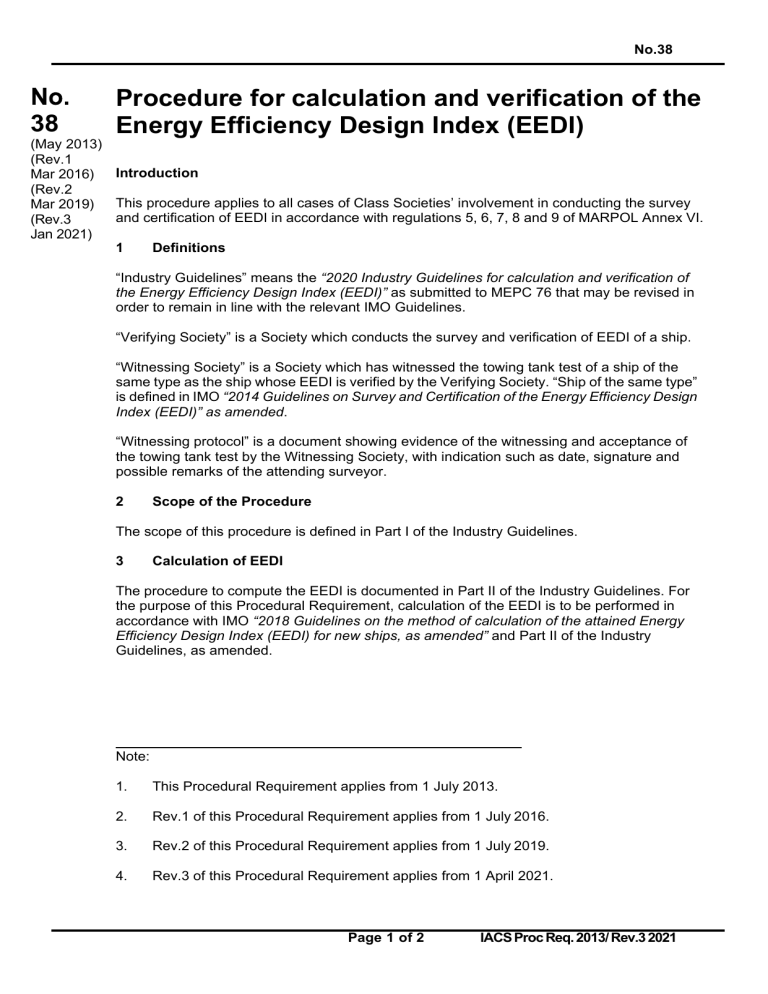

IACS PR38 Rev.3 - Procedure for calculation and verification of the Energy Efficiency Design Index (EEDI)

advertisement