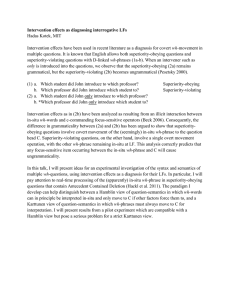

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/237711395 Interpretation of in-situ concrete strength test results Article · January 2009 CITATIONS READS 5 2,274 4 authors, including: Marios Soutsos Adrian E. Long Queen's University Belfast Queen's University Belfast 101 PUBLICATIONS 1,803 CITATIONS 101 PUBLICATIONS 1,773 CITATIONS SEE PROFILE SEE PROFILE Some of the authors of this publication are also working on these related projects: LowCoPreCon View project Hot weather concreting: Early age behaviour and cracking risk of concretes with GGBS View project All content following this page was uploaded by Adrian E. Long on 15 September 2014. The user has requested enhancement of the downloaded file. NDTCE’09, Non-Destructive Testing in Civil Engineering Nantes, France, June 30th – July 3rd, 2009 Interpretation of in-situ concrete strength test results Marios SOUTSOS1, John BUNGEY1, Adrian LONG2 and Geoff TICKELL1 1 Department of Engineering, The University of Liverpool, UK School of Planning, Architecture and Civil Engineering, Queen’s University Belfast, UK 2 Abstract A full scale insitu reinforced concrete building frame built in a laboratory provided an opportunity to assess the use of the in-situ pull-out test on a systematic basis during construction. Interpretation of strength correlations should take into account the uncertainties that exist and therefore should be made by the use of standard statistical procedures. Two procedures recently adopted by BS EN 13791:2007 “Assessment of in-situ compressive strength in structures and precast concrete components” for estimating the in-situ characteristic strength of a test region from in-situ test results have been examined. Both procedures account for the uncertainty of the strength correlation by requiring either the lower 95% confidence limit curve or a curve shifted downwards by a margin to be used. Overly conservative estimates of the in-situ characteristic strength are found to result. Résumé Le test d’arrachement fut utilisé systématiquement pendant la construction d’un bâtiment poteaux/poutres en béton armé in-situ de taille réelle. L’interprétation des corrélations de force doit prendre en compte les incertitudes qui existent et, de ce fait, doit être faite au travers de l’usage de procédures statistiques standardisées. Deux procédures récemment adoptées par le BS EN 13791 :2007, pour estimer la force caractéristique in-situ, ont été examinées mais ont donné des estimations sécuritaires. Keywords In-situ non-destructive tests, pullout (Lok) tests, strength correlation, statistical analysis. 1 Introduction An experimental full scale seven-storey in-situ advanced reinforced concrete building frame was constructed in a large airship hangar at Cardington in the UK, operated as a laboratory by Building Research Establishment Ltd (BRE). This encompassed a range of different mixes, including high strength concretes, and advanced construction techniques. It provided a focus for a number of construction-phase research investigations involving several Universities. These included the project reported in this paper, which was concerned with the capabilities and practicality of use on site of the Lok test, the Danish version of the pull-out test which conforms to ASTM C900 [1]. BS EN 13791:2007 [2] has been written mainly for assessment of in-situ compressive strength of existing structures. Nonetheless, the methodology described was adapted as much as possible so that it could be used for estimating the in-situ characteristic strength during construction. The requirement of at least fifteen in-situ tests at a particular location is unrealistic to expect if this is to be carried out during construction. The analysis of only a limited number of in-situ tests is presented herein but this represents the situation commonly met during construction. NDTCE’09, Non-Destructive Testing in Civil Engineering Nantes, France, June 30th – July 3rd, 2009 2 Experimental Programme It was important to balance the ‘research’ requirements with the practical and commercial requirements of the contractor to complete the work with a minimum of delay and disruption. One consequence was that limitations were placed upon the number of tests performed. Pull-out testing, involving preplanned inserts cast in the concrete, is particularly suitable for direct in-situ measurements of early age strength utilising cut-out panels in shutters where appropriate. One key feature is the good sensitivity of correlations to compressive strength and the relative insensitivity to mix variables such as aggregate type. Six different mixes were covered in this study which could be grouped into two strength