2018-Torrefaction-of-Woody-Waste-for-Use-as-Biofuel (1)

advertisement

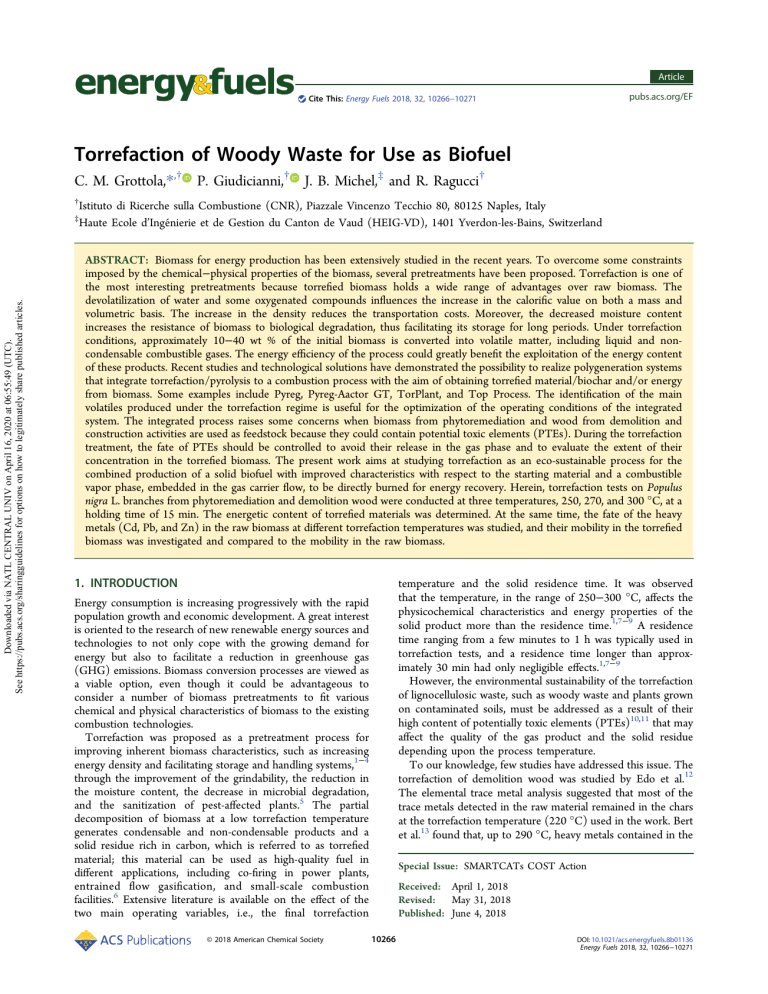

Article pubs.acs.org/EF Cite This: Energy Fuels 2018, 32, 10266−10271 Torrefaction of Woody Waste for Use as Biofuel C. M. Grottola,*,† P. Giudicianni,† J. B. Michel,‡ and R. Ragucci† † Istituto di Ricerche sulla Combustione (CNR), Piazzale Vincenzo Tecchio 80, 80125 Naples, Italy Haute Ecole d’Ingénierie et de Gestion du Canton de Vaud (HEIG-VD), 1401 Yverdon-les-Bains, Switzerland Downloaded via NATL CENTRAL UNIV on April 16, 2020 at 06:55:49 (UTC). See https://pubs.acs.org/sharingguidelines for options on how to legitimately share published articles. ‡ ABSTRACT: Biomass for energy production has been extensively studied in the recent years. To overcome some constraints imposed by the chemical−physical properties of the biomass, several pretreatments have been proposed. Torrefaction is one of the most interesting pretreatments because torrefied biomass holds a wide range of advantages over raw biomass. The devolatilization of water and some oxygenated compounds influences the increase in the calorific value on both a mass and volumetric basis. The increase in the density reduces the transportation costs. Moreover, the decreased moisture content increases the resistance of biomass to biological degradation, thus facilitating its storage for long periods. Under torrefaction conditions, approximately 10−40 wt % of the initial biomass is converted into volatile matter, including liquid and noncondensable combustible gases. The energy efficiency of the process could greatly benefit the exploitation of the energy content of these products. Recent studies and technological solutions have demonstrated the possibility to realize polygeneration systems that integrate torrefaction/pyrolysis to a combustion process with the aim of obtaining torrefied material/biochar and/or energy from biomass. Some examples include Pyreg, Pyreg-Aactor GT, TorPlant, and Top Process. The identification of the main volatiles produced under the torrefaction regime is useful for the optimization of the operating conditions of the integrated system. The integrated process raises some concerns when biomass from phytoremediation and wood from demolition and construction activities are used as feedstock because they could contain potential toxic elements (PTEs). During the torrefaction treatment, the fate of PTEs should be controlled to avoid their release in the gas phase and to evaluate the extent of their concentration in the torrefied biomass. The present work aims at studying torrefaction as an eco-sustainable process for the combined production of a solid biofuel with improved characteristics with respect to the starting material and a combustible vapor phase, embedded in the gas carrier flow, to be directly burned for energy recovery. Herein, torrefaction tests on Populus nigra L. branches from phytoremediation and demolition wood were conducted at three temperatures, 250, 270, and 300 °C, at a holding time of 15 min. The energetic content of torrefied materials was determined. At the same time, the fate of the heavy metals (Cd, Pb, and Zn) in the raw biomass at different torrefaction temperatures was studied, and their mobility in the torrefied biomass was investigated and compared to the mobility in the raw biomass. 1. INTRODUCTION Energy consumption is increasing progressively with the rapid population growth and economic development. A great interest is oriented to the research of new renewable energy sources and technologies to not only cope with the growing demand for energy but also to facilitate a reduction in greenhouse gas (GHG) emissions. Biomass conversion processes are viewed as a viable option, even though it could be advantageous to consider a number of biomass pretreatments to fit various chemical and physical characteristics of biomass to the existing combustion technologies. Torrefaction was proposed as a pretreatment process for improving inherent biomass characteristics, such as increasing energy density and facilitating storage and handling systems,1−4 through the improvement of the grindability, the reduction in the moisture content, the decrease in microbial degradation, and