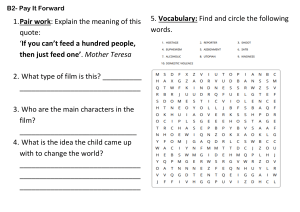

RFCCU CONSOLE OPERATOR CERTIFICATIO TEST AREA 5 - RFCCU General Safety Precautions 1. Based on PRefChem Incident Notification, Investigation and Reporting Procedure. The first notification should be done by the fastest means below: I. Phone call II. Text Message III. Incident Notification Form IV. Incident Management Online System A I, II B. I, III C. I, II, III D. All the above 2. Incident Notification, Investigation and Reporting for Non-Emergency Incident Rating 3 require notifying PRefChem Notification List (Internal) via _________ within _______. A. Text message, 1 hour B. Phone Call, 30 minutes C. Incident Notification Form, I day D. Incident Management Online System, 2 hours 3. According to Emergency Response Plan procedure, for initial response/action (This is the phase after notification and before the activation of the siren/emergency alarm) upon notification of emergency, what is the initial response for all other personnel located in respective plant under emergency? I. Work continue as usual II. Stop all works. III. IV. Switch off all vehicles and combustion engines. Leave all keys in motor vehicles. Proceed to emergency assembly area/toxic release shelter if evacuation alarm is sounded and remain there until all clear announcement is made A. B. C. D. Internal I, II, III, IV I, II, III I, II II, III, IV 4. Which of the following does not explain the operations of the 1st Regenerator A. B. C. D. It operates in partial combustion mode In partial mode combustion, only part of the coke is burnt to CO2 and balance of the coke turn to CO gas In partial combustion mode, the Regen 1 dilute phase temperature is maintained higher than the temperature of Regen 2 Complete Combustion Mode. 1st Regenerator pressure is always maintained higher than the 2nd Regenerator Pressure by 0.92 ~ 1.0 Barg 5. Which of the following does not explain the operations of the 2nd Regenerator? A. B. C. D. It operates in complete combustion mode In Complete Combustion mode, all Oxygen is consumed by the coke burning process. The pressure in the 2nd Regenerator is controlled lower than the pressure of the 1st Regenerator by 0.82 ~ 1.92barg. The temperature in 2nd Regenerator is always maintained lower than the temperate of 1st Regenerator. For the following question, refer to the above schematic of V-201 and its associate instrumentations 6. Any trip of WGC will cause the OH pressure to suddenly spike upwards. This situation will cause the RCSV dip and potentially trip in Low Low DP. Which of the following action shall you take not to trip of RCSV when WGC trips? A. Bleed in some constant amount of F/G into MF Gas Recovery Section by fixing a certain amount of FG make up B. Operate the WGC recycle feed back CVs on manual fixing it at a certain opening at all time C. Set PICA 4301 Set Point slightly higher than the Set Point of PIC-4307 D. Control PIC 4301 on Manual and open when required when pressure surge happen. Internal 7. Can RFCCU still run without WGC onstream? A. RFCCU still can run under cripple mode letting the wet gas stream diverted to flare B. The RFCCU still can be continue running by producing HCO, LCO and Slurry products while venting Wet Gas stream to flare C. RFCCU still can run at minimum turn down of 70% feed. D. RFCCU must be shut down, putting Hot catalyst circulation on by the help Torch Oil and if Torch Oil is not enough to retain the heat of the catalyst, prepare and light APH while waiting the WGC to get fixed. Figure 1 shows the schematic that indicates location of PIZA0202 -LL and its output signals. Before feed pump is started, PIZA 0202LL shows no pressure with the LL alarm is on. Explain how the pump can be started knowing that PIZA0202 -LL is still in alarm state? A. Pump is to be started by FO following the normal Standard Procedure B. Pump must be primed first before the instruction to start the pump is given C. PIZA 0202 LL must be put on OVERRIDE before the pump can be started and this override / SCE bypass must be immediately normalized after the discharge flow stable. D. Pump is to be started with PIZA 0202 LL override and this SCE bypass can be on for 24hrs. Internal 8. Slurry Quench Pumps failure will cause the MF bottom