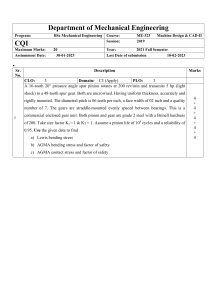

AGMA 923-C22 (Revision of AGMA 923-B05) AGMA Information Sheet AGMA 923-C22 Metallurgical Specifications for Steel and Cast Iron Gearing AMERICAN GEAR MANUFACTURERS ASSOCIATION American Gear Manufacturers Association AGMA 923-C22 Metallurgical Specifications for Steel and Cast Iron Gearing AGMA 923-C22 (Revision of AGMA 923-B05) CAUTION NOTICE: AGMA technical publications are subject to constant improvement, revision or withdrawal as dictated by experience. Any person who refers to any AGMA Technical Publication should be sure that the publication is the latest available from the Association on the subject matter. [Tables or other self-supporting sections may be referenced. Citations should read: See AGMA 923-C22, Metallurgical Specifications for Steel and Cast Iron Gearing, published by the American Gear Manufacturers Association, 1001 N. Fairfax Street, Suite 500, Alexandria, Virginia 22314, http://www.agma.org.] Approved August 2022 ABSTRACT This document identifies metallurgical quality characteristics which are important to the performance of steel and cast iron gearing. The AGMA gear rating standards identify performance levels of gearing by heat treatment method and grade number. For each heat treatment method and AGMA grade number, acceptance criteria are given for various metallurgical characteristics identified in this document. Published by American Gear Manufacturers Association 1001 N. Fairfax Street, Suite 500, Alexandria, Virginia 22314 Copyright © 2022 by American Gear Manufacturers Association All rights reserved. No part of this publication may be reproduced in any form, in an electronic retrieval system or otherwise, without prior written permission of the publisher. Printed in the United States of America ISBN: 978-1-64353-119-9 ©AGMA 2022 – All rights reserved i AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Contents Foreword ................................................................................................................................................ iv 1 Scope ................................................................................................................................................. 1 2 Normative references.......................................................................................................................... 1 3 Definitions ........................................................................................................................................... 3 4 Procedures ....................................................................................................................................... 16 4.1 Recommended test methods..................................................................................................... 16 4.2 Test coupons ............................................................................................................................ 25 4.2.1 Process control test coupons.......................................................................................... 25 4.2.2 Representative test coupon ............................................................................................ 25 5 Metallurgical requirements ................................................................................................................ 26 5.1 5.2 5.3 5.4 5.5 5.6 5.7 Through hardened gearing ........................................................................................................ 26 Carburized and hardened gearing ............................................................................................. 29 Induction or flame hardened gearing ......................................................................................... 36 Nitrided gearing......................................................................................................................... 41 Gray iron gearing ...................................................................................................................... 46 Ductile iron gearing ................................................................................................................... 47 Austempered ductile iron gearing, ADI ...................................................................................... 48 Annexes Annex A Bibliography ............................................................................................................................ 50 Tables Table 1 – Metallurgical characteristics for through hardened gearing...................................................... 27 Table 2 – Metallurgical characteristics for carburized and hardened gearing .......................................... 30 Table 3 – Metallurgical characteristics for induction or flame hardened gearing ...................................... 36 Table 4 – Metallurgical characteristics for nitrided gearing...................................................................... 42 Table 5 – Metallurgical characteristics for gray iron gearing ................................................................... 46 Table 6 – Metallurgical characteristics for ductile iron gearing ................................................................ 47 Table 7 – Metallurgical characteristics for austempered ductile iron gearing ........................................... 48 Figures Figure 1 – Continuous carbide network .................................................................................................... 4 Figure 2 – Semi-continuous carbide network............................................................................................ 5 Figure 3 – Discontinuous carbides ........................................................................................................... 5 Figure 4 – Dispersed carbides ................................................................................................................. 6 Figure 5 – Solid on shaft pinion blank ...................................................................................................... 8 Figure 6 – Bore style gearing blank .......................................................................................................... 8 Figure 7 – Disc style gearing blank .......................................................................................................... 8 Figure 8 – Web style gear blank............................................................................................................... 9 ©AGMA 2022 – All rights reserved ii AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Figure 9 – Intergranular oxidation in carburized gearing ......................................................................... 11 Figure 10 – Microcracks. Original magnification: 1000X, bright field ....................................................... 12 Figure 11 – Microcracks. Original magnification: 1000X, dark field ......................................................... 12 Figure 12 – Non-martensitic transformation products in carburized gearing ............................................ 13 Figure 13 – Tempered martensite and 5% retained austenite in carburized gearing ............................... 14 Figure 14 – Tempered martensite and 20% retained austenite in carburized gearing ............................. 15 Figure 15 – Tempered martensite and 30% retained austenite in carburized gearing ............................. 15 Figure 16 – Case depth measurement locations .................................................................................... 17 Figure 17 – Examples of ingot, bloom, billet/bar, and shaft forgings ....................................................... 20 Figure 18 – Example of upset disk forging ............................................................................................. 21 Figure 19 – Example of closed die forging ............................................................................................. 22 Figure 20 – Example of seamless rolled ring forging .............................................................................. 23 Figure 21 – Example bevel gearing blank .............................................................................................. 24 Figure 22 – Variations in hardening pattern obtainable on gear teeth with flame or induction hardening . 41 ©AGMA 2022 – All rights reserved iii AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Foreword [The foreword, footnotes and annexes, if any, in this document are provided for informational purposes only and are not to be construed as a part of AGMA 923-C22, Metallurgical Specifications for Steel and Cast Iron Gearing.] In November 1984, an ad hoc Metallurgy and Gear Rating Committee met to define the factors required to qualify the various metallurgical quality grades that were to be introduced into the gear rating standard that eventually became ANSI/AGMA 2001-B88, Fundamental Rating Factors and Calculation Methods for Involute Spur and Helical Gear Teeth. In May 1988, ANSI/AGMA 6033-A88, Standard for Marine Propulsion Gear Units – Part 1, Materials, was published using a short list of metallurgical factors in table form. In September 1988, ANSI/AGMA 2001-B88 was published using metallurgical factors in table form. Starting in July 1992, AGMA representatives participated in writing ISO 6336-5, Calculation of Load Capacity of Spur and Helical Gears – Part 5: Strength and Quality of Materials, which was a modification of the tables in ANSI/AGMA and DIN Standards. In February 1993, AGMA 6002-B93, Design Guide for Vehicle Spur and Helical Gears, was published using a modified version of the tables used in ANSI/AGMA 2001-B88. In September 1993, the AGMA Metallurgy and Materials Committee accepted the task of consolidating the various tables to avoid redundancies and conflicting requirements, and started work on AGMA 923-A00, Metallurgical Specifications for Steel Gearing. In January 1995, a revised ANSI/AGMA 2001-C95 was published using a version of the ANSI/AGMA 2001-B88 tables as revised by the AGMA Helical Gear Rating Committee. In November 1997, a revised ANSI/AGMA 2003-B97, Rating the Pitting Resistance and Bending Strength of Generated Straight Bevel, Zerol Bevel and Spiral Bevel Gear Teeth, was published using a version of the ANSI/AGMA 2001-B88 tables as revised by the AGMA Bevel Gearing Committee. The committee reviewed all metallurgical tables of the gear rating standards ANSI/AGMA 2001-B88, ANSI/AGMA 2003-A86, and ISO 6336-5:1996 and their proposed revisions to develop consolidated tables describing the metallurgical characteristics associated with each specific type of heat treatment and metallurgical quality grade. Effort was made to reference ISO specifications where possible. The consolidated tables were submitted to the gear rating committees for their agreement and are published here for reference by other standards. AGMA’s goal is to develop a consistent metallurgical specification which reflects the quality requirements for steel gearing. AGMA 923-A00 was such a document and was intended to be consistent with the applicable portions of ISO 6336-5:1996, to the extent possible while the two standards were in parallel development. The AGMA Technical Division Executive Committee approved the publication of AGMA 923-A00 in August 2000. AGMA 923-B05 incorporated changes to Item 8, microstructure, of Table 1, metallurgical characteristics for through hardened gearing. The balance of the document remains unchanged. The AGMA Technical Division Executive Committee approved the publication of AGMA 923-B05 in May 2005. AGMA 923-C22 replaces AGMA 923-B05. This edition of the information sheet was developed to be consistent with ISO 6336-5:2016. An expanded reduction ratio calculation methodology with new figures has been added to the procedures section. In addition, metallurgical tables have been updated as follows: a) listing of requirements sequentially; b) chemistry and cleanliness requirements were added; c) footnotes were reworded and renumbered for uniformity; d) new metallurgical tables were added for gray cast iron, ductile iron, and austempered ductile iron. The first draft of AGMA 923-C22 was created in November 2013. It was approved by the Technical Division Executive Committee (TDEC) in August 2022. Suggestions for improvement of this information sheet will be welcome. They should be sent to tech@agma.org. ©AGMA 2022 – All rights reserved iv AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 PERSONNEL of the AGMA Metallurgy and Materials Committee Chair: Carl R. Ribaudo........................................Timken Company, Retired Vice Chair: Liam Joseph Coen............................INNIO Waukesha Gas Engines, Inc ACTIVE MEMBERS D. Antos .............................................................Canton Drop Forge J. Bishar .............................................................GE Transportation, a Wabtec Company R. Errichello........................................................Geartech M. He .................................................................Scot Forge Company J. Lefevre ...........................................................Applied Process Inc. D. McLain ...........................................................General Motors LLC W. Skrzypek .......................................................Twin Disc, Incorporated A. Swiglo ............................................................Northern Illinois University T. Tressler ..........................................................Ellwood City Forge D. Weires ...........................................................Boeing Rotorcraft – Philadelphia F. Uherek ...........................................................Regal Rexnord Corporation D. Yatzook..........................................................Artec Machine Systems ©AGMA 2022 – All rights reserved v AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 American Gear Manufacturers Association – Metallurgical Specifications for Steel and Cast Iron Gearing 1 Scope Metallurgical quality characteristics for use in conjunction with AGMA gear rating standards are recommended. Three different metallurgical quality grades: grade 1, grade 2, and grade 3 are defined. Characteristics include raw material, heat treatment, post heat treat processing, and associated inspections. Gear design and rating, case depth, allowable stress numbers, and quality control sampling plans are not included. 