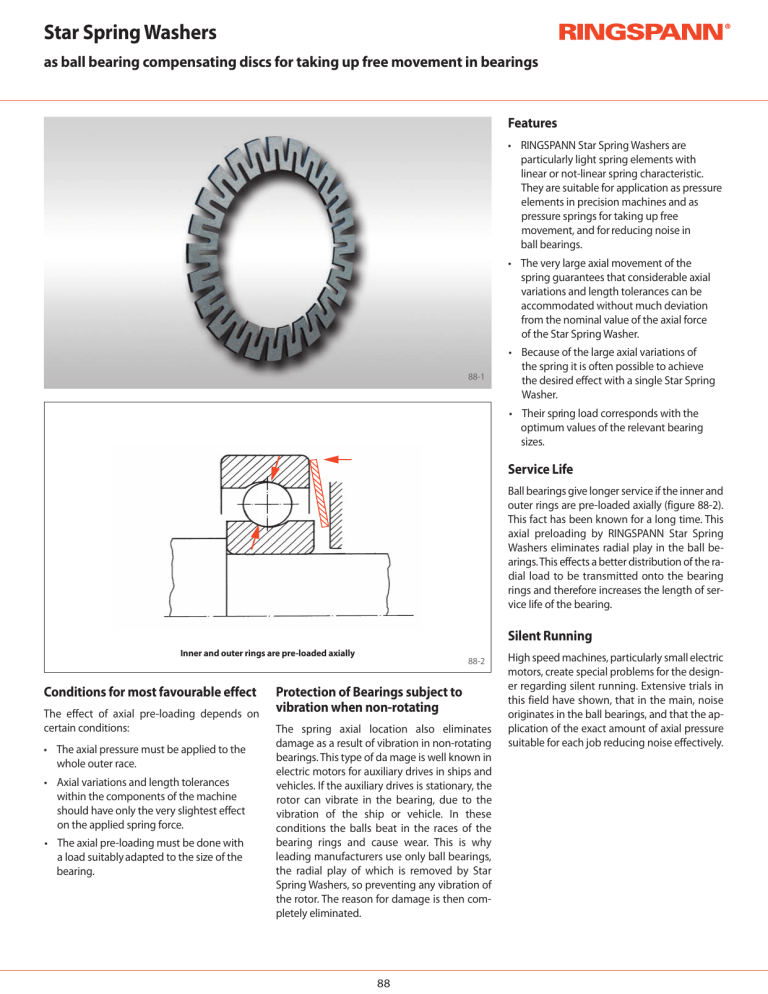

Star Spring Washers as ball bearing compensating discs for taking up free movement in bearings Features • RINGSPANN­Star­Spring­Washers­are­ particularly­light­spring­elements­with­ linear­or­not-linear­spring­characteristic. They­are­suitable­for­application­as­pressure elements­in­precision­machines­and­as­ pressure­springs­for­taking­up­free­ movement,­and­for­reducing­noise­in­ ball­bearings. • The­very­large­axial­movement­of­the­ spring­guarantees­that­considerable­axial variations­and­length­tolerances­can­be­ accommodated­without­much­deviation from­the­nominal­value­of­the­axial­force­ of­the­Star­Spring­Washer. 88-1 • Because­of­the­large­axial­variations­of­ the­spring­it­is­often­possible­to­achieve­ the­desired­effect­with­a­single­Star­Spring Washer. • Their­spring­load­corresponds­with­the­ optimum­values­of­the­relevant­bearing sizes. Service Life Ball­bearings­give­longer­service­if­the­inner­and outer­rings­are­pre-loaded­axially­(figure­88-2). This­fact­has­been­known­for­a­long­time.­This axial­ preloading­ by­ RINGSPANN­ Star­ Spring Washers­eliminates­radial­play­in­the­ball­bearings.­This­effects­a­better­distribution­of­the­radial­load­to­be­transmitted­onto­the­bearing rings­and­therefore­increases­the­length­of­service­life­of­the­bearing. Silent Running Inner and outer rings are pre-loaded axially 88-2 Conditions for most favourable effect Protection of Bearings subject to The­ effect­ of­ axial­ pre-loading­ depends­ on­ vibration when non-rotating certain­conditions: • The­axial­pressure­must­be­applied­to­the whole­outer­race. • Axial­variations­and­length­tolerances­ within­the­components­of­the­machine should­have­only­the­very­slightest­effect­ on­the­applied­spring­force. • The­axial­pre-loading­must­be­done­with­ a­load­suitably­adapted­to­the­size­of­the bearing. The­ spring­ axial­ location­ also­ eliminates­ damage­as­a­result­of­vibration­in­non-rotating bearings.­This­type­of­da­mage­is­well­known­in electric­motors­for­auxiliary­drives­in­ships­and vehicles.­If­the­auxiliary­drives­is­stationary,­the rotor­ can­ vibrate­ in­ the­ bearing,­ due­ to­ the­ vibration­ of­ the­ ship­ or­ vehicle.­ In­ these­ conditions­ the­ balls­ beat­ in­ the­ races­ of­ the­ bearing­ rings­ and­ cause­ wear.