temperature to increase very quickly. What action shall you take to quickly bring down the MF bottom temperature during upset? A. Investigate the course of why the pump fail to deliver, quickly start the slurry standby pump to recover back the quenches B. Reduce RFCC Feed. Line up feed residue using Reaction and Regeneration bypass line feeding residue directly into the MF Bottom to apply immediate quench. If pumps are unable to recover, take the feed out but keep the cat circulation on. C. Stop one of the pump, cool down, isolate and clean the filter letting the other 2 running D. Gag down the pump discharge to about 20% to recovery back the pump discharge pressure and slowly open the discharge. Note* Having good knowledge of how the Slide Valves work is very important for every Panel-man. This knowledge will avoid reverse flow and potential catastrophic process incident and explosion in RFCCU < 9. The differential pressure of Regenerated Catalyst Slide Valve, RCSV is controlled at 0.5 barg. What will happen to the RCSV differential pressure if the pressure of the Main Fractionator increased? A. B. C. D. the RCSV differential pressure will also increase the RCSV differential pressure will reduce the RCSV differential pressure remains same The RCSV does no move 10. What will happen to the SCSV when the Main Fractionator pressure start dropping? A. The differential pressure across the SCSV reduce B. The differential pressure across the SCSV will increase C. It will reduce the Stripper Pressure D. The differential pressure across the RCSV remains in the same position Internal 11. If the RCSV differential pressure, PDICA 1603 increases higher than its set point. The Slide Valve will A. B. C. D. Open more until the DP meets its set point Start to reduce its opening until the DP meets its set point Reduce it opening until it close fully. Remain in the same position. 12. If the Stripper/Dienggager pressure increased from 1.5 bar to 1.6 bar what will happen to Regen Catalyst Slide Valve differential pressure? A. B. C. D. Delta P Increase Delta P Decrease Delta P Remain the same Delta P Remain the same as the RCSV adjusted itself to maintain the DP SP. 13. If the Stripper/Dienggager pressure decreases from 1.4 bar to 1.3 bar what will happen to Regen Catalyst Slide Valve differential pressure? E. F. G. H. Delta P Increase Delta P Decrease Delta P Remain the same Delta P Remain the same as the RCSV adjusted itself to maintain the DP SP. 14. If we increase V-201 MF reflux drum pressure via injecting fuel gas in the system via HIC 4303 what will happen to the Differential Pressure of Spent Catalyst Slide Valve and Regenerate Catalyst Slide Valve? A. B. C. D. Internal SCSV differential pressure increase, RCSV differential pressure decrease Only spent catalyst slide valve differential pressure increase Only regenerated slide valve differential pressure increase Both increase For question 12 and 13, please refer the process schematic above 15. Which of the following describes V-201 Reflux Drum pressure controller, PICA 4307? A. PICA 4307 controls the Main Fractionator pressure by regulating the speed of WGC B. PICA 4307 Controls the Reflux Drum and MF Overhead pressure by regulating the amount of Fuel Gas make up to the drum C. PICA 4307 Controls the Reflux Drum and MF Overhead pressure by regulating the amount of the overhead gas CV opening to flare header D. PICA 4307 Controls the Reflux Drum and MF Overhead pressure by Split Range Control regulating the amount of the overhead gas CV opening to flare header as well as FG make up. 16. V-201 drum pressure controller PICA 4301 will open the pressure control valve if the Main Fractionator pressure is higher than its set point. The set point of this controller is controlled A. B. C. D. slightly lower than the PICA 4307 controller Set Point slightly higher than the PICA 4307 controller Set Point so that during any upwards pressure surge, CV will immediately release the excess pressure to flare preventing surge in RCSV that can trip the RFCCU on Cat Circn Failure. It automatically tracks the SP of PICA 4303 with the same SP It automatically tracks the SP of PICA 2401 with higher SP. 17. Sudden increase of the amount of vapors produced in MF overhead system