2 Normative references The following standards contain provisions which, through reference in this text, constitute provisions of this document. At the time of initial development, the editions shown were valid. All standards are subject to revision, and parties to agreements based on this document are encouraged to investigate the possibility of applying the most recent editions of the standards shown below. AGMA 904, Metric Usage ANSI/AGMA 1010, Appearance of Gear Teeth – Terminology of Wear and Failure ANSI/AGMA 1012, Gear Nomenclature, Definitions of Terms with Symbols ANSI/AGMA 2001, Fundamental Rating Factors and Calculation Methods for Involute Spur and Helical Gear Teeth ANSI/AGMA 2003, Rating the Pitting Resistance and Bending Strength of Generated Straight Bevel, Zerol Bevel and Spiral Bevel Gear Teeth ANSI/AGMA 2004, Gear Materials and Heat Treatment Manual ANSI/AGMA ISO 14104, Gears – Surface Temper Etch Inspection After Grinding – Chemical Method ANSI/AGMA 6002, Design Guide for Vehicle Spur and Helical Gears ASTM A29/A29M, Specification for Steel Bars, Carbon and Alloy, Hot-Wrought, General Requirements ASTM A148/A148M, Specification for Steel Castings, High Strength, for Structural Purposes ASTM A247, Standard Test Method for Evaluating the Microstructure of Graphite in Iron Castings ASTM A255, Standard Test Methods for Determining Hardenability of Steel ASTM A275/A275M, Test Method for Magnetic Particle Examination of Steel Forgings ASTM A370, Standard Test Methods and Definitions for Mechanical Testing of Steel Products ASTM A388/A388M, Standard Practice for Ultrasonic Examination of Steel Forgings ASTM A519/A519M, Standard Specification for Seamless Carbon and Alloy Steel Mechanical Tubing ASTM A534, Standard Specification for Carburizing Steels for Anti-Friction Bearings ASTM A536, Standard Specification for Ductile Iron Castings ©AGMA 2022 – All rights reserved 1 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 ASTM A609/A609M, Standard Practice for Castings, Carbon, Low-Alloy, and Martensitic Stainless Steel, Ultrasonic Examination Thereof ASTM A751, Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products ASTM A866-18, Standard Specification for Medium Carbon Anti-Friction Bearing Steel ASTM A897, Standard Specification for Austempered Ductile Iron Castings ASTM A941, Standard Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys ASTM A956, Standard Test Method for Leeb Hardness Testing of Steel Products ASTM A1038, Standard Test Method for Portable Hardness Testing by the Ultrasonic Contact Impedance Method ASTM E3, Practice for Preparation of Metallographic Specimens ASTM E8/E8M, Standard Test Methods for Tension Testing of Metallic Materials ASTM E10, Standard Test Method for Brinell Hardness of Metallic Materials ASTM E18, Standard Test Methods for Rockwell Hardness of Metallic Materials 1, 2 ASTM E23, Standard Test Methods for Notched Bar Impact Testing of Metallic Materials ASTM E45, Standard Test Methods for Determining the Inclusion Content of Steel ASTM E92, Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials ASTM E110, Standard Test Method for Indentation Hardness of Metallic Materials by Portable Hardness Testers ASTM E112, Standard Test Methods for Determining Average Grain Size ASTM E125, Standard Reference Photographs for Magnetic Particle Indications on Ferrous Castings ASTM E140, Standard Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Rockwell Superficial Hardness, Knoop Hardness, Scleroscope Hardness, and Leeb Hardness ASTM E350, Standard Test Methods for Chemical Analysis of Carbon Steel, Low-Alloy Steel, Silicon Electrical Steel, Ingot Iron, and Wrought Iron ASTM E351, Standard Test Methods for Chemical Analysis of Cast Iron – All Types ASTM E407, Standard Practice for Microetching Metals and Alloys ASTM E1077, Standard Test Methods for Estimating the Depth of Decarburization of Steel Specimens ASTM E1444, Practice for Magnetic Particle Examination ISO 185, Grey Cast Irons – Classification ISO 642, Steel – Hardenability test by end quenching (Jominy test) ISO 643, Steels – Micrographic determination of the ferritic or austenitic grain size ISO 683-1, Heat-treatable steels, alloy steels and free-cutting steels – Part 1: Direct-hardening unalloyed and low-alloyed wrought steel in form of different black products ISO 683-11, Heat-treatable steels, alloy steels and free-cutting steels – Part 11: Wrought casehardening steels ISO 945, Microstructure Of Cast Irons ISO 1083, Spheroidal Graphite Cast Irons – Classification ISO 4967, Steel – Determination of content of non-metallic inclusions – micrographic method using standard diagrams ©AGMA 2022 – All rights reserved 2 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 ISO 6336-5, Calculation of load capacity of spur and helical gears – Part 5: Strength and quality of materials ISO 17804, Founding – Ausferritic spheroidal graphite cast irons – Classification ISO 18265, Metallic Materials – Conversion of Hardness Values SAE/AMS 2300, Premium Aircraft-Quality Steel Cleanliness, Magnetic Particle Inspection Procedure SAE/AMS 2301, Cleanliness, Aircraft Quality Steel Magnetic Particle Inspection Procedure SAE/AMS 2304, Special Aircraft-Quality Steel Cleanliness, Magnetic Particle Inspection Procedure SAE/AMS-S-13165, Shot Peening of Metal Parts SAE J419, Methods of Measuring Decarburization SAE J423, Methods of Measuring Case Depth SAE J864, Surface Hardness Testing with Files 3 Definitions The terms used in this document, wherever applicable, conform to AGMA 904 and ANSI/AGMA 1012, but they have been modified to cover only those concepts applicable to this document. For definitions of technical terms not included in this clause, see ANSI/AGMA 1012, ANSI/AGMA 2004, and ASTM A941. Key terms used in this document are defined as follows: NOTE: The definitions used in this information sheet may differ from other AGMA publications. The user should assure themselves that they fully understand the terms, definitions, and symbols as contained in this publication. alloy steel: A steel containing specified quantities of alloying elements (other than carbon and the commonly accepted amounts of manganese, copper, silicon, sulfur, and phosphorus) added to increase hardenability and to affect changes in mechanical properties. annealing: Without an adjective annealing is assumed to mean full annealing. − full annealing: The heating to and holding at a suitable temperature above the upper transformation temperature and then cooling, typically in the furnace at a suitable rate, for reducing hardness, improving machinability, producing a desired microstructure, or obtaining desired mechanical properties. − subcritical annealing: Reheating to a temperature below the lower transformation temperature. For carburized gearing the temperature is typically 1200–1250°F (650–675°C) and is done after carburizing and before hardening. ausferrite: a cast iron matrix microstructure, produced by a controlled thermal process, which consists of predominantly acicular ferrite and high carbon austenite. austempering: Austempering is an isothermal heat treatment process that can be applied to ferrous materials to increase strength and toughness. Austempering consists of austenitizing, rapid quenching to avoid the formation of high temperature transformation products to a temperature above the martensite start temperature, and then holding to allow isothermal formation of either ausferrite in cast iron, or lower bainite in steel. A ferrous material heat treated by austempering is referred to as austempered. austenite: A solid solution of one or more elements in face-centered cubic iron. In carbon and low alloy steels this phase is stable only at elevated temperatures and is non-magnetic. austempered ductile iron: Also known as ADI or ausferritic ductile iron, is produced by giving conventional ductile iron an austempering heat treatment. austenitizing: The forming of austenite by heating a ferrous material into the transformation range (partial austenitizing) or above the transformation range (complete austenitizing). ©AGMA 2022 – All rights reserved 3 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 bainite: An aggregate of ferrite and cementite resulting from the transformation of austenite at temperatures below the pearlite range but above the martensite start temperature. Its appearance is feathery if formed in the upper part of the bainite transformation range (upper bainite) and acicular, resembling tempered martensite, if formed in the lower part (lower bainite). banding: Banding is alternating areas of different microstructures typically seen as metallographic dark and light etching areas as the result of localized chemical microsegregation. Elements which tend to segregate are sulfur, phosphorus, carbon, silicon, and manganese. Microsegregation is nonuniform distribution of alloying elements. base hardness: See hardness, base. bending strength: The strength of gear teeth related to their resistance to gear tooth bending failure. Bending failure is a fatigue phenomenon usually resulting in cracking at the tooth root fillet. Typical cracks and fractures are illustrated in ANSI/AGMA 1010. See standards such as ANSI/AGMA 2001 and ANSI/AGMA 2003. capable of: The producer documents that the material was produced with the processing steps and controls that the producer has established to assure compliance with the specification, but the testing to confirm compliance is not required. carbide: A microstructural phase which is a compound of metal (M) and carbon (C) having the chemical formula of MxCy. See Figure 1 through Figure 4 for photomicrographs of various classifications of carbide distribution (white constituent) in tempered martensite. 5% nital etch 400 X mag. Figure 1 – Continuous carbide network ©AGMA 2022 – All rights reserved 4 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 20 µm Figure 2 – Semi-continuous carbide network 20 µm Figure 3 – Discontinuous carbides ©AGMA 2022 – All rights reserved 5 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 20 µm Figure 4 – Dispersed carbides carbon potential: A measure of the ability of a furnace environment containing active carbon to alter or maintain, under prescribed conditions, the carbon content of the steel. carbon restoration: Carburizing to replace the carbon lost in the surface layer due to previous thermal processing. carbon steel: A steel having no specified minimum quantity of alloying elements except manganese and silicon. carbonitriding: A modified form of gas carburizing, in which steel (typically plain carbon and very low alloy) is austenitized in an ammonia enriched carburizing atmosphere. This results in simultaneous adsorption of carbon and nitrogen bearing gases, the dissociation of these gases, and diffusion of carbon and nitrogen atoms into the steel, which results in the formation of complex nitrides in a high carbon case. carburizing: A heat treatment process in which an austenitized steel is brought into contact with a carbonaceous atmosphere of sufficient carbon potential to cause adsorption of carbon bearing gases at the surface where they dissociate and by diffusion to create a carbon concentration gradient. Carburizing is generally followed by quenching and reheating (tempering) of an item to produce a hardened and tempered case. carburized and austempered: A heat treatment for carburizing grades of steels which produces a high carbon, hard bainitic case, and a softer tempered martensite or bainite core. case: The outer portion that has been made harder than the inner portion (see core hardness) as a result of altered composition, microstructure, or both, by treatments such as carburize and hardening, induction hardening, flame hardening, and nitriding. ©AGMA 2022 – All rights reserved 6 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 case depth, effective: The distance from the finished tooth surface to a specific sub-surface hardness value. Stock removal done after heat treating will reduce the as heat treated effective case depth and potentially the surface hardness. − carburized and hardened: The effective case depth is measured normal to the finished gear surface to a location where the hardness number is 50 HRC (542 HK500 or 515 HV500) minimum by conversion from a microhardness test result. Note that ISO 6336-5 uses 550 HV minimum, which converts to 52.4 HRC or 583 HK, as its criterion for determining the effective case depth. It is recognized that the effective case depth of carburized and hardened gear teeth varies with location on the gear tooth. − induction and flame hardened: For Grades 1 and 2 gearing, the effective hardened depth is measured from the finished surface to a location where the hardness number is equivalent to 10 HRC numbers below the specified minimum surface hardness. Grade 3 induction hardened gearing uses the carburized and hardened definition for its effective hardened depth definition. Note that ISO 6336-5 uses the distance from the surface to the location where the hardness is equal to 80% of the specified minimum surface hardness as its criterion for determining the effective hardened depth. − nitrided: The effective case depth is measured from the finished surface to a location where the hardness number is equivalent to 40.8 HRC (421 HK500 or 400 HV500) minimum by conversion from a microhardness test result. If the core hardness is more than 38.9 HRC (391 HK500 or 380 HV500), core hardness plus 54 HK500 or 50 HV500 (4.6 HRC) minimum may be used as the definition of nitrided effective case depth. Note that this is the same definition used in ISO 6336-5. case depth, total: For carburized gearing the maximum depth of diffused carbon. The total case depth for induction or flame hardened gearing is usually assumed to be the same as the hardened and effective case depths. The total case depth for nitrided gearing is the distance from the surface to the depth at which the HRC hardness number is 110% of the hardness number for the core case hardening: The generic terminology covering carburize and nitride hardening processes applicable to steel that change the chemical composition and microstructure of the surface layer by adsorption of carbon, nitrogen, or a mixture of the two and by diffusion, create a chemical composition gradient. Adsorption of carbon processes involve a subsequent quenching to harden, while adsorption of nitrogen does not require quenching to harden. case hardness: See hardness, case. cast iron: A family of alloys composed primarily of iron, carbon, and silicon, where the carbon exists in amounts higher than that which can remain in solid solution in austenite at eutectic temperature. cementite: A hard compound of iron and carbon, known chemically as iron carbide, having the chemical formula Fe3C. cold treatment: The preferred terminology for cooling carburized and hardened parts to temperatures typically below minus 80°F (minus 60°C) to reduce retained austenite. Cold treatment is also known as sub-zero treatment or deep freezing. If cooled to below minus 300°F (minus 185°C), the correct terminology is deep cryogenic treatment. controlling section: Controlling section is the diameter of the largest sphere that can be inscribed within the section of the pinion or gear containing teeth. Controlling section has the greatest effect in determining the rate of cooling during quenching at a location where the specified hardness is required. Figure 5 through Figure 8 illustrate the controlling section size for various gearing configurations whose teeth are machined after heat treatment and whose hardness should be maintained at the roots of the teeth. The maximum permitted section size for an alloy steel increases with the hardenability of the alloy steel. ©AGMA 2022 – All rights reserved 7 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Note that a flat plate with thickness equal to the diameter of a round bar will cool slower than the bar. The thickness of a plate equivalent in cooling rate to that of a round bar (equivalent controlling section size) is approximately 0.7 times the bar diameter. The controlling section size for the selection of an appropriate type of steel and specified hardness