­ This­ is­ why­ leading­manufacturers­use­only­ball­bearings, the­ radial­ play­ of­ which­ is­ removed­ by­ Star Spring­Washers,­so­preventing­any­vibration­of the­rotor.­The­reason­for­damage­is­then­completely­eliminated. 88 High­speed­machines,­particularly­small­electric motors,­create­special­problems­for­the­design­er­regarding­silent­running.­Extensive­trials­in this­field­have­shown,­that­in­the­main,­noise­ originates­in­the­ball­bearings,­and­that­the­application­of­the­exact­amount­of­axial­pressure suitable­for­each­job­reducing­noise­effectively. Star Spring Washers as ball bearing compensating discs for taking up free movement in bearings Bearing of an internal grinding spindle Spindle­ ball­ bearings­ are­ used­ as­ bearing­ support­for­grinding­spindles.­Bearings­of­this kind­exhibit­maximum­tracking­accuracy­at­high rotation­speeds.­ The­specific­properties­of­these­bearings­can­ be­fully­exploited­only­if­the­bearings­are­preclamped­with­a­precisely­defined­force. RINGSPANN­Star­Springs­Washers­enable­you­ to­realise­the­required­pre-clamping­ force­of­ the­spindle­bearings­with­a­high­degree­of­precision.­ Bearing of an internal grinding spindle 89-1 Pressure spring for ball bearing Silent­running­is­a­particular­requirement­for electric­motors.­For­this­purpose­a­RINGSPANN Star­Spring­Washer­acts­to­pre-load­the­outer race­of­the­bearing­as­illustrated. Pressure spring for ball bearing 89-2 Accommodating length tolerances As­shown­in­this­example­the­RINGSPANN­Star Spring­Washer­fitted­between­output­shaft­and NILOS­sealing­ring­makes­it­possible­to­accom­modate­wide­axial­tolerances. Accommodating length tolerances 89 89-3 Star Spring Washers as ball bearing compensating discs for taking up free movement in bearings H h (w) Spring under tension ød øD With­washers­stacked­in­ parallel,­the­pressure­ forces­are­added. Washers­with­dish­angles­ opposite,­the­spring­travels are­added. Spring released S 90-1 Dimension For­ball­bearing Height released D mm 634 635 635 E­3 E­4­ E­5 626 626 E­6 E­7 E­8 627 629 629 16100 16101 16002 16003 608 609 E­10­ E­14 E­15­ 6002­ 6003 E­16 E­19 E­19 L­17a Bo­15­ E­20 M­20 16006 16007 16008 16009 6000 6000 6001 E­9 E­13 E­11 E­12 16004 16005 16005 L­30 624 625 607 607 EA­17­ L­20­ L­25­ 6006 6007­ 6008 6200 6201 6201 6202 6300 6301 6203 6203 6004 Bo­17 6005 6005 6205 6302 6204 6206 6305 6403 6207 6306 6404 6303 6304 6009 