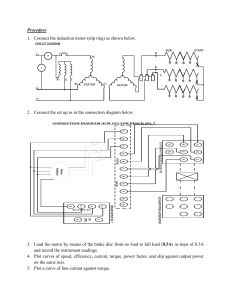

INDUCTION MACHINE Introduction Apparatus The 3-phase induction motor, directly connected to the electrical supply network is by far the most widely used, albeit least flexible, drive system used in industry. AC machine windings are usually simpler than dc machine windings. In this motor the 3 stator phase windings are electrically separate and have all ends brought out (6 terminals). See figure 1. * Induction motor, slip- ring type, 1.5kW, 380V, 4 pole. * Torque dynamometer, TERCO swinging frame dc machine, 2kW. * Load Resistor, 220V, 3kW, 20Ω. * Ammeter(MI), 6A. * Voltmeter(MI), 500V. * Centre zero ammeter(MC), unscaled ±5A. * Frequency meter, Frahm vibrating reed type. * WARNING * DO NOT START/STOP THE INDUCTION MOTOR ON LOAD Procedure Figure 1 As the stator winding currents sequentially rise to their maximae, the stator is never de-energised. Rather, the position where maximum current is found moves around the periphery. Current density may be viewed as a moving wave. The resultant pattern of flux also rotates. This flux also links the rotor circuits and induces voltages and currents therein, hence INDUCTION motor. In a majority of machines(squirrel cage) the rotor coils are shorted on themselves and no rotor terminals are needed. In this machine, the internally star connected rotor windings are brought out through sliprings and brushes to 3 terminals. A main purpose in bringing out the rotor circuits is to allow addition of resistance in order to reduce the level of induced current, but this is not for investigation today. Instead the rotor will be shorted directly. 1 CHECK RATINGS The rating plate lists leading data for the machine. Copy out this data. From it and knowing that the local line voltage is 380V, decide whether the stator windings must be connected in star or in delta. An incorrect decision would in practice lead to the destruction of the motor from overheating. 2 TESTS WITH MACHINE DISCONNECTED FROM TORQUE DYNAMOMETER Decouple the machine from the dynamometer. Make sure it is clamped to the bedplate. 2.1 Direct on-line start at rated voltage. This is the normal starting procedure for induction machines. It is a bit severe on a slip-ring induction machine designed to see rotor resistance during starting. Make only one such start. Use the fixed three phase supply. Short the rotor terminals. Make a clear diagram of your proposed connections, which should incorporate one ammeter. Represent the motor as in figure 1. Have the diagram checked by your demonstrator before switching on. Take care to observe the correct phase sequence to the motor. Use the standard RED/YELLOW/BLUE colour code for the 3 phases. Note the surge of starting current and rapid acceleration. Reference Slemon and Straughan, "Electric Machines", section 5 Objectives 1. Familiarisation. 2. Measurement of torque speed characteristic. 2.2 Measurement of no-load currents. In order to allow adjustment of the voltage to rated or other target values, and also to reduce the starting current, the non-isolated variable 3-phase supply is used for all the remaining tests. Make a new diagram of connections and have it checked. Start the M8.1 motor by smoothly increasing the voltage. Always reset the variac to zero before switching out. Bear in mind however, that in practice induction motors are not started in this way. Measure the average stator current from the bench supply ammeters (average of 3) at rated voltage. This is the induction motor "no load current". Record what fraction it is of the rated current. 2.3 Measurement of no-load slip frequency and no-load speed. For any p-pole ac machine ωs = ωm p + ωr 2 where ωs is the system electrical angular velocity, ie 50 Hz expressed in rads/S, ωm is the mechanical speed of rotation, ωr is the slip angular velocity, this is the angular velocity of the currents induced in the rotor. Slip is often expressed as a fraction of system frequency and slip s is defined as: s = ωr ωs Hence ωm 2 = (1- s) ω s p when slip is zero the synchronous mechanical speed ωsm is ω sm = ω s 2 p ie the mechanical speed is synchronised with the system speed. To measure the slip connect the centre zero dc ammeter to measure the current in one rotor phase, the rotor still "seeing" a 3-phase short circuit. By timing its slow movement with a watch over say, 30 seconds , measure the electrical frequency. This is the slip frequency ωr which will be very low indeed at no-load and rated voltage. Measure the slip frequency at 380V and 190V. What is the no-load slip of this machine at rated voltage? Compute the mechanical speed from the slip at 380V and 190V given that the synchronous mechanical speed for a 4-pole machine is 