the sanitization of pest-affected plants.5 The partial decomposition of biomass at a low torrefaction temperature generates condensable and non-condensable products and a solid residue rich in carbon, which is referred to as torrefied material; this material can be used as high-quality fuel in different applications, including co-firing in power plants, entrained flow gasification, and small-scale combustion facilities.6 Extensive literature is available on the effect of the two main operating variables, i.e., the final torrefaction © 2018 American Chemical Society temperature and the solid residence time. It was observed that the temperature, in the range of 250−300 °C, affects the physicochemical characteristics and energy properties of the solid product more than the residence time.1,7−9 A residence time ranging from a few minutes to 1 h was typically used in torrefaction tests, and a residence time longer than approximately 30 min had only negligible effects.1,7−9 However, the environmental sustainability of the torrefaction of lignocellulosic waste, such as woody waste and plants grown on contaminated soils, must be addressed as a result of their high content of potentially toxic elements (PTEs)10,11 that may affect the quality of the gas product and the solid residue depending upon the process temperature. To our knowledge, few studies have addressed this issue. The torrefaction of demolition wood was studied by Edo et al.12 The elemental trace metal analysis suggested that most of the trace metals detected in the raw material remained in the chars at the torrefaction temperature (220 °C) used in the work. Bert et al.13 found that, up to 290 °C, heavy metals contained in the Special Issue: SMARTCATs COST Action Received: April 1, 2018 Revised: May 31, 2018 Published: June 4, 2018 10266 DOI: 10.1021/acs.energyfuels.8b01136 Energy Fuels 2018, 32, 10266−10271 Article Energy & Fuels biomass were retained in the solid matrix. Nevertheless, other authors14,15 showed that, when some heavy metals are present in the form of chlorides, the devolatilization temperature was greatly reduced, mainly under anoxic conditions. No investigation has been conducted on the mobility of heavy metals retained in the torrefied biomass. In this work, a comprehensive approach is proposed for simultaneously studying the improvement of the energetic characteristics of two kinds of contaminated woody wastes and the environmental aspects related to the presence of contaminants. Contaminations from different sources were considered: Populus nigra L. branches (PN-B) containing heavy metals translocated from the soil to the plant organs during phytoremediation and demolition wood (DW) rich in heavy metals derived from operational activities during the construction and the disposal of woody shipping crates. The aim of the present work was 2-fold: studying the effect of the torrefaction temperature on the energetic properties of the torrefied biomass and evaluating the environmental impact of the process by monitoring the release of heavy metals in the vapor phase as well as their mobility in the torrefied materials. Torrefaction tests were conducted under oxygen-limited conditions at a constant heating rate (10 °C/min) and at three final temperatures ranging from light to severe torrefaction regime,16 namely, 250, 270, and 300 °C, with a residence time of 15 min. The product yields were determined, and the organic and inorganic fractions of the solid products were characterized. The mobility of PTEs in the torrefied materials was also investigated. Finally, condensable volatiles from torrefaction tests were collected separately and analyzed by gas chromatography (GC) to understand their potential utilization. Figure 1. Cross section of the “SOLO furnace”. this increase was reproducible in all of the tests and did not affect the average heating rate that remained equal to 5.6 °C/min. In all of the tests, a maximum overshoot of 2 °C was observed. The volatiles produced in the reaction unit entered the condensation device, which consists of two Pyrex condensers in series, where condensable volatiles cooled and condensed. At the outlet of the condenser, a Pyrex flask was allocated for the collection