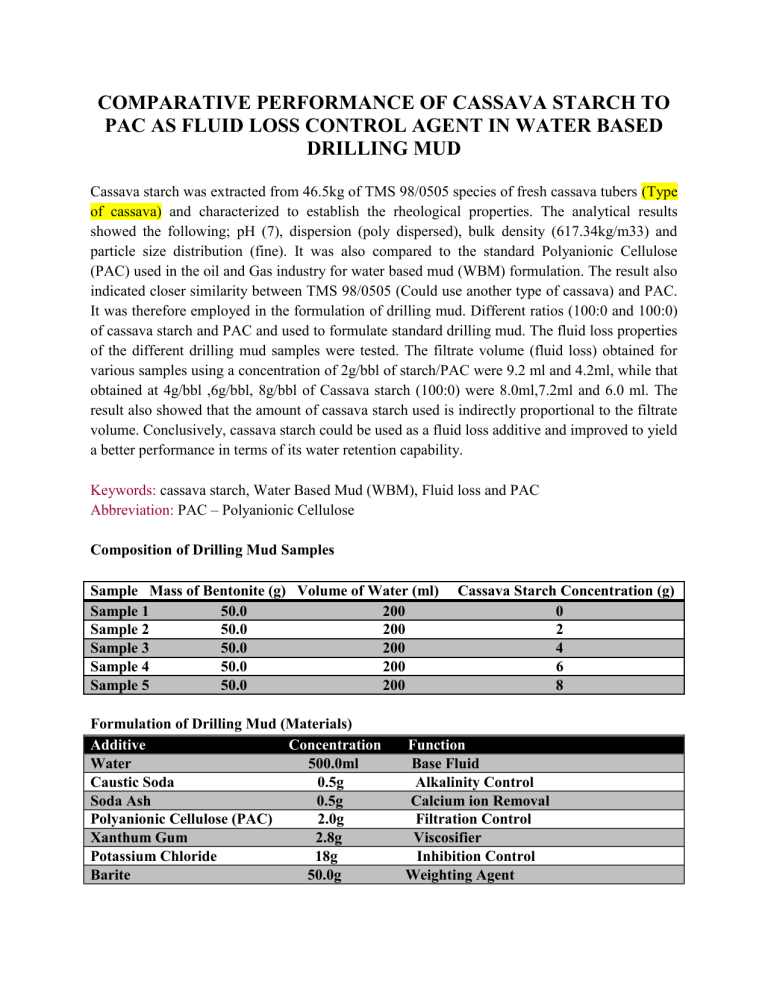

COMPARATIVE PERFORMANCE OF CASSAVA STARCH TO PAC AS FLUID LOSS CONTROL AGENT IN WATER BASED DRILLING MUD Cassava starch was extracted from 46.5kg of TMS 98/0505 species of fresh cassava tubers (Type of cassava) and characterized to establish the rheological properties. The analytical results showed the following; pH (7), dispersion (poly dispersed), bulk density (617.34kg/m33) and particle size distribution (fine). It was also compared to the standard Polyanionic Cellulose (PAC) used in the oil and Gas industry for water based mud (WBM) formulation. The result also indicated closer similarity between TMS 98/0505 (Could use another type of cassava) and PAC. It was therefore employed in the formulation of drilling mud. Different ratios (100:0 and 100:0) of cassava starch and PAC and used to formulate standard drilling mud. The fluid loss properties of the different drilling mud samples were tested. The filtrate volume (fluid loss) obtained for various samples using a concentration of 2g/bbl of starch/PAC were 9.2 ml and 4.2ml, while that obtained at 4g/bbl ,6g/bbl, 8g/bbl of Cassava starch (100:0) were 8.0ml,7.2ml and 6.0 ml. The result also showed that the amount of cassava starch used is indirectly proportional to the filtrate volume. Conclusively, cassava starch could be used as a fluid loss additive and improved to yield a better performance in terms of its water retention capability. Keywords: cassava starch, Water Based Mud (WBM), Fluid loss and PAC Abbreviation: PAC – Polyanionic Cellulose Composition of Drilling Mud Samples Sample Mass of Bentonite (g) Volume of Water (ml) Sample 1 50.0 200 Sample 2 50.0 200 Sample 3 50.0 200 Sample 4 50.0 200 Sample 5 50.0 200 Formulation of Drilling Mud (Materials) Additive Concentration Water 500.0ml Caustic Soda 0.5g Soda Ash 0.5g Polyanionic Cellulose (PAC) 2.0g Xanthum Gum 2.8g Potassium Chloride 18g Barite 50.0g Cassava Starch Concentration (g) 0 2 4 6 8 Function Base Fluid Alkalinity Control Calcium ion Removal Filtration Control Viscosifier Inhibition Control Weighting Agent Rheological properties of Cassava Starch Parameter TMS 98/0505 pH @ 25oC 7 Bulk Density (kg/m3) 617.3 Particle size Distribution Fine Dispersion Poly dispersed Appearance Whitish` PAC (Reference) 7 641-881 Fine Poly dispersed Whitish PH The pH accounts for the acidic or basic nature of substances. The level of hydrogen cyanide (HCN) content in cassava is the basis for its toxicity. The cassava starch sample was in the range of 7-8 indicating neutral or slightly alkaline on the pH meter. TMS 98/0505 had a pH value of 7. The HCN content in cassava is inversely proportional to the pH value, i.e the higher the content of HCN, the lower the pH value and vice versa. The starch sample had the same pH value as the PAC. 20.0g of cassava starch sample was weighed separately and 200ml of distilled water was mixed with sample in a Hamilton Beach mixer cup with the aid of an electric stirrer to obtain homogenous mixture (complete dissolution). The pH of starch solutions were determined by dipping the indicator probe into the solution. Three repetitions were made for each of the samples and the mean value recorded. Fluid Loss Test The mud sample was poured into the API filter press assembly and using the 50 filter paper, the reservoir was filled up to the scribed mark. A previously graduated measuring cylinder was kept in place under the mud reservoir. Then, pressure of 100 Psi was applied to the reservoir at 25oC for 30 minutes. The filtrate in the cylinder was read and recorded as the fluid loss after 30minutes. The amount of filtrate