5 P-5 Production 46.94 45 8- 1.219m 8P-1A P-6 Production 46.63 45 8- 1.219m 8P-1A P-7 Production 44.20 56 8- 1.219m 8P-1A T-1 Telecommunication 43.93 63 3-0.914m 3P-1 2 Copyright © 2005 by ASME The platforms are located in water depths 35 – 50m. The categories of platform are: • Production • Drilling • Gathering • Compression • Habitation • Telecommunication Some of the platforms have changed their usage and additions and alterations have been made to the deck to accommodate new equipment. The naming of the platforms has not been changed after the change of service. The service life listed is the total service life including the present age and the additional life extension desired. The majority of the platforms are 8-legged platforms with varying pile diameters. There is one 4-pile and one tripod platform. Depending on the vertical framing pattern of broadside Rows A and B, the 8-pile platforms can be categorized essentially in six categories. Some of the categories also have some variations. The transverse framings of the Rows 1, 2, 3 and 4 are very similar and consist of V-braces. The vertical framing configurations of the 3-pile, 4-pile and 8-pile platforms are shown in Figure 1. The platforms, in general, have one or two boat landings, risers, riser guards, barge bumpers and other appurtenances like anodes. The Drilling and Gathering platforms also have conductors. The Telecommunication platform has a telecommunication tower on the deck. The platforms are also bridge connected to other platforms in the same complex. 3 PUSHOVER ANALYSIS For platform reassessment, Pemex NRF-003 [1] requires that nonlinear pushover analysis be performed for environmental loads to evaluate the ultimate strength before collapse of the platform and a minimum Reserve Strength Ratio (RSR) be maintained. Pushover analysis is an ultimate strength analysis procedure that includes the member failures due to yielding, buckling, soil-pile failure as well as joint failure. This provides an unbiased estimate of platform capacity by removing all the safety factors. RSR is defined as the ratio of a platform's ultimate lateral load capacity to the lateral load (base shear) due to the ‘reference level’ environmental condition which corresponds to the 99-year wave. There are three risk categories: Moderate, High and Very High for the ultimate load analysis. The environment for the ‘Very High’ category is the highest, whereas for the ‘Moderate’ category it is the lowest. The RSR depends on the category of the platform. The categories are specified by Pemex depending on criteria such as the production potential. The assessment criteria for different categories are shown in Table 2. The associated wind and current used for analyses with the design waves mentioned in the table conform to NRF-003. The drag and inertia coefficients for wave load calculations are in accordance with API RP 2A [2]. The wave loads on the deck have been included where applicable. Table 2 Parameters for Assessing Existing Platforms EXPOSURE CATEGORY EVALUATION PARAMETERS MODERATE HIGH VERY HIGH Reference (99-year) Wave Height (m) 15.0 15.0 15.0 Wave Height for Push-over Analysis (m) 21.0 21.5 23.0 1.30 (1) 1.40 (1) 1.60 (1) 1.50 (2) 1.60 (2) 1.90 (2) Minimum required Reserve Strength Ratio (RSR) (1) (2) Without considering wave load on deck. Considering wave load hitting the lower deck 3 Copyright © 2005 by ASME 8P-1A 8P-1B 8P-2B 8P-5 8P-2A 8P-3 8P-6 8P-4 8P-Transverse 3P-1 4P-1 Figure 1 Platform Configurations For the structural model, the basic jacket geometry consists of the jacket legs, vertical diagonals, horizontals, interior members and ungrouted piles inside the jacket. The conductors, risers, riser guards, boat landing structures and the barge bumpers have been modeled as nonstructural groups. The pile-soil system is modeled as part of the soil-structure interaction option. The piles are modeled up to the actual penetration. Damages to the jacket members are modeled appropriately using the modeling provisions of the computer program used [4]. This included modeling of the bents, dents and cracks of the members. All structural members have been assumed to have their nominal yield strength. All the jacket tubular members and piles have been considered for possible plasticity under load. Major deck members are considered to have plastic properties. The ultimate strength of the structure is derived using a progressive collapse analysis method. The basic principle of this analysis method is to represent every physical element in the structure by one finite (beam) element. Non-linear geometric and material properties are accounted for. The beam model includes possibility of three plastic hinges, one at each end and one at the middle. Plastic hinges are introduced at locations where the element cross section reaches its ultimate capacity. This is determined by the interaction surface. First the