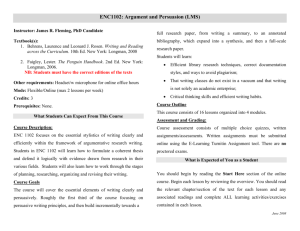

ATTACHMENT-1 RAILROAD CROSSING DESIGN CALCULATIONS API Recommended Practice 1102 Pipe, Operational, Installation & Site Characteristics Steel Grade Specified Minimum Yield Strength Values Units Gr. X60 SMYS 60,000.00 psi Es 2.90E+07 psi vs 0.30 αT 6.50E-06 Design Factor for Location Class Design Factor for Effective Stress Outside Diameter F1 0.72 F2 0.90 D 12 inches Nominal Wall Thickness Depth tw 0.375 inches H 67 inches Young's Modulus Poisson's Ratio Coefficient of Thermal Expansion Bored Type per oF Trenching Bored Diameter Bd Maximum Allowable Operating Pressure Temperature at time of Installation P 14.70 T1 81.00 o T2 196.00 o T 1.00 Operating Temperature Max Temperature Derating Factor Spec No. & Pipe Class 12 inches (API 1102 Para. 4.7.2.1) psig F F (B31.8 Table 841.1.8-1) API 5L - Electric Welded Longitudinal Joint Factor E Soil Type 1.00 (B31.8 Table 841.1.7-1) Loose Sands and Gravels Modulus of Soil Reaction Resilient Modulus Soil Unit Weight Axle load per SAES-L-460 Section 4 Type of Longitudinal Weld Fatigue Endurance Limit of Girth Weld E' 500.00 psi (API 1102 Table A-1) Er 10,000.00 psi (API 1102 Table A-2) γ 0.069 Ib/in3 E-80 P (Ibs) : E-80 ERW - Electric-Resistance-Welded F. E. L. of Longitudinal Weld SFG 12,000.00 psi (API 1102 Table 3) SFL 23,000.00 psi (API 1102 Table 3) Check Allowable Barlow Stresses [S Hi (Barlow) = pD ⁄ 2t w ] ≤ F × E × T × SMYS SHi Actual Barlow Stress Allowable Barlow Stress SMYS x F 1 (API 1102 Equation 8a/8b) 235.20 psi 43,200.00 psi Actual Barlow Stress < Allowable Stress SAFE Stress Due to Earth Load The circumferential stress at the pipeline invert caused by earth load, SHe, is determined as follows S He = K He B e E e γD KHe Be γ Stiffness factor for circumferential stress from earth load Burial factor for earth load Excavation factor for earth load Soil unit weight D Pipe outside diameter Ee (API 1102 Equation 1) Earth Load stiffness Factor, KHe, accounts for the interaction between the soil and the pipe tw/D 0.03 Modulus of Soil Reaction Stiffness Factor E' KHe 500.00 psi 1,449.00 Burial Factor, Be H/Bd (API 1102 Figure 3) 5.58 Soil Type A Be 1.13 Excavation Factor (1 as Existing pipeline) Ee 0.83 Circumferential Stress Due to Earth Load SHe 1,125.27 Burial Factor (API 1102 Figure 4) Excavation Factor, Ee Bd/D 1.00 (API 1102 Figure 5) psi Stresses due to Live Loads Surface Live Loads, due to the rail load applied at the surface of the crossing. Impact Factor Applied Design Surface Pressure FI 1.75 w 13.900 (API 1102 Figure 7) psi (API 1102 Para 4.7.2.2.1) Railroad Cyclic Stresses Cyclic Circumferential Stresses The cyclic circumferential stress due to rail load, ∆SHr may be calculated from the following ∆S Hr = K Hr G Hr N H F i w KHr GHr (API 1102 Equation 3) NH Fi Railroad stiffness factor for cyclic circumferential stress Railroad geometry factor for cyclic circumferential stress Railroad single or double track factor for cyclic circumferential stress Impact factor w Applied design surface pressure Railroad stiffness factor, KHr tw/D Resilient Soil Modulus Stiffness Factor 0.03 Er KHr 10,000.00 psi 310.00 (API 1102 Figure 8) Railroad geometry factor, GHr