collected for each sample at the same period of time is shown in Table 1. For a drilling mud to be accepted, the fluid loss additive used should be able to give filtrate loss volume less than 15 ml over a period of 30 minutes (API 13 A, 1993). All the mud samples met these criteria. From the graph above it is seen that sample 2 which is 2g/bbl PAC had the least filtrate volume while the volume of filtrate was observed to be in reduction as the concentration of the cassava starch was increasing. This reduced fluid loss may be due to the similarities in the polyanionic cellulose and cassava starch molecules. The cassava starch molecules are attracted towards the polyanionic cellulose molecules and also induce the formation of micelles. The main attraction forces are hydrophobic and the presence of oppositely charged particles enhances interaction (Odeh, 2006). It was also observed that as more concentration of cassava starch was added to the formulation of Sample 1 the volume of the fluid loss was reduced implying that more concentration of cassava starch was required for a less concentration of PAC. Table 1; Fluid properties of Produced Mud Samples Sample 1 2 3 4 5 Volume of Filtrate (ml) 9.2 4.2 8.0 7.2 6.0 20 18 16 14 12 Plastic viscosity Cp 10 Starch mass 8 6 4 2 0 1 2 3 4 Bulk Density The values of bulk density of starch sample showed slight differences, it was observed that starch from different varieties had large differences in bulk density depending on the specie source, (Moorthy 1999). However, starch sample is whitish similar to that of PAC. Bulk density for starch; The industry standard measurement for producing water based drilling fluid sample is based on pounds per barrel (lb/bbl). This is the expected density of the drilling fluid which determines the proportions of the other additives. Mass of starch = 0.05kg, Volume of occupied = 0.000081m3 Density of starch = 617.3kg /m3 Identifying the density of mud is very important, considering the function of the drilling sludge is quite strategic and critical such as primary well control against formation pressure and hydrostatic, hole cleaning, and drill bit lubrication, density in the program mentions to 9.0ppg Water-Based Mud (WBM), on reference other drilling locations with the same mud phase ranges from 9.8-10.5 even. The value is pure without the LCM mixture weighed with Fann 140 Regular Mud Balance, and any additional concentration will be weighed. The effects of LCM can make the density of mud reduced or increased, and the condition is influenced by the composition of LCM. Mud balance Measurement of plastic viscosity, yield point, and gel strength We use a Mash funnel viscometer, cup and measured time in seconds. Fill the cup until a designated level with mud sample is the initial step before initiating the measurement test. Allow the filtrate to pass through to the cup and then measure the time taken in seconds on the timer for it to fill the cup. Rotate rotor at 600 RPM continuously until reached a stable dial readings. Reduce rotor velocity gradually to 300, 200, 100, 6, and 3 RPM followed by the recording of dial readings at each velocity. Determination of plastic viscosity follows the equation (1) is plastic viscosity in centipoise (cp) while R600 and R300 are Dial readings at 600 and 300 RPM rotor velocity (in degree unit). Using value, calculate yield point value (YP) in lb/100 ft2 using equation (2): Procedure for calculating gel strength (in lb/100ft2) is conditioning the mud sample inside the mash funnel by constantly rotate the rotor at 600 RPM for 10 seconds, turn off the rotor for 10 seconds and then re-run the rotor