gravity load is applied followed by the environmental loads for the pushover condition in small increments. The stiffness matrix is modified to account for the plastic hinge and the load increased until the next cross section reaches its ultimate capacity. This process continues until a complete mechanism is formed and the load cannot be increased further. Conventional pushover analysis assumes that the joint where two or more tubes are connected is a rigid joint having unlimited strength. In reality, shell behavior of the tubes implies that any joint would have flexibility when a brace is loaded by axial loads and/or bending moments. Depending on the geometry, the capacity of the brace/chord connection could be less than the brace capacity. If this happens the brace cannot be utilized fully. The available recommended practices and codes, such as API RP 2A, give 4 Copyright © 2005 by ASME methods of calculating the joint strength capacity for different joint types. Once the loads and moments for the members meeting at the joint are known, it is possible to perform a ‘joint check’ to identify if the capacity has been exceeded or not. The capability for inclusion of joint flexibility as well as strength capacity in nonlinear pushover analysis is a recent development. The software used [4] has the capability to include nonlinear behavior of joints under the combined action of axial loads and in-plane and out-of-plane moment loads across the full range of load-deformation response. There are two joint strength models available: a) API model, b) MSL Model. The API model uses the joint capacities based on the API equations. The MSL model is based on semi-empirical method developed from a database of tubular joint tests and FE analyses. Both the models use load-deformation (P-δ or M-θ) curves developed considering the joint geometry and material properties. Pushover analyses were carried out for twelve directions of wave approach covering full 360° at 30° intervals. The minimum value obtained is the final RSR for the platform. Pushover analyses have also been performed for seismic loading. However, as the geographical area under consideration is a mild seismic area, seismic loads do not govern the platform assessment. Therefore, this is not discussed further. 4 SPECTRAL FATIGUE ANALAYSIS Fatigue analysis is performed for the long term wave climate for all major jacket joints. The long term statistical sea state environment is represented by a combined annual wave scatter diagram for the Bay of Campeche. Spectral analysis is used for determining the stress response to sea state loadings. In this process a transfer function is constructed after performing structural analysis and combined with the wave energy spectra for the sea states to calculate the stress response. Dynamic structural analyses of the platform model are performed for a number of wave periods to construct the transfer functions for different wave approach directions. The analysis is done for steady state regular wave response using the ‘wave response’ technique of the software [3]. This analysis is based on the modal superposition technique but handles the nonlinearities of the wave loading without drag linearization using Fourier decomposition of the loading. The piles below the soil are appropriately linearized for the modal analysis. The importance of LJF has also been recognized in API RP 2A and in some recent studies. The present analysis has used the equations and implementation philosophy formulated by Buitrago [5]. The method involves inserting a short ‘flex-element’ at the end of the brace to represent the axial and bending stiffness of the joint. For each fatigue load condition, represented by a scatter data point, the wave sea state is represented by a Pierson-Moskowitz (P-M) spectrum. Using the transfer function and the wave spectrum for a sea state the response spectrum is computed. Rayleigh distribution is used to evaluate the stress range distribution and corresponding number of cycles from the response spectrum. The general methodology is in accordance with API RP 2A. Efthymiou [6] method is used for SCF determination of tube to tube connections with both overlapped and non-overlapped joints. The basic SCFs are determined for T/Y, X, K and KT joints using the various geometry factors for axial, in-plane bending and out-of-plane bending loads in the brace. For a given location at the perimeter of the brace to chord connection, hot spot stress is calculated using the brace member loads and the Influence Function algorithm which is a generalization of the joint classification approach based on geometry and loading pattern. This has the benefit that multi-planar joints can be handled for the important case of axial forces. The stress range is calculated as the difference between load cases with maximum base shear and minimum base shear positions. Eight points around the footprint of the brace are considered for fatigue assessment. There are some members in a few jackets that have been grouted in the past. For joints where the chord is grouted, the beneficial effect is taken in SCF determination. The procedure follows the recommendations of draft ISO 19901 [6]. The API X S-N curves are used for the fatigue damage calculation. Thickness correction is included. The total fatigue damage for a hotspot is given by summing the damages for each sea state for every direction. 