classes with minimum 28-day characteristic cube strengths of 37 and 85 MPa. The principal variables for the concretes covered by this study were: concrete grade (C37N-10 and C37N11 with different cement contents and C85), chemical admixtures (plasticiser and superplasticiser) and aggregate type (gravel and limestone). Tests were performed at different levels of the structure, on columns at different heights (top, middle and bottom), and on slabs, both adjacent to columns and in mid bay (top and bottom). In-situ tests using the Lok-test, were undertaken at 1 day (or as soon as practicable), 3 days, 7 days and 28 days. Results for corresponding air cured 150mm cubes were also made available which permitted the development of Lok-test strength correlations. The detailed results of this comprehensive study can be found elsewhere [3]. The establishment of good correlations between a measured property and the strength is a key to successful in-situ testing, and for normal practice these should ideally be prepared in advance of the construction starting date. In this case, however, bearing in mind the number of mixes involved, the short time-scale for preparatory work, the BRE intention to set up a laboratory on site, and the need to avoid duplication of effort, correlation specimens were cast on-site during concreting of the structure. In each case these comprised four 200mm timber moulded cubes with four Lok-inserts attached to the vertical sides together with cubes cast using standard 150mm steel moulds which were subsequently tested by a commercial test house for compressive strength. All the specimens were air-cured adjacent to the building. The strength correlations were therefore determined using 150mm cubes rather than cores as is the requirement of BS EN 13791:2007 [2]. 3 Results and Discussion To make an in place strength estimation it is necessary to have a known relationship between the result of the in-place test and the strength of the concrete for the particular mix concerned. The usual practice is to treat the average values of the replicate air-cured cube compressive strength and in-place test results at each strength level as one data pair. These are plotted using the in-place test value as the independent value (or X variable) and the compressive strength as the dependent value (or Y variable). Regression analysis is performed to obtain the best-fit estimate of the strength relationship, see Figure 1. The envelope of the best fit lines, allowing for possible errors in intercept and slope, determined using the least squares method, indicated that the general correlation for all mixes would be encompassed by these [4]. The possible errors in intercept and slope values is affected by the number of sets of data which will also affect the confidence limits of any strength predictions made with these correlations. In order to get a wide range of values, all the data points from the different mixes were grouped together. The equation of the combined strength correlation, based on air-cured cube compressive strengths, was found to be: Measured Cube Compressive Strength (MPa) NDTCE’09, Non-Destructive Testing in Civil Engineering Nantes, France, June 30th – July 3rd, 2009 110 Correlation for ALL mixes (Linear Regression) C85MS C85MK C37N-10 C37N-11 C37F C37P 100 90 80 Manufacturer's Recommended Correlation 70 60 C37N-10 C85MS 50 40 C37F 30 C37N-11 C85MK 20 C37P 10 MS is for microsilica MK is for metakaolin F is for superplasiticizer P is for plasticizer 0 0 10 20 30 40 50 60 70 Measured Lok Force (kN) Figure 1: Lok test strength correlations [3] f c = −4.71 + 1.59 Fu (1) where fc is the mean cube compressive strength (N/mm2) and Fu is the pull-out force (kN). This equation was used for all in-situ strength predictions and this was justified since BS EN 13791:2007 [2] allows “well-established relationships” despite recommending the linear relationship: f F = 1.33(F − 10) 10 ≤ F ≤ 60 (2) where fF is the in-situ core (N/mm2) and F is the pull-out force (kN). This is very close to the Manufacturer’s Correlation [5] which has been derived from a wide range of concrete mixes made with gravel, limestone and granite aggregates. The wisdom of assuming that all the data obtained from the different mixes belong to one population seems to be justified by the observed similarity to the Manufacturer’s recommended correlation. BS EN 13791:2007 [2] requires “the standard error of estimate” to be computed and “the confidence limits for the best fit line” to be determined. The 95% confidence limit, since none other was specified, has been used and this is shown in Figure 2. Grouping all the mixes together resulted in twenty-two data sets and this undoubtedly had the effect