IIW Collection Recommendations for Fatigue Design of Welded Joints and Components

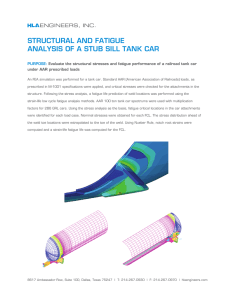

advertisement