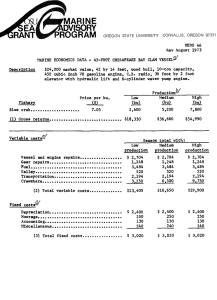

Operator's Information Document Title: Accidents Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Safety rules when operating/Operating instructions Accidents Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo WARNING Risk of serious injury. More than one person in the cab while operating could cause accidents and serious injury. Only the operator, seated in the operator’s seat, may be in the cab when operating. All other persons must keep at a safe distance from the machine. In case of an accident: Report accidents and and incidents to the site management immediately. Leave the machine in position if possible. Take necessary action so as to reduce the effect of damage, especially personal injuries. Avoid action which may make an investigation more difficult. Take part in the emergency plan for the working site or other instructions about measures in case of accidents. Wait for further instructions from the site management. Operator's Information Document Title: Auto engine shutoff (optional equipment) Information Type: Operator's Information Profil e: L70G Volvo Location: Operating instructions Date: 11- 08-202 3 Auto engine shutoff (optional equipment) Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo The equipment is standard with Fire Suppression System. Engine shut-down takes place after a predetermined time. The time is set with VCADS Pro service tool. The following conditions are required for engine shut-down: The machine is stationary The engine is idling The gear selector is in neutral position The hand throttle is not activated When the conditions have been met and there is one minute left of the predetermined time, a message is shown on the display unit. Engine shut-down can then be interrupted by activating the accelerator pedal, hand throttle, or gear selector. When automatic engine shut-down has taken place: The parking brake is applied The start key remains in position 1, running position Any lights or other connected current-consuming devices remain connected. Operator's Information Document Title: Automatic shifting (APS) Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Gear shifting/Operating instructions Automatic shifting (APS) Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo Figure1 Mode selector The mode selector allows the machine operator to select different automatic shifting programs (modes) depending on the operating conditions. Operating in APS position Select operating mode with the mode selector (position AUTO is recommended) Select directional gear. Accelerate, the machine starts in 2nd gear (basic gear). Upshifting and downshifting takes place between 2nd –4th gear forward and reverse. When travel direction has been changed the machine will start in 2nd gear. Downshifting to 1st gear, see "Fully automatic downshifting (FAPS)", page Cab post panelor"Kick-down function" on page Kick-down function. Positions L and M Position "L" means that shifting will take place at low engine rpms and machine speed. Position "M" means that shifting will take place at slightly higher engine rpms and machine speed. With the accelerator pressed down all the way, upshifting takes place according to position "H". Optimal use is obtained with less throttle application since the difference in upshifting rpms between the different modes (L, M, and H) becomes clear. Results in lower fuel consumption and lower noise level. Mode H The machine does not shift until higher engine and travel speeds have been reached. Preferably used in cases where the machine changes gears up and down (gear-hunting) when operating uphill or at high rolling resistance. Mode AUT The machine chooses APS-program according to the operator's operating method. Mode(service mode) NOTE! Risk of machine damage. May only be used by service technicians, with the exception of checking the parking brake, see page Parking brake, checking. Operator's Information Document Title: Brake test Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Braking/Operating instructions Brake test Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo (Checking service brakes) WARNING The brake test must only be performed in a place where there is no risk of accidents. The brake test is performed using computer software, which measures the machine's average retardation. The test can be run by the machine operator from the display unit. Conditions 1 Brake test must only be performed in an area without accident risks (risk of being run into from behind, etc.). . The ground must be level and the surface have good friction. 2 The machine must not be loaded. . Machine speed must be above 20 km/h (12.4 mph) when the service brakes are applied. 3 . NOTE! 4 Acceptable values can only be obtained if the test is run on dry asphalt, dry concrete, or other similar surfaces. . Measuring method Make sure that the conditions according to the previous page are met. Figure1 1 . 2 . 3 . Select SERVICE on the keypad, see page Keypad, information display unit. Select the submenu with the arrow key. Start driving the machine (gear selector position A). When the speed is above 20 km/h (12.4 mph), ashort signal sounds and the display shows "0.0 m/s2² 0.00 g", which means that the speed for the test has been reached. Instead, if the display shows "X.X m/s² X.XX g", the speed is too low (below 20 km/h (12.4 mph)). To obtain credible and useful test values, the brake application must be performed: 4 . Without wheels locking or skidding. With the brakes applied as hard as possible and without letting up the brake pedal during the test. Result and evaluation The test result is shown on the display when the machine stops, when machine speed is 0, and remains until the speed once again is above 10 km/h (6.2 mph). In order to eliminate tests during which the wheels have locked, brake applications where the retardation exceeds 8 m/s² (0.82 g) are not registered. In this case “X.X m/s² X.XX g” will be shown on the display unit. Minimum value for brake test: 4.75 m/s² (0.48 g) If the measured retardation is less than 4.75 m/s² (0.48 g), a new test has to be run. If this test also is below 4.75 m/s² (0.48 g), the brake system should be checked at a workshop authorized by Volvo. Operator's Information Document Title: Braking Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Braking/Operating instructions Braking Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo NOTICE Risk of machine damage. Using the transmission’s disengagement function in transport operation could lead to machine damage. Do not use the transmission’s disengagement function in transport operation. Brake smoothly. This is especially important when operating with a load and on slippery ground. Ifrequired during certain operations, automatic disengagement of the power transmission can be obtained when braking. This function is activated on the cab's pillar panel, see page Cab post panel. Engine braking using the downshift button is advantageous, especially when operating downhill. In this way it is possible to reduce warming of the axle oil, see page Engine braking / downshifting. Operator's Information Document Title: Comfort Drive Control, CDC (optional equipment) Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Steering/Operating instructions Comfort Drive Control, CDC (optional equipment) Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo Figure1 NOTICE When working in areas with risk of electromagnetic fields, EMF, Comfort Drive Control (CDC) shall always be deactivated. See page Electrical magnetic field (EMF). By changing between using lever steering and the steering wheel, the operator obtains a more varied movement pattern. The system consists of a folding armrest where three functions are concentrated, i.e., steering, forward/reverse and kick-down function. The system is activated with the button on the armrest (see the next page). The armrest must be lowered in order tobe able to activate the function. Comfort Drive Control (CDC) is deactivated by raising the armrest. For adjustment of armrest for Comfort Drive Control (CDC), see page Controls. Figure2 Comfort Drive Control (CDC) is deactivated by raising the armrest or by moving the gear selector from neutral position. The CDC-function is also deactivated when the gear selector is moved from neutral position. The control light on the instrument panel turns on when Comfort Drive Control (CDC) is activated. Figure3 Control light, Comfort Drive Control The machine's max. speed is limited when Comfort Drive Control (CDC) is activated. WARNING Always use the steering wheel when operating on public roads and when operating on work sites at speeds above 20 km/h (12.4 mph). When operating on public roads the armrest must always be raised. Operating with activated Comfort Drive Control (CDC) on public roads is prohibited. Figure4 Very little physical effort is required to operate the joystick. The steering speed is proportional to the deflection (stroke) of the l ever. The function of the steering wheel always remains and has priority over the CDC-function. This means that if you attempt to steer to the right with the CDC and to the left with the steering wheel, the machine will steer in the direction the steeringwheel was moved. NOTE! Deactivate the CDC when the text "CDC failure" is shown on the display and bring the machine to a safe stop using the steering w hee l. NOTE! When activating with CDC, the machine's speed is limited to 30 km/h (18.6 mph). 