will result in an increase in Reflux Drum V-201 pressure. The Wet Gas Compressor will respond accordingly reacting to the action of the drum’s pressure controller PIC 4307 by A. Opening more the spill back valve B. Increasing the motor speed of the air condenser E-201A~P Internal C. Reducing the speed D. Increasing the speed 18. Which of the following statement is WRONG about the function of V-201 Hand Controller HIC 4303 A. It is used to manually regulate the pressure in the Main Fractionator Overhead System during upset. B. It helps to control slide valves differential pressure C. It helps to avoid WGC from going into surge by injection F/G to V-201 D. It automatically open when WGC trip Refer to the schematic above and answer the question no. 16 & 17 19. Which of the following explain the correct Operation of the LOW SELECTOR placed between the Stripper TICA 1310 and RCSV PDICA 2405 A. B. C. D. Internal It compares whichever lower signal between the Stripper TICA output and RCSV PDICA 2405 output. The selected lower signal will control and regulate the SV, Select the signal which is higher between Stripper TICA output and RCSV PDICA 2405 output The Low Selector overrides the lower signal that comes from the TICA and PDIC It does not react with any of the controller output. 20. During normal running, the 2nd regenerator level controller, LICA 2202 controls the opening of the plug valve UC 1904. If the level of the 2nd Regenerator starting to get higher, the LICA 2202 will A. B. C. D. open the plug valve more close the plug valve more open the plug valve more provided the level in the 1st Regenerator is not low close the plug valve more provided the level in the 1st Regenerator is not high Note* Afterburn will cause rapid temperature increase in the 1st Regenerator going above the design temperature. Damage the Cyclones causing long shut down, loss of production and costly repair. 21. Which of the statements are correct about Afterburn? I. Oxygen escaping from 1ST Regn to the dilute phase will cause afterburn where CO will react with the Oxygen and produce CO2 and releasing HEAT. II. The HEAT causes high temperature that could damage the cyclone. (Max design temperature is 770°C) III. After burn can be reduced by injecting CO Promotor into the catalyst where the CO promotor helps to burn the CO inside the dense phase and consuming the excess oxygen there. In this way, the amount of Oxygen that slip up to the dilute phase has been reduced and Afterburn also reduced. IV. After burn is caused by over injecting of the combustion air, Sudden reduction of feed, poor air distribution, channeling of air from air grid and poor air grid design. A. I, II, & III B. II, III, & IV C. III & IV D. All the above 22. Which of the followings explain the correct operation of WGC Surge Controller? i. It was programmed in order to protect the compressor from surging ii. Surging occurs when the compressor is unable to receive enough inlet suction flow iii. Intermittent loss of suction flow and pressure can result in flow reversal that can severely damage the compressor causing prolong shutdown and costly repair. iv. The Anti Surge control will open the spill back control valve when the compressor start to experience surge condition by feeding the discharge gas back to the suction and subsequently move away from the surge condition. A. B. C. D. Internal I, II, & III II, III, & IV III & IV All of the above 23. What you do if the WGC is moving into urge condition? A. Wait until the ASC of the compressor corrects itself B. Stop one of the Air Condenser Motor C. Increase the Set Point MF using pressure controller PIC 4307 on reflux drum D. Open HIC 4303 to import more F/G into V-201 reflux drum until the compressor move away from surge. 24. What happen to RCSV if WGC trip? A. The RCSV will experience spike in pressure due to a sudden increase of MF Pressure. It may potentially loss the DP suddenly causing it to trip the unit B. The is no effect on the DP of the RCSV C. The RCSV is on Auto Control and it will adjust it position accordingly D. The RCSV will experience sudden increase in DP and it will respond by reducing the valve opening accordingly. 