of the liquid products. The non-condensing phase was fed to the analytical system for online characterization (Horiba Mexa 7170D). After the process, the aluminum container was quenched by immersing it rapidly in a glass beaker with 5 L of water at a temperature of 10 °C. The water cooled the container, and any contact between the torrefied material and water was avoided. At the end of the test, the sample was immersed in a metal vessel containing 10 °C water. The quenched sample was heated in the furnace for 24 h at 105 °C before the final weight measurement to remove the water. Solid yields were determined gravimetrically with respect to the fed sample. 2.2. Material Characterization. 2.2.1. Solid Materials. PN-B were collected during phytoremediation tests conducted in Litorale Domitio, Agro Aversano NIPS (Campania region, South Italy) in the framework of the European LIFE Project ECOREMED (LIFE11/ ENV/IT/275, ECOREMED), whereas DW was obtained from the disposal of shipping crates. The material was ground, and the sieved fraction, in the 400−600 μm size range, was recovered for the torrefaction tests. The samples were oven-dried at 105 °C for 24 h and kept in the desiccator before the characterization analyses and torrefaction tests. The moisture content of feedstock and torrefied biomass was measured with a thermobalance (Sartorius moisture analyzer, model MA35) according to the ISO 18134-3 procedure. The CHONS content was measured using the elemental analyzer Analyseur Flash 2000 (Thermo Scientific) according to the ISO 16948:2015 procedure. The Carbolite AFF 1100 furnace was used for the determination of ash and volatile contents according to the ISO 1171/18123:2015 and ISO 18123:2015 procedures, respectively. Fixed 2. MATERIALS AND METHODS 2.1. Torrefaction System. The experimental tests were performed in a small-scale reactor “SOLO furnace”, available at HEIG-VD, Switzerland. The cross section of the furnace is shown in Figure 1. The reactor is divided into two connected and concentric cylindrical zones separated by a perforated plate: the internal cylinder is the torrefaction chamber (diameter of 20 cm and height of 40 cm), whereas the external cylinder is for gas recirculation (diameter of 50 cm and height of 80 cm). A cylindrical steel container (diameter of 15 cm and height of 20 cm) with a perforated plate at the bottom is positioned in the internal section of the reactor and is used to accommodate the feedstock (100 g for each test run) packed in an aluminum paper (15 × 5 cm) and closed with a metal ring. The lid is provided with a hole that allows the passage of the gas outlet line and the thermocouple. In the external section, the recirculation of the exhausted gases produced during the torrefaction test occurs. The recirculation is provided through a fan located at the bottom of the external section under a perforated grid (frequency = 30 Hz). No nitrogen flux was used during the experiments. The fan located at the bottom of the reactor and the extractor placed on the top section are both regulated with the aim to reduce the oxygen content in the reaction environment. The temperature of the sample and the reaction environment was monitored constantly through six K-type thermocouples sketched in Figure 1, connected to a Keysight (Agilent/HP) 34970A data acquisition/data logger switch unit variable drive. The heat flux of the heating coil was used as an adjustable variable in a proportional− integral−derivative (PID) controller to produce a nominal heating rate equal to 10 °C/min during the tests. The temperature of the sample (TC2) was used as the set point temperature. As a result of the thermal inertia of the system, the actual heating rate was 5.6 °C/min, up to 220 °C. At higher temperatures, the heating rate increased, probably as a result of the exothermic decomposition of hemicellulose.17 In any case, 10267 DOI: 10.1021/acs.energyfuels.8b01136 Energy Fuels 2018, 32, 10266−10271 Article Energy & Fuels Table 1. Feedstock Characterization: Elemental Analysis and HHVa C (wt %, daf) H (wt %, daf) N (wt %, daf) O (wt %, daf) HHV (MJ/kg) 47.7 (0.3) 47.1 (0.2) 6.1 (0.2) 5.9 (0) 2.1 (0.4) 0.7 (0.1) 42.6 (0.1) 41.5 (0.1) 19.2 (0.3) 19.0 (0.3) DW PN-B a The relative