1 Activating (CDC) Figure5 Control light, Comfort Drive Control In order to be able to use the steering, forward/reverse and kick-down functions from the armrest,the armrest must be lowered and the system activated with button1. Before activation is possible, these actions must also be performed: The armrest must be lowered to its lowest position. Figure 6 Comfort Drive Control (CDC) is deactivated by raising the armrest or by moving the gear selector from neutral position. NOTE! In certain positions the armrest must be moved to the right, in towards the seat in order to reach its lowest position. The directional gear selector on the armrest, the ordinary gear selector, and the F/N/R-control by the lever carrier must be in neutral position. The engine must be running, but the machine must be stationary. When the system is activated, a control light on the instrument panel is on. NOTE! Comfort Drive Control (CDC) is deactivated by raising the armrest. Comfort Drive Control (CDC) is also deactivated by moving the gear selector from neutral position. 2 Joystick (steering lever) Figure7 1 Activating CDC 2 Joystick (steering lever) 3 Kick-down button 4 Directional gear selector 5 Adjustment armrest, sideways 6 Adjustment armrest, height (vertically) Very little physical effort is required to operate the joystick. The steering speed is proportional to the deflection (stroke) of the lever. The steering wheel's function always remains operational. 3 Kick-down button With the kick-down button pressed in = The machine downshifts to 1st gear if the gear selector is in either of positions 2,3 or 4. Other instructions, see page Kick-down function. 4 Directional gear selector Switch, front part pressed down = Forward drive. Switch, rear part pressed down = Reverse drive. There is a neutral position between the forward and reverse positions. NOTE! The ordinary gear selector control always has priority, i.e., if the ordinary gear selector is actuated, the selection made from the armrest is cancelled. 5 Adjustment armrest, sideways Loosen the lock knob and adjust the armrest sideways to desired position. Then tighten the lock knob. 6 Adjustment armrest, height (vertically) Loosen the lock knob and adjust the armrest's height to desired position. Then tighten the lock knob. Operator's Information Document Title: Delayed engine shutoff Information Type: Operator's Information Profil e: L70E, L70G Volvo Location: Operating instructions Date: 11- 08-202 3 Delayed engine shutoff Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo Figure1 Symbol showing when engine shut-down is permitted The function instructs the operator to not turn off the engine until the engine has idled for a certain time to prevent damage to the turbo. A symbol is shown on the display when engine shut-down is permitted. NOTE! If the operator turns off the engine before the symbol is shown on the display, an error message will be shown on the display at next start. However, if the machine has held less than 1,000 rpm for 2 minutes, no error message will be shown. Check Figure2 Turbo Hot Shut Down Operator's Information Document Title: Emergency exit Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Safety rules when operating/Operating instructions Emergency exit Showing Selected Profile Valid for serial numbers ModelProduction site L70E, L70G Volvo Figure1 Right side window from inside the cab Serial number start Serial number stop Figure2 Pins to be removed The cab has two emergency exits, the door and the right side window. 1.Break the window with the emergency hammer located on the cab pillar. 2.Press out the strip in the middle to exit the cab. If the machine is equipped with "Side window protection" 1 . 2 . 3 . Break the window as described above. Remove the four pins that hold the window protection grill in place by holding on to the ring and pulling them out. Press out the window protection grill. Operator's Information Document Title: Engine block heater Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Starting engine/Operating instructions Engine block heater Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo (Optional equipment) Figure1 Connection for engine block heater (located to the left of the steps under the battery disconnector) This equipment is used to reduce the engine load that causes wear in the engine when it is startedin areas with cold weather. Recommended connection time for engine block heater ᵒC –20ᵒC –10ᵒC (–4ᵒF) (+14ᵒF) Hours 3 2 0ᵒC (+32ᵒF) 1 +10ᵒC (+50ᵒF ) 1 NOTE! For extra safety, use a ground fault interrupter (GFI) on the wall outlet and check for any damage on the connecting cable. Operator's Information Document Title: Engine braking / downshifting Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Gear shifting/Operating instructions Engine braking / downshifting Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo Figure1 A Engine brake/downshifting Figure2 Using the button for engine brake/downshifting enables immediate downshifting in one or two steps or to prevent unwanted upshifting. In this way the warming up of the axle oil is reduced. One press of the button at higher speeds results in downshifting from 4th to 3rd gear. Another press of the button at a lower speed results in downshifting to 2nd gear. NOTE! If certain critical rpms and machine speeds are exceeded, upshifting takes place. Under these circumstances, lower the speed, or select a higher gear to reduce the engine speed. Operator's Information Document Title: Engine protection -Software Information Type: Operator's Information Profil e: L70E, L70G Volvo Location: Operating instructions Date: 11- 08-202 3 Engine protection -Software Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo The function informs the operator and limits the engine speed and torque and also the travelling speed of the machine in order to prevent any engine damage. Engine shutdown does not take place until the speed has dropped to below 2 km/h (1.2 mph). This makes it possible always to be able to move the machine away from dangerous situations before engine shutdown takes p lace. The function is monitored by the engine control unit E-ECU and depending on which component is causing the alarm any of the following functions will be activated: reduction of engine torque limiting engine speed limiting travelling speed of machine engine shutdown Operator's Information Document Title: Fuel, filling Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Safety rules when operating/Operating instructions Fuel, filling Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo WARNING Risk of explosion! The fumes in an empty fuel container are explosive. Severe personal injury or death could result. Keep open flames and sparks away from fueling area. Do not smoke. Never cut or weld on fuel lines, tanks or containers. Safety procedures during refuelling Turn off the engine and turn off all electrical switches, cab heaters, and the battery disconnector. Do not refuel in enclosed areas. Ensure that the refuelling area is well ventilated. Do not refuel with the engine running. Allow the engine to cool before refuelling. Use handholds and steps provided to get to the fuel tank, if applicable. Use care when removing the fuel tank cap. To prevent static electricity sparks from igniting the fuel vapours, maintain good ground contact by keeping the fuel nozzle in constant contact with the fuel tank's filler neck. Do not mix gasoline or any other non-specified material with diesel fuel. Highly combustible vapours may result. Use the correct fuel grade for the operating season. Do not fill the fuel tank to full capacity. Clean up any spilled fuel immediately. Install and tighten the fuel tank's cap. NOTE! Should the fuel tank cap be lost, replace it only with a genuine manufacturer's approved cap. Usinga non-approved cap without proper venting may result in pressurization of the fuel tank. Operator's Information Document Title: Gear shifting Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Gear shifting/Operating instructions Gear shifting Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo Figure1 Select a suitable gear by turning the gear selector to the desired gear position and then select travel direction forward or reverse. NOTE! The transmission can drive the machine with a gear engaged, even at idle rpm, if the parking brake is not applied. Directional gear WARNING The gear selector control must never be moved to neutral when operating downhill, as this means loss of engine braking effect. This may also cause damage to the power transmission, or lead to the operator losing control of the machine. WARNING Never leave the machine with the gear selector in forward or reverse while the engine is running –there is a risk that the machine may begin to move. Figure2 Lever in position N = Neutral Lever in position F = Operating forward Lever in position R = Operating in reverse When changing from forward to reverse or vice versa, the machine's speed and the engine rpm shouldbe reduced as much as possible, especially if the machine is working on solid ground. Shifting between forward and reverse may only take place in 1st and 2nd gear. Operator's Information Document Title: Kick-down function Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Gear shifting/Operating instructions Kick-down function Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo Figure1 A Kick-down button, control lever carrier Kick-down is obtained, if the mode selector is within the automatic range, the gear selector control is in either of positions 2, 3, or 4 and either of the kick-down buttons is actuated. When the kick-down button is pressed, 1st gear will be engaged if the travelling speed already is below 8 km/h (5.0mph) or if the speed drops below 8 km/h (5.0 mph) within 8 seconds after the button was depressed. When 1st gear has been engaged the buzzer will give off one short pip. 1st gear will remain engaged unless the kick-down function switch is actuated a second time or if the engine speed becomes extremely high (when the switch is actuated a second time, 2nd gear will be engaged). If the direction of travel is changed, the machine will start in 2nd gear, if automatic shifting position is selected. NOTE! If the machine, as optional extra, is equipped with lever steering (CDC) the kick-down function is also available on the armrest. Operator's Information Document Title: Measures before operating Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Measures before operating/Operating instructions Measures before operating Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo WARNING When operating on a public road , it is prohibited to have the lever steering activated –use the steering wheel. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. Perform daily service, see page Check, oil change and lubrication. Clear the platform on the right side by the engine's air intake from snow. Clean/scrape the windows. Clean and adjust mirrors and cameras. See page Mirrors, adjusting. Check that there are no defective/loose parts or leaks that can cause damage. Check that the battery disconnector is on. Check that the wheels are not blocked. Check that engine hood and inspection hatches are closed and that the radiator casing is closed andsecured. Check that there are no persons near the machine, see page Operator's obligations. Adjust the operator's seat, see page Operator seat) and the steering wheel, see page Controls. Fasten the lap-type seatbelt. Check that there is sufficient fuel in the tank. After operating Fill the fuel tank, as this will counteract the formation of condensation water. Make sure that there is enough anti-freeze in the cooling system (see page Coolant) and in the washer fluid at temperatures below 0 °C. Operator's Information Document Title: Measures when getting stuck Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Measures when getting stuck/Operating instructions Measures when getting stuck Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo Figure1 If the machine has got stuck, it is usually best to reverse out. If you cannot reverse or drive forward, try the following: 1.Engage the differential lock with the foot switch. 2.Select a low gear (1st or 2nd). 3.Reverse and steer the machine fully to the left and then to the right alternately (like a duck's waddle). If only the front wheels have got stuck proceed in either of the following ways: 1.Lift the front wheels, supporting the machine on the bottom of a flat bucket and reverse. 2.Steer to the right or to the left, press the bucket against the ground, lift up the front wheels and steer the other way, raise the bucket slightly and reverse. 3.Lift up the front wheels using the bucket. Manually fill the holes under the wheels with branches, pieces of wood or similar and reverse. 4.If the machine needs to be recovered, see page Retrieving and towing. You must never engage the differential lock when one of the wheels is slipping. Lower the engine speed until the wheel has stopped. Then engage the differential lock. Operator's Information Document Title: Operating on public roads Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Safety rules when operating/Operating instructions Operating on public roads Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo Road signs, barrier arrangements, and other safety devices that may be required when considering traffic speed, intensity, or other local conditions must be used. When moving a machine with a suspended load, special attention must be observed. When required, a signal man must be used. Rotating beacon may be used: on machine during road maintenance work, e.g., snow removal. on attached or connected implement that is wider than the machine itself. when the machine is an obstacle or danger to other traffic. when working on or by the side of the road. follow local rules and regulations. Operator's Information Document Title: Operating instructions Information Type: Operator's Information Profil e: L70E, L70G Volvo Location: Operating instructions Date: 11- 08-202 3 Operating Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo This section contains rules that must be followed for safe work with the machine. However, these rules are to be followed in conjunction with laws and other national regulations applicable to road safety and labour welfare. Alertness, judgement and respect for applicable safety regulations are conditions for avoiding risk of accidents. Operator's Information Document Title: Operator’s safety Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Safety rules when operating/Operating instructions Operator’s safety Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo Always use the lap-type seatbelt. Figure 1 Always sit in the operator's seat with the seatbelt fastened when starting the machine (engine) andwhen operating levers and switches. Check that the seatbelt is not worn, see page Lap-type seatbelt. The machine must be operational, i.e., defects that can cause accidents must be repaired. Wear suitable clothing for safe handling and a hard hat. A loose mobile telephone may not be used, as it may interfere with important electronics. The mobile telephone shall be permanently connected to the machine's electrical system and with a fixed aerial on the outside of the machine. Keep your hands away from areas where there is a risk of crushing, e.g., covers, door and windows. Use steps and handholds when entering or leaving the machine. Use the three-point stance, i.e., twohands and one foot, or two feet and one hand. Always face the machine –do not jump! Figure 2 The door must be closed during work and transport operations. The vibration (shaking) that occurs when operating may be harmful to the operator. Reduce this by: adjusting the seat and tightening the seatbelt. choosing the smoothest operating surface for the machine (level the surface if needed). adapt the machine's speed. The cab is for the protection of the machine operator and it meets the requirements for Roll Over Protective Structures according to the test standard (ROPS). Therefore, hold on firmly to the steering wheel if the machine should roll over – Do not jump! The cab is also designed to meet the requirements for falling objects, the weight of which corresponds to stated test methods (FOPS). Only walk and stand on surfaces with slip protection. Figure 3 (Principle diagram) Stepping surfaces Do not enter or leave the machine during a thunderstorm. If you are outside the machine, keep a good distance away from the machine until the thunderstorm has passed. If you are in the cab, remain seated with the machine stationary until the thunderstorm passes. Do not touch any controls or anything made of metal. Check that the attachment is properly attached and locked. The cab has two emergency exits, the door and the right side window. Operator's Information Document Title: Operator's obligations Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Safety rules when operating/Operating instructions Operator's obligations Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo WARNING Risk of fatal accidents. Unauthorised persons within the work area around the machine could lead to serious crushing injury. • Clear all unauthorised personnel from the working area. • Keep a lookout in all directions. • Do not touch control levers or switches during start. • Sound the horn before beginning operation. The machine operator must operate the machine in such a way that the risk of accidents is minimizedboth for the operator, other road users, and persons present on the work site. The machine operator must be thoroughly familiar with how to operate and maintain the machine and should preferably undergo required training on the machine. The machine operator must follow the rules and recommendations given in the Operator's Manual, but also pay attention to any statutory and national regulations or specific requirements or risks that apply at the work site. The machine operator must be thoroughly rested and must never operate the machine under the influence of alcohol, medicine, or other drugs. The machine operator is responsible for the machine's load both when operating on public roads as well as when working on site. There must be no risk of the load falling off while operating. Refuse to take a load that is an obvious safety risk. Respect the rated load capacity of the machine. Note the effect of varying distances to the centre of gravity and the effect of additional units. Figure 1 The danger zone around operating machines is at least 7 m (275.5 in). The machine operator must be in control of the machine's work area. Prevent persons from walking or standing under raised lift arms, unless they have been secured or supported. Prevent persons from entering or remaining in the danger zone, that is, the area around the machineand at least 7 m (275.5 in) beyond the attachment's maximal reach. The machine operator is responsible for the machine not being used to transport or lift persons, unless it is equipped and approved for this purpose. Contact a dealer for more information. Operator's Information Document Title: Parking and Storage Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Parking/Operating instructions Parking and Storage Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo Figure1 1.If possible, place the machine on level ground. If this is not possible, block the wheels so that the machine cannot start rolling. Lower the attachment against the ground. 2.Check that all switches and controls are in the "off" position or in neutral. 