25. What action shall you take if during feed in, the WGC fail to open its Spill Back Controller causing it to surge and transforming the MF and the Reactor/ Disengager pressure into vacuum condition? (Note that the WGC running without Spill back behaves like a big vacuum cleaner. The MF and reactor are not designed to operate under vacuum condition and if this happen, it will rupture causing catastrophic fire, major explosion, Asset damage and injury to us) A. B. C. D. Internal Open the HIC 4303 to introduce the FG into the MF gas recovery section and move the WGC away from its surge condition BEFORE vacuum condition develop. If pressure too low and moving towards a vacuum condition, trip the WGC. Keep the unit and WGC running and call instrument personnel to look and retune the WGC ASC Stop a few of E-201 A-H MF Overhead Air Condensers to temporarily make more gas in Gas Recovery Section Inform supervisor and wait for further instruction meanwhile closely monitor the situation. 26. In order to prevent pressure spike in RCSV during MF WGC upset that would cause the RCSV trip Low Low DP, which of the following action shall you take? A. Bleed in some constant amount of F/G into MF Gas Recovery Section by fixing a certain amount of FG make up B. Operate the WGC recycle feed back CVs on manual fixing it at a certain opening at all time C. Set PICA 4301 Set Point slightly higher than the Set Point of PIC-4307 D. Control PIC 4301 on Manual and open when required when pressure surge happen. 27. Can RFCCU still run without WGC onstream? A. RFCCU still can run under cripple mode letting the wet gas stream diverted to flare B. The RFCCU still can be continue running by producing HCO, LCO and Slurry products while venting Wet Gas stream to flare C. RFCCU still can run at minimum turn down of 70% feed. D. RFCCU has to be shut down, putting Hot catalyst circulation on by the help Torch Oil and APH while waiting the WGC to get fixed. Internal For Question No 28, 29 & 29, below, refer to the above schematic. 28. When WGC trip, what will happen to the Sour Fuel Gas that used as a reactor instrument purge? A. The pressure of the Sour Gas instrument purge gas will also drop and causing the Nitrogen to cut in replacing the Sour Gas as purge medium to the reactor instrument tapings B. The pressure of the secondary absorber will increase, and the Sour Gas instrument purges is still be healthy C. The pressure remains the same because the pressure controller of Secondary Absorber PICA 0101 is still in control of the treated fuel gas export to FG and SCU. D. The Sour Gas continue to operate supplying purge gas to the Reactor / Stripper section. 29. During cracking reaction in the reactor riser, massive amount of cracked hydrocarbon gas is produced and collected in the MF Gas Recovery Section. Which of the followings describe the way the pressure of the Gas Recovery Section is controlled? A. The Pressure of the gas collected in the Gas Recovery Section is controlled by the Wet Gas Compressor B. The gas in the gas recovery section is controlled by the V-201 Pressure Controller where the excess pressure will be routed to Flare by the action of the Pressure Controller PIC 4301. C. The pressure of the Gas Recovery Section is controlled by PIC 0101 located on the outlet overhead line of C-303 Secondary Absorber exporting Treated Gas to SCU and FGS D. The pressure of the Gas Recovery Section is controlled by the WGC Spill Back Controller. 30. Which of the following statement below explain correct operations of the PIC 0101? i. FCV 0101 A supplies RFCC I&2 cracked gas to Steam Cracker Unit ii. PCV 0101 B Supplies RFCC I&2 cracked gas to Fuel Gas System iii. PCV-101A and B is split range control. If the pressure getting lower FCV 010B starts to close first – closing the gas supply (export) to FG System with the controller Output range of 50 to 100%. If pressure is still getting lower, PCV-101A start to reduce the amount of RFCCU gas export to SCU. iv. If RFCCU train 1 trip, the other running train will supply the gas to FG and SCU. If both trains trip SCU the gas supply to SCU will be cut off completely. Internal A. I, II, & III B. II, III, & IV C. III & IV D. All the above 31. Which or the equipment equipped with Torch Oil Injectors? A. 1st Regenerator only B. 2nd Regenerator only C. Both Regenerators D. Reactor Riser 32. At what catalyst bed temperature we can start to light torch oil firing? A. B. C. D. 300 degC 100 degC 370 °C and above 200 degC 33. Which of the following statement is wrong about the operations of the 2nd Regenerator? A. It is operated in complete combustion mode B. In Complete Combustion mode, all Oxygen is consumed by the coke burning process. C. The 2nd Regenerator pressure is controlled lower than 1st Regenerator pressure. D. The temperature of 2nd Regenerator is always maintained lower than the temperature of 1st Regenerator temperature. 