of narrowing the 95% confidence limit interval. The mean in-situ compressive strength of n test results, fm(n),is, estimated using the lower 95% confidence limit curve was then used to estimate the in-situ characteristic strength of the test region, fck,is, from the following equation: (3) f ck ,is = f m (n ),is - k 1s where s is the standard deviation of the test results or 3.0 N/mm2, whichever is the highest value, and k1 is a coefficient dependent on the number of in-situ tests. The value of k1 is given as 1.48 in BS EN 13791:2007 [2] since it assumes/requires fifteen test locations. Values of k1 given for less than fifteen tests only go down to nine tests and these are plotted in Figure 3. These appear to be slightly different from values published for one-sided tolerance factors for ten percentile strengths at 75% confidence. Nonetheless, since the number of in-situ tests was either 3 or 4, values of k1 had to be obtained from tables given in Natrella [6]. These k1 values are also plotted in Figure 3 and they were 2.501 and 2.134 for 3 and 4 test locations NDTCE’09, Non-Destructive Testing in Civil Engineering Nantes, France, June 30th – July 3rd, 2009 110 Cube Compressive Strength (N/mm2) 100 Correlation for ALL mixes (Linear Regression) 90 80 95% Confidence Limit 70 60 50 85% of characteristic strength of standard specimens 40 30 20 Estimated In-situ Characteristic Strength 10 0 0 10 20 30 40 50 60 70 Measured LOK Force (kN) Figure 2: Characteristic strength estimates of in-situ concrete. respectively. The values used for Figure 1 and 2 to obtain the strength correlation, are the mean compressive strengths of cubes taken from the same batch of concrete. A margin to allow for production variability was taken as: M = 1.64 x8 = 13.12 N/mm 2 based on 5% defectives and an estimated standard deviation of 8 N/mm2 [7]. To obtain the characteristic compressive strength from the target or in-situ mean strength, the correlation in Figure 1 needs to be shifted downwards by: f c = f m − M = 13.12 N/mm 2 . BS EN 13791:2007 [2] recognizes that the in-situ characteristic strength may be less than that measured on standard test specimens taken from the same batch of concrete, and allows for a ratio of 85% which is part of the safety factor, γc, in EN 1992-1-1:2004 [8]. This is shown in Figure 2 as a long dashed line 3.5 95% Confidence Level 3.0 k value 75% Confidence Level 2.5 2.0 1.5 BS EN 13791:2007 9 to 15 4 to 9 1.0 0 5 10 15 20 25 30 Number of tests Figure 3: One-sided tolerance factor for 10% defective level. NDTCE’09, Non-Destructive Testing in Civil Engineering Nantes, France, June 30th – July 3rd, 2009 Cube Compressive Strength (N/mm2) 110 100 Correlation for ALL mixes (Linear Regression) 90 80 95% Confidence Limit 70 60 Correlation Shifted by -k1.s 50 85% of characteristic strength of standard specimens 40 30 20 Estimated In-situ Characteristic Strength 10 0 0 10 20 30 40 50 60 70 Measured LOK Force (kN) Figure 4: Characteristic strength estimates of in-situ concrete based on a shift of the strength correlation of –k1s. after having allowed for the margin, M, of 13.12 N/mm2. The placing of the concrete, despite being in a real structure, employed strict quality control procedures and strength correlations were obtained from the same batches that were placed in the structure. The quality of the concrete was therefore known and the strength correlation for the pull-out tests represents the average in-situ concrete strength. Converting this into characteristic strength should therefore have indicated that all the concrete placed met the acceptance criteria. The in-situ characteristic strength of the test region, fck,is, was estimated from Equation 3 with the use of the mean in-situ compressive strength of n test results, fm(n),is. The dashed line showing the 85% characteristic strength of standard specimens appears as if it is a regression line through the estimated in-situ characteristic strengths, but it is worrying that almost half the estimates do not meet the acceptance criteria. It is not that the in-situ concrete did not have the required strength. The characteristic strength estimates are significantly lower than the in-situ average strength estimates and this is a consequence of using only 3 or 4 test locations for the Lok tests. The use of the corresponding k1 values for such small number of test locations requires k1 values to be relatively high. A larger number of test locations would reduce the k1 values and assuming that the standard deviation, s, value did not increase then the predicted in-situ characteristic strengths would not only have less scatter but they would all shift closer to the strength correlation. BS EN 13791:2007 [2] accounts