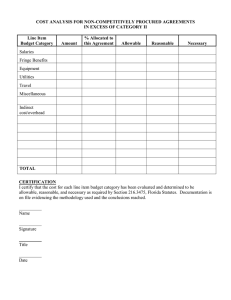

LINDE STANDARD S Gen neral tolerances LS 103-10 1 Part P 3 Page 1 of o 9 Contentts 1 2 3 3.1 3.2 3.3 3.4 4 4.1 4.2 4.3 4.4 4.5 4.6 4.7 4.8 5 6 6.1 6.2 6.3 6.4 Scope S .................................................................2 Normative N re eferences ........................................2 Machining M ...........................................................2 Allowable A de eviations for linear dimens sions except e diame eters ...............................................2 Allowable A de eviations for diameters d ...................3 Angular A dime ensions ...........................................3 Allowable A de eviations for not-standard n ized vessel v flange es....................................................4 Noncutting N w work ................................................5 Allowable A de eviations for linear dimens sions and a diameterrs (measured d along the circumferenc c ce)...................................................5 Allowable A de eviations for angular a dime ensions ....5 Admissible A o out-of-roundn ness for vess sels ..........5 Allowable A mi salignment of o plate edge es of vessels v ...............................................................6 Allowable A de eviation from axes and straightness s ........................................................6 Allowable A de eviations for shell s diamete ers of heat h exchang gers with rem movable bundles.........6 Allowable A de eviations for bundle b length hs of heat h exchang gers with stra aight tubes .................6 Allowable A de eviations for different d components c and connecttions ...........................6 Sketches S .............................................................8 Tolerances T fo or pressure vessels v acco ording to t ASME BPV V Code Secttion VIII/1 an nd Section S VIII/2 2 .....................................................9 Roundness R o of a shell at internal press sure.........9 Roundness R o of a shell at external e pres ssure........9 Dished D head s at internal pressure ....................9 Dished D head s at externall pressure ...................9 Remarks o on the curren nt issue: Revision: pa ara.1 Scope Previous isssues: 02.2011 Responsible e departmen nt(s) for the te echnical con tent: MFCP Confidentiality class 2 in n accordance e with LS 104 4-03: For pro oject specific c use only 02.201 11 LEHQ / MFCPD/ Hieringe er LE-HQ//PAP/Hiering ger LEHQ Q / MFCQ/ Ca appel LEHQ Q / ENCS 1/ Lerzer L LE-HQ Q/ PAQ/Capp pel 07.201 10 PAP/Hieringer PAQ/C Cappel X 0 03 09.201 11 X 0 02 X 0 01 Status Isssue Date e Prepared d Refer to prottection notice ISO 16016. Checke ed LEHQ / ENM M1-S / Thom mas LE-HQ/TAW W-N/Thomas TAW-N/Thomas Approved File nname: LS S 103-10.T3 (E EN) e AG, Enginee ering Division Linde 1 Issue 03/09.2011 LS 103-100 Part 3 Page 2 of o 9 Scope This Linde S Standard (LS S) specifies the allowable e deviations (during ( fabric cation) from a nominal dimension givven in a drawing g without individual tolera ance. This standa ard shall not be b applied in n those casess where tolerances are prescribed p byy other stand dards (e.g. fo or holes in tube semi-finishe ed materials, forgings, ca astings, boreh esheets etc.). 