34. Which of the following is wrong about the operations of the 1st Regenerator A. It is operated In partial combustion mode B. In partial mode combustion, only part of the coke is burnt to CO2 and balance of the coke turn to CO gas C. The temperature is maintained higher than the temperature of Complete Combustion Mode in 2nd Regenerator. D. 1st Regenerator pressure is always maintained higher than the 2nd Regenerator Pressure and it is maintain at around 1.92barg 35. Which of the following explanation is wrong about the process of swinging the operations modes of the 1st Regenerator? A. B. C. D. Internal To swing the regenerator 1 operation from complete burn to partial burn at the beginning state of the startup, first we slowly reduce the combustion air. While reducing the combustion air, we observe for any CO starts to appear at the outlet analyzer of the 1st Regenerator Once the CO start to appear, the regenerator is already going into the Partial Burnt Mode and we reduce the air further until the ratio of CO2/(CO2+CO) is maintain at 62.5 The amount of CO2 will reduce if more air is injected at the bottom of Reg2. 36. Which statement below are correct about to Afterburn? i. Oxygen that present in the dilute phase will cause afterburn where CO will react with the Oxygen foaming CO2. ii. Burning of CO to CO2 in Regen 1 dilute phase release the combustion heat causing high temperature that could damage the cyclone. (Max design temperature is 770°C) iii. After burn can be reduced by injecting CO Promotor into the catalyst where the CO promotor helps to burn the CO inside the dense phase and consuming the oxygen there. In this way, the amount of Oxygen that slip up to the dilute phase has been reduced. iv. Afterburn is caused by, among other things, over injecting of the combustion air at any point of the coke burning process, poor air distribution, channeling of air from air grid and poor air grid design. A. B. C. D. I, II, & III II, III, & IV III & IV All the above statements are correct 37. Which of the following will be initiated as the consequences of High high liquid level in Feed Surge Drum, V-105 under the 1311- UZ-207 Safeguarding Logic Interlock? A. The LZA 0201 HH will trigger the feed pump P-101A or P-101B, whichever in operations to stop. B. The LZA 0201 HH will trigger the feed emergency circulation UZV 0401 to trip open and initiate feed circulation back to the surge-drum V-105 to open C. The LZA 0201 HH will trigger the stand-by feed pump P-101A or B to cut in. D. The LZA 0201 HH will initiate 1311-UZ-207 and subsequently trip shut the UZV-201 TSOV located on the V-105 feed line to close Internal 38. Which of the followings describe the reason of the feed surge drum safeguarding UZ-207 is put in place? A. B. C. D. To prevent pump run dry causing overheating and subsequent seal failure To prevent lost of feed to RFCCU and trips the RFCCU Unit To prevent the rupture of the surge drum To prevent vessel overfill causing liquid carry over to flare and subsequently creating a fireball condition in the flare system FIGURE 1 39. Figure 1 shows the schematic that indicates location of PIZA/LL and the output signals. After analyzing the above trip signal, What is the reason to put the PIZA 0202LL on override (SCE Bypass) so that the pump can be started A. To temporarily overcome the trip signal from PIZA 0202 LL B. To cancel the alarm on 1311-PIZA- 0202 LL C. To enable us to reset the feed pump. D. To enable us to reset the emergency circulation line TSOV. Internal 40. 