3.Apply the parking brake after the machine has come to a complete standstill. 4.Remove the keys. 5.Turn off the electric power with the battery disconnector, if the machine is to be left unattended for some time. 6.Make sure that there is enough anti-freeze in the cooling system (see page Coolant) and in the washer fluid at temperatures below 0 °C when parking. 7.Lock all covers, windows and the door. Remember that the risk of theft and break-in can be minimized if one: removes the ignition key when the machine is left unattended. locks doors and covers after the end of the working shift. turns off the electric power with the battery disconnector and removes the handle. avoids parking the machine in places with high risk of theft, break-ins and malicious damage. removes all valuable items from the cab, e.g., mobile telephone, computer, radio, and bags. It is easier to identify stolen machines if PIN-number or registration number is etched onto the windows. Long-term parking and taking machine out of service NOTICE If the machine is not going to be used every day, all cylinders should be protected against corrosion. The temperature may not be below -40 °C or above +70 °C. Check that the batteries are fully charged. Carry out the measures as described above. Wash the machine and touch up any damaged paint finish to avoid rusting. Treat exposed parts with rustproofing, lubricate the machine thoroughly and apply grease to unpainted surfaces (lift and tilt cylinders, etc.). Fill the fuel tank and the hydraulic oil tank to the max. marks. Cover the exhaust stack (parking outdoors). Remove the fuse for the voltage converter. Otherwise there is a risk that the batteries will be discharged. Check the tire pressure and protect the tires against strong sunlight. Check after long-term parking and after machine has been out of service All oil and fluid levels Tension of all belts Air pressure Air cleaner Install the fuse for the voltage converter NOTE! If any protective agents (rustproofing, etc.) have been used on the machine to prepare for long-term parking, follow the manufacturer's instructions for safety measures and methods for removing. Operator's Information Document Title: Parking brake, mechanical release Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Retrieving and towing/Operating instructions Parking brake, mechanical release Showing Selected Profile Valid for serial numbers ModelProduction site L70E, L70G Volvo Figure1 1 . 2 . Brake disc Adjusting screw Serial number start Serial number stop Figure2 1 . 2 . 3 . 4 . Outer piston Inner piston Brake pads, 2 pcs. Brake disc Park the machine in service position, see page Service position. Remove the rubber protection. Use counterhold and turn the adjusting screw counter-clockwise until the inner piston's surface is flush with the outer piston, then the parking brake has been released mechanically. 1 . 2 . The parking brake is now non-functional. The machine may only be towed if it is connected to another vehicle by a towbar. 3. Reinstall the rubber protection. WARNING NOTE! If the machine is left without restoring the parking brake, this must be indicated by a message on the steering wheel with the information that the parking brake has been disabled and the wheels have been blocked. Restoring 1 . 2 . Start the engine and let it idle. Release the parking brake with the switch. Remove the rubber protection and turn the adjusting screw so that the inner piston has contact with the brake disc. Turn out 1/2 turn. Check the parking brake's function. Operator's Information Document Title: Perform a regeneration Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Exhaust aftertreatment system/Operating instructions Perform a regeneration Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo WARNING Risk for fire. Regeneration generates hot exhaust and causes hot exhaust pipe. Do not perform regeneration in a flammable environment. WARNING Risk of severe burns. Exhaust system components get very hot during regeneration and could cause severe burns to unprotected skin. Avoid contact with engine compartment covers, interior components and structure during regeneration. Start of regeneration Switch, regeneration Figure1 1 START of regeneration . STOP of regeneration in progress 2 . Semi-automatic regeneration When the soot content in the diesel particle filter has reached 100%, a message is shown on the display. Regeneration begins automatically after one minute. If you do not wish to wait one minute, you can alternatively start the regeneration manually by pressing in the upper section of the switch. If you press the lower part of the regeneration button before the regeneration has begun, it will be delayed. After 14 minutes, the message is shown again. The message is not shown if the parking brake is applied. If you apply the parking brake before regeneration begins, the regeneration is delayed until the parking brake is released. Symbol Figure2 Regeneration starts within 1 minute Symbol Figure3 Regeneration cancelled Manual regeneration (optional equipment) Alarm figure Figure4 Regeneration necessary Symbol Figure5 Time for regeneration When the soot content in the diesel particle filter has reached 100%, an alarm figure is shown on the operating information display and a symbol lights up on the instrument panel, see page Front instrument panel. NOTE! The engine hood must be closed during all regeneration of the engine's exhaust cleaning system. NOTE! It is not possible to run a regeneration unless the machine has requested it. That is, the light for regeneration has to be on in the display. To start regeneration, press the upper part of the switch. Under normal conditions, the operator should start regeneration immediately. This applies if the machine is in a fireproof area and there is no plan to turn off the machine during the regeneration phase. Regeneration takes between 25–40 min. depending on if the machine is operated or stationary when the regeneration is run. The symbol indicating higher temperature for the outlet pipe's exhausts, compared to normal operation, is on during the entire regeneration phase. NOTE! The machine must be in a fireproof location during the entire regeneration phase (the symbol is on). Symbol Figure6 High exhaust temperature (regeneration in progress) Fully automatic regeneration (optional equipment) When the machine is equipped with fully automatic regeneration, you can let the regeneration startin idle. When the parking brake is applied the following message is shown on the display, see Fig 1. If you want to allow regeneration at idle, press start r egen erati on. Regeneration at idle Figure7 Press start regen to allow regeneration at idle Fig. 1 Allow regeneration at idle by pressing on the upper part of the regeneration switch. A display message shows that the function is active, see Fig. 2. The message disappears from the display after 20 seconds. Regeneration at idle Figure8 Function active. Fig. 2 If you do not want regeneration to start at idle, you can leave the machine and the message (Fig. 1) disappears from the display after 20 seconds. Figure9 1.START of regeneration 2.STOP of regeneration in progress Regeneration will be delayed if you press the lower part of the regeneration switch when regeneration has started. Fuel consumption A regeneration that takes place when the machine is idling uses less fuel than a regeneration whenthe machine is operating. Delay regeneration Regeneration can be delayed if the machine is in a fire-hazardous area, or the plan is to turn off the machine during the regeneration phase. The alarm figure on the display can be acknowledged (removed) by pressing ESC on the keypad for theinformation display. The alarm figure returns after approx. 15 minutes. NOTE! It is important to not delay regeneration unnecessarily. Consequences of delaying regeneration: reduced engine power due to increased back-pressure. the engine system reduces the power. higher fuel consumption. shorter service life for particulate filter. in case of a long delay of regeneration, there is risk of damage to the aftertreatment system. NOTE! Service personnel must run the regeneration in case of an extremely high soot load. Figures shown on information display unit when regeneration is needed Display figure Text on information display unit Regeneration necessary Check, amber Alarm level Action Run regeneration as soon as buzzer sounds possible. — —— — NOTE! The alarm figure The machine must be in a returns after fireproof area during the approx. 15 entire regeneration minutes Figure 10 Request for Check, amber reg enera tion buzzer Run sounds immediately. regeneration ———— The alarm figure returns after approx. 15 minutes the engine's power is reduced (but is restored after finished regeneration) Figure 11 NOTE! The machine must be in a fireproof area during the entire regeneration Alarms that require special actions Display figure Text on information display unit Request for Warning, red stationary (parked) reg enera tion Figure 12 Alarm level buzzer sounds red central warning on the engine's power is significantly reduced (but is restored after finished regeneration) Action 1. 2. Park the machine in a fireproof area. Apply the parking bra ke. Start regeneration. NOTE! Regeneration is cancelled if the parking brake is deactivated Service requiredWarning, red Figure 13 1 Park the machine in buzzer sounds a fireproof area. red central . Turn off the engine. warning on Contact a workshop the engine's 2 authorized by Volvo power is for regeneration. significantly . reduced (but is 3 restored after . NOTE! finished Regeneration is only regeneration) possible with Volvo's service tool Service requiredWarning, red Figure 14 Cancelling regeneration in progress NOTE! buzzer sounds red central warning on the engine's power is reduced significantly (but is restored after regeneration is complete) 1 . 