5 WEIBULL DISTRIBUTION Deterministic spectral fatigue analysis produces the short term distribution of stress ranges at a hotspot for each sea state from the transfer function of the stress range and the wave spectrum. The statistics for the number of stress cycles and the stress range distribution is produced from the spectral analysis for each sea state. An alternate but equivalent approach is to construct a long-term distribution of the stress range from a weighted average of the short-term distributions. When performing a risk-based inspection 5 Copyright © 2005 by ASME planning it is an unnecessary complication to use this long-term distribution expressed as a summation of short term responses. Instead, it is advantageous to fit the computed long term distribution to a simpler distribution expressed as a two-parameter Weibull distribution. The method used in this project yields the Weibull scale and shape parameters use of which would closely approximate the total damage as well as the damage distribution obtained originally by the sum of Rayleigh distributions. For the purpose of risk analysis Fatigue Design Factor of safety is defined as: FDF = Calculated Fatigue Life / Service Life API RP 2A requires a minimum FDF of 2.0 for all jacket joints. However, for risk screening purposes for inspection planning, the hotspots that have Fatigue Design Factor (FDF) of less than 10 have been identified. Only these hotspots are the candidates for RBI. 6 REDUNDANCY ANALYSIS For subsequent risk analysis for fatigue failure of joints, the RSR values conditional on fatigue failure of selected joints (or member) have to be evaluated. The importance of a fatigue failure is measured by the Residual Influence Factor (RIF) defined as: damaged RIF = RSR int act RSR The RSRintact is the value for the intact structure and RSRdamaged is the value for the structure damaged by fatigue failure of a joint. The redundancy pushover analysis is conducted by removing the concerned brace member one at a time from the jacket model. 7 RISK BASED INSPECTION PLANNING Offshore structures are designed subject to certain assumptions in regard to integrity and deterioration. Inspections may be implemented to ensure that these assumptions are satisfactorily maintained throughout the service life of the structures. In principle two types of inspections can be distinguished, namely, 1) inspections directed toward the control of degradation processes which can be predicted to some extent by means of models (with uncertainty) and 2) inspections performed with the aim of identifying degradation and damages which in principle can be anticipated but not predicted. For the inspections aimed at controlling the development of predictable degradation such as fatigue crack growth, the inspection effort can be targeted such that the risks implied by the degradation are kept within acceptable limits. Risk, here, being understood as that associated with collapse of the platform due to the impact of extreme loads acting on a degraded (fatigue damaged) structure. For degradation due to fatigue crack growth Risk Based Inspection (RBI) planning strategies can be developed and such strategies have been implemented for these platforms. However, the other type of inspections must not be disregarded as these serve as an important means to ensure that the general design assumptions in regard to the integrity of the structure are maintained. For the present platforms inspections in regard to the control of fatigue crack growth have been planned using the RBI methodology. It has been assumed that all inspections are performed using ACFM or MPI inspection techniques. In the RBI formulation, the long term stress history at a given hotspot is simulated by a two-parameter Weibull distribution obtained from the fatigue analysis. The RIF is used to select the acceptable probability of fatigue failure of the particular joint. The acceptability criteria employed also meets the NRF-003 requirements. 