Outside Diameter Depth Geometry Factor D 12.000 inches H 67.000 inches GHr Railroad single or double track factor, NH NH (1.00 for single track) Circumferential Stress Due to Rail Load SHr 1.000 (API 1102 Figure 9) 1.09 (API 1102 Figure10) 8,219.42 psi Cyclic Longitudinal Stresses The cyclic longitudinal stress due to rail load, ∆SLr may be calculated from the following ∆S Lr = K Lr G Lr N L F i w KLr GLr (API 1102 Equation 4) Railroad stiffness factor for cyclic longitudinal stress NL Fi Railroad geometry factor for cyclic longitudinal stress Railroad single or double track factor for cyclic longitudinal stress Impact factor w Applied design surface pressure Railroad stiffness factor, KLr tw/D 0.031 Resilient Modulus Stiffness Factor Er 10,000.000 KLr 420.00 psi (API 1102 Figure 11) Railroad geometry factor, GLr Outside Diameter Depth Geometry Factor D 12.00 inches H 67 inches GLr 1.00 (API 1102 Figure 12) 1.00 (API 1102 Figure13) Railroad single or double track factor, NL NL (1.00 for single track) SLr Longitudinal Stress Due to Rail Load 10,216.50 psi Stresses due to Internal Load The circumferential stress due to internal pressure, SHi may be calculated from the following; S Hi = p(D – t w ) ⁄ 2t w p Internal pressure taken as MAOP or MOP D Tw Pipe Outside Diameter Wall thickness (API 1102 Equation 7) Circumferential stress due to internal pressure, SHi SHi 227.850 psi Check for allowable Stresses S 1 = S He + ∆S H + S Hi Maximum Circumferential Stress S1 Maximum Circumferential Stress 9,572.53 (API 1102 Equation 9) psi S 2 = ∆S L – E s αT(T 2 – T 1 ) + ν s (S He + S Hi ) Maximum Longitudinal Stress S2 Maximum Longitudinal Stress -11,055.065 S 3 = –p = –MAOP or –MOP Maximum Radial Stress S3 S = 1 -14.700 [(S −S (API 1102 Equation 10) psi (API 1102 Equation 11) psi )2 + (S −S )2 + (S −S )2 ] eff 2 2 3 3 1 2 1 (API 1102 Equation 12) Total Effective Stress The check against the yielding of the pipeline may be accomplished by assuring that the total effective stress is less than 90% SMYS per combined stress. Total Effective Stress Allowable Effective Stress Seff 17,878.79 psi SMYS x F 2 54,000.00 psi S eff ≤ SMYS × F Actual Effective Stress < Allowable Stress (API 1102 Equation 13) SAFE Check for fatigue Girth Welds The cyclic stress that must be checked for potential fatigue in a girth weld located beneath a railroad crossing is the longitudinal stress due to live load. Girth Welds RF SLr / NL 4,903.92 psi F1 x SFG 8,640.00 psi RF RF 0.48 (API 1102 Figure18-A/18-B) Longitudinal stress reduction factor for fatigue. The general form of the design check against girth weld fatigue is given by the following R F ∆S Lr / N L ≤ S FG × F (API 1102 Equation 15) Longitudinal Stress < Fatigue Endurance Limit SAFE Longitudinal Welds The cyclic stress that must be checked for potential fatigue in a longitudinal weld located beneath a railroad crossing is the circumferential stress due to live load. Longitudinal Welds SHr / NH 7,540.75 psi F1 x SFL 8,640.00 psi The general form of the design check against longitudinal weld fatigue is given by the following ∆S Hr / N H ≤ S FL × F Circumferential Stress < Fatigue Endurance Limit (API 1102 Equation 19) SAFE