2 . 3 . Park the machine in a fireproof area. Turn off the engine. Contact a workshop authorized by Volvo to replace the diesel particulate filter. NOTE! Resetting of the soot load is only possible with Volvo's service tool A cancelled regeneration must be started over from the beginning. Therefore, only cancel in case of an emergency. 1.Press the lower part of the regeneration button. An alarm figure on the instrument panel confirms that regeneration has been cancelled. Alarm figure Figure15 Regeneration cancelled Regeneration is cancelled automatically when: a malfunction occurs machine operation starts and there is a request for stationary (parked) regeneration (Level 3). if the machine is turned off. Operator's Information Document Title: Retrieving and towing Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Retrieving and towing/Operating instructions Retrieving and towing Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo WARNING If braking and steering functions are limited in this situation, the machine should only be towed in emergencies, over the shortest possible distance, and under the supervision of trained and qualified personnel. If possible, transport the machine on a trailer. In order to release the parking brake, see manual release of parking brake foreach machine type. Figure1 Actions If possible, the engine should be running so that brakes and steering work. If the engine cannot be started or, for any other reason, enough pressure cannot be built up to release the parking brake, it is possible to release the parking brake mechanically, see page Parking brake, mechanical release. NOTE! The connecting device on the counterweight or the eyes on the rear frame inside the rear wheels must not be used when recovering or towing. Recovering Figure2 Eyes under counterweight when recovering, towing, and lashing When recovering backwards, use the eyes under the counterweight, which are intended for lashing themachine. When recovering forwards, use the eyes by the front axle attachment intended for lashing the machine. To avoid shear stresses, pull the machine straight back/forward. Try to distribute the load by connecting to both eyes. Figure3 Figure4 Max. towing capacity (kN) Front Rear L60G 215 kN 120 kN L70G 245 kN 120 kN L90G 280 kN 120 kN Towing The towing vehicle or machine must weigh at least as much as the machine in tow, and must have adequate engine power and braking capacity to tow the vehicle in question. Do not tow longer distances than absolutely necessary, otherwise the transmission may be damaged. When towing longer distances (more than 10 km (6.2 miles) or when towing faster than 10 km/h (6.2 mph), both front and rear propeller shafts must be disconnected, see below, or the machine should be transported on atrailer. Connect in a corresponding way as when recovering. NOTE! It is not possible to start the engine by towing. Follow national regulations where required. Figure5 Attaching point for lashing Disconnecting propeller shafts WARNING Before taking any action for towing or recovering, the parking brake must be applied and the wheelsmust be blocked to prevent the machine from starting to roll. Work with extreme care when towing to avoid personal injuries and, at worst, fatalities. 1 Place the machine in service position, see page Service position. . Block the wheels in a suitable way, for example, with wedges. 2 Remove the propeller shaft bolts and disconnect the propeller shafts from the drive axles. . 3 recovering and towing After . The following safety actions must be performed before the tow cable is removed: 1.Stand the machine on level ground. 2.Block the wheels to prevent the machine from rolling. 3.Restore the propeller shafts. NOTE! The parking brake function is lost when the propeller shafts have been disconnected. If the machineis left without restoring the parking brake, this must be indicated by a message on the steering wheel with the information that the parking brake has been d isabled. Connecting device on counterweight NOTE! The connecting device on the counterweight must not be used when recovering, towing, or when operating on a road. Follow national regulations. Figure6 Connecting device on counterweight Max. temporary force on the counterweight's connecting device incl. attachment may not exceed the following: L60G/L70G/L90G, a horizontal force of 110 kN and a vertical force of 10 kN. NOTE! Make sure that the puller bolt's lock pin with lock clamp is securely fastened when using the connecting device. Figure 7 The connecting device may only be used temporarily to transport necessary maintenance supplies needed by the machine on the work site (attachments, tools, fuel, oils, etc.). The new total weight (machine as well as unbraked trailer with load) may not be heavier than the max. machine weight, see page Machine weights. Operator's Information Document Title: Running-in instructions Information Type: Operator's Information Profil e: L70E, L70G Volvo Location: Operating instructions Date: 11- 08-202 3 Running-in instructions Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo During the first 100 hours, the machine should be operated with particularly great care. During the running-in period it is important to check oil and fluid levels often. Wheel bolts should be check-tightened after 8 hours operation, see page Wheel bolts, checking tightening. Operator's Information Document Title: Safety rules in case of fire Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Safety rules when operating/Operating instructions Safety rules in case of fire Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo If your own safety is not immediately compromised, take the following actions. In case of fire on the work site 1 . 2 . 3 . 4 If possible, move the machine away from the hazardous area. Lower the attachment to the ground. Turn off the engine by turning the start key counter-clockwise or by pressing in the emergency stop(optional equipment) in the cab. Leave the cab. Turn off the main electric power with the battery disconnector located under the steps on the machine's left side. If possible, take active part in putting out the fire and call the fire department if needed. In case of fire in the machine . If the machine is being operated: 5 . 1.If6possible, park in a fireproof location. 2.Lower the attachment to the ground. . 3.Turn off the engine by turning the start key counter-clockwise or by pressing in the emergency stop(optional equipment) in the cab. 4.Leave the cab. 5.If possible, turn off the main electric power with the battery disconnector located under the stepson the machine's left side. 6.Try to put out the fire. 7.Call the fire department if needed. In case of fire in machine with Fire Suppression System (optional equipment) If the machine is operated (operator-dependent activation of sprinkler system): 1.If possible, park in a fireproof location. 2.Turn off the engine with the emergency stop (optional equipment) in the cab or by turning the startkey countercl ockw ise. NOTE! The sprinkler system is activated if fire is detected. 3.Leave the cab. NOTE! It is also possible to activate the sprinkler system with the manual activation button (outside thecab), see page Fire suppression system. 4.If possible, turn off the main electric power with the battery disconnector located under the stepson the machine's left side. Be ready with the handheld fire extinguisher since there may still be fire deep inside the machine that could flare up. 5 Call the fire department if needed. . 6 . NOTE! If the machine is not operated or if the parking brake is applied, the sprinkler system is activated automatically. Operator's Information Document Title: Secondary steering Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Steering/Operating instructions Secondary steering Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo (Optional equipment) Figure1 Warning low steering pressure The machine can be equipped with a secondary steering system. Follow national legislation and regulations. If "Warning low steering pressure" appears in the display, stop the machine immediately and contact a qualified service technician. Operator's Information Document Title: Starting engine Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Starting engine/Operating instructions Starting machine Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo WARNING The engine may only be started with the ignition in the cab. Figure1 If the machine is equipped with theft protection, see page Theft protection. 1.Place the gear selector in neutral. 2.Turn the key in the ignition to running position (1) so that a system test is run for about 4–5 seconds. 3.At the same time check that all lights turn on and that the gauges indicate readings. 4.Turn the ignition key to starting position (2). If the engine does not start, turn the key back to the "0" position, before making a new start attempt. 5.Check that all control and warning lights are off when the engine has started. 6.Let the engine idle for at least 30 seconds. 7.Check that the attachment is securely fastened to the machine by pressing it against the ground. 8.Release the parking brake. 