for the uncertainty of the strength correlation by requiring the lower 95% confidence limit curve to be used to estimate the insitu characteristic strength of the test region, fck,is. Another way of allowing for this uncertainty is by shifting downwards the strength correlation by k1s and this is shown in Figure 4. The k1s in this case refers to the correlation specimens and therefore k1 can be taken as 1.48 since twenty two data sets were used. The standard deviation, s, was calculated to be 3.42 N/mm2. The similarity of this line to the lower 95% confidence limit is evident. The subsequent analysis of converting in-situ mean strengths to in-situ characteristics strengths again requires use of Equation 3 but in this case the k1 and s refer to the tests carried out insitu. The values of in-situ characteristic strength predicted with this alternative procedure are not dissimilar from those estimated from the lower 95% confidence limit. In estimating the insitu characteristic strength, both procedures assume that the variability of the in-place compressive strength is the same as the variability of the in-place test results. ACI Committee NDTCE’09, Non-Destructive Testing in Civil Engineering Nantes, France, June 30th – July 3rd, 2009 228 [9] acknowledges that this assumption will make the estimates of the in-situ characteristic/tenth-percentile strength overly conservative. It has been acknowledged that the within-test variability of in-place test results is generally greater than compressive test results. 4 Conclusions Interpretation of in-situ non-destructive test results is not simply their averaging and then computing the equivalent compressive strength by means of an established strength relationship. It is necessary to design a concrete mix to have a mean strength greater than the specified characteristic strength, by an amount termed the margin, in order to account for the variability of concrete in production. The in-situ characteristic strength of the test region can be estimated from in-situ test results by the use of standard statistical procedures that take into consideration the quality control, number of tests and the required confidence level in the predictions. The use of as few as three or four test results, as is the norm during construction, results in overly conservative estimates of the in-situ characteristic/tenth percentile strength. This is exacerbated by the fact that the procedure assumes that the variability of the in-place compressive strength is the same as the variability of the in-place test results when it has been acknowledged that the latter has a within-test variability generally greater than the former. Acknowledgements The authors gratefully acknowledge the helpful collaboration of the Building Research Establishment, Byrne Bros., and Ready Mixed Concrete Ltd. The successful onsite testing for this project was carried out by Dr. G. D. Henderson and this is gratefully acknowledged. References 1. 2. 3. 4. 5. 6. 7. 8. 9. View publication stats ASTM C900-94, “Standard Test Method for Pullout Strength of Hardened Concrete,” Annual Book of ASTM Standards, Vol. 04.02: Concrete and Aggregates, 1999, p. 4. BS EN 13791: 2007 “Assessment of in-situ compressive strength in structures and precast concrete components”, ISBN 978-0-580-50271-2, BSI, London, 2007, p. 29. Bungey, J. H; Soutsos, M. N.; Long, A. E.; and Henderson, G. D., “A Radical Re-Design Of The In-Situ Concrete Frame Process – Task 6: Early Age Acceptance Of Concrete (Improved Quality Management),” (Building Research Establishment (BRE) Ltd., Report BR 387, 2000). Soutsos, M.N.; Bungey, J.H.; and Long, A.E., “Pull-Out Testing And Maturiry Measurements During The Construction Of The European Concrete Frame Building Project,” ACI Materials Journal, Vol. 102, No. 6, November 2005, pp. 422-428. Petersen, C. G., “Lok-Test and Capo-Test Pullout Testing – Twenty Years Experience,” In: Proceedings of the International Conference on NDT in Civil Engineering, J. H. Bungey (Ed.), Brit. Inst. NDT, 1997, pp. 77-96. Natrella, M. G., “Experimental Statistics,” Handbook No. 9, National Bureau of Standards, U.S. Government Printing Office, Washington, D.C., USA, 1963, p. 451. Teychenne, D. C., Franklin, R. E., and Erntroy, H. C., “Design of normal concrete mixes,” ISBN 1-6081-172-8, 2nd edition, Building Research Establishment, 1997, p. 38. BS EN 1992-1-1:2004 “Eurocode 2: Design or concrete structures – General rules and rules for buildings,” ISBN 978-0-580-61759-1, BSI, London, 2004, p. 230. ACI Committee 228, “In-Place Methods For Determination Of Strength Of Concrete,” Technical Committee Document 228.1R-03, American Concrete Institute, PO Box 19150, Detroit, MI 48219, 2003, p. 44.