combination should consider part configuration at the time of heat treatment. Special stock additional allowances, such as those used to minimize distortion during heat treatment, should be considered. Figure 5 – Solid on shaft pinion blank NOTE: If the bore diameter is less than 20% of the length of the bore, then the controlling section is determined by Figure 5 or Figure 7. Figure 6 – Bore style gearing blank Figure 7 – Disc style gearing blank ©AGMA 2022 – All rights reserved 8 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Figure 8 – Web style gear blank converted hardness: See hardness, converted. core hardness: See hardness, core. crack: Separation of a material matrix to form a linear discontinuity with a sharp tip; not to be confused with microcrack. decarburization: The loss of carbon from the near-surface of a ferrous material. deep freeze treatment: See cold treatment. deoxidizing: The removal of oxygen from molten steel by addition of suitable elements, such as silicon and aluminum which react with oxygen, primarily forming discard slag. DI (ideal critical diameter): DI is the diameter of a given steel that will produce 50% martensite at its center when quenched at an ideal quench severity of H = ∞. DI can be calculated per ASTM A255. An actual critical diameter for a given steel and quench rate can be determined by quenching a series of long round bars of increasing diameters in a given quench medium and measuring a hardness profile across the bar diameter on a transverse section taken from the mid-length of the bar. The bar with center hardness corresponding to the critical level for hardening, usually the 50% martensite level, determines the critical diameter. direct quenching: The quenching of carburized gearing directly after the carburizing operation, generally from a reduced temperature within the austenitic range. ductile iron: A cast iron which is treated with a nodularizing agent, typically Mg, in the molten state causing the graphitic carbon to precipitate out preferentially into spheroids. These graphite spheroids are commonly referred to as nodules. effective case depth: See case depth, effective. ferrite: A solid solution of one or more elements in body-centered cubic iron. In carbon and alloy steels this phase is stable at room temperature. flame hardening: A surface hardening process in which only the surface layer of the work piece is heated by a flame to above the upper transformation temperature and immediately quenched. free ferrite: The ferrite that is formed directly during cooling without simultaneous formation of carbide. full annealing: see annealing. grain size: The dimensions of the grains, or crystals, in a polycrystalline metal exclusive of twinned regions and sub-grains when present. The ASTM grain size is a designation bearing a relationship to number of grains per square inch at 100 times magnification. Commercial grain size is categorized as either coarse (grain size 1–4) or fine (grain size 5 or finer). graphite flake: The predominate form of graphitic carbon in gray iron having a curved plate-like structure. graphite nodule: The predominate form of graphitic carbon in ductile iron having a polycrystalline radial structure commonly referred to as a spheroid or nodule. ©AGMA 2022 – All rights reserved 9 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 gray iron: Cast iron that has graphitic carbon predominately in the form of flakes. hardenability: The property of a ferrous alloy that determines the depth and distribution of hardness induced by quenching. hardened depth: For induction or flame hardened gearing, alternative terminology for effective case depth. hardened zone: The area hardened by a surface hardening process. hardness, base: The surface hardness in the tooth area that was developed by through hardening and not changed by subsequent heat treatments. If the material selected has adequate hardenability for the required hardness and section size combination, this surface hardness represents the expected hardness at the intersection of the root circle and the centerline of the tooth at mid-face width. Base hardness is applicable to through hardened, induction hardened, flame hardened, and nitrided gearing, but not to carburized and hardened gearing. hardness, case: For carburized and hardened gearing and induction or flame hardened gearing the hardness is measured at 0.002–0.004 inches (0.05–0.10 mm) below the surface using a microhardness test technique. For nitriding specifications, surface hardness is typically used rather than case hardness. Case hardness is not to be confused with surface hardness. hardness, converted: The hardness number reported on a scale different from the scale used for hardness testing. For example, an actual microhardness test reading of 542 HK500 has a converted hardness of 50 HRC and would be properly reported as 50 HRC (542 HK500) with the hardness number and scale in parentheses representing the actual testing result and method. hardness, core: The hardness at the intersection of the root circle and the centerline of the tooth at midface width that was developed during the hardening of carburized gearing. An alternative location is given by ISO 18265. See relevant application standards for additional guidance. The material should have adequate hardenability for the required hardness and section size combination for the required core hardness to be achieved. The quench severity should also be adequate in order to achieve the required core hardness. The term core hardness is applicable to carburized and hardened gearing. Induction, flame, and nitride hardened gearing may use the term base hardness. The core hardness of non-tooth portions, such as journal areas of carburized and hardened gearing, is the hardness at a specified location such as surface, quarter radius, mid-radius, or centerline. hardness, surface: The hardness measured directly on the functional surface, after appropriate surface preparation. Surface hardness is not to be confused with case hardness, which is taken on a metallographic cross-section using a microhardness tester. In cases where teeth are small such that surface hardness measurements are impractical, a microhardness measurement within 0.004 inches (100 micrometers) depth below the surface may be used to qualify surface hardness. hardness conversion chart: A published document for use in converting from one hardness testing scale to another. Hardness conversion charts should be used with great caution since discrepancies of 0.3 HRC numbers at 30 HRC to 3.9 HRC numbers at 60 HRC have been noted between various published conversion charts. Therefore, it is suggested that the conversion chart used for testing and reporting be specified. Some of the more popular hardness conversion charts are found in ASTM A370, ASTM E140, ISO 6336-5, and certain individual corporate documents and standards. For this document, ASTM E140 is used and should be used whenever no other document is specified. induction hardening: A surface hardening process in which only the surface layer of the work piece is heated by electrically induced currents to above the upper transformation temperature and immediately quenched. ©AGMA 2022 – All rights reserved 10 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 intergranular oxidation (IGO): The preferential oxidization of certain alloying elements along grain boundaries during gas carburizing. See Figure 9 for a photomicrograph of intergranular oxides (black constituent). Figure 9 – Intergranular oxidation in carburized gearing linear indication: An indication with length at least three times its width. macropitting resistance: Endurance limit adequate to resist contact fatigue. Initial pitting and progressive macropitting are illustrated and discussed in ANSI/AGMA 1010. See standards such as ANSI/AGMA 2001 and ANSI/AGMA 2003. marquench: Quenching into a liquid media whose temperature is above the martensite start transformation temperature, typically 300–500°F (150–260°C), held at this temperature until temperature is uniform throughout, and then cooled to form martensite. Marquenching is used to achieve reduced distortion when compared to conventional quenching. martensite: A generic term for microstructures formed by the diffusionless phase transformation of austenite. Martensite is characterized by an acicular or needle-like pattern in the microstructure and is the hardest of the austenitic transformation products in steel. metallurgical notch: If an induction or flame hardened gear with type B flank hardening has a pattern that terminates (runs out) at the surface of the root fillet it is accompanied by tensile residual stress that adds to the bending stress, which greatly reduces the bending fatigue resistance. This is known as a “metallurgical notch.” microcracks: Microscopic discontinuities that specifically occur only across or alongside martensite plates. Some prefer to call these discontinuities broken martensitic needles or platelets. They are a quantifiable feature of the martensitic case microstructure of carburized parts. The use of microcrack measurements in critical crack size calculations is considered inappropriate. Microcracks may be associated with reduced macropitting resistance resulting from cold treating which may be prohibited to avoid the potential problem. See Figure 10 and Figure 11. ©AGMA 2022 – All rights reserved 11 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Figure 10 – Microcracks. Original magnification: 1000X, bright field. Field area = 11000 µm2 (0.011 mm2) Figure 11 – Microcracks. Original magnification: 1000X, dark field. Field area = 11047.5 µm2 (0.011 mm2 ) nitriding: The introduction of nascent nitrogen into a suitable solid ferrous alloy by holding at a suitable temperature in contact with a nitrogenous material. Adsorption of nascent nitrogen produces case hardening without quenching. ©AGMA 2022 – All rights reserved 12 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 nitrocarburizing: A heat treating process in which carbon and nitrogen bearing gases are absorbed on the surface of a ferrous material, the gases dissociate, and carbon and nitrogen atoms diffuse into the metal to produce case hardening without quenching. This modified nitriding process can be performed in either ferritic or austenitic temperature ranges. nodularity: The unit of measure for the volumetric proportion of spheroidal graphite to all graphite in a ductile iron. Type I and Type II graphite as defined by ASTM A247 of the graphite nodules in ductile iron. nodule: See graphite nodule. nodule count: The measurement of the number of nodules in a given section of ductile iron, in nodules per unit area. The nodule count influences the strength and toughness of the iron. non-martensitic structures: Inclusive terminology for ferrite, carbide, retained austenite, pearlite, and bainite due to incomplete transformation to martensite or incomplete austenization. Retained austenite is not included in the quantitative metallographic measurement of non-martensitic structures. non-martensitic transformation products (NMTP): Inclusive terminology for ferrite, carbide, pearlite, and upper bainite in the surface microstructure of carburize hardened gearing due to incomplete transformation to martensite. See Figure 12 for a photograph of non-martensitic transformation products in martensite. 5% nital etch 400 X mag. Figure 12 – Non-martensitic transformation products in carburized gearing normalizing: The heating of a ferrous alloy to a suitable temperature above the upper transformation temperature and then cooling, in air or vacuum, until transformation is complete. pearlite: A microstructural constituent consisting of lamellar ferrite and cementite resulting from the transformation of austenite at temperatures above the bainite range. process control test coupon: For carburized and hardened gearing or nitrided gearing, a test coupon used primarily to monitor the consistency of the heat treatment process in terms of carbon or nitrogen penetration and case microstructure. Sometimes called a standardized test coupon. For procedures associated with process control test coupons, see 4.2.1. Due to differences in quench cooling rates and hardenability, the microstructure and hardness of process control test coupons used for carburized and hardened gearing is likely to not be the same as that of the finished gear tooth. quench and temper: Austenitizing, followed by rapid cooling (quenching) and reheating (tempered) to a temperature generally below 1275°F (690°C). ©AGMA 2022 – All rights reserved 13 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 reduction ratio: In forging and rolling, the total reduction ratio is the product of all steps used to produce a forging or bar. Depending on the type of deformation, the total reduction can be any combination of the following: − changing cross-sectional area by elongating: the ratio of initial cross-sectional area and the final cross-sectional area. − upset: the ratio of initial height and the final height. − ring rolling: ratio of initial wall cross-sectional area and the final wall cross-sectional area. For tapered ingots or any other non-uniform as-cast starting stock, the mean cross-sectional area is typically used to calculate the reduction. Unless otherwise specified, when a multiple cross-sectional area forging is produced, the reduction ratio of the largest diameter where the gear teeth will be machined should be used. reheat quenching: The quenching of carburized gearing after the carburizing operation, by first slow cooling below the austenitic range, then re-austentizing and quenching. representative test coupon: A test coupon designed to represent the quenching rate of the finished gearing tooth. If the coupon is to be used only to determine the case properties, it can be smaller than one used to determine the core properties of the gear tooth. A representative test coupon sized for determining the core hardness and microstructure can also be used for determining the case properties or as a process control test coupon. A representative test coupon sized for determining the case properties can also be used as a process control test coupon but not for determining core properties unless substantiated by documented test data. For procedures associated with representative test coupons, see 4.2.2. retained austenite: The metastable austenite contained within a quenched microstructure. The amount of retained austenite is a function of carbon content, alloy content (especially nickel and manganese), quench temperature and subsequent thermal or mechanical treatments. See Figure 13 through Figure 15 for examples of visual estimates of retained austenite (white constituent) in tempered martensite. More precise measurements of retained austenite can be obtained by X-ray diffraction techniques. 