9.Select gear position and increase the engine speed. Turbocharger The turbocharger is lubricated and cooled by the engine's lubrication system and coolant. Figure2 Air Lubrication oil Exhaust Important for the function of the turbocharger is that: Figure3 A Exhaust inlet B To exhaust system C C Air inlet D Compressed air lubrication and cooling is safeguarded by not racing the engine immediately after it has been started. let the engine run at low idle rpm for at least 2 minutesbefore turning it off. Figure 4 engine oil is changed and oil filters are changed at prescribed intervals. the air cleaner is serviced regularly and that the exhaust system and lubrication oil lines do not leak. Change the turbocharger immediately in case it generates noise or vibrations. Work on the turbocharger should be done at a workshop authorized by Volvo. Starting machine in cold weather (below 0ᵒC, 32ᵒF) WARNING Starting aids, for example, ether, may cause an explosion in the engine's induction manifold. Contact a workshop authorized by Volvo if the engine does not start. The preheating function is controlled by the engine ECU. 1.Turn the start key to running position (1). 2.If there is a need of preheating, the function will be activated automatically. 3 . 4 . A symbol lights up on the front information display unit showing that preheating is engaged, see page Operating Information display screen. When the symbol turns off, the engine can be started by turning the start key to starting position (2). Let the engine run at low idle for at least 60 seconds. Racing the engine immediately after it has been started may also jeopardize lubrication and coolingof the turbocharger, resulting in high risk of bearing seizure. NOTE! Do not use the working hydraulics at full speed until the hydraulic oil is warm. The hydraulic oil filter does not filter all of the oil when the oil temperature is below 15 ºC at high flow. This means that unfiltered oil is pumped out in the system and may result in machine damage and malfunctions. Operator's Information Document Title: Starting with booster battery Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Starting engine/Operating instructions Starting with booster batteries Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo Figure1 A.Battery box B.Grounding point The following must be observed when starting with booster batteries: Check that the booster batteries or other current sources have the same voltage as the standard batteries. WARNING Risk of explosion. Batteries could explode due to the current surge if a fully charged battery is connected to a completely discharged or frozen battery. Do not boost start a machine with a completely discharged or frozen battery. Take the following actions: 1.Move the gear selector to neutral. 2.Check that the booster batteries or any other power source has the same voltage as the batteries onthe machine. 3.Do not, for any reason, disconnect the cables from the standard batteries! 4.Remove the terminal caps from the battery terminals. 5 . 6 . 7 . 8 . 9 . Connect the plus cable from the booster battery to the right battery's plus terminal. Connect the minus cable from the booster battery to the intended grounding point under the battery box. Start the engine with the start key in the cab. If the alternator charges, remove the jump-start cable from the grounding point and the booster battery's minus terminal. Then remove the jump-start cable between the plus terminals. Reinstall the terminal caps on the battery terminals. Operator's Information Document Title: Steering Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Steering/Operating instructions Steering Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start L70E, L70G Volvo NOTE! In case the engine stops, stop the machine immediately and apply the parking brake. The machine is frame-steered (articulated) and has a hydrostatic steering system. Serial number stop Operator's Information Document Title: Stopping Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Stopping/Operating instructions Stopping Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo Figure1 NOTICE Do not turn off the battery disconnect switch when the engine is running. The electrical system maybe damaged. 1 . 2 . 3 . 4 . Lower the engine speed. Brake the machine and, when the machine has come to a stop, move the gear selector to neutral position. Lower the attachment to the ground. Apply the parking brake after the machine has come to a complete standstill. NOTE! It is important to run the engine at low idle rpm for at least two minutes before turning it off tomake sure that the turbo receives adequate lubrication and cooling, see page Delayed engine shutoff. NOTE! Do not turn off the engine until the symbol is shown on the display (see figure). NOTE! It is important to not cancel a regeneration and immediately turn off the engine in order to avoid unnecessary heat stress on components under the engine hood . Run the machine for a few minutes before turning off the engine after the symbol has been shown. Figure 2 Symbol showing when engine shut-down is permitted Turn the start key counter-clockwise so that the control lights go out and the engine stops. 5. Figure3 If the operator has to leave the cab with the engine running, care has to be taken so that the steering wheel is not turned inadvertently as the operator leaves the cab. This applies particularly if the steering wheel is provided with a knob. NOTE! If the operator turns off the engine before the symbol is shown on the display, an error message isshown in the display at next start. However, if the machine has had less than 1,000 rpm during 2 minutes, the error message will not be shown. WARNING Always use the three-point approach to access or leave the cab, i.e., two hands and one foot or onehand and both feet. Use stepping surfaces and handholds. Always face the machine when entering or stepping down from themachine. Do not jump off! Operator's Information Document Title: Transporting machine Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Transporting machine/Operating instructions Transporting the machine Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo Actions before transporting machine NOTE! Before loading the machine for transport, deactivate the transmission disengagement, see page Cab post panel. WARNING If the machine is to be driven from a loading dock onto the platform of a truck trailer or railway car, make sure that the vehicle is securely braked, for example, wheels blocked. Make sure that there is no risk that the vehicle cannot roll over or sway in a dangerous manner when the machine is driven on. NOTE! To avoid air being forced into the exhaust stack during transport, resulting in damage to the turbocharger, the exhaust stack must be covered with suitable protection (not plastic). On another vehicle Figure1 Frame joint lock The frame joint must be locked if the machine is lifted up onto another vehicle. Use intended attaching points for lifting. Lock the frame joint. If the machine is driven up on to another vehicle, the frame joint must not be locked. The frame joint must be locked first when the machine has been driven up on the trailer. Tie down (lash) the machine according to the following pages. Over ramp First check that the ramp is wide enough and has the required strength and that it will not be displaced. In an elevator or other confined space 1 Reverse the machine in. . Apply the parking brake and stop the engine before starting the elevator. 2 . Otherwise, follow the national rules and regulations. Lifting the machine Figure2 The machine's maximum total weight is as follows: L60G 14,500 kg (31,967 L70G lbs) L90G (36,376 lbs) 19,000 16,500 kg kg (41,888 lbs) NOTE! The rear fender (mudguard) shall be removed when lifting the machine. Lift the machine using the intended lifting eyes (see figure). The frame joint must be locked before lifting. Securing cargo (machine) that has been loaded See the following conditions for securing a machine that has been loaded as well as instructions and values for each machine in the following tables. Conditions for securing cargo The instructions on the following pages are only valid if the following conditions have been fulfilled: Acceleration requirements The machine is subjected to a max. acceleration of; 0.8 g forward, 0.5 g backward, 0.5 g sideways, and 0.2 g upward.[1] Acceleration forward, backward, and sideways act individually and they are combined with 1 g downward.⁽¹⁾ Acceleration upward is not combined with other accelerations.⁽¹⁾ A safety factor of 1.25 has been used to compensate for uneven distribution of forces in the lashings. The arrangement can also withstand an acceleration of 1 g forward without safety factor.⁽¹⁾ The machine The machine (with or without attachment) is manufactured by Volvo Construction Equipment. The machine's weight is max. 14,500 kg (31,967 lbs) for L60G, 16,500 kg (36,376 lbs) for L70G, 19,000 kg (41,888 lbs) for L90G. The machine has new or normally used rubber tires or wood-covered rims of pine or birch. If the wood-covering is made of birch, then rubber spacers shall be used between wood-covering and ground surface for the friction 0.5. If rubber spacers are not used the friction is only 0.2. Loading and securing on the load carrier The machine stands centred sideways (± 5 cm (2 in)) and is supported on at least half of the tires'width. The parking brake is applied and functional, and can handle an inclination (grade) of at least 14°. The frame joint is locked. The machine is loaded and secured in such a way that no parts, i.e., painted surfaces or tires, canbe damaged. Load carrier The machine is loaded on a vehicle with trailer bed of wood, plyfa (plywood), grooved aluminum plates, unpainted or painted steel plates. The distance sideways between tie-down points on the load-carrying transport vehicle is approx. 