8 RESULTS OF ANALYSES FOR A TYPICAL PLATFORM The results of various analyses for a selected platform (D-11) are discussed here. 8.1 Pushover Analysis Considering the risk of life safety and consequence of failure, the platform is categorized under ‘High’ storm exposure. The minimum RSR value obtained is 2.03 for 30º direction. This is more than the Pemex required minimum value of 1.60. The final failure is due to plasticity of piles and some of the jacket members. No significant joint failure has been observed. The load level due to horizontal base shear vs. resultant lateral displacement for a selected node at main deck is shown in Figure 2. The load level indicates the proportion of the maximum base shear due to the pushover environmental conditions. The RSR is 6 Copyright © 2005 by ASME obtained by multiplying the maximum load level by the ratio of the base shear due to the pushover environment and the reference level environment. Load-Displacement Plot at Node #1301 1 0.9 0.8 Load Level 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 0 0.1 0.2 0.3 0.4 0.5 0.6 Displacement (m) Figure 2 Load-displacement for a Node in Main Deck 8.2 Spectral Fatigue Analysis The calculated fatigue life statistics is given below: • Minimum fatigue life is 104 years • Number of hotspots having FDF < 1 is 0 • Number of hotspots having FDF < 5 is 6 • Number of hotspots having FDF < 10 is 20 Fatigue lives of joints are shown in Figure 3 as a typical example. 104. 324. 124. 240. 187. 136. 107. 318. 228. 330. Z X 1 280. 2 3 Z X 4 161. 326. 1 2 Row A 309. 177. 3 4 Row B Figure 3 Fatigue Lives of Joints in Row A & B 8.3 Weibull Distribution For the joints having FDF<10 the Weibull parameters are calculated as described earlier. These are used for RBI calculations. A typical long term stress range distribution for a hotspot using original Rayleigh distribution from fatigue analysis and the approximate Weibull distribution is shown in Figure 4. 7 Copyright © 2005 by ASME Long Term Stress Range Distribution 4.0 3.0 2.0 ln(-ln(1-Probj)) 1.0 -3.00 -2.00 -1.00 0.0 0.00 1.00 2.00 3.00 4.00 Rayleigh Weibull Max. Damage Fit -1.0 -2.0 -3.0 -4.0 -5.0 ln(Sj) Figure 4 Longterm Distribution of Stress Ranges using Rayleigh and Weibull Distributions 8.4 Redundancy Analysis Pushover analysis is conducted for all chord-brace pairs which have FDF<10 by removing the concerned member from the jacket. Since the member would still be physically present when fatigue failure takes place, the external loads on the member such as wave loads, weight etc. would still be present. The results for redundancy analyses have shown that for most cases the RIF is close to 1.0, the minimum being 0.86. The lower the RIF the higher is the importance of presence of the member for strength. The high value of RIF is due to the high redundancy of the jacket structure which in general is good for strength. The minimum damaged RSR obtained is 1.75, which is higher than the minimum required RSR of 1.6. Therefore, although RIF for some chord-brace pairs is less than 1.0, the minimum RSR is still met. 8.5 RBI Analysis The RBI study indicates that of the above 20 hotspots having FDF<10, 17 need inspection to maintain the desired reliability. These joints are shown in Figure 5. This figure also shows the joints that have been inspected using the prevalent criteria at Pemex. Note that none of these joints coincide with those requiring inspection as per the RBI plan. The results of the RBI inspection planning are shown in Table 3. From the inspection plans it is seen that the required inspection efforts related to fatigue crack growth are moderate and can easily be coordinated with the other inspection types necessary to ensure the integrity of the platform. Of the 17 joints that need inspection, 10 hotspots do not show any need of inspection beyond year 2004. However, since recent detailed inspection report does not cover these joints, it would be prudent to perform inspection for these joints as well at the earliest to confirm the assumptions of no crack detection made in the analysis. If no cracks were detected for these joints, further inspection would not be necessary. If cracks are detected remedial measures need to be considered. 8 Copyright © 2005 by ASME 606 581 502 402 406 637 665 381 384 600 302 663 303 307 306 652 654 282 281 659 646 204 Z X 1 2 285 284 3 648 205 Z X 4 65 1 2 Row A 646 670 207 208 3 4 64 Z Y B Row 1 Row B B 205 A 505 419 502 427 333 571 469 335 A 501 1 2 3 4 Y X Z Z Y A EL @ -20.00FT Y B A B Row 2 Row 4 Joints to be inspected Joints inspected previously Chord member Brace member Figure 5 Fatigue Prone Joints Requiring Inspection Table 3 Risk Based Inspection Plan Inspections Elev. Z (m) Member JA-JB Type 501 -6.096 307 -31.089 501- 395 501- 335 307- 654 307- 285 307- 663 307- 384 505- 442 505- 333 303- 652 303- 282 303- 600 303- 381 205- 646 205- 64 205- 646 205- 65 208- 670 208- 285 406- 665 406- 384 284- 207 284- 206 284- 306 284- 307 402- 637 402- 381 204- 659 204- 282 207- 648 207- 284 281- 302 281- 303 281- 203 281- 202 502- 419 502- 427 206- 647 206- 284 201- 643 201- 82 CHD BRC CHD BRC CHD BRC CHD BRC CHD BRC CHD BRC CHD BRC CHD BRC CHD BRC CHD BRC CHD BRC CHD BRC CHD BRC CHD BRC CHD BRC CHD BRC CHD BRC CHD BRC CHD BRC CHD BRC 505 -6.096 303 -31.089 205 -44.196 208 -44.196 406 -17.678 