5% nital etch 400 X mag. Figure 13 – Tempered martensite and 5% retained austenite in carburized gearing ©AGMA 2022 – All rights reserved 14 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 5% nital etch 400 X mag. Figure 14 – Tempered martensite and 20% retained austenite in carburized gearing 5% nital etch 400 X mag. Figure 15 – Tempered martensite and 30% retained austenite in carburized gearing shot peening: A cold working process performed by bombarding the surface of a part with small spherical media. This results in a thin layer of high magnitude residual surface compressive stress and generally improves the bending strength in the roots of gear teeth. Shot peening should not be confused with grit blasting or shot blasting which are cleaning operations. specialty nitriding steel: A steel typically alloyed with 1% aluminum to provide higher surface hardness after nitriding than normally attained with nitrided through hardening steels. standardized test coupon: Alternate terminology for a process control test coupon. ©AGMA 2022 – All rights reserved 15 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 sub-zero treatment: See cold treatment. subcritical anneal: See anneal, subcritical. surface hardening: The generic terminology for selective induction or flame heating of a surface layer and then quenching that layer to produce a hardened surface layer that may be thinner than the heated area but is harder than the unheated base material. With induction or flame hardening there is no significant alteration of the chemical composition of the surface layer. surface hardness: See hardness, surface. surface temper: Localized overheating on ground surfaces. Can be detected and classified using a chemical etch method. tempering: The reheating of a hardened ferrous alloy part to a temperature below the transformation range and holding at temperature followed by cooling it at any rate. test bar: A sample used for tensile or impact strength testing. Also used as alternate terminology for a test coupon used for hardness and microstructure testing. test coupon: See specific type of test coupon, such as process control or representative. through hardening: The process of using a rapid quench to increase hardness throughout a steel alloy for the purpose of increasing its strength. Through hardening typically consists of three steps: the heating of an alloy above critical temperature to alter its mechanical properties, a rapid quench in a medium, such as oil, salt or caustic, and a reheating, or tempering, to eliminate excess brittleness from the treated alloy. total case depth: See case depth, total. total nominal alloy content: The sum of the mid-points of the specified ranges for all alloying elements added to increase hardenability (e.g., Mn, Cr, Ni, Mo). transformation temperature: The temperature at which a phase change occurs. traveling indication: An uninterrupted ultrasonic testing signal on the display which moves horizontally on the sweep line as the transducer is moved on the scanning surface. Travel of the signal indicates varied depth of the discontinuity from the scanning surface, often indicative of a crack. 4 Procedures In order to have comparable test results between inspectors and evaluators, a consistent set of test methods and procedures is necessary to comply with the definitions, requirements, recommendations, and considerations contained in this document. 4.1 Recommended test methods The test methods listed in this clause are to be used when no other method is clearly defined or specified. These are the methods to be used for evaluations to the requirements of Clause 5. Testing of the actual part is preferred and should always be used whenever practical. However, properly selected test coupons can also be used. The dimensions in this document are always to be measured normal (not oblique) to the surface. banding: The coupons should be hardened and evaluated in the as-quenched condition. Microhardness indentations should be taken per ASTM E384 Vickers using loads of 200g or higher. carbon: See surface carbon. case hardness: For carburized and hardened gearing, unless otherwise specified, the case hardness is determined at a location 1/2 of tooth height at least midway between the end faces (or from a representative test coupon). For induction or flame hardened gearing, unless otherwise specified, the case hardness is determined at a location 1/4 of tooth height above the root at least midway between the end faces. ©AGMA 2022 – All rights reserved 16 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 For nitrided gearing, unless otherwise specified, the case hardness is determined at a location 1/2 of tooth height at least midway between the end faces (or from a process control or representative test coupon). chemistry: Analyzed per ASTM A751 for steels. core hardness: Per a standard or superficial hardness testing method listed under “hardness” see Figure 16 for test location. decarburization: Per any of three methods: − Method 1: File hardness. The flanks of a tooth are file hardness tested per SAE J864 or ISO 6336-5, Annex D with lack of file hardness indicating possible decarburization or nonmartensitic structures. − Method 2: Reduction of hardness. Surface hardness readings are taken in the same area using two different hardness testing loads, such as HRC and HR15N with major loads of 150 kg and 15 kg respectively. The two sets of readings are compared using a standard hardness conversion chart, such as ASTM E140. Decarburization is indicated by a lower converted hardness for the lighter load compared to that from the heavier load, presuming that proper hardness testing techniques were used for both sets of tests. − Method 3: Metallographic evaluation. A metallographic specimen is prepared per ASTM E3, etched per ASTM E407, and evaluated per ASTM E1077 or SAE J419. effective case depth: Per SAE J423 microhardness test method. For carburized and hardened gearing, Figure 16 indicates where to measure case depth and core hardness. It is based on reference [6] for carburized gearing. The 30° line defines the approximate location for effective case depth measurement at the root fillet. Figure 16 – Case depth measurement locations − Location A, at approximately mid-height of the tooth, is the location for measuring case depth and case hardness at the flank. − Location B is the location for measuring case depth and case hardness at approximately 30° normal to the root fillet. − Location C is the location for measuring case depth and case hardness at the tooth tip. − Location D is the location at the root diameter for measuring core hardness. For nitrided gearing, unless otherwise specified, the effective case depth is determined at a location 1/2 of tooth height (or from a representative test coupon). For induction or flame hardened gearing, unless otherwise specified, the effective case depth or hardened depth is determined at a location 1/4 of tooth height above the root. ©AGMA 2022 – All rights reserved 17 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 grain size: Per ASTM E112 or ISO 643. For carburized parts see Table 2, notes. hardenability: Per ASTM A255 or ISO 642 end-quench test or by hardenability calculation per ASTM A255. hardness: Listed below are each method and the associated processes which are tested by that method. − ASTM E10, Brinell hardness testing o o Through hardened gearing Base hardness of flame, induction, or nitride hardened gearing − ASTM E18, Rockwell hardness testing o Through hardened gearing o Carburized and hardened gearing o Flame and induction hardened gearing o Nitrided gearing − ASTM E92, Vickers hardness testing o Through hardened gearing o Carburized and hardened gearing o Flame and induction hardened gearing o Nitrided gearing − ASTM E384, Microhardness testing o Carburized and hardened gearing o Flame and induction hardened gearing o Nitrided gearing If standard hardness testing per ASTM E10 or ASTM E18 is not practical due to size of gearing and test location, portable testing may be accomplished by ASTM E110. If ASTM E110 is not appropriate, alternative portable methods are ASTM A956 and ASTM A1038. Measurement of surface hardness per ASTM E18 is used as a nondestructive method to evaluate the conformity of individual work pieces to the surface hardness requirements. The measurement method should be appropriate for the size and configuration of the work pieces. The teeth area requirements for hardness measurements include the root of the tooth. Alternate methods of hardness measurement, including file testing in accordance with SAE J864 or ISO 6336-5, Annex D, may be used. Due to the state of the art of alternate microhardness testing methods, results may vary by the equivalent of three points HRC from actual HRC measurements per ASTM E18. The significance and interpretation of those results should be agreed upon between the parties. intergranular oxides: In the unetched condition, see metallography and Figure 9. magnetic particle: Per ASTM E1444 regardless of form, or alternatively ASTM E125 for castings or ASTM A275 for forgings. mechanical testing: Per ASTM E8 for tensile testing and ASTM E23 for impact testing (also see hardness). metallography: Performed at a magnification of 400–600 diameters. Metallographic samples should be prepared per ASTM E3 and etched per ASTM E407, except for intergranular oxidation which should be evaluated in the unetched condition. microhardness: See hardness. microstructure: See metallography. ©AGMA 2022 – All rights reserved 18 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 nodularity: Analyzed per ASTM A247 or ISO 945. nodule count: Analyzed per ASTM A247 or ISO 945. nonmetallic inclusions: Per any of the following methods: − SAE/AMS 2301, for aircraft steels − SAE/AMS 2300, for premium aircraft quality − SAE/AMS 2304, for special aircraft quality − ASTM A534, for carburizing bearing steels − ASTM A866, for through hardening bearing steels − ASTM E45, for inclusion count − ISO 4967, by comparison to micrographic diagrams, Method A − SAE J422, by comparison to micrographic diagrams reduction ratio: The reduction ratio can be calculated by the following equations; other appropriate methods exist and may be used with best engineering judgement. For tapered ingots or any other nonuniform as-cast starting stock, unless otherwise specified the mean cross-sectional area should be used to calculate the reduction ratio. When a multiple cross-sectional area forging is produced, the reduction ratio in the area of the largest diameter where the gear teeth will be machined should be used. For forgings with varying reductions along the tooth profile, the portion with the least reduction in the teeth area should be used for the calculation of reduction ratio. Piercing operations and any associated expansion do not contribute to the reduction ratio. The total reduction from the as-cast dimension to the final forged dimension is the mathematical product of all the individual applicable forging steps. These calculation steps are examples of hot working sequence for a given final shape, other forging sequences are possible, the reduction calculation should be based on the actual reduction sequence employed. RR = R1R 2 R3 R 4 R5 ...R x : 1 (1) where RR is reduction ratio; Rx is the mechanical reduction of each individual forging step. Sample reduction ratio calculation methods are shown below. Other forging sequences are possible. For bar stock and shaft forgings produced by axial elongation such as in Figure 17: A R1 = i Af where (2) Ai is the initial cross-sectional area of the as-cast material, in2 (mm2); Af is the final cross-sectional area at the largest forged diameter in the area where the teeth will be, in2 (mm2); and R2, R3, R4, and R5 = 1 ©AGMA 2022 – All rights reserved 19 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Figure 17 – Examples of ingot, bloom, billet/bar, and shaft forgings For disks produced by axial elongation and upsetting such as in Figure 18: RR = R1 R 2 : 1 (3) A R1 = i Af (4) D R 2 = i Df (5) where Ai is the initial cross-sectional area of the as-cast material, in2 (mm2); Af is the final cross-sectional area of the axially elongated material prior to upsetting, in2 (mm2); Di is the initial height of the cutoff forged material prior to upsetting, inch (mm); is the final height of the finish forged upset disk in the area where the teeth will be, inch (mm); and R3, R4, and R5 = 1. Df ©AGMA 2022 – All rights reserved 20 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Figure 18 – Example of upset disk forging For closed die forgings with a portion that is raised such as in Figure 19: RR = R1 R 2 R3 : 1 (6) A R1 = i Af (7) D R 2 = i Df (8) H R3 = f Hi (9) where Ai is the initial cross-sectional area of the as-cast material, in2 (mm2); Af is the final cross-sectional area of the axially elongated material prior to upsetting, in2 (mm2); Di is the initial height of the cutoff forged material prior to upsetting, inch (mm); Df is the final height of the disk prior to raising, inch (mm); Hf is the final height of the finished closed die forging in the raised area where the teeth will be, inch (mm); Hi is the initial disk height prior to the raising, inch (mm); and R4 and R5 = 1. ©AGMA 2022 – All rights reserved 21 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Figure 19 – Example of closed die forging For forged or rolled rings such as in Figure 20: RR = R1 R 2 R4 : 1 (10) A R1 = i Af (11) D R 2 = i Df (12) WA i R 4 = WAf (13) where Ai is the initial cross-sectional area of the as-cast material, in2 (mm2); Af is the final cross-sectional area of the axially elongated material prior to upsetting, in2 (mm2); Di is the initial height of the cutoff forged material prior to upsetting, inch (mm); Df is the final height of the upset blank after upsetting before any piercing, inch (mm); WAi is the initial wall cross-sectional area of the upset disk after piercing, disregarding any expansions associated with piercing, in2 (mm2); WAf is the final wall cross-sectional area of the finish forging or rolled ring in the area where the teeth will be, in2 (mm2); and R3 and R5 = 1. ©AGMA 2022 – All rights reserved 22 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Figure 20 – Example of seamless rolled ring forging For gearing blanks where the pitch line of the teeth is not parallel to the forging centerline (such as for bevel gearing) as in Figure 21: RR = R1 R 2 R3 R5 : 1 (14) A R1 = i Af (15) D R 2 = i Df (16) B R5 = i Bf (17) where Ai is the initial cross-sectional area of the as-cast material, in2 (mm2); Af is the final cross-sectional area of the axially elongated material prior to upsetting, in2 (mm2); Di is the initial height of the cutoff forged material prior to upsetting, inch (mm); Df is the final height of the finish forged upset disk, inch (mm); Bi is the initial cross-sectional area of the teeth portion of blank before additional mechanical working; Bf is the cross-sectional area of the portion of blank receiving additional mechanical working where the teeth will be; and R3, R4 = 1. ©AGMA 2022 – All rights reserved 23 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Figure 21 – Example bevel gearing blank surface carbon: Per one of the following methods: − Method 1: Spectrometric. Per ASTM E415. − Method 2: Combustion. The combustion method utilizes chips from a machining cut of 0.001–0.004 inch (0.02–0.10 mm) in thickness on a carbon control specimen. The chips from this cut are collected and analyzed by combustion for carbon content per ASTM E350. The specimen should be machined dry with high-speed steel cutting tools on centers, and at least one gram of clean chips free of contamination should be used for analysis. Both methods require that prior to carburizing the process control