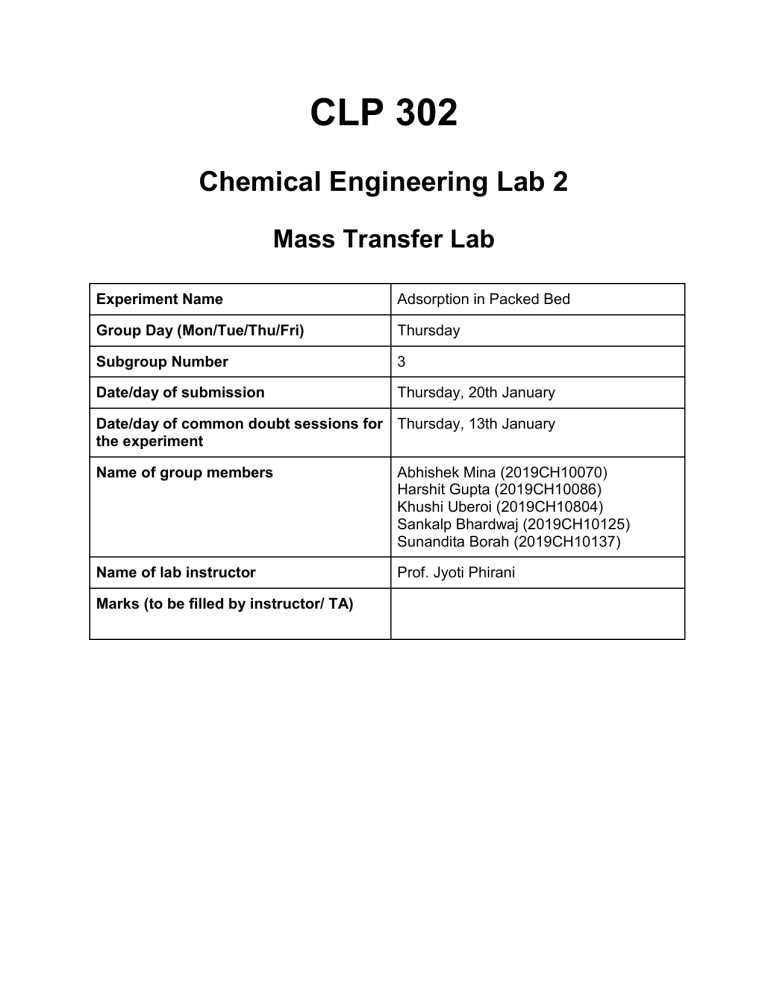

CLP 302 Chemical Engineering Lab 2 Mass Transfer Lab Experiment Name Adsorption in Packed Bed Group Day (Mon/Tue/Thu/Fri) Thursday Subgroup Number 3 Date/day of submission Thursday, 20th January Date/day of common doubt sessions for Thursday, 13th January the experiment Name of group members Abhishek Mina (2019CH10070) Harshit Gupta (2019CH10086) Khushi Uberoi (2019CH10804) Sankalp Bhardwaj (2019CH10125) Sunandita Borah (2019CH10137) Name of lab instructor Prof. Jyoti Phirani Marks (to be filled by instructor/ TA) a) Objective To study Adsorption in a packed bed for a Solid-Liquid system and to find the breakthrough curve and the length of the unused bed. b) Experimental Setup For the process of adsorption in packed columns with solid-phase being static &, fluid phase is flowing. ● A rotameter has been given for the flow of liquid. ● Three borosilicate columns have been given which have got different diameters & lengths. ● Valves have been provided to feed only one column at the time being at the inlet of the column. ● Liquid tanks are given to empty out the apparatus and Valves at the lower region. ● For the prevention of the charcoal from draining, filters have been given too. Requirements: 1. Electric supply: Single phase, 220 V, 50 Hz, 5-15 Amp socket with earth connection 2. Water Supply 3. Colorimeter or Spectrophotometer 4. Chemical required: KMnO4 5. Test tubes 6. Measuring cylinders c) Theory The selective transfer of a solute from a fluid phase to a batch of stiff particles is known as adsorption. The normal selectivity of a sorbent between solute and carrier fluid or between distinct solutes allows particular solutes to be separated from the carrier or from each other. When molecules in the fluid phase are retained for a period of time by attractive forces due to the adsorbent surface, this is known as adsorption. The surface of a solid indicates a large discontinuity in its structure, and atoms at the surface have molecular forces that are not fulfilled by neighboring atoms such as those in the structure’s body. The Adsorption wave Let C0 be the solute concentration in the feed stream, and C be the solute concentration in the bulk fluid at any axial location z in the bed. q0 is the concentration of adsorbent in the solid in equilibrium with the feed (i.e. saturated bed). At the axial location z in the bed, the solute concentration in the adsorbent is q. When feed is first poured into a new bed (total length of bed = L), the initial rate of adsorption is quite high, especially around the bed entrance. Because of adsorption, the concentration of the solute in the bed falls as the gas passes through it. At any time, the solute concentrations in the fluid and solid fluctuate along the bed, as well as with time at any place in the bed [i.e. C = C(z, t), and q = q(z, t)]. a. No part of the bed is ’saturated’ at a short time (t = 0+). The bed becomes saturated near the intake (i.e. x’ = q/q0 = 1 at z = 0) at a later time t = t1, but the adsorbed solute concentration declines along the bed up to z = L (Adsorption of the solute happens in the unsaturated region of the bed, 0 z L). The mass transfer zone is defined as section 0 z L. (MTZ) b.The mass transfer zone (Lb z L) and the concentration profile of the adsorbed solute in the bed at time tb are depicted in the diagram below. The leading edge of the mass transfer zone reaches the top of the packed section (z = L) at this