1311-UZ-209 is a functional logic interlock that applied for feed pump protection. Which of the following statements it true about the operations of 1311-UZ-209? i. Low Low level in feed Surge Drum will trigger 1311-LIZA-0201AB which initiates the 1311-UZ-209 II. 1311-UZ-209 will shut down the running feed pump iii. Low Low Pressure of the feed pump discharge PIZA 0202 ABC 2oo3 will initiate 1311-UZV-209 and shut down the feed pump. iv. The PIZA 0202 ABC LL need to be put on SCE bypass (override) for the pump in order to enable it to to be started start during feed startup. A B C D I,II & III I & II & III I, III & IV I,II,III & 1V 41. Which of the followings is not the cause of RFCCU Feed Outage (Feed Trip) based on the Instrumented Protective Function 1311-UZ-201 A. B. C. D. Stripper / Disengager outlet very Low Temperature UZ- 202 Catalyst Circulation Failure Low Feed Surge Drum Level Very High Level in MF Bottom 42. Other than the conditions stipulated in question 41 above what are other 2 (two) conditions that will result in FRCCU feed to trip (feed outage)? I. II. III. IV. A. B. C. D. IFZA LL 0401 Very Low Flow At Riser Inlet Low feed surge drum level Lost of one of the feed Pump P-101A or P-101B HS 0401 DCS Panel Hand switch I & II III & IV I & IV II & III 43. The followings are the results of feed outage based on the actions initiated by UZ-201 except A. B. C. D. Shut down the feed pump whichever is running Open UZV on feed Recycle Line - diverting the feed back to feed Surge Drum Close UZV on feed line to feed injectors Full open the steam supply CVs to feed injectors (8X) 44. The followings are the results of feed trip based on the actions initiated by UZ-201 except A. Full open the steam supply CVs to Stabilization Steam injectors (5X) B. Close UZV to stop the flow of Sour Fuel Gas from Secondary Absorber to Fuel Gas Drum C. Trip close the Catalyst Cooler Circulation Pump D. Close UZ on HN Quench to Vapor quench Injector Internal 45. Other than conditions stipulated in Question 34 and 34 above, the following Safeguarding actions are also initiated when FRCCU Feed trip except: A. Metal Passivator Injection Pumps will be automatically stopped (X2) B. Both Regenerated Catalyst Slide Valve (RCSV) and the Spent Catalyst Slide Valve (SCSV) will stop automatically C. MF Corrosion Control Injection Pump will be automatically stopped (A201 P01AB) D. Close UZV of the LCO Flushing Oil line on Instrument in Reactor Feed and HCO Back Flush Oil line (X2) FIGURE 2 46. A very low Stripper / Disangger top temperature (Figure 2) will result in significant amount of unvapourized feed reaching the regenerator via Stripper. This scenario will lead to: A. The unvapourized hydrocarbon enter the 1st regenerator via the stripper causing temperature incursion (sudden increase in temperature) that can overheat and damage the Regenerator B. Coke build up in SCSV stand pipe C. Amount of excessive coke build up in regenerator. D. Stripper blockage in packing area. Internal HANDLING PLANT UPSET AND MERGENCY – FEED SYSTEM For questions number 18 to 19, please refer to the schematic below: 47. The feed to the RFCC unit can be taken out during emergency by Console Operator via DCS Screen feed via feed outage by HS-0201A. Which is the correct action that Console Operator shall take immediately once he receives an emergency radio call from the Field Operator that one of the feed pump, P-101A is on big fire? A. Trip the feed to the unit immediately using HS-0201. Inform Supervisor and RSM, initiate ERP as per procedure. Prepare to stabilize the Regenerators and Stripper/Diseggager operation as per Emergency Feed Outage Procedure to keep the catalyst on circulation B. Inform the supervisor and RSM that the feed pump is on fire, initiate emergency response as per ERP procedure and wait for his next instruction. C. Wait for the supervisor’s or RSM instruction knowing that they are already at the place of the incident. D. Inform Supervisor & RSM, Reduce the feed to minimum, adjust the R&R Parameters accordingly and wait for Supervisors instruction. 