specimen, sufficient stock be machined from the surface to be carburized, in order to remove all material with non-uniform surface chemistry. surface temper: Per ANSI/AGMA ISO 14104. test coupons: Microstructure and microhardness can be determined from either actual parts or test coupons. Core hardness can be determined from either actual parts or representative coupons. See 4.2 for the specific type of test coupon (process control or representative). ultrasonic inspection: Ultrasonic inspection is recommended for large parts to detect flaws before incurring the expense of machining. When ultrasonic inspection is specified, the following guidelines should apply: − For wrought products the straight beam procedures described in ASTM A388 should apply. Either the flat bottom hole or back reflection method may be used. The sensitivity for the flat bottom hole method should utilize standard test blocks per ASTM E428 with the reflector size as specified in Table 1 through Table 4 of this information sheet. The metal test distance for the blocks should be 4.000 inches (101.6 mm). This sensitivity should be used when radially scanning the portion of the wrought material that will comprise the tooth area. The tooth area includes only those portions of the gearing material where the teeth will be located to a depth below the finished tooth tips of at least 1.5 times the tooth height. The balance of the part may be scanned using a distance amplitude correction curve (DAC) whose construction is detailed in ASTM A388. − For cast products, the straight beam procedures described in ASTM A609 should apply. The back reflection method should be used. ©AGMA 2022 – All rights reserved 24 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 4.2 Test coupons 4.2.1 Process control test coupons Process control test coupons are used to monitor various heat treatment process parameters, their variation, their interactions, and to verify that these parameters are maintained within their expected control range. The process control test coupons may be made of various steel grades, different sizes, and differing geometry depending on the parameter to be monitored and the heat treat facility’s quality control plan. Process control test coupons are not intended to be used for final acceptance. The properties of a process control coupon may be correlated by experience to the properties of the finished gearing with regard to hardness and case depth. The process control test coupon microstructure may be correlated to the condition of the finished gear. The method of correlation should be documented. Process control test coupons may be used to determine surface carbon concentration, carbon penetration, carbon gradients, nitride depth, white layer thickness, intergranular oxidation depth, and process repeatability. Shim stock is often used to monitor atmospheric carbon potential. Variations from expected process control limits are used as indicators of unacceptable heat treat process variations. As long as the process control test coupons are within expected control limits, the parts being heat treated should have the expected metallurgical properties. The process control test coupon for carburize and hardening should have minimum dimensions of 5/8 inch (16 mm) diameter by 2 inches (50 mm) long and is suitable for gearing 4.5 normal diametral pitch (module 5.6) and finer. A 1-inch (25 mm) diameter by 2 inches (50 mm) long coupon may be used for coarser pitch (module) carburized gearing to 1.5 normal diametral pitch (module 17). The size of the coupon for coarser than 1.5 normal diametral pitch (module 17) gearing should be agreed upon and should approximate the inscribed diameter at mid height of the tooth cross section. The coupon length should be a minimum of 2 times the diameter. Test disks or plates may be used whose minimum thickness is 70% of the appropriate test bar diameter. The minimum inscribed diameter on a test disc (or plate dimensions) should be three times its thickness. For determination of case hardness, case depth, and case microstructure, the process control test coupon should be examined on a section normal to its axis and at least one diameter from the end of the test coupon. Case hardness is to be measured by a microhardness method at a depth 0.002 to 0.004 inch (0.05 to 0.10 mm) below the surface. Any post-heat treat stock removal should be considered. 4.2.2 Representative test coupon The representative test coupon should be from the same grade of alloy steel with similar hardenability as the production part but need not necessarily be from the same heat of steel. Representative test coupon proportions of a minimum diameter of 6 divided by the normal diametral pitch (6 times module) but not less than 5/8-inch diameter (16 mm), and a minimum length 2 times its diameter, as used in ISO 6336-5, are recommended. A representative test coupon may contain a tooth form that will be used to verify the heat treat process. With customer approval, representative test coupon proportions of a minimum diameter of 3 divided by the normal diametral pitch (3 times module) but not less than 5/8-inch diameter (16 mm), and a minimum length 2 times its diameter, as used in ISO 6336-5, may be used. A representative test coupon should have the same heat treat condition prior to carburizing as the part(s) represented. This coupon should remain with the part(s) represented throughout the entire heat treat process, with the possible exception of heat treatments prior to carburizing. The representative test coupon, when positioned in a heat treat load in the same general area but separate from the piece part, is intended to represent the metallurgy of the heat-treated tooth section. The microstructure at the center of the minimum size representative test coupon approximates the core microstructure of the tooth section. ©AGMA 2022 – All rights reserved 25 AMERICAN GEAR MANUFACTURERS ASSOCIATION 5 AGMA 923-C22 Metallurgical requirements Metallurgical characteristics defined in the tables of this clause are intended to assure the quality of the finished gear teeth. Individual AGMA rating standards may have specific modifications to the metallurgical characteristics grading. Users of this document should be aware that the Grade 1, Grade 2, and Grade 3 gearing produced by different heat treatment processes have different ratings. In addition, the definition of Grade 1, 2, and 3 differs between AGMA standards. Refer to the applicable gear rating standards for specific gear ratings. Individual customers and manufacturers may have specific modifications to the metallurgical grade requirements or special material and processing conditions that are not covered in these tables. These modifications and special conditions are permissible with mutual agreement. The following tables suggest limits on metallurgical characteristics to differentiate materials between different grades. As individual gearing designs increase in size and complexity of features, they become more difficult to manufacture, heat treat, and inspect. This document, as a general rule, does not differentiate based on gearing size. However, where necessary, specific notation is made to reflect the special processing methods, techniques and inspections required for large gear manufacturing. All requirements for a metallurgical quality grade should be met in order to use the stress value, from the AGMA rating standard, for that grade. This can be accomplished by specifically certifying each requirement where necessary, or by establishing practices and procedures to obtain the requirements on a production basis, see Clause 3 for the definition of “capable of” as used in following tables. It is not the intent of this document that all requirements for metallurgical quality grade be certified, but that practices and procedures be established for their compliance on a production basis. Intermediate values are not classified since the effect of deviations from the quality standards cannot be evaluated easily. Specific sampling plans and test methods should be addressed by either the manufacturer, the customer, or both. The various characteristics are listed in the order in which that characteristic is typically evaluated during the manufacturing sequence. Each individual characteristic has the same item number in Table 1 through Table 7 whenever it is used, regardless of which table it appears. Some characteristics are only applicable to specific heat treat methods. Therefore, some item numbers are not used in some tables. Characteristics that are typically evaluated at the same time are grouped by having the same number before the decimal point and modified with different numbers after the decimal point for the individual characteristics evaluated at that time. 5.1 Through hardened gearing The major metallurgical characteristics that affect through hardened gearing performance are shown in Table 1. Suggested minimum characteristics are noted that would normally apply to differentiate materials between different grades. Consult the specific product or application standard for actual requirements. It is expected that all criteria in a specific grade should be met for the material to be considered meeting the grade requirements. ©AGMA 2022 – All rights reserved 26 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Table 1 – Metallurgical characteristics for through hardened gearing TH Item # 1 1.1 Characteristic 1) 2) Material chemistry Wrought product Grade 1 Grade 2 A material grade chemistry that is adequate to achieve the desired hardenability should be specified with the following additional requirements. Not specified Alloy steel Alloy steel 0.25–0.60% Carbon 0.30–0.60% Carbon 0.025% Sulfur max 0.015% Sulfur max Maximums: 25 ppm Calcium 25 ppm Oxygen 2.0 ppm Hydrogen 100 ppm Nitrogen 1.2 Cast product 2 Grain size 3 Hardenability 3) 4 Non-metallic inclusions (cleanliness, steelmaking) 4) Wrought product 4.1 Grade 3 Not specified 5 or finer Verification not required Not specified Not specified Maximums: 10 ppm Calcium 25 ppm Oxygen 2.0 ppm Hydrogen 100 ppm Nitrogen Alloy steel Not applicable 0.30–0.60% Carbon 0.025% Sulfur Max 5 or finer. Test report per ASTM E112 or certified by ASTM A29. A minimum hardenability which is appropriate for part size and quench severity should be specified. Alternative A: Alternative A: − Capable of meeting bearing quality − Certified ASTM A866 per ASTM A866 Alternative B, all of the following: Alternative B, all of the following: − The steel should be certified: − The steel should be certified: o electric furnace practice o electric furnace practice o ladle refined o ladle refined o deoxidized o deoxidized o vacuum degassed o vacuum degassed o bottom poured ingot o bottom poured ingot or strand o protected from re-oxidation cast during teeming or casting o protected from re-oxidation o certified cleanliness by during either ASTM E45 or ISO o teeming or casting 4967 Method A. Acceptable o Capable of cleanliness if does not exceed: confirmation by either Type Fine Thick ASTM E45 or ISO 4967 Method A (sulfide) 2.5 1.5 A. Acceptable if does not B (alumina) 2.0 1.0 exceed: C (silicate) 0.5 0.5 Type Fine Thick D (globular oxide) 1.0 1.0 2.0 A (sulfide) 3.0 3.0 DS 6) B (alumina) 2.5 1.5 Alternative C: C (silicate) 2.5 1.5 − Certified SAE/AMS 2300 D (globular oxide) 2.0 1.5 or/AMS 2304 Alternative C: − Capable of meeting SAE/AMS 2301 4.2 Cast product 5 5.1 Material form Wrought product Not specified ©AGMA 2022 – All rights reserved Alternative D 5) − Magnetic particle inspection of finished gearing to the requirements of Item 22, Grade 3 Only permissible if primarily round (Type 1) 7) sulfide inclusions Not applicable Forgings per ASTM A788 or equivalent Bar stock per ASTM A29 or equivalent or ISO 683-1 Tubing per ASTM A519 or equivalent 27 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Table 1 – Metallurgical characteristics for through hardened gearing (continued) TH Item # 5.2 5.3 6 7 8 9 9.1 9.2 12 Characteristic 1) 2) Grade 1 Grade 2 Grade 3 − At least 7 to 1 for strand or continuous cast 8) − At least 3 to 1 for ingot cast 8) Castings per ASTM A781 Not applicable Not specified Quench and temper 900°F (482°C) minimum temper. Mechanical properties Hardness testing is required. Other mechanical testing is required only if specified. See after heat treatment 9) applicable rating standard for location of required hardness value. Microstructure 4) Sound metallurgical practice dictates that the microstructure should be commensurate with steel grade, section size and sampling location. Unless otherwise specified, non-martensitic transformation products within the microstructure are not a reason for rejection if the hardness complies with the specified values. Ultrasonic inspection and In addition to ultrasonic inspection and when specified by the customer, magnetic particle magnetic particle inspection may be used to detect laps, cracks, and seams. The limits for the inspection inspection 4) 8) 10) should be agreed upon with the purchaser. Ultrasonic inspection 8) Inspection recommended to the Inspection required to the Wrought material. following limits: following limits: − Flat bottom hole (FBH) Not specified − No indications giving a signal − No indications giving a signal technique response greater than an 8/64-inch response greater than a 5/64o The test includes a (3.18 mm) reference standard. inch (1.98 mm) reference − No indications giving a signal radial scan from the standard. − No indications giving a signal response greater than 50% of the outside diameter response greater than 50% of reference standard if accompanied using a 4.00-inch test the reference standard if by a 50% loss of back reflection. metal distance, which accompanied by a 50% loss of − No indications which are is described in back reflection. continuous over an area twice the Clause 4. o Areas beyond the − No indications which are diameter of the search unit. tooth area are subject continuous over an area twice to agreement between the diameter of the search unit. the purchaser and manufacturer. Wrought product Material reduction ratio Cast product Heat treatment 3) Not specified − Back reflection technique o The test includes a radial scan from the outside diameter using a 4.00-inch test metal distance, which is described in Clause 4. o It is recommended that the FBH method be used to evaluate indications found that do not meet the criteria of the table. Castings − Back reflection technique Not specified Surface hardness in tooth area (or on a representative surface) 9) − No indications giving a signal − No indications giving a signal response greater than 10% of back response greater than 5% of reflection. back reflection. − No multiple indications that lower − No multiple indications that the amplitude of the first back lower the amplitude of the first reflection by more than 40%. back reflection by more than − No traveling indications whose 20%. amplitude is greater than 5% of − No traveling indications whose back reflection and length is amplitude is greater than 5% greater than 0.75 inch (19 mm). of back reflection and length is greater than 0.50 inch (13 mm). Not specified − ASTM A609 Level 1 from outside Not applicable surface to the lesser of 1.5 times tooth height below finished tooth tips or 1 inch below the tooth root. − ASTM A609 Level 2 greater than the lesser of 1.5 times tooth height below finished tooth tips or 1 inch below the tooth root. Hardness testing is recommended. See applicable rating standard for required hardness value. Hardness should be obtained at roots with 900°F (482°C) minimum temper. ©AGMA 2022 – All rights reserved 28 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Table 1 – Metallurgical characteristics for through hardened gearing (concluded) TH Item # 16 16.3 21 22 Characteristic 1) 2) Surface microstructure considering subsequent stock removal Decarburization. Any of the following methods are acceptable: − Method 1. File testing Grade 1 Grade 2 Grade 3 Should meet the following surface related characteristic: Not applicable Not applicable − Method 2. Reduction of surface hardness by two load method 9) Not specified Maximum 2 HRC points or equivalent by conversion − Method 3. Metallographic evaluation Surface cracks 10) Not specified No total or partial decarburization apparent on the finished gear tooth Magnetic particle inspection of finished gearing 8) 10) 11) 22.1 Below mid tooth height 22.2 Above mid tooth height 23 Normal diametral pitch Module ≤3 ≥8 >3 to 10 >2.5 to <8 ≥10 ≤ 2.5 Shot peening 13) Cracks, bursts, seams, and laps are not permissible in the exposed surface bounded by the outside diameter of the teeth, the root diameter of the teeth, and the face width of the teeth including all chamfers, reliefs, filets, and ends of the teeth. Cracks in other areas of the part require engineering disposition. Not specified Inspection recommended to the following limits: If Alternative D is selected in 4.1 Non-metallic inclusions, magnetic particle inspection is required using the acceptance criteria from Table 2 item 22 Grade 3. Not specified No indications Indication, maximum 12) inch mm 1/8 3.2 3/32 2.4 1/16 1.6 Shot peening per SAE/AMS-S-13165 and AGMA 938 may be used to increase surface residual compressive stress. Not specified NOTES: 1) See Clause 3 for definitions and Clause 4 for test methods. 