error of three replicates is reported in parentheses. Table 2. Feedstock Characterization: Proximate Analysis and Heavy Metal Contenta moisture (wt %, as received) volatiles (wt %, db) fixed carbon (wt %, db) ash (wt %, db) Cd (mg/kg) Cu (mg/kg) Pb (mg/kg) Zn (mg/kg) 1.1 (0.1) 7.0 (0.4) 80.2 (0.8) 77.0 (0.4) 18.3 (0.7) 18.2 (0.4) 1.5 (0) 4.8 (0) 0.1 (6) 2.2 (4) 6.4 (6) 8.2 (1.7) 30.6 (5.5) 60.3 (4.8) 142.4 (6.2) 50 (8.9) DW PN-B a The relative error of three replicates is reported in parentheses. carbon was calculated as the amount required to complete the mass balance. The calorific value was determined using a bomb calorimeter (Oxygen Combustion Vessel 1108, Parr Instrument Company) according to EN 14918. Ash composition was determined by dissolving the biomass samples via microwave-assisted acid digestion based on United States Environmental Protection Agency (U.S. EPA) methods 3051 and 3052. The digested samples were then analyzed by inductively coupled plasma mass spectrometry (ICP/MS) using an Agilent 7500CE instrument. The results were reported in terms of the content of the inorganic species and ion recovery in the torrefied biomass. The first is defined as the mass of ion per mass of char and is used to calculate the ion recovery by multiplying it by the torrefied yield and then dividing by the mass of ions in the raw biomass. The energy yields of the torrefied materials were calculated on a dry basis by eq 1, where “t” stands for torrefied material and “f” stands for feedstock. energy yield = HHV(t) × mass yield(t) × 100 HHV(f) 3. RESULTS AND DISCUSSION The results of the chemical characterization of PN-B and DW samples are reported in Tables 1 and 2. It should be noted that, Figure 2. Torrefied biomass yields at T = 250, 270, and 300 °C. (1) even though the origin of the waste was different, the results of the elemental analysis were comparable, except for those of the nitrogen content. The biomass from phytoremediation was richer in ash than DW. The higher nitrogen content of DW compared to that of PN-B could be attributed to adhesives used in the production of timber goods (such as particle boards) that ended up in the DW wood waste stream.19 The proximate analysis highlighted a comparatively higher content of volatiles in DW and a higher ash content in PN-B, whereas the fixed carbon content was comparable. The heavy metals present in both samples were Cd, Cu, Pb, and Zn, with the last two being the most abundant, as shown in Table 2. The torrefied biomass yields are shown in Figure 2. As expected, for both the PN-B and DW, the mass yield decreased with the torrefaction temperature. Despite the similar results obtained from the elemental analysis and the higher volatile content of DW, at each temperature, the mass loss was higher for PN-B than for DW. The mass yield of the torrefied biomass varied between 74.6 and 64.0 wt % for PN-B and between 87.4 and 80.5 wt % for DW. Basu et al.20 reported a yield of 78 wt % for poplar wood torrefied at 250 °C, whereas Kim et al.21 obtained solid yields between 92 and 60 wt % for yellow poplar torrefied in the temperature range of 240−280 °C. The results on DW mixed with refuse-derived fuel (RDF) are available in the temperature range of 220−270 °C12,22 and show yields varying in the range between 94 and 84 wt %. According to the previous findings, in the torrefaction regime, hemicellulose is the main component undergoing devolatilization.23 The higher solid yield observed for DW in this study could be explained by the lower content of hemicellulose in the raw sample. Metal mobility was determined through a leaching test on biomass and corresponding torrefied materials using water and an ethylenediaminetetraacetic acid (EDTA)−NH4 solution, as reported by Gonsalvesh et al.18 The amount of heavy metals in the leachate was estimated on the basis of the PTEs recovered in the torrefied biomass. The ion release was the ratio between the amount of PTEs released in the leachate and the amount of PTEs in the torrefied material. 