point, resulting in a modest dimensionless concentration of the solute in the solid at the top of the bed, say x; Similarly, the effluent fluid from the bed contains a modest but detectable quantity of the solute, C = Cb, at time t = tb. Breakthrough is defined as the presence of a modest but detectable quantity in the effluent from the bed. Length of Unused Bed Calculation The length of the mass transfer zone determines the Length of the Unused Bed (LUB). The Breakthrough curve would be the vertical line at S, which can be located so that the shaded areas are equal if the mass transfer rate were infinitely fast. The adsorption zone in the figure can then be idealised as a plane, with the length of bed ZS upstream of the plane at concentration Yt equal to the length of unused bed Z-ZS downstream (LUB). If the field flow is maintained until the breakthrough time, almost all of the solute entering the bed will be collected. The solute appears in the effluent with steadily increasing concentration as the feed flow is continued. Calculation: If V = velocity of advancement of the “adsorption plane”, then at breakthrough ZB = VθB Also, Z =VθS Therefore, LUB=Z-ZB =VθS -VθB =Z(θS -θB)/θS θB = Time when the colour of product starts changing rapidly θS = Time required for idealized breakthrough θT = Total time θS =(θB +θT )/2 MTZ = 2* LUB Therefore, if till the breakthrough time the field flow keeps on continuing, virtually every single one of the solute which was entering the bed gets occupied. And on further prolongation of the feed flow, the solute presents up in the effluent with rising concentration eventually. d) Method Experimental Procedure: 1. Keep checking that all the valves have been closed properly. 2. Calibrate the rotameter. 3. Check that in all the columns the activated charcoal has been filled. 4. Prepare a solution of KMnO4 with water of 20 liters. 5. The colored KMnO4 solution shouldn’t be too strong. 6. in the feed tank (upper tank) fill it with the colored solution. 7. the valve of the column to be operated should be open. 8. The minimum flow rate should be fixed while using a rotameter and starting the pump. 9. At fixed durations, keep taking the samples of the output from the column. 10. As a reference sample, take water in the colorimeter. 11. The optical density of the different samples with respect to the referred sample should be measured. 12. Draw a calibration curve of distinct concentrations and their respective optical densities. 13. From the calibrated curve which has been drawn, find the color’s concentration. 14. Write the concentration, time, and flow rate. 15. Keep working on the experiment until you notice the output liquid’s color has almost become stable. 16. Stop the pump and close the valve of the column. 17. Repeat the experiment for the second and third column. OBSERVATIONS e) Calculations and Results f) Discussion Question 1: What is the conclusion of the experiment? Is the objective fulfilled? Answer: We generated breakthrough curves for different columns and found the length of the immersed bed. The objective was fulfilled and we were able to find the length of the immersed bed, although with a few deviations as compared to the theory. Question 2: Give a physical interpretation of your results. Provide any additional suitable inference. Answer: Interpretation of the results can be as follows: We know, Efficiency = (L − LUB) /L ∗ 100. If we compare efficiency with our results, we can see that efficiency decreases with increase in length. Therefore, for any industrial process we should take into consideration the efficiency of the column and cost to optimize the most. Question 3: Compare your results with those obtained from theory/literature. Justify the differences in these, if any. Answer: The differences observed were as follows: 1. Concentration didn’t reach to 1 at saturation and attained only about 80% of the initial concentration prepared. 