2) The metallurgical requirements assume homogeneous composition. In practice, microsegregation and banding occurs in steels. This microsegregation can produce variations in microstructure and properties that should be assessed. 3) Specifying “H” grades of alloys will assure hardenability values are reported (either calculated or measured) The controlling section size, diametral pitch (module) and DI should be considered. The designer should specify hardenability values. 4) The grade requirements for non-metallic inclusion, ultrasonic and microstructure characteristics apply only to those portions of the gearing material where the teeth will be located to a depth below the finished tooth tip of at least 1.5 times the tooth height. 5) Care should be exercised when using Alternative D because of the risk of rejection after the expense of further manufacturing processes. 6) DS is only applicable to certification in accordance with ISO 4967. 7) Sims and Dhale Morphology of MnS per [1]. 8) In-process ultrasonic and/or magnetic particle inspection of gearing blanks is recommended for large diameter parts to detect flaws before incurring the expense of further machining. 9) See ASTM A370 or ASTM E140 for hardness conversion tables. 10) Removal of defects that exceed the stated limits is acceptable, provided the integrity of the gear is not compromised. 11) Cracks in non-functional areas require engineering disposition. 12) Limits: Maximum of one indication in any inch (25 mm) of face width with a maximum of five such indications per any 5 inches (125 mm) of face width of any one tooth flank. Indications less than 1/32 inch (0.8 mm) are not considered. 13) It is recommended that ANSI/AGMA 2004 be reviewed to determine if the benefits of surface residual compressive stress achieved by shot peening may be beneficial to the particular application. Shot peening of the flanks of gear teeth should be reviewed to ensure that no detrimental effects are caused to the gear set. 5.2 Carburized and hardened gearing The major metallurgical characteristics that affect carburized and hardened gearing performance are shown in Table 2. Carburizing in this document does not include carbonitriding. Suggested minimum characteristics are noted that would normally apply to differentiate materials between different grades. Consult the specific product or application standard for actual requirements. It is expected that all criteria in a specific grade should be met for the material to be considered meeting the grade requirements. ©AGMA 2022 – All rights reserved 29 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Table 2 – Metallurgical characteristics for carburized and hardened gearing CH Item Characteristic 1) 2) # 1 Material chemistry 1.1 1.2 Wrought product Cast product 2 3 Initial grain size Hardenability 4) 4 Non-metallic inclusions (cleanliness, steelmaking) 5) Wrought product 4.1 4.2 Cast product 5 5.1 Material form Wrought product 5.2 Wrought product Material reduction ratio Cast product 5.3 Grade 1 Grade 2 Grade 3 A material grade chemistry that is adequate to achieve the desired hardenability should be specified with the following additional requirements Specified Alloy steel Alloy steel 0.30% Carbon max 0.30% Carbon max 0.025% Sulfur max 0.015% Sulfur max 0.025% Phosphorus max 0.025% Phosphorus max Recommended Maximums: Maximums: 25 ppm Calcium 3) 10 ppm Calcium 3) 25 ppm Oxygen 25 ppm Oxygen 2.0 ppm Hydrogen 2.0 ppm Hydrogen 100 ppm Nitrogen 100 ppm Nitrogen Specified Alloy steel 0.30% Carbon max Not permitted 0.025% Sulfur max 0.025% Phosphorus max 5 or finer. Test report per ASTM E112 or certified by ASTM A29. Not specified A minimum hardenability which is appropriate for part size and quench severity should be specified. Not specified Not specified Alternative A: − Capable of meeting bearing quality per ASTM A534 or ASTM A1089 Alternative A: − Certified ASTM A534 or ASTM A1089 Alternative B: The steel should be certified: − electric furnace practice − ladle refined − deoxidized − vacuum degassed − bottom poured ingot or strand casted − protected from re-oxidation during teeming or casting − capable of cleanliness confirmation by either ASTM E45 or ISO 4967 Method B Plate II Acceptable if does not exceed: Type Fine Thick A (sulfide) 3.0 3.0 B (alumina) 2.5 1.5 C (silicate) 2.5 1.5 D (globular oxide) 2.0 1.5 Alternative B: The steel should be certified: − electric furnace practice − ladle refined − deoxidized − vacuum degassed − bottom poured ingot − protected from re-oxidation during teeming or casting − certified cleanliness by either ASTM E45 or ISO 4967 Method A. Acceptable if does not exceed: Type Fine Thick A (sulfide) 2.5 1.5 B (alumina) 2.0 1.0 C (silicate) 0.5 0.5 D (globular oxide) 1.0 1.0 DS 7) 2.0 Alternative C: Alternative C: − Capable of meeting SAE/AMS 2301 − Certified SAE/AMS 2300 or SAE/AMS 2304 Alternative D 6) : − Magnetic particle inspection of finished gearing to the requirements of Item 22, Grade 3. Only permissible if primarily round Not applicable (Type 1) sulfide inclusions 8) Forgings per ASTM A788 or equivalent Bar stock per ASTM A29 or ISO 683-11 Tubing per ASTM A519 or equivalent Not specified − At least 7 to 1 for strand or continuous cast 9) − At least 3 to 1 for ingot cast 9) Castings per ASTM A148 or ASTM A781 ©AGMA 2022 – All rights reserved Not applicable 30 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Table 2 – Metallurgical characteristics for carburized and hardened gearing (continued) CH Item Characteristic 1) 2) # 8 Microstructure 5) 9 9.1 Grade 1 Grade 2 Grade 3 Sound metallurgical practice dictates that the microstructure should be commensurate with steel grade, section size and sampling location. Unless otherwise specified, non-martensitic transformation products within the microstructure are not a reason for rejection if the hardness complies with the specified values. Ultrasonic inspection 5) 9) 10) In addition to ultrasonic inspection and when specified by the customer, magnetic particle inspection may be used to detect laps, cracks and seams. The limits for the inspection should be agreed upon with the purchaser. Ultrasonic inspection 9) Inspection recommended to the Inspection required to the Wrought product following limits: following limits: − Flat bottom hole (FBH) Not specified − No indications giving a signal − No indications giving a signal technique. response greater than an 8/64-inch response greater than a 5/64o The test includes a (3.18 mm) reference standard. inch (1.98 mm) reference − No indications giving a signal radial scan from the standard. − No indications giving a signal response greater than 50% of the outside diameter using response greater than 50% of same reference standard if a 4.00-inch test metal the reference standard if accompanied by a 50% loss of back distance, which is accompanied by a 50% loss reflection. described in Clause 4. o Areas beyond the of back reflection. − No indications which are continuous − No indications which are tooth area are subject over an area twice the diameter of continuous over an area twice to agreement between the search unit. the diameter of the search the purchaser and manufacturer. unit. − Back reflection technique o It is recommended that the FBH method be used to evaluate indications found that do not meet the criteria of the table. Not specified − No indications giving a signal response greater than 10% of back reflection. − No multiple indications that lower the amplitude of the first back reflection by more than 40%. − No traveling indications whose amplitude is greater than 5% of back reflection and length is greater than 0.75 inch (19 mm). 9.2 Cast product − Back reflection technique Not specified − ASTM A609 Level 1 from outside surface to 1.5 times tooth height below finished tooth tips − ASTM A609 Level 2 greater than 1.5 times tooth height below finished tooth tips 11 Tempering after case Recommended Required hardening Surface hardness in tooth area. Alternative method of Hardness testing is recommended and surface hardness should meet the following inspection is case hardness 11) 12) 13) characteristics: Tooth flank 55-64 HRC or 58-64 HRC or equivalent 58-64 HRC or equivalent equivalent Tooth root − Normal diametral pitch 3 53 HRC minimum 56 HRC minimum or equivalent 58 HRC minimum or equivalent (module 8) and coarser or equivalent 12 12.1 12.2 13 13.1 13.2 − Normal diametral pitch finer than 3 (module 8) Case properties considering subsequent stock removal, see Figure 16 11) 12) Effective case depth in finished condition 14) Effective case depth minimum at root radius, as determined by bending strength rating 14) 55 HRC minimum or equivalent 58 HRC minimum or equivalent − No indications giving a signal response greater than 5% of back reflection. − No multiple indications that lower the amplitude of the first back reflection by more than 20%. − No traveling indications whose amplitude is greater than 5% of back reflection and length is greater than 0.50 inch (13 mm). Not applicable 58 HRC minimum or equivalent Should meet the following characteristics when inspected per ASTM E-384 or SAE J423: Minimum and maximum effective case depth requirements for the finished gear tooth should be specified in accordance with the appropriate rating standard. Minimum effective case depth requirements at the root radius should be specified in accordance with the appropriate rating standard. ©AGMA 2022 – All rights reserved 31 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Table 2 – Metallurgical characteristics for carburized and hardened gearing (continued) CH Item Characteristic 1) 2) # 13.5 Case hardness as determined on a representative test specimen using a 500gram minimum load 13.6 Case hardness near surface within 0.004-in (0.05–0.10 mm) 14 Core hardness after case hardening 11) 12) 15) 14.1 For macropitting resistance rating, 14.2 For bending strength rating, 15 Surface carbon (typical) 17) 15.1 15.2 15.3 16 16.1 16.2 16.2.1 16.2.2 For up to 2.5% total nominal alloy content 2.5% to 3.5% total nominal alloy content Over 3.5% total nominal alloy content Surface microstructure considering subsequent stock removal 12) 18) Intergranular oxidation (IGO), see Figure 9 Minimum specified effective case depth inch (mm) <0.030 <(0.75) 0.030/0.059 (0.76/1.50) 0.060/0.089 (1.51/2.25) 0.090/0.120 (2.26/3.00) >0.120 >(3.00) Non-martensitic transformation products (NMTP), see Figure 12 19) Minimum specified effective case depth inch (mm) <0.030 <(0.75) 0.030/0.059 (0.76/1.50) 0.060/0.089 (1.51/2.25) 0.090/0.120 (2.26/3.00) >0.120 >(3.00) NMTP requirements on flank for macropitting resistance rating NMTP requirements on root for bending strength rating Grade 1 Grade 2 Grade 3 55-64 HRC or equivalent 58-64 HRC or equivalent 58-64 HRC or equivalent Should meet surface hardness No partial decarburization apparent at 400X minimum, except in unground roots No partial decarburization apparent at 400X minimum Not specified 21 HRC minimum 21 HRC minimum 21 HRC minimum 25 HRC minimum 30 HRC minimum 16) Some alloys may have desired case carbon content outside of these ranges; therefore, the range should be specified by the gear designer 0.60–1.10%C 0.60–1.10%C 0.60–1.00%C 0.60–1.10%C 0.60–1.00%C 0.60–1.00%C 0.60–1.10%C 0.65–0.95%C 0.65–0.95%C The first 0.002–0.003 inch (0.05–0.08 mm) of case microstructure in the tooth area should meet the surface hardness requirement of the specific grade and also meet the following surface related characteristics and the requirements of Item 17. Not specified Maximum allowable IGO depth inch 0.0007 0.0010 0.0014 0.0018 0.0025 (µm) (17) (25) (35) (45) (60) Maximum allowable IGO depth inch 0.0005 0.0008 0.0008 0.0010 0.0012 (µm) (12) (20) (20) (25) (30) Not specified Maximum allowable NMTP depth Not specified Not specified ©AGMA 2022 – All rights reserved inch (µm) 0.0007 (17) 0.0010 (25) 0.0014 (35) 0.0018 (45) 0.0025 (60) 5% maximum within allowable NMTP depth 10% maximum within allowable NMTP depth, except in unground roots Maximum allowable NMTP depth inch (µm) 0.0005 (12) 0.0008 (20) 0.0008 (20) 0.0010 (25) 0.0012 (30) Trace amount within allowable NMTP depth 5% maximum within allowable NMTP depth 32 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Table 2 – Metallurgical characteristics for carburized and hardened gearing (continued) CH Item Characteristic 1) 2) # 16.3 Decarburization. Any of the following methods are acceptable. − Method 1. File testing. Grade 1 − Method 3. Metallographic evaluation. 