12,7 15,7 18,7 18,7 20,7 21,7 23,7 25,7 25,7 27,7 29,7 31,7 31,7 34,7 36,7 37,7 39,7 39,7 41,7 43,5 46,5 46,5 51,5 54,5 61 67 71 74 d mm 5,3 7,5 7,5 9,2 10,5 11 11 11 13,5 15 15 15 18 20 20 20 20 23 27 27 27 30 35 35 40 45 45 50 s mm 0,3 0,3 0,3 0,3 0,3 0,5 0,5 0,5 0,5 0,65 0,65 0,65 0,65 0,9 0,9 0,9 0,9 0,9 0,9 0,9 0,9 0,9 0,9 1,15 1,15 1,15 1,15 1,15 H mm 1,1 1,1 1,4 1,2 1,3 1,6 1,8 2,0 1,7 1,9 2,1 2,3 2,0 2,4 2,6 2,7 2,9 2,6 2,4 2,6 2,9 2,6 2,6 3,1 3,3 3,4 3,8 3,6 under pressure h mm 0,7 0,7 0,7 0,7 0,7 0,9 1,0 1,0 1,0 1,1 1,1 1,1 1,1 1,4 1,4 1,4 1,4 1,4 1,4 1,4 1,4 1,4 1,4 1,7 1,7 1,7 1,7 1,7 Tolerance for h Spring travel Pressure Spring const. Article­ number mm (w) mm F N c N/mm 1051- ±­0,15 ±­0,15 ±­0,15 ±­0,15 ±­0,15 ±­0,15 ±­0,2 ±­0,2 ±­0,2 ±­0,2 ±­0,21 ±­0,2 ±­0,21 ±­0,2 ±­0,21 ±­0,2 ±­0,2 ±­0,2 ±­0,2 ±­0,2 ±­0,2 ±­0,2 ±­0,2 ±­0,25 ±­0,25 ±­0,25 ±­0,25 ±­0,25 0,4 0,4 0,7 0,5 0,6 0,7 0,8 1,0 0,7 0,8 1,0 1,2 0,9 1,0 1,2 1,3 1,5 1,2 1,0 1,2 1,5 1,2 1,2 1,4 1,6 1,7 2,1 1,9 14 9 10 11 7 34 33 31 30 52 38 46 36 89 92 84 81 103 76 68 74 72 61 98 110 90 110 130 35 23 14 22 12 49 41 31 43 65 38 38 40 89 77 65 54 86 76 57 49 60 51 70 69 53 52 68 012001 015001 018001 018002 020001 021001 023001 025001 025002 027001 029001 031001 031002 034001 036001 037001 039001 039002 041001 043001 046001 046002 051001 054001 061001 067001 071001 074001 Mounting Generally­it­will­be­found­most­suitable­for­the Star­Spring­Washer­to­work­on­the­outer­ring­of the­ball­bearing.­The­Star­Spring­Washer­outside diameters­given­in­the­following­table­­corre­spond­therefore­with­the­ball­bearing­outside diameters.­The­RINGSPANN­design­with­slots and­dished­shape­guarantees­even­axial­pressure­on­the­whole­outer­race.­If­an­axial­pressure is­applied­to­the­shaft­in­one­direction­only,­the Star­Spring­Washer­must­be­mounted­in­such­a way­that­there­is­no­axial­pressure­on­it­(figure 89-2).­If­the­axial­pressures­vary­or­are­in­both­di- 90 rections,­a­Star­Spring­Washer­has­to­be­mounted­both­sides­of­the­ball­bearings.