2 Normative references This LS con ntains undate ed references s to incorporrate provision ns of other publications. T The normativ ve reference es are cited at the respectivve place in th he text and tthe publicatio ons are listed d below. Issuues valid at th he effective date of conttract shall ap pply. AD2000 HP P1 AD2000 HP P5/1 ASME Sec. VIII/1 ASME Sec. VIII/2 ISO 2768-1 ISO 2768-2 EN ISO 581 17 EN ISO 100 042 EN ISO 139 920 EN 13445-4 4 DIN 28030--2 3 Design and cons struction Manufacture and d testing of jo oints – Principles of weldiing practice Boile er and pressu ure vessel co ode – Rules for constructtion of presssure vessels Boile er and pressu ure vessel co ode – Rules for constructtion of presssure vessels – Alternative e ruless Gene eral toleranc ces – Part 1: Tolerances for f linear and d angular dim mensions witthout individu ual tolerrance indications Gene eral toleranc ces – Part 2: Geometricall tolerances for f features w without individual tolerrances indica ations Weld ding – Fusion n-welded join nts in steel, nickel, n titaniu um and their alloys (beam m welding exclu uded) – Quality levels forr imperfections Weld ding – Arc-welded joints iin aluminium m and its alloy ys – Quality llevels for imperfections Weld ding – Generral tolerancess for welded construction ns – Dimensiions for lengths and anglles, Shap pe and positiion Unfirred pressure e vessels – P Part 4: Fabric cation Flanged joints for vessels and d apparatus – Part 2: Tolerances on flange dimen nsions M Machining e.g. turning, drilling, plan ning, milling, broaching, e etc. 3.1 Allowable de eviations for linear diimensions except dia ameters (e.g. lengthss, widths, he eights, thicknesses, offsett dimensions s, center-to-c center distan ces and distances betwe een axes, radii, etc.) Allowable deviations acccording to DIN ISO 2768 8 - m (excerp pt)): Table e 1: Allowab ble deviation ns for linearr dimensions s (except di ameters) up to 6 ab bove 6 to o 30 0 0,1 0,2 Allowab ble deviationss for nomina al dimension range ve above above above ab bove abov 120 400 1000 30 20 000 to to to to to 400 1000 2000 120 000 40 0,3 3 Refer to prottection notice ISO 16016. 0,5 0,8 1,2 2 abovve 40000 to 80000 3 File nname: Dim. No. (1) LS S 103-10.T3 (E EN) e AG, Enginee ering Division Linde 3.2 Issue 03/09.2011 LS 103-100 Part 3 Page 3 of o 9 Allowable de eviations for diamete ers A difference e is made be etween inside e diameter (h hole) and outtside diamete er (shaft). Inside diameters are performed with h plus toleran nce (+) only and a outside diameters d wiith minus tole erance (-) on nly. As the plus tolerances (+) are correlated to the h hole and the minus tolera ances to the sshaft, the ran nge of tolerance iss reduced by half. Allowable deviations accc. to ISO 276 68 - m (exce erpt) see table e 2. Tab ble 2: Allow wable deviatiions for diam meters up to 6 Outside diametter - 0,1 (shafts) Inside diameterr + 0,1 (holes) 3.3 Allowable A de eviations for nominal dimension rangee above a above ove above abo above above 6 3 1000 2000 30 120 0 400 to to to to o to to 30 2000 4000 400 1 20 0 1000 - 0,2 - 0,3 - 0,5 5 - 0,8 - 1,2 -2 + 0,2 + 0,3 +0,5 5 + 0,8 + 1,2 +2 Dim. No. (2) Angular dim mensions Allowable deviations accc. to ISO 276 68 -m (excerrpt): Table 3: Allowable d f angular dimensions d s deviations for Allowable deviations fo or nominal dimension ran nge (Length off the shorter leg) abo ove 50 bove 120 ab bove above 10 ab up to 10 mm to 50 mm to 1 120 mm to 400 mm 40 00 mm 1° 30' 20' 10' *) 5' *) Dim. No. (3) *) devviation of ISO O 2768-m Refer to prottection notice ISO 