50/2 rev/S or 1500 rpm. 2.4 Tests with open circuit rotor. Remove the short circuit from the rotor. Will the machine turn? (Two of the test machines will even though there is no current in the rotor windings. Hysteresis in the rotor iron causes the flux to lag behind the rotating stator mmf giving a small torque. See Slemon, p.501, "Hysteresis motors".) Now connect the frequency meter and voltmeter across rotor terminals. Bring the voltage as high as possible without causing the shaft to turn. Note the rotor frequency and see how it varies when the shaft is turned by hand, with or against the direction of the rotating flux. With the rotor locked, the induction machine acts like a transformer. The stator windings may be seen as the primary, the rotor windings as the secondary. The transformation ratio is the ratio of stator to rotor voltage. Measure it. Does the transformation ratio accord with the rating-plate data? 2.5 Single Phase Excitation With the rotor open-circuited excite one phase winding only of the stator at 220V (phase-neutral!). This will produce a pulsating rather than a rotating mmf. Measure the rotor voltage and note its dependence on angular position. You should see 4 maximae per revolution. This is a way of confirming that the machine is wound 4-pole, and also allows you to think of the windings as having angle dependent mutual inductance. 3 TORQUE SPEED CHARACTERISTIC (see curve in Slemon p.399) Couple the motor to the torque dynamometer and reclamp. Check that the couplings are not in metallic contact and that the shafts are aligned (misalignment causes wear and vibration). Check that the spring balance is zeroed. Connect the shunt regulator for the dynamometer field supply. Connect the 3 kW load to the armature. Replace the short circuit of the induction motor rotor, retaining the centre-zero dc ammeter. (cf. figure 2) Draw a complete circuit diagram of this circuit, connect up and have it checked by your demonstrator. P = Tω m where P = Mechanical power and T = Torque. First run up the machine with the dynamometer field not excited. Is the rotation direction correct as indicated by the arrow on the machine? How would you reverse it? Run the motor in the reverse direction. The dynamometer frictional torque is of course a load on the machine. Do not use this as the no-load reading. Calculate the rated torque at rated speed from the nameplate data. Have this confirmed by your demonstrator. Ensure that the machine is rotating in the correct direction. Take readings of torque versus ω from zero to rated torque by adjusting the dynamometer field current, calculating ω from s as in 2.3. M8.2 Figure 2 To measure the remainder of the torque speed curve without exceeding the machine ratings the test must be conducted at reduced voltage. The curve has the same profile at this voltage but must be scaled by a factor of 2 the square of the voltage ratio (380/Vs) . This allows the torque speed characteristic to be measured in the range 0 to rated rpm. Remove the dc ammeter from the rotor circuit for these readings and replace the ammeter with a short circuit. Set and maintain the supply voltage (LINE) at Stator line voltage (V) Torque maintain at 380V 0 . . . (Nm) 100 volts. Take readings of torque and speed as the dynamometer load is increased at regular speed intervals down to 500 rpm. As the load is increased the induction motor stator currents rise rapidly. Do not exceed 150% rated current. Do not maintain overloads unnecessarily. Remember, torque measurements taken at reduced voltage must be scaled as shown in the table below. Tidy up all leads and switch off bench supply and instruments after experiment. Adjusted torque (Nm) Speed Tactual compute from slip ωm =(1-s)ωsm (rpm) Trated maintain at 100V . . . . . 2 Tactual(380/100) speed from rpm meter M8.3 Requirements for report Questions for discussion * No theory required except as requested for discussion. Concise answers are required to the questions in the discussion. * Present neat clear diagrams of all circuits used. 1. Explain what you understand by rotor slip. What is the value of s at standstill and at synchronous mechanical speed? Write down the equation relating synchronous speed to the electrical supply frequency and the number of poles. * Present all calculations and results clearly. * For the discussion it is sufficient to answer the questions below. 2. Comment on the torque speed characteristic. Indicate the full load torque, starting torque and synchronous mechanical speed. 3. Why does excitation of just one sinusoidally distributed stator winding fail to get the machine to rotate? What in principle, is the minimum number of stator phases necessary to get motor action? M8.4