­In­this­case and­in­any­doubtful­cases­we­will­be­pleased­to submit­an­installation­proposal. Star Spring Washers as ball bearing compensating discs for taking up free movement in bearings H h (w) Spring under tension ød øD With­washers­stacked­in­ parallel,­the­pressure­ forces­are­added. Washers­with­dish­angles­ opposite,­the­spring­travels are­added. Spring released S 91-1 Height released D mm 16010 6010­ 16011 16012 16013 16014 16015 6011­ 6012 6013­ 6014­ 6015 16016 16017 16018 16019 16020 16021 16022 16024 6016­ 6017­ 6018­ 6019 6020­ 6021­ 6022­ 6024­ 16026 16028 6026­ 6028 16030 6030 6208 6209 6210 6307 6405 6308 6406 6211 6212 6309 6310 6407 6408 6213 6214 6215 6216 6311 6409 6312 6313 6410 6411 6217 6218 6219 6220 6221 6222 6314 6315 6316 6317 6318 6319 6412 6413 6224 6320 6321 6414 6415 6416 6417 6418 6226 16032 6032 6322 6228 16034 6034 6324 79 84 89 94 99 109 114 119 124 129 139 144 149 158 168 178 188 198 208 213 223 228 238 248 258 d mm 58 63 63 68 73 78 83 88 93 98 98 103 108 118 123 133 138 143 163 168 183 188 198 211 223 s mm 1,15 1,15 1,15 1,15 1,15 1,15 1,15 1,15 1,15 1,15 1,25 1,25 1,25 1,5 1,5 1,5 2,1 2 2 2 2 2 2 2 2 H mm 3,3 3,3 3,8 3,8 3,8 4,2 4,2 4,2 4,2 4,2 5,3 5,3 5,3 5,5 6 6 7 7,5 6,2 6,4 6,1 6,2 6,4 6,2 6,2 under pressure h mm 1,7 1,7 1,7 1,9 1,9 2,0 2,0 2,0 2,0 2,0 2,3 2,3 2,3 2,5 2,7 2,7 3,3 3,3 3,0 3,1 3,0 3,0 3,1 3,0 3,0 Explanation concerning the table Apart­from­the­listed­ball­bearing­series­the­Star Spring­Washers­can­also­be­used­for­series­32, 33,­42,­72­and­73.­Pressure­F­is­attained­at­height h.­The­ spring­ constant­ c,­ i.e.­ the­ pressure­ increase­per­mm­spring­travel­can­only­be­given up­to­size­74­x­50­x­1,15.­ Tolerance for h Spring travel Pressure Spring const. Article­ number mm (w) mm F N c N/mm 1052- ±­0,25 ±­0,25 ±­0,25 ±­0,4 ±­0,4 ±­0,4 ±­0,4 ±­0,4 ±­0,4 ±­0,4 ±­0,5 ±­0,5 ±­0,5 ±­0,5 ±­0,5 ±­0,5 ±­0,5 ±­0,5 ±­0,5 ±­0,5 ±­0,5 ±­0,5 ±­0,5 ±­0,5 ±­0,5 1,6 1,6 2,1 1,9 1,9 2,2 2,2 2,2 2,2 2,2 3,0 3,0 3,0 3,0 3,3 3,3 3,7 4,2 3,2 3,3 3,1 3,2 3,3 3,2 3,2 290 320 290 260 280 180 200 270 250 250 330 330 370 410 470 600 520 660 1160 1120 1200 1160 1120 1160 1180 Diminishing­spring­characteristic Dimension For­ball­bearing 079001 084001 089001 094001 099001 109001 114001 119001 124001 129001 139001 144001 149001 158001 168001 178001 188001 198001 208001­ 213001 223001 228001 238001 248001 258001 Example for ordering With­larger­Star­Spring­Washers­the­spring­characteristic­is­not­linear­but­diminishing.­With­tolerances­of­the­installation­height­h­the­pressure F­therefore­changes­even­less­than­with­smaller washers. 91 Star­ Spring­Washer­ for­ ball­ bearings­ of­ series 16011: • Article­number 1052-089001