2.2.2. Liquid Product. For the identification and quantification of the main condensable species, liquids obtained from torrefaction tests at 250, 270, and 300 °C were filtered with 0.20 μm microfilters (Millex-FG). Chemical analysis was performed by a gas chromatograph coupled with a flame ionization detector (GC/FID, Agilent Technologies 7820A GC system) and a DB-1701 capillary column (60 m × 0.25 mm inner diameter, 0.25 mm film thickness). Helium (99.9999%) was used as carrier gas with a constant flow of 1.0 mL/ min. The oven temperature was programmed from 318 K (4 min) to 508 K at a heating rate of 3 K/min and held at 508 K for 30 min. The injector and the FID were kept at 523 and 573 K, respectively. A sample volume of 1 μL (4.5 wt % pyrolysis liquid in acetone) was injected. The identification of the main compounds (acetic acid, hydroxyacetone, furfural, 5-methylfurfural, and 5-hydroxymethylfurfural) is based on the match with the retention times of the corresponding standards (Sigma-Aldrich 319910) analyzed by GC/FID under the same conditions. The identified compounds were quantified by the internal standard method, using fluoranthene as an internal standard. A calibration curve was prepared by the injection of four standard solutions. The concentration range was determined by successive approximations until it became relatively narrow and encompassed the quantified value. Injections of the liquid samples were made in duplicate, and the maximum relative error observed was ±5% of the average values. 10268 DOI: 10.1021/acs.energyfuels.8b01136 Energy Fuels 2018, 32, 10266−10271 Article Energy & Fuels Figure 3. (a) Gas species and (b) liquid compound concentration obtained from PN-B torrefied at T = 300 °C. Table 3. Elemental Analysis and Energy Properties of Torrefied DW and PB-N Obtained at 250, 270, and 300 °Ca C (wt %, daf) DW 250 DW 270 DW 300 PN-B 250 PN-B 270 PN-B 300 a H (wt %, daf) 50 (1.0) 53 (0.5) 54.4 (0.8) 51.4 (0.9) 51.8 (0.6) 54.2 (0.5) 5.8 5.8 5.8 5.4 5.2 5.1 N (wt %, daf) (0.2) (0.1) (0.2) (0.1) (0.1) (0.1) 2.4 3.0 3.4 1.0 0.8 0.9 O (wt %, daf) (0.3) (0.6) (0.2) (0.1) (0.1) (0.1) 39.0 36.0 34.5 38.0 37.3 34.0 HHV (MJ/kg) (1.3) (0.5) (0.7) (0.6) (0.9) (0.6) 19.3 21.5 22.5 20.8 21.5 23.3 energy yield (%) (0.7) (0.2) (0.1) (0.9) (0.7) (0.3) 88.1 95.6 94.3 78.1 75.8 75.0 The relative error of three replicates is reported in parentheses. Table 4. Proximate Analysis and Heavy Metal Content of Torrefied DW and PB-N Obtained at 250, 270, and 300 °Ca moisture (wt %, as received) DW 250 DW 270 DW 300 PN-B 250 PN-B 270 PN-B 300 a 1.3 1.5 1.3 1.2 1.5 1.6 (0.5) (0.1) (0.1) (0.7) (0.5) (0.2) volatiles (wt %, db) 71.8 71.9 70.3 69.1 67.9 62.5 (6) (0.8) (0.6) (0.1) (2.8) (0.1) fixed carbon (wt %, db) 25.4 25.9 27.9 25.7 27.2 31.7 ash (wt %, db) (5.0) (1.2) (0.6) (0.5) (3.2) (0.2) 2.7 2.1 1.8 5.1 4.9 5.8 (1) (0.5) (0) (0.1) (2.8) (0.1) Cd (mg/kg) Cu (mg/kg) Pb (mg/kg) Zn (mg/kg) 0.1 0.2 0.2 2.5 2.6 3.2 8.3 8.5 8.9 9.6 9.7 11.4 51.7 (10) 52.9 (17) 54.1 (71) 70.4 (10) 72.3 (3.2) 89 (4.6) 185 (7) 188 (15) 195.4 (7) 61 (0.6) 65.4 (4) 73.2 (0.1) (19) (4) (2) (3.4) (1.8) (3.5) (5) (26) (7) (0.3) (4.3) (5) The relative error of three replicates is reported in parentheses. Table 5. Ion Recovery of Torrefied DW and PB-N Obtained at 250, 270, and 300 °Ca ion recovery DW 250 DW 270 DW 300 PN-B 250 PN-B 270 PN-B 300 a Cd (g/g) Cu (g/g) 0.99 1.00 1.15 0.99 1.01 1.02 0.98 (4.9) 1.15 (5) 1.1 (6) 0.97 (4.9) 1.07 (5) 1.04 (6) (1.5) (1.5) (6) (3) (1.5) (7) Pb (g/g) 1.12 0.95 1.12 1.05 1.02 1.03 (9.7) (1.75) (5) (2.8) (1.75) (5) Zn (g/g) 1.06 0.97 1.00 0.99 1.00 1.06 (6.8) (3) (4) (3) (3) (7) The relative error of three replicates is reported in parentheses. compounds. Among the detected liquid compounds, acetic acid is the most abundant, followed by acetol and furan derivatives. However, the torrefaction liquids are typically greatly diluted in water.24 3.1. Torrefied Biomass Characterization. The results of characterization of torrefied DW and PN-B obtained at different temperatures are reported in Tables 3 and 4. With an increasing torrefaction temperature, for both the feedstocks, an increase in the amount of elemental carbon and a decrease in the elemental oxygen and hydrogen amounts were observed, in agreement with the literature.1 This result is due to the breaking of the weak C−O and C−H bonds in the hemicellulose matrix responsible for the release of volatile species and permanent