2,500 mm (100 in). The tie-down points on the trailer have at least the same breaking strength as the lashings. Tie-downs (lashings) The lashings are pre-loaded to at least 4,000 N during the whole transport. The lashings are located symmetrically in pairs and are fastened in the intended tie-down points onthe machine. Only one lashing shall be fastened to each tie-down point. It shall not be possible for the tie-down hooks to lose their grip if the lashings become slack. Safe loading in the chain (MSL/LC/SWL) is at least 50% of the breaking strength (MBL). Dampers should be used when short, vertical lashings are used on machines with rubber tires to reduce the jerking and shocks to which the chains may be subjected. The following applies if blocks are used or the machine is blocked against the goose-neck: When using blocks, these must be well fastened, have an angle of approx. 37° (3:4:5), a height of at least 25 cm (10 in), and be located in pairs; 1, 2, 3, or 4 pairs according to above tables with block placement. Placement of rubber tires/wood-covered rims against wheel slots corresponds to the use of blocks. Blocking of bucket, loader linkage, rear part of machine, or of the wheel pairs in the direction upto at least half of the wheel radius against goose-neck prevents forward movement. Blocking with sufficient height against the inside or outside of all four wheels prevents sideways movements. Cargo securing certificate L60G, loaded with the front facing forward L D E is the distance between points Dand E. is the calculated point, laterally at right angles to the edge of the platform from the lashing point Con the wheel loader. is the lashing point on the platform. The relationship L between and L is the same. Figure 3 Values and instructions in the following table are only valid if the conditions described earlier in the section under the heading "Conditions for securing cargo" are fulfilled. (F=Travel direction) Lashings' permitted distance interval in metres (1 m = 39.4 in) Friction Blocks surfaces blocking or Chain min. class 8 Ø10 mmChain min. class 8 Ø13 mm MBL 12 ton, LC 60 kN (6 ton)MBL 20 ton, LC 100 kN (10 ton) L ₍LLLL ᵒ ᵉᵈ₎ ₍ ᵉ Rubber, pine, No blocksNon-approved cargo securing alternatives birch with 1 pair0,8–2,50,3–1,00,6–1,5 rubber (dry or 2 pairs0,5–2,50,3–1,00,6–1,5 wet): µ = 0.53 pairs0,5–2,5Not needed0,5–1,5 4 pairs ᵒ ᵈ₎₍ ᵒ ᵉᵈ₎ L 0,5– 0,3–1,0 ₍ ᵒ 0,6– 2,5 Not needed 1,5 0,5– ᵉᵈ₎ 0,6– 2,5 0,5–2,5 Not needed 1,5 0,5–1,5 0,5– Not needed 0,5– sideways 2,5 0,3–1,0 1,5 Blocking forward 0,8–2,5Not needed0,5–1,5 and sideways 0,5– Blocking forward0,8–2,5Not needed0,5–1,5 Blocking Non-approved cargo securing alternatives Frost, ice, No blocksNon-approved cargo securing alternatives snow, dirt, 1 pair1,2–2,50,3–1,00,8–1,5 birch without 2 pairs0,5–2,50,3–1,00,8–1,5 rubber: µ = 0.23 pairs0,5–2,5Not needed0,6–1,5 4 pairs Blocking forward1,2–2,5Not needed0,5–1,5 Blocking Non-approved cargo securing alternatives sideways Blocking forward 1,2–2,5Not needed0,5–1,5 and sideways (1) Cargo securing not needed (if used the permitted interval is 0.0 –0.6 m) (2) Cargo securing not needed (if used the permitted interval is 0.0 –1.4 m) 0,6– 2,5 Not needed 1,5 0,5– 0,3–1,0 0,5– 2,5 Not needed 0,7– 2,5 0,7– 0,7– 2,5 2,5 0,7– 0,5– 2,5 2,5 Not needed Not needed Not needed 0,3–1,0 Not needed 1,5 0,7– 1,5 0,5– 0,8– 1,5 1,5 0,7– 0,8– 1,5 1,5 0,5– 0,7– 2,5 0,5– 0,5– 1,5 2,5 2,9 Cargo securing certificate L60G, loaded with the front facing the rear L is the distance between points D and E. Dis the calculated point, laterally at right angles to the edge of the platform from the lashing point Con the wheel loade r. Eis the lashing point on the platform. The relationship between L and L is the same. Figure 4 Values and instructions in the following table are only valid if the conditions described earlier in the section under the heading "Conditions for securing cargo" are fulfilled. (F=Travel direction) Lashings' permitted distance interval in metres (1 m = 39.4 in) Friction Blocks surfaces blocking or Chain min. class 8 Ø10 mmChain min. class 8 Ø13 mm MBL 12 ton, LC 60 kN (6 ton)MBL 20 ton, LC 100 kN (10 ton) L ₍LLLL ᵒ ᵉᵈ₎ ₍ ᵉ Rubber, pine, No blocks0,8–1,50,4–1,01,3–2,5 birch with 1 pair0,8–1,5Not needed1,2–2,5 rubber (dry or 2 pairs0,5–1,5Not needed1,2–2,5 wet): µ = 0.53 pairs0,5–1,5Not needed0,5–2,5 4 pairs ᵒ ᵈ₎₍ ᵒ ᵉᵈ₎ L 0,5– Not needed ₍ ᵒ 1,2– 1,5 Not needed 2,5 0,5– 0,7– 1,5 0,5–1,5 Not needed 2,5 0,5–2,5 Blocking forward0,8–1,5Not needed0,5–2,5 0,5– Not needed 0,5– Blocking 0,8–1,50,4–1,01,3–2,5 sideways 1,5 Not needed 2,5 0,5– Blocking forward 0,8–1,5Not needed0,5–2,5 and sideways 1,5 Not needed 2,5 Frost, ice, No blocksNon-approved cargo securing alternatives snow, 1 pair dirt, 0,5– Not needed 0,5– 1,5 Not needed birch without 2 pairs0,5–1,50,4–1,01,7–2,5 rubber: µ = 0.23 pairs0,5–1,5Not needed0,6–2,5 4 pairs 0,6– Blocking sideways 1,5 0,6– 0,6– 1,5 1,5 0,6– 0,5– Blocking forward and sideways 1,5 1,5 Blocking forwardNon-approved cargo securing alternatives (1) Cargo securing not needed (if used the permitted interval is 0.0 –0.6 m) (2) Cargo securing not needed (if used the permitted interval is 0.0 –1.4 m) ᵉᵈ₎ 1,2– Not needed Not needed Not needed Not needed Not needed 2,5 1,5– 2,5 0,5– 0,8– 2,5 2,5 1,5– 0,8– 2,5 2,5 0,5– 0,6– 1,5 0,5– 0,5– 2,5 1,5 2,5 Cargo securing certificate L70G, loaded with the front facing forward L D E is the distance between points Dand E. is the calculated point, laterally at right angles to the edge of the platform from the lashing point Con the wheel loader. is the lashing point on the platform. The relationship L between and L is the same. Figure 5 Values and instructions in the following table are only valid if the conditions described earlier in the section under the heading "Conditions for securing cargo" are fulfilled. (F=Travel direction) Lashings' permitted distance interval in metres (1 m = 39.4 in) Friction Blocks surfaces blocking or Chain min. class 8 Ø10 mmChain min. class 8 Ø13 mm MBL 12 ton, LC 60 kN (6 ton)MBL 20 ton, LC 100 kN (10 ton) L ₍LLLL ᵒ ᵉᵈ₎ ₍ ᵉ Rubber, pine, No blocksNon-approved cargo securing alternatives birch with 1 pair0,9–3,50,3–1,00,7–1,5 rubber (dry or 2 pairs0,5–3,50,3–1,00,7–1,5 wet): µ = 0.53 pairs0,5–3,5Not needed0,5–1,5 4 pairs ᵒ ᵈ₎₍ ᵒ ᵉᵈ₎ L 0,5– 0,3–1,0 ₍ ᵒ 0,7– 3,5 Not needed 1,5 0,7– 0,5– Not needed 1,5 0,5–1,5 3,5 Not needed 0,5– sideways 0,5– 0,3–1,0 1,5 Blocking forward 0,9–3,5Not needed0,5–1,5 and sideways 3,5 0,5– Frost, ice, No blocksNon-approved cargo securing alternatives snow, dirt, 1 pair1,4–3,50,4–1,00,9–1,5 birch without 2 pairs0,5–3,50,4–1,00,9–1,5 rubber: µ = 0.23 pairs0,5–3,5Not needed0,7–1,5 4 pairs 3,5 Blocking forward0,9–3,5Not needed0,5–1,5 Blocking Non-approved cargo securing alternatives Blocking forward1,4–3,5Not needed0,5–1,5 Blocking Non-approved cargo securing alternatives sideways Blocking forward 1,4–3,5Not needed0,5–1,5 and sideways (1) Cargo securing not needed (if used the permitted interval is 0.0 –0.6 m) (2) Cargo securing not needed (if used the permitted interval is 0.0 –1.4 m) Cargo securing certificate L70G, loaded with the front facing the rear 3,5 ᵉᵈ₎ 0,5– 0,5– 3,5 0,5– 3,5 0,7– Not needed 1,5 0,4–1,0 0,5– Not needed Not needed Not needed 0,7– 0,5– Not needed 3,5 3,5 0,7– 0,4–1,0 3,5 0,7– Not needed 3,5 0,7– 0,7– 3,5 1,5 0,7– 1,5 0,5– 0,9– 1,5 1,5 0,7– 0,9– 1,5 1,5 0,5– 0,5– 1,5 1,5 0,5– 3,5 0,5–L is the distance between points D and E. 3,5 Dis the calculated point, laterally at right angles to the edge of the platform from the lashing point Con the wheel loade r. Eis the lashing point on the platform. The relationship between L and L is the same. Figure 6 Values and instructions in the following table are only valid if the conditions described earlier in the section under the heading "Conditions for securing cargo" are fulfilled. (F=Travel direction) Lashings' permitted distance interval in metres (1 m = 39.4 in) Friction Blocks surfaces blocking or Chain min. class 8 Ø10 mmChain min. class 8 Ø13 mm MBL 12 ton, LC 60 kN (6 ton)MBL 20 ton, LC 100 kN (10 ton) L ₍LLLL ᵒ ᵉᵈ₎ ₍ ᵉ Rubber, pine, No blocks0,9–1,50,4–1,01,8–3,5 birch with 1 pair0,9–1,5Not needed1,5–3,5 rubber (dry or 2 pairs0,5–1,5Not needed1,5–3,5 wet): µ = 0.53 pairs0,5–1,5Not needed0,5–3,5 4 pairs ᵒ ᵈ₎₍ ᵒ ᵉᵈ₎ L 0,5– Not needed ₍ ᵒ 1,4– 1,5 Not needed 3,5 0,5– 0,8– 1,5 0,5–1,5 Not needed 3,5 0,5–3,5 Blocking forward0,9–1,5Not needed0,5–3,5 0,5– Not needed 0,5– Blocking 0,9–1,50,4–1,01,8–3,5 sideways 1,5 Not needed 3,5 0,5– Blocking forward 0,9–1,5Not needed0,5–3,5 and sideways 1,5 Not needed 3,5 Frost, ice, No blocksNon-approved cargo securing alternatives snow, 1 pair dirt, birch without 2 pairs0,5–1,5Not needed2,1–3,5 rubber: µ = 0.23 pairs0,5–1,5Not needed0,7–3,5 4 pairs 0,5– Not needed 0,5– 1,5 Not needed 3,5 Not needed Not needed 1,8– 0,7– Blocking sideways 1,5 0,7– 0,7– 1,5 1,5 0,7– 0,5– Blocking forward and sideways 1,5 2,5 Blocking forwardNon-approved cargo securing alternatives (1) Cargo securing not needed (if used the permitted interval is 0.0 –0.6 m) (2) Cargo securing not needed (if used the permitted interval is 0.0 –1.4 m) ᵉᵈ₎ 1,4– Not needed Not needed Not needed Not needed 3,5 0,5– 1,0– 3,5 3,5 1,8– 1,0– 3,5 3,5 0,5– 0,7– 1,5 0,5– 0,5– 3,5 1,5 3,5 Cargo securing certificate L90G, loaded with the front facing forward L D E is the distance between points Dand E. is the calculated point, laterally at right angles to the edge of the platform from the lashing point Con the wheel loader. is the lashing point on the platform. The relationship L between and L is the same. Figure 7 Values and instructions in the following table are only valid if the conditions described earlier in the section under the heading "Conditions for securing cargo" are fulfilled. (F=Travel direction) Lashings' permitted distance interval in metres (1 m = 39.4 in) Friction Blocks surfaces blocking or Chain min. class 8 Ø10 mmChain min. class 8 Ø13 mm MBL 12 ton, LC 60 kN (6 ton)MBL 20 ton, LC 100 kN (10 ton) L ₍LLLL ᵒ ᵉᵈ₎ ₍ Rubber, pine, No blocksNon-approved cargo securing alternatives birch with 1 pair1,1–2,50,4–1,00,8–1,5 rubber (dry or 2 pairs0,5–2,50,4–1,00,8–1,5 wet): µ = 0.53 pairs0,5–2,5Not needed0,5–1,5 4 pairs Blocking forward1,1–2,5Not needed0,5–1,5 Blocking Non-approved cargo securing alternatives sideways Blocking forward 1,1–2,5Not needed0,5–1,5 and sideways Frost, ice, No blocksNon-approved cargo securing alternatives snow, 1 pair dirt, birch without 2 pairs rubber: µ = 0.23 pairs0,5–2,50,3–1,00,5–1,5 4 pairs Blocking forward1,8–2,5Not needed0,5–1,5 Blocking Non-approved cargo securing alternatives ᵒ ᵉᵈ₎₍ ᵒ ᵉᵈ₎ 0,6– 0,4–1,0 ₍ ᵒ 0,8– 2,5 Not needed 1,5 0,6– Not needed 0,9– 2,5 Not needed 1,5 L 0,5– 0,9– 2,5 0,6–2,5Not needed0,5–1,5 1,5 0,5– 0,6–2,5 0,4–1,0 0,8–1,5 0,5– 2,5 0,6–2,5Not needed0,5–1,5 1,5 ᵉᵈ₎ Non-approved cargo securing alternatives 0,9–2,5 0,3–1,0 0,5–1,5 0,5–2,5 0,3–1,0 0,5–1,5 0,5–2,5Not needed0,5–1,5 0,9–2,5Not needed0,5–1,5 sideways Non-approved cargo securing alternatives Blocking forward 1,8–2,5Not needed0,5–1,5 and sideways 0,9–2,5Not needed0,5–1,5 (1) Cargo securing not needed (if used the permitted interval is 0.0 –0.6 m) (2) Cargo securing not needed (if used the permitted interval is 0.0 –1.4 m) Cargo securing certificate L90G, loaded with the front facing the rear L is the distance between points D and E. Dis the calculated point, laterally at right angles to the edge of the platform from the lashing point Con the wheel loade r. Eis the lashing point on the platform. The relationship between L and L is the same. Figure 8 Values and instructions in the following table are only valid if the conditions described earlier in the section under the heading "Conditions for securing cargo" are fulfilled. (F=Travel direction) Lashings' permitted distance interval in metres (1 m = 39.4 in) Friction Blocks surfaces blocking or Chain min. class 8 Ø10 mmChain min. class 8 Ø13 mm MBL 12 ton, LC 60 kN (6 ton)MBL 20 ton, LC 100 kN (10 ton) L ₍LLLL ᵒ ᵉᵈ₎ ₍ ᵒ ᵉᵈ₎₍ ᵒ ᵉᵈ₎ L Rubber, pine, No blocksNon-approved cargo securing alternatives0,6–1,5Not needed1,9–2,5 birch with 1 pair0,6–1,5Not needed0,9–2,5 rubber (dry or 2 pairs0,5–1,5Not needed1,9–2,50,5–1,5Not needed0,9–2,5 wet): µ = 0.53 pairs0,5–1,5Not needed0,5–2,50,5–1,5Not needed0,5–2,5 4 pairs ₍ ᵒ ᵉᵈ₎ Blocking forwardNon-approved cargo securing alternatives0,6–1,5Not needed0,5–2,5 Blocking 0,6–1,50,4–1,00,8–2,5 sideways Blocking forward 0,6–1,5Not needed0,5–2,5 and sideways Frost, ice, No blocksNon-approved cargo securing alternatives0,8–1,50,4–1,01,0–2,5 snow, dirt, 1 pair0,8–1,5Not needed1,1–2,5 birch without 2 pairs0,5–1,50,4–1,00,8–2,50,5–1,5Not needed1,1–2,5 rubber: µ = 0.23 pairs0,5–1,5Not needed0,8–2,50,5–1,5Not needed0,5–2,5 4 pairs Blocking forwardNon-approved cargo securing alternatives0,8–1,5Not needed0,5–2,5 Blocking 0,8–1,50,4–1,01,0–2,5 sideways Blocking forward 0,8–1,5Not needed0,5–2,5 and sideways (1) Cargo securing not needed (if used the permitted interval is 0.0 –0.6 m) (2) Cargo securing not needed (if used the permitted interval is 0.0 –1.4 m) [1]The acceleration data meets the basic requirements in almost all road regulations and standards, however, certain countries may have national rules and guidelines that require other or supplementary blocking and/or lashing. Operator's Information Document Title: Travelling on public roads Information Type: Operator's Information Date: 11- 08-202 3 Profil e: L70E, L70G Volvo Location: Safety rules when operating/Operating instructions Travelling on public roads Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo As a machine operator you are considered to be a road user and therefore required to know and follow local regulations and national traffic regulations. It is important to remember that the machine, compared to other traffic, is a slow-moving and wide vehicle that may be an obstacle. Keep this in mind and pay attention to the traffic behind you. Facilitate overtaking. SMV-sign (Slow-Moving Vehicle) shall be used. It should be placed in a position at the rear on the machine where it is clearly seen, not inside the rear window or any other window. It should be located at a height of 0.6–1.8 m (23.6–70.9 in) above the ground measured from the bottom of the sign. Figure 1 SMV-sign The attachment should be empty, lowered to the transport position (30–40 cm (12–16 in) above ground) and fully tilted back. The front end of the material handling arm must be marked with a red flag. Lock the control levers with the control lever lockout. All work lights and any rotating beacon should be off. Hazard flashers may not be used except in emergency situations. Attachments and buckets that restrict visibility must not be used. Make sure that large attachments/buckets do not get in the way of the headlights. According to legislation, the machine's headlights must provide sufficient light and visibility in front of the machine. Additional tools such as buckets, shovels, and iron bars must be thoroughly secured with tensioningstraps or chains. If a trailer is to be towed behind the machine, see page Retrieving and towing. The connecting device on the counterweight must not be used when recovering, towing, or when operating on roads. Follow national regulations. Comfort Drive Control (CDC) may not be used. NOTICE Follow national and state regulations. Operator's Information Document Title: Visibility Information Type: Operator's Information Profil e: L70E, L70G Volvo Location: Operating instructions Date: 11- 08-202 3 Visibility Showing Selected Profile Valid for serial numbers ModelProduction site Serial number start Serial number stop L70E, L70G Volvo The following information applies to machines delivered to countries within the EU and may also apply to machines delivered to countries outside the EU. WARNING Some attachments and equipment may reduce the operator's visibility. Pay attention to blind spots, where there is no visibility, when operating on work sites and public roads. When needed, use a signal man. It may be impossible to obtain visibility to all areas around the machine. Optional devices and equipment such as warning systems, mirrors, back-up alarm, and monitoring cameras (CCTV), etc., may be used to obtain acceptable visibility. NOTE! Some parts of the basic machine may restrict visibility, e.g., the cab's pillars and frames, exhaust pipe, engine hood, as well as optional equipment such as buckets, pallet forks, grapples, etc. The load that is handled with theseattachments may also restrict vi si bilit y. To minimize risks caused by restricted visibility, the management shall establish rules and procedures for the work site. For example: Make sure that operators and persons on the site have received thorough safety instructions. Conduct training for operators and staff on the site. Control traffic flow for machines and other vehicles. Restrict the machine's work area. Use a signal man to assist the operator. Use hand signals according to the signal diagram, see pageSignalling diagram. Make available equipment for two-way communication when needed. Make sure that persons on the site communicate with the operator before approaching the machine. Restrictions for maximum permitted speed as well as for reversing the machine over long distances. Visibility standards to meet EU's machine directive The standard ISO 5006 "Earthmoving machinery –Operator’s field of view" deals with the operator's visibility around the machine and is intended to be used to measure and evaluate visibility. Conforming to this standard is a requirement in EUcountries and offers improved visibility around the machine. The machine is tested according to methods and criteria according to this standard. The method usedto evaluate visibility cannot include all aspects of the operator's visibility, but gives information to determine if optional equipment for indirect visibility is necessary, e.g., warning systems. The test was performed on a stationary machine without load, with standard equipment and standard attachment, and with the bucket in carry position. ISO 14401 "Earthmoving machinery -Field of vision of surveillance and rear-view mirrors". ISO 16001 "Earthmoving machinery -Hazard detection systems and visual aids -Performance requirements and tests" (Earthmoving machinery -Visibility using cameras). If the machine is modified or retrofitted with other equipment or attachments, which result in reduced visibility, it shallbe tested again according to ISO 5006, ISO 14401, and ISO 16001, and provided with optional visibility-enhancing equipment as needed. Actions before and during operation Figure1 The danger zone around operating machines is at least 7 m (276 in). Walk around the machine and check that there are no obstacles next to the machine. Check that mirrors and other visibility-enhancing equipment is in good condition, clean, and properly adjusted. Check that the horn, back-up warning signal, and the rotating beacon (optional equipment) work correctly. Check if the management has established rules and procedures for the work site. Always keep a look-out and pay attention to the area around the machine so that any obstacles can be identified. Prevent persons from entering or remaining in the danger zone, that is, the area around the machineand at least 7 m (276 in) beyond the attachment's maximal reach. The operator may allow a person into the danger zone, but then the operator must be very careful and only operate the machine when the person can be seen or has given clear indications of their whereabouts.