16.3.1 16.3.2 In root for bending strength rating 17 Case microstructure considering subsequent stock removal, disregarding corner effects 12) Carbide precipitation in the case 17.1 17.2 Retained austenite in the case 20) 17.3 Microstructure limits for macropitting resistance rating. Microstructure of the case to a depth of 0.010 inch (0.25 mm) or the first 20% of the minimum specified effective case depth, whichever is smaller, along the flank.21) Grade 3 Not specified, but should meet surface hardness − Method 2. Reduction of surface hardness by two load method or reduction of case hardness.11) Minimum specified effective case depth inch (mm) <0.030 <(0.75) 0.030/0.059 (0.76/1.50) 0.060/0.089 (1.51/2.25) 0.090/0.120 (2.26/3.00) >0.120 >(3.00) On flank for pitting resistance rating Grade 2 Should meet surface hardness Not specified Gear tooth surfaces should be file hard to the minimum surface hardness. Maximum 3 HRC points or equivalent Maximum 1.5 HRC points or below maximum measured hardness equivalent below maximum by conversion but measuring at least measured hardness by 58 HRC or equivalent by conversion conversion but measuring at in the finished state. least 58 HRC or equivalent by conversion in the finished state. No partial decarburization apparent No partial decarburization on active tooth profile. No ferrite (total apparent on the gear tooth decarburization) is permissible in the including the root. No ferrite case microstructure of the gear tooth. (total decarburization) is permissible in the case microstructure of the gear tooth. Maximum allowable decarb. depth in root inch (µm) 0.0007 (17) 0.0010 (25) 0.0015 (38) 0.0020 (50) 0.0025 (60) No partial decarburization apparent No partial decarburization within allowable depth apparent within allowable depth No partial decarburization apparent within allowable depth, except in unground roots No partial decarburization apparent within allowable depth The microstructure of the first 20% of the minimum specified effective case depth should be predominantly tempered martensite. Additional requirements for the case microstructure are given in Item 16 and the following case related characteristics: Continuous Semi-continuous carbide network per Discontinuous carbides per carbide network Figure 2 is not acceptable. Figure 3 are not acceptable. per Figure 1 is not Discontinuous carbides per Figure 3 Dispersed carbides per Figure acceptable. Semi- are acceptable. Maximum acceptable 4 are acceptable. Maximum continuous dimension of any carbide, in any acceptable dimension of any carbide network direction, is 0.0008 inch (0.02 mm). carbide, in any direction, is per Figure 2 is 0.0004 inch (0.01 mm). acceptable. Not specified Retained austenite 30% maximum determined metallographically by comparison with Figure 15. Rejection of piece parts should only be based on case hardness. The minimum microhardness at 0.004 inch (0.1 mm) or through the area of highest retained austenite should be 58 HRC (690 HK500).11) 18) Not specified. Primarily tempered martensite with Primarily tempered martensite Untempered 5% maximum non-martensitic with only trace non-martensitic martensite is structures, carbide precipitation per structures permissible, carbide acceptable. Item 17.1, retained austenite per Item precipitation per Item 17.1, 17.2, and other surface retained austenite per Item microstructures as defined under 17.2, and other surface Items 16.1 through 16.3. microstructures as defined under Items 16.1 through 16.3. ©AGMA 2022 – All rights reserved 33 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Table 2 – Metallurgical characteristics for carburized and hardened gearing (continued) CH Item Characteristic 1) 2) # 17.4 Additional microstructure limits for macropitting resistance rating. Microstructure of the case from a depth of 0.010 inch (0.25 mm) or the first 20% of the minimum specified effective case depth, whichever is smaller, to a depth equal to 40% of the minimum specified effective case depth along the flank.14) − Normal diametral pitch 3 (module 8) and coarser. − Normal diametral pitch finer than 3 (module 8). 17.5 Additional microstructure limits for bending strength rating. Microstructure of the case to a depth of 0.010 inch (0.25 mm) or the first 20% of the minimum specified effective case depth, whichever is smaller, at the root fillet.21) 17.6 Additional microstructure limits for bending strength rating. Microstructure of the case from a depth of 0.010 inch (0.25 mm) or the first 20% of the minimum specified effective case depth, whichever is smaller, to a depth equal to 40% of the minimum specified effective case depth at the root fillet.14) Normal diametral pitch 3 (module 8) and coarser. Normal diametral pitch finer than 3 (module 8). 17.7 Microcracks in case (cracks across more than one platelet) 18 Core microstructure 5) 11) 18.1 Final grain size 18.2 Non-martensitic transformation products Grade 1 Grade 2 Grade 3 Not specified Not specified Not specified Not specified 5% maximum non-martensitic structures Primarily tempered martensite with 10% maximum non-martensitic structures, carbide precipitation per Item 17.1, retained austenite per Item 17.2, and other surface microstructures as defined under Items 16.1 through 16.3. Only trace non-martensitic structures Primarily tempered martensite with 5% maximum nonmartensitic structures, carbide precipitation per Item 17.1, retained austenite per Item 17.2, and other surface microstructures as defined under Items 16.1 through 16.3. Not specified Not specified Not specified Not specified 10% maximum non-martensitic structures Not specified 5% maximum non-martensitic structures 10 maximums per 0.0001 in2 (0.064 mm2) field.20) 22) Untempered martensite is acceptable. Untempered martensite is acceptable. Untempered martensite is acceptable. Sound metallurgical practice dictates that the microstructure should be commensurate with steel grade, section size and sampling location. 5 or finer, 5 or finer, test report per ASTM E112 23) verification not required Not specified Sound metallurgical practice dictates that the core microstructure requirements are maintained in the tooth area to a depth of twice the minimum specified effective case depth or 0.100 inch (2.5 mm), whichever is less, below the minimum specified effective case depth. The microstructure in this zone should be predominantly tempered martensite. This microstructure zone should be free of ferrite, pearlite, and measurable bainite. Unless otherwise specified by agreement, nonmartensitic transformation products within the microstructure are not a reason for rejection if the hardness complies with its specified values. Below this zone the core microstructure should be free of ferrite and be primarily tempered martensite with some acicular ferrite and bainite permissible. ©AGMA 2022 – All rights reserved 34 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Table 2 – Metallurgical characteristics for carburized and hardened gearing (continued) CH Item Characteristic 1) 2) # 18.3 Banding in flank/tooth area at a depth of 2.0 to 2.5 times the specified effective case depth. 20 Surface temper etch inspection of ground teeth 21 Surface cracks 10) 22 Magnetic particle inspection of finished gearing 9) 10) 24) 22.1 22.2 23 Below mid tooth height Above mid tooth height Normal diametral pitch Module ≤3 ≥8 >3 to 10 >2.5 to <8 ≥10 ≤2.5 Shot peening 26) Grade 1 Grade 2 Grade 3 Not specified Microhardness readings of alternating dark and light areas should not vary by more than 5 HRC points by conversion. Not specified FB2, which allows light tempering on FB1, which allows light 25% of functional area. tempering on 10% of functional area. Cracks, bursts, seams and laps are not permissible in the exposed surface bounded by the outside diameter of the teeth, the root diameter of the teeth, and the face width of the teeth including all chamfers, reliefs, fillets, and ends of the teeth. Cracks in other areas of the part require engineering disposition. Not specified Not specified Inspection recommended to the following limits: If Alternative D is selected in 4.1 Non-metallic inclusions, magnetic particle inspection is required using the following acceptance criteria. Not specified No indications No Indications Indication, maximum 25) Indication, maximum 25) Not specified inch mm inch mm 1/8 3.2 3/32 2.4 3/32 2.4 1/16 1.6 1/16 1.6 1/32 0.8 Shot peening per SAE/AMS-S-13165 or AGMA 938 may be used to increase surface residual compressive stress. NOTES: 1) See Clause 3 for definitions and Clause 4 for test methods. 2) The metallurgical requirements assume homogeneous composition. In practice, microsegregation and banding occurs in steels. This microsegregation can produce variations in microstructure and properties that should be assessed. 3) Intentional additions of calcium or calcium alloys for deoxidation or inclusion and shape control are not permitted unless specifically approved by the purchaser. The use of lime or fluorspar, or both, in the steelmaking slag is acceptable. 4) Specifying “H” grades of alloys will assure hardenability values are reported (either calculated or measured). The controlling section size, diametral pitch (module) and DI should be considered. The designer should specify hardenability values. 5) The grade requirements for non-metallic inclusion, ultrasonic, and microstructure characteristics apply only to those portions of the gearing material where the teeth will be located to a depth below the finished tooth tip of at least 1.5 times the tooth height. 6) Care should be exercised when using Alternative D because of the risk of rejection after the expense of further manufacturing processes. 7) DS type inclusion is only applicable to certification in accordance with ISO 4967. 8) Sims and Dhale Morphology of MnS per [1]. 9) In-process ultrasonic and/or magnetic particle inspection of gearing blanks is recommended for large diameter parts to detect flaws before incurring the expense of further machining. 10) Removal of defects that exceed the stated limits is acceptable, provided the integrity of the gear is not compromised. 11) See ASTM A370 or ASTM E140 for hardness conversion tables. 12) See Clause 3 and Clause 4 for a discussion of test coupons. 13) Root hardness may be less than flank hardness, depending on the size of the gear and the quench process. 14) When specifying minimum case depth, note that the “optimum” values for macropitting resistance and bending strength capacity are not the same. A maximum case depth is prescribed in order to minimize the risk of embrittlement in the tooth area, including the tips. 15) Core hardness requirements for macropitting resistance and bending strength are considered independently. The gear rating may be limited by either macropitting resistance or bending strength for the selected metallurgical quality grade and its core hardness requirement. 16) Minimum hardness of 30 HRC for Grade 3 may be difficult to achieve on coarse pitch gearing. Due to the tooth section size of 3 normal diametral pitch (module 8) gearing and coarser, the alternate (ISO 6336-5) core hardness test location may be used provided documented testing or experience is available. 17) Optimum macropitting resistance is best achieved at surface carbon levels above the eutectoid carbon for a given alloy chemistry. 18) If excessive, salvage may be possible by processes such as shot peening per Item 23 or by grinding provided the integrity of the gearing is not compromised. 19) At maximum allowable depths, the surface may not be file hard and may not have the expected residual stress profile. ©AGMA 2022 – All rights reserved 35 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Table 2 – Metallurgical characteristics for carburized and hardened gearing (concluded) NOTES (concluded): 20) 21) 22) 23) 24) 25) 26) If cold treatment is performed, it is recommended that it be preceded by tempering at 300°F (150°C) minimum in order to minimize formation of microcracks. Retempering is required after cold treatment. Cold treatment should not be used to transform large amounts of retained austenite (e.g., 50%) to gain excessive improvements in hardness, even with prior tempering. Bainite, observable at 200X, that extends from the core microstructure into the case area is considered a ratable characteristic. This bainite is the result of slower heat extraction rates due to part section size, mass of furnace load, marginal agitation, elevated quenchant temperatures, and generally follows alloy segregation and material flow lines. The bainite that results in a fine pepper structure at 400–600X, but is still not resolvable at 800X, is considered non-ratable (trace). Maximum limit of microcracks (Item 17.5) for Grade 3 gearing may be difficult to achieve if cold treatment is used to transform the retained austenite level to 30% maximum. Report the as-carburized/hardened grain size, the specimen should not be re-austenitized as part of sample preparation for grain size determination that could change the as-carburized/hardened grain size. Cracks in nonfunctional areas require engineering disposition. Limits: Maximum of one indication in any inch (25 mm) of face width with a maximum of five such indications per any 5 inches (125 mm) of face width of any one tooth flank. Indications less than 1/32 inch (0.8 mm) are not considered. It is recommended that ANSI/AGMA 2004 be reviewed to determine if the benefits of surface residual compressive stress achieved by shot peening may be beneficial to the particular application. Shot peening of the flanks of gear teeth should be reviewed to ensure that no detrimental effects are caused to the gear set. 5.3 Induction or flame hardened gearing The major metallurgical characteristics that affect induction or flame hardened gearing performance are shown in Table 3. Suggested minimum characteristics are noted that would normally apply to differentiate materials between different grades. Consult the specific product or application standard for actual requirements. It is expected that all criteria in a specific grade should be met for the material to be considered meeting the grade requirements. Table 3 – Metallurgical characteristics for induction or flame hardened gearing Item 1 1.1 1.2 Characteristic Material chemistry 1) 2) Wrought product Cast product 2 Grain size 3 Hardenability 3) 4 Non-metallic inclusions (cleanliness, steelmaking) 4) Grade 3 Spin induction Type A Grade 1 Grade 2 (Contour) only A material grade chemistry that is adequate to achieve the desired hardenability should be specified with the following additional requirements Not specified Alloy steel Alloy steel 0.25 – 0.60% Carbon 0.30 – 0.60% Carbon 0.025% Sulfur max 0.015% Sulfur max Not specified 5 or finer. Verification not required. Not specified ©AGMA 2022 – All rights reserved Maximums: Maximums: 25 ppm Calcium 10 ppm Calcium 25 ppm Oxygen 25 ppm Oxygen 2.0 ppm Hydrogen 2.0 ppm Hydrogen 100 ppm Nitrogen 100 ppm Nitrogen Alloy steel 0.30 – 0.60% Carbon Not applicable 0.025% Sulfur max 5 or finer. Test report per ASTM E112 or certified by ASTM A29. A minimum hardenability which is appropriate for part size and quench severity should be specified. 