2. Breakthrough curve was not symmetrical. Also, θS did not lie between θB and θT possibly due to the non-uniform flow across the cross-section area. 3. Also, LUB was not found independent of length which should have been the case which might be due to the mass transfer zone assumed unchanged throughout. Question 4: What is the mechanism or steps for adsorption to occur? Compare the rate constants of these steps to the superficial velocity and describe how the velocity of the propagation of adsorption-plane depends on these. Answer: The steps for adsorption to occur are: 1. Diffusion of adsorbate from stationary solvent film. 2. Diffusion through macropores. 3. Diffusion through micropores. 4. Adsorption at site. The step 4 happens very fast compared to step 2. Effect of viscosity change through the bed on breakthrough curve is seen followed by broadening of tail of the curve. With the increase in flow rate, the breakthrough curve becomes more sharper. Question 5: What is the mechanism or steps for adsorption to occur? Compare the rate constants of these steps to the superficial velocity and describe how the velocity of the propagation of adsorption-plane depends on these. Answer: From Langmuir kinetics: g) Precautions 1. Before starting the pump, make sure the bypass valve is fully closed and the rotameter is properly closed. 2. Before starting the apparatus, check that the drain valves of all columns are properly closed. 3. Make sure there are no leaks at the bottom of the column. 4. Let there be only one feed valve open at a time. 5. Drain the apparatus as soon as possible as the color of liquid might start clotting the inner surfaces of the apparatus, which will yield incorrect results. h) Error analysis SOURCES OF ERROR 1. It is possible that the adsorption column did not yet have the full adsorption capacity at the beginning of the experiment, i.e. it had already developed a breakthrough. 2. The colorimeter or spectrophotometer reference settings may be incorrect, resulting in inaccurate calibration data. 3. The readings may have been taken at a longer than ideal time interval. ERROR ANALYSIS i) Scope of Improvement 1. The initial readings should be taken more often, i.e. the interval between two consecutive readings should be reduced, in order to capture the period when the concentration begins to rise. This would allow us to avoid using an approximation for ΘB. 2. The values of absorbance at successive instants in the video were not increasing monotonically as they should have been. This could have happened as a result of inaccurate calorimeter calibration or sample mixing. To avoid this, make sure that the test tubes are numbered and that the calibration is done correctly before collecting the samples. 3. Sieves can be used at some locations inside the column for ensuring the uniform flow inside the packed bed. This is hampered because of: a. Channeling of the fluid at the wall b. During the release of the heat of adsorption, a temperature gradient is created.