16016. File nname: LS S 103-10.T3 (E EN) e AG, Enginee ering Division Linde 3.4 Issue 03/09.2011 LS 103-100 Part 3 Page 4 of o 9 Allowable de eviations for not-stan ndardized vessel v flanges The allowab ble deviations are in parts s taken from DIN 28030 Part 2. Tolerrances providded with *) are a not in conformity w with DIN. d5 Type F female face d7 t2 d7 d8 Type T E male face t4 t3 d5 d6 Ty ype D with grroove t1 Type e C with tong gue A de eviations fo or flange dim mensions Table 4: Allowable Dim h1 d2 d3 d9 De esignation d1 Connecting for weldin ng neck flanges and welding flanges with cylindrica al board d2 Flange ou utside diame eter d3 Bolt circle e diameter d4 d1 d10 d4 d5 bis d8 h2 h1 d2 d3 d4 s1 s2 d1 Bolt hole diameter Diameterr for tongue and a groove orr male and female fa ace d9 Raised fa ace diameterr d10 Bore diam meter h1 Flange th hickness h2 Length th hrough hub s1 Mating th hickness 1) Nom minal dime nsional raange 300 tto 1000 from m 1000 to 44000 Allowable deviations to 22000 ±2 *) +3 *) -2 *) ±1 ±2 abovve 2000 to 11600 abovve 1600 -1 *) -2 *) to 22000 abovve 2000 300 tto 2000 from 22000 to 40000 300 tto 2000 from 22000 to 40000 too 60 from m 60 to 1150 abovve 150 too 6 from m 6 to 8 aboove 8 d5 5;d8 -0,5 -1 ±0,5 d6;d7 7 +0,5 5 +1 -3 -4 +1,5 +2,5 +2 *) +3 +4 +6 +1 +1,5 +2 Centre-to o-centre chhord distances s between tw wo ±1 2) dimeension adjacent bolt holes t1 Groove depth d -0,5 t2 Female depth d t3 Tongue height h +0,5 t4 Male heig ght 1) Th hese allowab ble deviations s shall be refferred to the actual bore diam meter. 2) Th he sum of the e successively measuredd bolt hole dis stances shalll not d deviate by more m than 1,5 5 mm from thhe sum of the e nominal dime ensions. s2 Refer to prottection notice ISO 16016. File nname: LS S 103-10.T3 (E EN) e AG, Enginee ering Division Linde 4 Issue 03/09.2011 LS 103-100 Part 3 Page 5 of o 9 Noncutting g work Noncutting w work means sheet metal forming, con nstruction off vessels, stru uctural steel etc. Vessels s within the sense of this standard are a also heat exchangerss, columns, ta anks, etc. 4.1 Allowable de eviations for linear diimensions and diame eters (meassured along the ciircumferen nce) They shall a apply to all co omponents except e that g given in Para a. 4.6, 4.7 and d 4.8 and exxcept the ass sembly dimensions for vessels with w assemb bly welds. Allowable deviations accc. to EN ISO O 13920 - B (e excerpt): Table 5: 5 Allowable e deviations for linear dimensions 4.2 above 2 to 30 above 30 to 400 above a 4 400 t to 1 1000 1 2 3 Allowa able deviatio ns for nomin nal dimension n range ove e above above above a abo above 4000 8000 100 00 2000 12000 to to to to to o 8000 12000 16000 4000 200 00 4 6 8 10 aboove 160000 to 200000 e above 20000 0 14 16 6 12 Dim. No. (4) Allowable de eviations for angularr dimension ns They shall a apply to all co omponents expect e that sspecified in Para. P 3.7. Allowable deviations accc. to EN ISO O 13920 - B (e excerpt): Table 6: Allowable d f angular dimensions d s deviations for Allowa able deviation ns for nominal dimension n range (Length off the shorter leg) above abovve 400 to 400 mm 000 mm 1000mm m to 10 45' 4 4.3 30' Dim. No. 20' (5) Admissible out-of-roun ndness forr vessels Table T 7: Ou t-of-roundness for vess sels Out--of-roundnes ss for vessel diameters e above a 500 above 1800 0 above 20 000 above 33000 above to 1800 mm to 2000 mm m to 3000 mm m to 40000 