gases (mainly CO and CO2)25 that are Figure 4. Van Krevelen diagram for untreated and torrefied PN-B and DW. Nevertheless, the results of DW suffer heavily from the inhomogeneity of this type of woody refuse, and as a consequence, this makes it impossible to draw firm conclusions for these materials. The evolution of the gas composition during the torrefaction of PN-B at 300 °C (Figure 3a) and the main liquid compounds identified at 300 °C (Figure 3b) confirm that the hemicellulosic fraction of the PN-B sample is decomposed, producing mainly CO2 from the decomposition of side chains (acetyl and carboxylic groups), CO from the carbonyl end groups left after dehydration of the side chain groups, and condensable 10269 DOI: 10.1021/acs.energyfuels.8b01136 Energy Fuels 2018, 32, 10266−10271 Article Energy & Fuels Figure 5. Ion release of heavy metals in (a) water and (b) EDTA−NH4 leaching solution. decrease in the O/C ratio in the char is smaller for PN-B than that for DW. This result implies that DW released a lower amount of vapors (condensable and permanent gases) with a greater oxygen content. It is likely that mainly H2O was produced and released and that most of the energy-containing volatiles were still in the torrefied material.28 As a consequence, with an increasing temperature, the increase in the char calorific value is greater than the mass loss, thus determining the increase in the energy yield. The concentration and ion recovery of the detected heavy metals, namely, Cd, Pb, Cu, and Zn, for the torrefied materials are reported in Tables 4 and 5, respectively. The concentration increased with the torrefaction temperature for both feedstocks. The ion recovery for all torrefied materials is very close to 1, and thus, it can be inferred that the condensable and gas phases evolved from the torrefaction tests were essentially free of heavy metals. To investigate the effect of torrefaction on the mobility of the heavy metals retained in the torrefied PN-B samples, two leaching tests were performed, in water and in an EDTA−NH4 solution. A higher ion release in water was observed for Zn, followed by Cu, Cd, and Pb, and their mobility decreased with an increasing torrefaction temperature (Figure 5). This result could be related to the increase in the hydrophobic character of the torrefied biomass with the torrefaction temperature.1 Leaching with EDTA−NH4 was more severe, and all metals were released from the raw materials. The temperature did not have any effect on the PTE mobility up to 300 °C, where part of the metals retained in the char are immobilized in the solid matrix, even in more severe leaching conditions. It is likely that, in acid conditions, the acid groups, associated with lignin, hemicellulose, and extractives, were easily removed together with the associated inorganic elements.29 rich in oxygen and hydrogen, thus causing the deoxygenation of the torrefied biomass. The thermal behavior of elemental nitrogen was different in the two feedstocks, revealing a different chemical nature of the N compounds in PN-B and DW. The nitrogen content always increased with the torrefaction temperature for the DW sample, whereas for the PN-B sample, the trend was not evident. The O/C and H/C ratios, represented in the Van Krevelen diagram in Figure 4 for both the PN-B and DW torrefied samples, are considered important parameters to characterize solid biofuel composition with respect to coal. Typical H/C and O/C values for torrefied biomass are in the range of 1−1.5 and 0.4−0.65, respectively.26 An increase in the torrefaction temperature reduced both H/C and O/C ratios to values that are within the typical ranges observed for other torrefied biomasses, even though they were still high in comparison to the characteristic values of coal. At 300 °C, it was observed that the O/C and H/C ratios were greatly decreased to values close to the lignite coal range.27 The lowest torrefaction temperature significantly affected the O/C ratio for the PN-B sample, indicating that significant devolatilization of oxygenated compounds occurred even at a low temperature, in agreement with the observed weight loss (Figure 2). At the highest torrefaction temperature, DW and PN-B were characterized