284 -37.642 402 -17.678 204 -44.196 207 -44.196 281 -37.642 502 -6.096 206 -44.196 201 -44.196 Year 19 79 19 80 19 81 19 82 19 83 19 84 19 85 19 86 19 87 19 88 19 89 19 90 19 91 19 92 19 93 19 94 19 95 19 96 19 97 19 98 19 99 20 00 20 01 20 02 20 03 20 04 20 05 20 06 20 07 20 08 20 09 20 10 20 11 20 12 20 13 20 14 20 15 Hotspot Identification Common Joint X X X X X X X X X X X X X X X X X X X X X X X X 9 Copyright © 2005 by ASME 9 SUMMARY OF RESULTS FOR ALL PLATFORMS The main results for all the platforms studied are summarized in Table 4. The results are sorted with increasing minimum fatigue life. Each color code designates different platform type. From the results the following observations are made: • Most platforms meet the criteria of minimum Reserve Strength Ratio for its own category except for G-1 which falls short by a small margin. • The natural periods of the platforms lie between 1.2 – 2.3 seconds. • The lowest fatigue life occurs for the Drilling platforms. These platforms are subjected to higher wave loads due to the presence of conductors. They also have high deck weight. • Compression platforms C-2 and C-1 have the highest deck weights but do not show very low fatigue life, probably because of the large diameter of the piles. • Production and Habitation platforms generally have high fatigue lives. • The maximum number of potential fatigue hotspots requiring inspection is shown for D-2 and D-4. • No general conclusion could be drawn as to the effect of the framing type on the fatigue results except that D-4 which showed a large number of fatigue prone joints has a unique framing. 10 CONCLUSIONS A comprehensive study for reassessment for twenty-eight platforms has been carried out and the principal results reported in this paper. The paper presented a state-of-the-art approach for reassessment of old platforms for life extension. Both the critical aspects of strength of the platform and fatigue life of welded joints have been addressed. Finally, risk based inspection planning has been recommended for extension of life for achieving the desired level of reliability for the complete intended service life. The detailed joint inspection has to be supplemented by usual visual and other inspections that are normally carried out for condition assessment such as corrosion, marine growth, scour, member damages due to boat impact or dropped objects etc. ACKNOWLEDGMENTS We have the pleasure to acknowledge approval and participation of Pemex Exploration y Producción, the owner and operator of the platforms, for the presentation and publication of this paper. REFERENCES 1. 2. 3. 4. 5. 6. “Diseño y Evaluación de Plataformas Marinas Fijas en la Sonda de Campeche”, NRF – 003 – Pemex – 2000, Rev. 0, December 2000. “Recommended Practice for Planning, Designing & Constructing Fixed Offshore Platforms – Working Stress Design”, API RP 2A, 20th Edition, 1993. StruCAD*3D - User’s Manual, Computer Software for Analysis and Design, Version 4.3, 2003. USFOS – Version 8, distributed by DNV, Norway. “Local Joint Flexibility of Tubular Joints”, J. Buitrago, Healy, B. E. and Chang T.Y., OMAE, 1993. Draft International Standard ISO 19901, Petroleum and Natural Gas Industries – Offshore Structures. 10 Copyright © 2005 by ASME HABITATION GATHERING DRILLING DRILLING TELECOMMUNICATION GATHERING DRILLING PRODUCTION GATHERING PRODUCTION COMPRESSION HABITATION PRODUCTION L-1 G-2 D-10 D-11 T-1 G-1 D-12 P-2 G-3 P-1 C-2 L-3 P-4 PRODUCTION HABITATION L-2 P-7 DRILLING D-1 PRODUCTION DRILLING D-9 P-6 DRILLING D-8 PRODUCTION DRILLING D-4 P-5 46 DRILLING D-7 PRODUCTION DRILLING D-6 COMPRESSION 55 DRILLING D-5 P-3 55 DRILLING D-3 C-1 41 DRILLING D-2 56 45 45 64 45 44 65 45 63 63 36 41 56 44 54 67 36 36 55 46 57 55 35 35 Operation Total Service Life (years) Nomenclature Platform 1281 1008 474 435 365 345 323 277 252 222 191 140 132 119 104 104 94 81 68 66 62 42 41 40 13 11 9 2 Lowest Calculated Fatigue Life (years) 3 5 5 2 4 5 7 11 6 20 3 20 19 4 6 4 22 15 25 56 39 67 68 32 55 FDF<10 11 FDF >10 for all joints FDF >10 for all joints FDF >10 for all joints 0 0 0 0 0 2 1 4 1 13 3 6 4 4 3 1 13 5 11 24 16 40 37 13 35 FDF<5 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 4 1 5 5 4 16 FDF<1 Number of Potential Fatigue Spots Table 4 Summary of Results for all Platforms 2.014 1.748 1.890 1.986 1.753 1.743 2.003 2.293 1.483 1.785 1.643 1.987 1.387 1.496 1.829 1.954 1.294 1.877 1.574 2.073 2.060 1.850 1.903 1.832 2.122 2.253 1.824 1.905 Natural Period (sec) VH H H H VH VH M H VH VH VH M VH M H VH VH M M M H VH VH VH VH H VH H Exposure Category 2.43 2.24 3.08 1.77 2.77 2.80 2.57 3.36 3.29 2.22 3.12 2.26 1.70 2.07 2.03 1.94 2.28 2.37 2.28 1.56 2.59 2.17 2.34 2.21 2.32 2.22 2.14 2.19 Pushover Intact RSR Copyright © 2005 by ASME 2776 2626 2841 6327 1653 2419 1930 7436 2300 2045 2288 2384 2738 203 2698 2958 987 1882 1570 5276 3979 2598 2542 2142 3300 4866 3500 3598 Deck Weight (MT)