mm 4000 mm up to 500 0 mm Vessel g general 0,5 % 1% Columns w with trays Column ns with Linde-pa ackings 0,5 % 0,5 % 0,4 % 0,33 % u 2 ( Dmax Dmin) Dmax Dmin 0,,25 % (6 6) 1% q For ovality tthe following formula acc cording to AD D2000Merkblatt HP1 shall app ply: Out-of-roundness m. Dim No o. 1000 [%] For flattenin ng the followiing formula shall s apply: Out-of-roundness u 4q 100 Da Refer to prottection notice ISO 16016. %] [% Da File nname: LS S 103-10.T3 (E EN) e AG, Enginee ering Division Linde 4.4 Issue 03/09.2011 LS 103-100 Part 3 Page 6 of o 9 Allowable misalignmen m nt of plate edges of vessels v For the allow wable misalignment of pllate edges A AD-Merkblatt HP 5/1 and DIN 8563 Paart 3 shall ap pply. 4.5 Allowable de eviation fro om axes an nd straighttness Table 8: Allowable A de eviation from m axes and straightnesss Dim. No. 1mm pe er 1m length Vesse els Columns wiith trays 0,5mm per p 1m length Colu umns with Linde packing 4.6 D ≤ 1800 0,5mm/m 1800 < D ≤ 4000 1 mm/m D > 4000 2 mm/m m (7) eviations for shell dia ameters off heat exchangers witth removab ble bundles s Allowable de The diamete ers are meassured directly y (not calcula ated from the e circumference). Table 9: Allowablle deviations for shell diameters d Allowable de eviations for shell outside e diiameters above 120 above 1000 abovve 315 to 315 5 to 1 1000 +2 2 4.7 +4 +3 Dim. No. (8) Allowable de eviations for bundle llengths of heat excha angers with h straight tubes t Table 10: Allowab ble deviation ns for bundle lengths Bu undle length 4.8 Allowa able deviations Dim. D No. N 6mm (9) Allowable de eviations for differen t compone ents and co onnectionss Table 11 1: Allowable e deviations s for nozzle dimensions d s Deviationss from the position on the circumfere ence as a fun nction of vess sel Nozzle incclination to ve essel wall Positioning g of bolt hole es Distance o of nozzles forr level gauge es and alignment of flange faccings Refer to prottection notice ISO 16016. 800 < Ø 2000 mm m Ø > 2000 0 mm Ø 800 mm m 30' 45' 20' 0 0,5 degree in n each directiion max. 5m m 1,5 mm 1 mm 1 File nname: Dim m. No o. (10 0) (11 1) (12 2) (31 1) LS S 103-10.T3 (E EN) e AG, Enginee ering Division Linde Issue 03/09.2011 LS 103-100 Part 3 Page 7 of o 9 Table 12: 1 Allowable deviations s for vessell skirt/suppo ort mating d dimensions Dim m. No o. Bottom edg ge of supporrting skirt or saddle s to reference lline Bottom edg ge support bra acket to referrence line (bottom) Bottom edg ge support bra acket to ref. liine (top) Distances between sup pporting sadd dles Bolt holes centre-to-centre distance es (also from position on circumferenc c ce) Deviationss from positio on of supportting brackets on circumfere ence as a fun nction of vessel Ø 800 mm m Deviationss of bottom edges from ho orizontal -10 - mm (13 3) +10 + mm (14 4) -10 - mm 3 mm (14a a) (15 5) 3 mm (16 6) 800 < Ø 2000 m mm 00 mm Ø > 200 45' 30' 20 0' 1° 1 in each dirrection, but w within (13) (17 7) (18 8) T Table 13: Allowable dev viations for dimensions d of column ttrays Dim m. No o. Inclination o of the tray su upport rings and/or a trays rresp. to horizonta al Height of inlet and down n comer weirr Distance be etween down n comer and tray 0,2% of the diameterr, max 3mm (19 9) 1 mm +4 mm -2 mm Minimum m distance sam me as (21)) (20 0) Distance be etween down n comer and inlet weir Distance be etween top surface of tray y support rin gs 2 mm (tray