by comparable O/C ratios. At each temperature, the H/C ratio, similar in both feedstocks, was always lower for torrefied PN-B, denoting the devolatilization of a greater amount of compounds containing saturated C−H bonds as well as bound water. Table 4 shows that, as expected, the volatile content of both torrefied feedstocks decreased with the temperature, whereas the fixed carbon content increased. According to the higher mass loss observed for PN-B than for DW, the fixed carbon content was higher and the volatile content was lower for the corresponding material torrefied at 270 and 300 °C. The fixed carbon content of torrefied DW and in particular the PN-B sample increased greatly and was comparable to that of coal.1 The higher heating values (HHVs) of torrefied solids were remarkably improved at higher torrefaction temperatures and were always slightly higher for PN-B than those for DW across the whole temperature range. However, it should be noted that the energy yield was always lower for PN-B as a result of the higher devolatilization. Moreover, in the case of DW, the energy yield had a non-monotonous trend with the temperature, showing a maximum at 270 °C. In contrast, the energy yield decreased with the temperature for PN-B. As the temperature increased from 250 to 270 °C, the char yields decreased for both PN and DW. Nevertheless, in the case of PN-B, the mass loss is greater than that for DW. In contrast, the 4. CONCLUSION The torrefaction of woody waste (demolition wood and biomass from soil phytoremediation) was studied with the aim of evaluating the energetic properties of the torrefied material and the fate of heavy metals during the pretreatment. It was found that, with an increasing torrefaction temperature, the energy properties of both torrefied biomasses were improved. In particular, the study revealed that DW has a high potential in terms of its energy content as well as energy yield. Some concerns arise for the high nitrogen content of DW compared to that of PN-B in both the raw and torrefied materials. For both feedstocks, PTEs were retained in the torrefied biomass up to 300 °C, allowing for the production of a 10270 DOI: 10.1021/acs.energyfuels.8b01136 Energy Fuels 2018, 32, 10266−10271 Article Energy & Fuels (14) Abanades, S.; Flamant, G.; Gauthier, D. Kinetics of heavy metal vaporization from model wastes in fluidized bed. Environ. Sci. Technol. 2002, 36 (17), 3879−3884. (15) Yu, J.; Sun, L.; Xiang, J.; Hu, S.; Su, S. Kinetic vaporization of heavy metals during fluidized bed thermal treatment of municipal solid waste. Waste Manage. 2013, 33 (2), 340−346. (16) Matsakas, L.; Gao, Q.; Jansson, S.; Rova, U.; Christakopoulos, P. Green conversion of municipal solid wastes into fuels and chemicals. Electron. J. Biotechnol. 2017, 26, 69−83. (17) Yang, H.; Yan, R.; Chen, H.; Lee, D. H.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86 (12−13), 1781−1788. (18) Gonsalvesh, L.; Yperman, J.; Carleer, R.; Mench, M.; Herzig, R.; Vangronsveld, J. Valorisation of heavy metals enriched tobacco biomass through slow pyrolysis and steam activation. J. Chem. Technol. Biotechnol. 2016, 91 (6), 1585−1595. (19) Jermer, J.; Ekvall, A.; Tullin, C. Inventory of Contaminants in Waste Wood; Värmeforsk Service AB: Stockholm, Sweden, 2001; Report 732, pp 6−64. (20) Basu, P.; Rao, S.; Dhungana, A. An investigation into the effect of biomass particle size on its torrefaction. Can. J. Chem. Eng. 2013, 91 (3), 466−474. (21) Kim, Y. H.; Lee, S. M.; Lee, H. W.; Lee, J. W. Physical and chemical characteristics of products from the torrefaction of yellow poplar (Liriodendron tulipifera). Bioresour. Technol. 