at 3 RPM. Record the maximum dial reading during this time and repeat until 10 minutes rotation time. Repeat gel strength procedure to obtain 10 minutes gel strength. Repeat all procedure of measurement with different mud composition. Plastic viscosity This is a resistance to flow caused by movements between solids in the mud, solids - liquid and friction between layers of liquid. Plot of plastic viscosity over a sample contain various composition of starch additive is displayed below. Plastic viscosity increase as the concentration of cassava starch from 2 g to 10 g. This due to the viscous nature of starch that affects the flow resistance of the drilling mud. High plastic viscosity has an advantage regarding the cutting removal issue. Concentration of starch(g) RPM(600) RPM(300) seconds Plastic seconds viscosity(cp) 2 10 4 12 6 16 8 18 10 21 25 20 15 Plastic viscosity Cp Starch mass 10 5 0 1 2 3 4 5 Yield point Yield point is measuring the electro-chemical force between solids, liquids, liquids and solids in chemicals in dynamic conditions associated with flow patterns. Calculation result of mud yield point with various composition of starch plotted in fig. 10. By adding more starch additive to drilling mud results a higher yield points. Higher yield point is effective because the rheology of fluid change to non-Newtonian fluid that is better in cutting removal from the wellbore to surface. The equation of the trend line yield point = 2.714 + 1.257 starch mass, meaning an increase in starch mass gives a positive influence on starch mass that is equal to 1.257. In the test obtained a correlation value of 0.994 or a positive value, means two variables increase together. Concentration starch (g) of cassava RPM(300) Plastic seconds viscosity(cp) 2 10 4 12 6 16 8 18 10 21 Yield point 25 20 15 Plastic viscosity Cp Starch mass 10 5 0 1 Gel strength 2 3 4 5 6 Gel strength is a value that shows the mud ability to hold solids in a reservoir. Gel strength shows the thickness of mud in a static condition for a certain period. Gel strength value with the addition of cassava starch additive is shown below. The value of Gel strength increase from 0.40.6 lb./100 ft2 when the starch mass rise from 2 g to10 g. The main reason of this phenomenon is the nature of cassava starch as polymeric substance. Thicker mud has higher gel strength value, which is effective at the time of circulation stops. Result from the software indicates a linear trend line with 98.9% R-sq (adj) value. The obtained equation is gel strength = 0.3371 + 0.2741 starch mass, means an increment in 1 unit starch mass has a positive influence on gel strength that is equal to 0.2741. In the test obtained a correlation value of 0.996 or a positive value which means that the two variables increase together. Concentration of starch(g) Gel strength (lb/100ft2) 2 0.40 4 0.45 6 0.50 8 0.55 10 0.60 25 20 15 Plastic viscosity Cp Starch mass 10 5 0 1 2 3 4 5 CONCLUSION For a drilling mud to pass this crucial test it filtrate loss volume must be less than 15 ml over a period of 30 minutes (API 13 A, 1993). All the mud samples met the criteria. The result of the properties of the starch from the cassava specie measured shows that TMS 98/0505 has closer similarities in terms of pH value and bulk density to PAC. Consequently, starch obtained from improved cassava varieties and increased concentration in formulation can replace PAC as a fluid loss control agent in the formulation of the water based drilling fluid. Existence of cassava starch with higher concentration yields drilling mud with higher with plastic viscosity, yield point, and gel strength.