48. One of the condition causing the feed outage is lost of Catalyst Circulation This is done in order to A. prevent hydrocarbon-laden Spent Catalyst entering the Regenerator when the Cat Circulation is reestablished during the next catalyst circulation restart. B. Prevent upset in the Main Fractionator Gas Recovery Section C. Prevent lost of coke production from cracking proceed. Coke is needed to continuously maintain the heat in the Regenerator D. It is ok to continue feed injection to the riser as long as the Stripping and Pre-stripping steam is still healthy and maintained at design value. Internal STARTUP & SHUT DOWN 49. Which of the followings must be achieved prior startup preparation activities and state of readiness in other downstream sections before feed in introduced to the Reactor injectors? I. K-101 Main Air Blower is running with the blow off valves tested and working as intended with Combustion Air to 1st and 2nd Regenerator, Lift Air, Cat Cooler Fluffing Air on stream. II. Both Regenerators and Stripper has been successfully pressure tested (Cold and Hot) and leak free. III. Flue Gas Section: UZV 8501 and UZB 8503 Diverter valves are both closed to COB and opened directly to Scrubber. CO incinerator is already onstream generation mode with the Economizer E102 is on stream ready to receive hot flue gas at any moment. IV. Catalyst Cooler 1311-E-103 on Circulation with CCSV in close position. A. B. C. D. Internal i & ii & iii iii & iv ii & iii All of the above statements are true. 50. After the Regen 1 has been warmed up and heated up with APH F-101 until 400°C, what is the reason of the regenerator temperature start to drop when the catalyst start to enter the 1st regenerator during toping up activities? A. The cold catalyst transferred from the e cat hopper absorbs the heat from the regenerator causing it temperature to drop. B. The air preheater outlet hot air starts to transfer the heat to the catalyst entering the Reg 1 C. The air cool down the catalyst that just entering the Reg 1 D. The heat in the Reg1 is transferred to the catalyst causing the temperature of the atalyst to increase. 51. What should you do to increase the temperature at the same time, topping up the Cat into the Reg1. A. Increase the APH outlet temperature accordingly. If the temperature increases too low, slow down the cat transfer and wait for the Reg1 temp to pick up again B. Keep on adding the catalyst at the same rate and Air Preheater will be able to pick it up the initial drop of the temperature again C. Reduce the amount of cat transfer temporarily and restart transfer catalyst when the temperature increases back to normal D. Reduce the amount of lift air rate coming out from the APH so that the air get more hotter 52. At this state of startup, APH, F-101 is on-stream with FG firing and still picking up heat - targeted at 650°C. The next step is to inject torch oil. At what level and RG1 temperature you can start introducing the Torch Oil Firing? A. Torch oil can be introduced into Regen 1 bed at any time if the bed temperature is already > 370°C B. Torch oil can be introduced into Regen 1 bed as early as possible when the catalyst level already appeared and the APH is on stream C. Torch oil can be introduced into Regen 1 bed when bed temperature is already > 370°C and the catalyst level is 500mm above the TO nozzles D. Torch can be introduced after the catalyst is put on circulation 53. What is other 2 indication that you refer to ensure that the Torch Oil nozzle is already submerged in the catalyst dense bed? A. The bed elevations must be at least 11800m or a 6.7% of level transmitter reading LT 1701. B. The level of catalyst based on any transmitter reading C. The elevation of 10000mm of the catalyst bed D. The temperature of the catalyst and a healthy Spent Cat Slide valve DP. 54. Why must the Torch Oil Nozzle be submerged into the dense bed of the catalyst before it can be light up? A. To ensure that there is enough heat given by the dense catalyst so that it can be light up easily B. To ensure that there will be minimum erosion take place on the Torch Oil injectors C. To ensure a safe and proper ignition of the oil and efficient dispersion of the heat into the catalyst bed. D. To ensure that the catalyst has enough air to get it burn safely. Internal 55. What can happen if the torch oil is commissioned with the nozzles unsubmerged? A. The torch oil will be difficult to light up without hot catalyst surrounding the nozzle where it did not have physically contact with hot