2012, 116, 120− 125. (22) Verhoeff, F.; Arnuelos, A. A.; Boersma, A. R.; Pels, J. R.; Lensselink, J.; Kiel, J. H. A.; Schukken, H. Torrefaction Technology for the Production of Solid Bioenergy Carriers from Biomass and Waste; Energy Research Centre of the Netherlands (ECN): Petten, Netherlands, 2011; ECN Report ECN-E-11-039. (23) Giudicianni, P.; Gargiulo, V.; Grottola, C. M.; Alfè, M.; Ragucci, R. Effect of alkali metal ions presence on the products of xylan steam assisted slow pyrolysis. Fuel 2018, 216, 36−43. (24) Chen, W. H.; Kuo, P. C. Torrefaction and co-torrefaction characterization of hemicellulose, cellulose and lignin as well as torrefaction of some basic constituents in biomass. Energy 2011, 36 (2), 803−811. (25) Giudicianni, P.; Cardone, G.; Sorrentino, G.; Ragucci, R. Hemicellulose, cellulose and lignin interactions on Arundo donax steam assisted pyrolysis. J. Anal. Appl. Pyrolysis 2014, 110, 138−146. (26) Bridgeman, T. G.; Jones, J. M.; Shield, I.; Williams, P. T. Torrefaction of reed canary grass, wheat straw and willow to enhance solid fuel qualities and combustion properties. Fuel 2008, 87 (6), 844− 856. (27) McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83 (1), 37−46. (28) Pahla, G.; Ntuli, F.; Muzenda, E. Torrefaction of landfill food waste for possible application in biomass co-firing. Waste Manage. 2018, 71, 512−520. (29) Wigley, T.; Yip, A. C.; Pang, S. The use of demineralisation and torrefaction to improve the properties of biomass intended as a feedstock for fast pyrolysis. J. Anal. Appl. Pyrolysis 2015, 113, 296−306. heavy-metal-free vapor-phase fuel. The higher the torrefaction temperature, the lower the PTE release by water leaching of torrefied material, thus increasing the safety of the material storage in open areas. ■ AUTHOR INFORMATION Corresponding Author *Telephone: +39-081-768-2245. E-mail: cm.grottola@irc.cnr.it. ORCID C. M. Grottola: 0000-0002-3994-9489 P. Giudicianni: 0000-0002-6700-8205 Notes The authors declare no competing financial interest. ■ ACKNOWLEDGMENTS This paper is based on work from COST Action SMARTCATs (CM1404), supported by the European Cooperation in Science and Technology (COST, http://www.cost.eu). This work was supported by the European Commission (Project LIFE11/ ENV/IT/275, ECOREMED) and the Accordo di Programma CNR-MSE 2013-2014 under the contract “Bioenergia Efficiente”. ■ REFERENCES (1) Tumuluru, J. S.; Sokhansanj, S.; Hess, J. R.; Wright, C. T.; Boardman, R. D. A review on biomass torrefaction process and product properties for energy applications. Ind. Biotechnol. 2011, 7 (5), 384−401. (2) Chen, W. H.; Liu, S. H.; Juang, T. T.; Tsai, C. M.; Zhuang, Y. Q. Characterization of solid and liquid products from bamboo torrefaction. Appl. Energy 2015, 160, 829−835. (3) http://www.pyreg.de (accessed May 18, 2018). (4) McCormick, K.; Kautto, N. The bioeconomy in Europe: An overview. Sustainability 2013, 5 (6), 2589−2608. (5) Correia, R.; Gonçalves, M.; Nobre, C.; Mendes, B. Impact of torrefaction and low-temperature carbonization on the properties of biomass wastes from Arundo donax L. and Phoenix canariensis. Bioresour. Technol. 2017, 223, 210−218. (6) Acharya, B.; Sule, I.; Dutta, A. A review on advances of torrefaction technologies for biomass processing. Biomass Convers. Biorefin. 2012, 2 (4), 349−369. (7) Bergman, P. C.; Boersma, A. R.; Zwart, R. W. R.; Kiel, J. H. A. Torrefaction for Biomass Co-firing in Existing Coal-Fired Power Stations; Energy Research Centre of the Netherlands (ECN): Petten, Netherlands, 2005; ECN Report ECN-C-05-013. (8) Sadaka, S.; Sharara, M. A.; Ashworth, A.; Keyser, P.; Allen, F.; Wright, A. Characterization of biochar from switchgrass carbonization. Energies 2014, 7 (2), 548−567. (9) Poudel, J.; Oh, S. C. Effect of Torrefaction on the Properties of Corn Stalk to Enhance Solid Fuel Qualities. Energies 2014, 7 (9), 5586−5600. (10) Lievens, C.; Carleer, R.; Cornelissen, T.; Yperman, J. Fast pyrolysis of heavy metal contaminated willow: Influence of the plant part. Fuel 2009, 88 (8), 1417−1425. (11) Dilks, R. T.; Monette, F.; Glaus, M. The major parameters on biomass pyrolysis for hyperaccumulative plantsA review. Chemosphere 2016, 146, 385−395. (12) Edo, M.; Skoglund, N.; Gao, Q.; Persson, P. E.; Jansson, S. Fate of metals and emissions of organic pollutants from torrefaction of waste wood, MSW, and RDF. Waste Manage. 2017, 68, 646−652. (13) Bert, V.; Allemon, J.; Sajet, P.; Dieu, S.; Papin, A.; Collet, S.; Gaucher, R.; Chalot, M.; Michiels, B.; Raventos, C. Torrefaction and pyrolysis of metal-enriched poplars from phytotechnologies: Effect of temperature and biomass chlorine content on metal distribution in end-products and valorization options. Biomass Bioenergy 2017, 96, 1− 11. 10271 DOI: 10.1021/acs.energyfuels.8b01136 Energy Fuels 2018, 32, 10266−10271