distancce) -2 mm Height of do own comer Tray diametter and width h 2 mm Distance be etween stud bolts or bolt holes 3 mm Distance fro om column centre line to inside edge of 2 mm down come er support Maximum a allowable devviation for the e down come er + 4 mm support from m the vertica al (to the tray) Sagging of tthe trays 1 mm/m The tray sup pport rings shall s have a flat f top surfacce, in order to t ensure a good g supportt of the tray plates. p The deviatio on from the flatness f of the supporting g rings shall not n be more than 0,8 mm m across a distance of 300 mm. Refer to prottection notice ISO 16016. File nname: (21 1) (22 2) (23 3) (24 4) (25 5) (26 6) (27 7) (28 8) (29 9) (30 0) LS S 103-10.T3 (E EN) e AG, Enginee ering Division Linde 5 Issue 03/09.2011 LS 103-100 Part 3 Page 8 of o 9 Sketches The sketche es shall serve as explanatio on and betterr finding only of o the allowab ble dimensionnal deviations s. They do no ot give any info ormation on th he extent of dimensional d cchecks during g inspection. (The circled n umbers are referring r to the e particular tab ble number). (7) ( A-B B Nozzle es on dish hed heads (19) (7) (17) Ø5 (29) (20) (4) (11) (2 23) (28) (20) (26) (27) (21) (10) (7) (4) (4) (22) (4) (16) (25) (16) (24 4) (30 0) ( (18) 1 (31) (4) R Reference (14a) line (22) (14 4) (20) (21) (4) (6) Reference lin ne X (4) (13) (12) (1 18) Ø Ø3 (4) ( (4) (4) (4) (6) (6) (8) (13) (15) (4) (4) (4) (4) (2) (18) (1) (16) (9) Refer to prottection notice ISO 16016. File nname: LS S 103-10.T3 (E EN) e AG, Enginee ering Division Linde 6 Issue 03/09.2011 LS 103-100 Part 3 Page 9 of o 9 To olerances s for press sure vesse els accord ding to AS SME BPV C Code Secttion VIII/1 an nd Section n VIII/2 These tolera ances shall apply a to man nufacture accc. to ASME in n addition to or in lieu of tthe tolerance es given in Para.2 to 4.. 6.1 Roundness of a shell at a internal pressure Requiremen nts according g to Section VIII/1 Para. U UG-80 (a) re espectively Section S VIII/2 Para. 4.3.2:: D min m d d D max Opening with nominal d r e t e m a i d e d i s n i D m in 2d d D max lD a nr i e mt oe nm a hi t id w e ld l i e s hn Si Cross sectio on X-X: Dmaax Dmin 0,01D 0,02 e range of 2dd) 2 d (shall apply within the Cross sectio on Y-Y: Dmaax Dmin 0,01D 6.2 Roundness of a shell at a external pressure The allowab ble deviations from the ro oundness of a shell at external pressu ure shall be iin conformity y with Section VIII/1 Para. UG--80 (b) respe ectively Sect ion VIII/2 Para. 4.4.4. 6.3 Dished head ds at intern nal pressurre The surface es of dished heads shall not n deviate ffrom the spec cified shape by more thaan: - outside of the specified d shape: 0,0125 0 D 0625D he specified shape: 0,00 - inside of th - out-of-roun ndness of the e cylindrical skirt: Dmax Dmin 0,01 0 D The knuckle e radius r sha all not be les ss than that sspecified. Such deviattions shall be e measured perpendicula ar to the spec cified shape and shall noot be abrupt. (Section VIIII/1 Para. UG G-81(a) respe ectively Secttion VIII/2 Pa ara. 4.3.2.2). 6.4 Dished head ds at extern nal pressurre They shall in addition fulfil the requirrements for sspheres acc. to Section VIII/1 V Para. U UG-81(b). Th herefore shall be valid: L / D0 0,5 . Cyl. skirt e p a h s d e i f i c e p S D ︵ Refer to prottection notice ISO 16016. n o 0,00625D i s n e m i d l 5D a 0 ,0 1 2 n i m o n r ︶ File nname: LS S 103-10.T3 (E EN)