catalyst surface B. The Torch will not be able to light up when there is not enough heat transfer from the hot catalyst to the torch oil nozzles. C. The droplets of Torch Oil, if unsubmerged, will not properly distributed all around the hot catalyst and it will not be burnt. D. The unsubmerged torch oil nozzles will cause the small atomized droplet to occupy the dilute phase, move around to the cyclone areas and with a right proportion with air it can cause explosion in the dilute phase of the regenerator 56. Why must the Torch Oil only can be commissioned when the regenerator catalyst temperature is above 370°C A. 370°C is the Auto Ignition temperature of the Torch Oil Once introduced, it will automatically be ignited. B. 370°C is chosen to light up the torch oil automatically when hot air being supplied to the droplets. C. 370 °C is the boiling point of T.Oil and it will be easily ignite with the present of air and enough heat. D. The torch oil will be easily vaporized and ignite instantly at 370°C 57. What is the correct sequences of the next main step in startup of R&R Section after the Regen 2 temperature reach 650°C i. Keep T. Oil firing ii. reduce APH firing iii. top up cat until maximum level of 54.3% on LI 1701B & LI-1702B. iv. Start transfer catalyst from Reg 1 to Regen 2 A III, II, I, IV B. II , III , I , IV C. IV , III , II , I D. I , II , III , IV Internal 58. What are the next start up step sequence? Start transfer the catalyst from 1st to 2nd Regenerator as quickly as possible by slowly open the plug valve maintaining the ΔP at about 0.7 Barg on by decreasing the 2nd Regenerator Pressure regulating PCV-8505 until the level reaches 500mm above Torch Oil Nozzle (at 10.8% at LI-2201B), AS soon as possible ii. Prepare the stripper effluent to the MF Bottom inlet spectacle blind removal meanwhile open on Manual SCSV to transfer catalyst from 2nd Regenerator into the stripper in order to fill up the Stripper stand pipe with hot catalyst maintaining the temperature increment < 60℃ to avoid thermal stress iii. Keep on transfer catalyst upwards submerging the cyclone dip legs and move on until targeted max level of 63.5% at LI-2201 is reach). From now on, let the Torch Oil control the 2nd Regenerator Temperature at 650℃. Reduce APH F-102 firing to minimum but do not cut it off since it may be needed later. iv. When both Regenerators has met the required catalyst level, stop transferring the catalyst. Change the Stripper/Disengager/Reactor from air environment switching it to steam injection environment i. A. B. C. D. I, III , IV , II III ,IV, II , I IV , III , , II I ,II , III , IV 59. What is the following step after catalyst transfer from Regen 1 to Regen2 has been completed? Prepare the stripper effluent to the MF Bottom inlet blind removal meanwhile open on Manual SCSV to transfer catalyst from 2nd Regenerator into the stripper in order to fill up the Stripper stand pipe with hot catalyst ii. maintaining the temperature increment < 60℃ to avoid thermal stress and continue incremental bath by bath transfer while maintaining Stripper bed temperature not exceeding 565℃. iii. When temperature increment can be controlled, open SCSV more to start a continuous Cat Circulation until the stripper level reaches 1000mm below the RS2 Diplegs or about 37.4% at Long Level LI-3401 for Sealless Operation iv. The Reactor is now ready to feed the Oil in after the Stripper Effluent Spectacle Blind has been pulled out replaced by the Ring Spacer. i. E. F. G. H. I , III ,IV , II III ,IV , II , I IV , III , II I , II , III , IV 60. About an hour after the catalyst circulation has been started, the circulation is tripped by low low SCSV differential pressure. What should you do? A. Investigate and rectify reason of trip, quickly get the SCSV delta P normalized again by adjusting either MF Pressure or / and Regenerator Pressure, restart the catalyst circulation, reset the feed TSOV, switch both of the low selectors from manual to auto. and feed the oil in again as usual if the catalyst temperature in the 2nd Regen is still hot (normal) B. Trip the feed and introduce torch oil firing into both regenerators. C. Line up the feed to the bottom of the MF D. Put slurry bottom circuit on heating mode. Internal