36 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Table 3 – Metallurgical characteristics for induction or flame hardened gearing (continued) Item 4.1 Characteristic Wrought product 1) 2) 4.2 Cast product 5.1 Material form 5.2 8 Wrought product Material reduction ratio Cast product Heat treatment prior to surface hardening Mechanical properties prior to surface hardening.9) See also Item 14. Hardness – flank Hardness – root Other mechanical properties Microstructure 4) 9 Ultrasonic inspection 4) 8) 10) 5.3 6 7 7.1 7.2 7.3 Grade 1 Not specified Grade 2 Alternative A: − Capable of meeting bearing quality per ASTM A534 Grade 3 Spin induction Type A (Contour) only Alternative A: − Certified ASTM A534 Alternative B, all of the following: The steel should be certified: − electric furnace practice − ladle refined − deoxidized − vacuum degassed − bottom poured ingot or strand casted − protected from re-oxidation during teeming or casting − capable of cleanliness confirmation by either ASTM E45 or ISO 4967 Method B Plate II. Acceptable if does not exceed: Type Fine Thick A (sulfide) 3.0 3.0 B (alumina) 2.5 1.5 C (silicate) 2.5 1.5 D (globular oxide) 2.0 1.5 Alternative B, all of the following: The steel should be certified: − electric furnace practice − ladle refined − deoxidized − vacuum degassed − bottom poured ingot − protected from re-oxidation during teeming or casting − certified cleanliness by either ASTM E45 or ISO 4967 Method A. Acceptable if does not exceed: Alternative C: Capable of meeting SAE/AMS 2301 Alternative C: Certified SAE/AMS 2300 or/AMS 2304. Type A (sulfide) B (alumina) C (silicate) D (globular oxide) DS 6) Fine 2.5 2.0 0.5 1.0 2.0 Thick 1.5 1.0 0.5 1.0 Alternative D 5) Magnetic particle inspection of finished gearing to the requirements of Item 22, Grade 3. Not specified Only permissible if primarily Not applicable round (Type 1) 7) sulfide inclusions. Forgings per either ASTM A788 or equivalent. Bar stock per ASTM A29 or equivalent or ISO 683-1. Tubing per ASTM A519 or equivalent. Not specified − At least 7 to 1 for strand or continuous cast.8) − At least 3 to 1 for ingot cast.8) Castings per ASTM A781 Not Applicable Not specified Quench and temper 900°F (480°C) minimum temper. Not specified Not specified 28 HRC minimum 30 HRC minimum 28 HRC minimum 30 HRC minimum Other mechanical testing is required only if specified Sound metallurgical practice dictates that the microstructure should be commensurate with steel grade, section size and sampling location. Unless otherwise specified, non-martensitic transformation products within the microstructure are not a reason for rejection if the hardness complies with the specified values. In addition to ultrasonic inspection and when specified by the customer, magnetic particle inspection may be used to detect laps, cracks, and seams. The limits for the inspection should be agreed upon with the purchaser. ©AGMA 2022 – All rights reserved 37 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Table 3 – Metallurgical characteristics for induction or flame hardened gearing (continued) Item 9.1 9.2 10 11 12 13 13.1 13.2 1) 2) Characteristic Ultrasonic inspection 8) Wrought material. − Flat bottom hole (FBH) technique o The test includes a radial scan from the outside diameter using a 4.00 inch test metal distance, which is described in Clause 4. o Areas beyond the tooth area are subject to agreement between the purchaser and manufacturer. − Back reflection technique o The test includes a radial scan from the outside diameter using a 4.00 inch test metal distance, which is described in Clause 4. o It is recommended that the FBH method be used to evaluate indications found that do not meet the criteria of the table. Cast product − Back reflection technique Overheating, especially at the tooth tips and end faces 11) 12) Tempering after surface hardening Surface hardness on a representative surface. Alternative method of inspection is hardened zone hardness 9) 11) Hardened depth considering subsequent stock removal. Also see Item 19.9) 11) 12) Hardened depth in finished condition Hardened depth minimum at root radius, or on representative sample with same geometry and material as work piece, as determined by bending strength rating. Grade 1 Not specified Grade 2 Inspection recommended to the following limits: − No indications giving a signal response greater than an 8/64 inch (3.18 mm) reference standard. − No indications giving a signal response greater than 50% of the same reference standard if accompanied by a 50% loss of back reflection. − No indications which are continuous over an area twice the diameter of the search unit. Grade 3 Spin induction Type A (Contour) only Inspection required to the following limits: − No indications giving a signal response greater than a 5/64 inch (1.98 mm) reference standard. − No indications giving a signal response greater than 50% of the reference standard if accompanied by a 50% loss of back reflection − No indications which are continuous over an area twice the diameter of the search unit. − No indications giving a signal − No indications giving a signal response greater than 10% of response greater than 5% of back back reflection. reflection. − No multiple indications that − No multiple indications that lower lower the amplitude of the first the amplitude of the first back back reflection by more than reflection by more than 20%. 40%. − No traveling indications whose − No traveling indications whose amplitude is greater than 5% of amplitude is greater than 5% of back reflection and length is back reflection and length is greater than 0.50 inch (13 mm). greater than 0.75 inch (19 mm). Not specified − ASTM A609 Level 1 from Not applicable outside surface to 1.5 times tooth height below finished tooth tips. − ASTM A609 Level 2 greater than 1.5 times tooth height below finished tooth tips. Avoid surface temperatures that result in grain growth, incipient melting or unfavorable residual stresses. Larger chamfers minimize this problem. 1 hour minimum at temperature; furnace temper is required 13) 50 HRC minimum or 54 HRC minimum as required by rating standard Should meet the following characteristics: Minimum and maximum hardened depth should be specified in accordance with the rating standard. A hardening pattern per Figure 22 should be specified. Not specified ©AGMA 2022 – All rights reserved 50% of minimum specified hardened depth at 1/4 tooth height above the root recommended. 58–64 HRC or equivalent Minimum and maximum hardened depth should be specified in accordance with the rating standard. Figure 22 Type A contour pattern only should be specified. 100% of minimum specified hardened depth at 1/4 tooth height above the root recommended, and 66% of minimum specified hardened depth at the root. 38 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Table 3 – Metallurgical characteristics for induction or flame hardened gearing (continued) Item 14 14.1 14.2 16 16.2 16.3 17 17.3 Grade 1 Grade 2 Grade 3 Spin induction Type A (Contour) only Not specified 28 HRC minimum 30 HRC minimum Not specified 28 HRC minimum 30 HRC minimum 1) 2) Characteristic Base hardness after surface hardening. Also see Item 7.9) 11) 14) Base/core hardness for macropitting resistance rating. Base/core hardness for bending strength rating Surface microstructure considering subsequent stock removal 11) 15) Flank for macropitting resistance rating. Non-martensitic transformation products, see Figure 12.16) Minimum specified hardened depth inch (mm) <0.030 <(0.75) 0.030/0.059 (0.76/1.50) 0.060/0.089 (1.51/2.25) 0.090/0.120 (2.26/3.00) 0.120 >(3.00) Root for bending resistance rating 9) Case microstructure considering subsequent stock removal, disregarding corner effects 11) Microstructure of case along flank (for macropitting resistance rating). 17.6 Microstructure at root (for bending strength rating). 18 18.1 Core microstructure 11) Final grain size 18.2 Non-martensitic transformation products (NMTP) 18.3 Banding in flank/tooth area at a depth of 2.0 to 2.5 times the specified hardened depth. The first 0.002–0.003 inch (0.05–0.08 mm) of hardened zone microstructure in the tooth area should meet the surface hardness requirement of the specific grade and also meet the following surface related characteristics and the requirements of Item 17. Should meet Should meet specified hardness Should meet specified hardness specified hardness Maximum allowable depth Maximum allowable depth inch (µm) inch (µm) 0.0007 (17) 0.0005 (12) 0.0010 (25) 0.0008 (20) 0.0015 (38) 0.0008 (20) 0.0020 (50) 0.0010 (25) 0.0025 (60) 0.0012 (30) Should meet No partial decarburization No partial decarburization apparent specified apparent at 400X, except in at 400X hardness unground roots The first 20% of the case microstructure should be predominantly tempered martensite. The microstructure should be free of undissolved pearlite observable at 100X and measurable bainite observable at 400–600X. The following case microstructure characteristics for each grade should be met: Primarily fine acicular martensite Primarily fine acicular tempered martensite. Non-martensitic structures anywhere in the case should not exceed 5%. Primarily fine acicular tempered martensite with no non-martensitic structures. Primarily fine acicular martensite Primarily fine acicular tempered martensite. Non-martensitic structures anywhere in the case should not exceed 10%. Primarily fine acicular tempered martensite. Non-martensitic structures anywhere in the case should not exceed 5%. 5 or finer, verification not required Not specified ©AGMA 2022 – All rights reserved 5 or finer, test report per ASTM E112 17) Sound metallurgical practice dictates that the core microstructure requirements are maintained in the tooth area to a depth of twice the minimum specified effective case depth or 0.100 inch (2.5 mm), whichever is less, below the minimum specified effective case depth. The microstructure in this zone should be predominantly tempered martensite. This microstructure zone should be free of ferrite, pearlite, and measurable bainite. Unless otherwise specified by agreement, nonmartensitic transformation products within the microstructure are not a reason for rejection if the hardness complies with its specified values. Below this zone the core microstructure should be free of ferrite and be primarily tempered martensite with some acicular ferrite and bainite permissible. Not specified Microhardness readings of alternating dark and light areas should not vary by more than 5 HRC points by conversion. 39 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Table 3 – Metallurgical characteristics for induction or flame hardened gearing (concluded) Item 19 1) 2) Characteristic Heat affected zone. Also see Item 13.11) 12) 20 Surface temper etch inspection of ground teeth 21 Surface cracks 10) 22 Magnetic particle inspection of finished gearing 8) 10) 18) 22.1 22.2 23 Below mid tooth height Above mid tooth height Normal diametral Module pitch ≤3 ≥8 >3 to 10 >2.5 to <8 ≥10 ≤ 2.5 Shot peening 20) Grade 3 Spin induction Type A Grade 1 Grade 2 (Contour) only Induction and flame hardening heat treatments have a characteristic heat affected zone that is caused by the surface heating process. This zone can have lower hardness and different microstructure than the base material. The case depth specification should be established to avoid gear failure which might initiate in this zone. Not specified FB2, which allows light FB1, which allows light tempering on tempering on 25% of functional 10% of functional area. area. Cracks, bursts, seams and laps are not permissible in the exposed surface bounded by the outside diameter of the teeth, the root diameter of the teeth, and the face width of the teeth including all chamfers, reliefs, fillets, and ends of the teeth. Cracks in other areas of the part require engineering disposition. Not specified Inspection recommended to the following limits: If Alternative D is selected in 4.1 Non-metallic inclusions, magnetic particle inspection is required using the acceptance criteria from Table 2 item 22 Grade 3. Not specified No indications Indication, maximum 19) Indication, maximum 19) inch mm inch mm 1/8 3.2 3/32 2.4 3/32 2.4 1/16 1.6 1/16 1.6 1/32 0.8 Shot peening per SAE/AMS-S-13165 or AGMA 938-A05 may be used to increase surface residual compressive stress. Not specified NOTES: 1) See Clause 3 for definitions and Clause 4 for test methods. 2) The metallurgical requirements assume homogeneous composition. In practice, microsegregation and banding occurs in steels. This microsegregation can produce variations in microstructure and properties that should be assessed. 3) Specifying “H” grades of alloys will assure hardenability values are reported (either calculated or measured) The controlling section size, diametral pitch (module) and DI should be considered. The designer should specify hardenability values. 4) The grade requirements for non-metallic inclusion, ultrasonic, and microstructure characteristics apply only to those portions of the gear material where the teeth will be located to a depth below the finished tooth tip of at least 1.5 times the tooth height. 5) Care should be exercised when using Alternative D because of the risk of rejection after the expense of further manufacturing processes. 6) DS is only applicable to certification in accordance with ISO 4967. 7) Sims and Dhale Morphology of MnS per [1]. 8) In-process ultrasonic and/or magnetic particle inspection of gearing blanks is recommended for large diameter parts to detect flaws before incurring the expense of further machining. 9) See ASTM E140 or ASTM E140 for hardness conversion tables. 10) Removal of defects that exceed the stated limits is acceptable, provided the integrity of the gear is not compromised. 11) See Clause 3 and Clause 4 for a discussion on test coupons. 12) The hardness pattern, depth, facilities and process method should be established, documented and verified to be repeatable. The process equipment and methods should be sufficiently accurate to reproduce the specified results. Excessive case depth can generate unfavorable residual stress conditions. 13) Induction tempering is recommended for Grade 3 as a crack preventing stress relief heat treatment prior to furnace tempering. 14) Mechanical properties, including core hardness, may not be the same after induction or flame hardening as they were before induction or flame hardening. 15) Microstructure analysis of induction hardened test specimens have shown indications of undissolved pearlite or “ghost pearlite.” This is especially true with rapid (short) heating cycles. This “ghost pearlite” should not be present. 16) At maximum allowable depths, the surface may not be file hard and may not have the expected residual stress profile. 17) Report the as-carburized/hardened grain size, the specimen should not be re-austenitized as part of sample preparation for grain size determination that could change the as-carburized/hardened grain size. 18) Cracks in non-functional areas require engineering disposition. 19) Limits: Maximum of one indication in any inch (25 mm) of face width with a maximum of five such indications per any 5 inches (125mm) of face width of any one tooth flank. Indications less than 1/32 inch (0.8 mm) are not considered. 20) It is recommended that ANSI/AGMA 2004 and AGMA 938 be reviewed to determine if the benefits of surface residual compressive stress achieved by shot peening may be beneficial to the particular application. Shot peening of the flanks of gear teeth should be reviewed to ensure that no detrimental effects are caused to the gear set. ©AGMA 2022 – All rights reserved 40 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 NOTES: − − − − Type A indicates that flanks and roots are hardened for contour or non-contour patterns. Only spin hardening Type A (Contour) is applicable to Grade 3. Type B indicates that the flanks are hardened only to the form diameter. For Type B, the full active profile should be hardened with the transition zone not in the root fillet area. Figure 22 – Variations in hardening pattern obtainable on gear teeth with flame or induction hardening 5.4 Nitrided gearing The major metallurgical characteristics that affect nitrided gearing performance are shown in Table 4. Suggested minimum characteristics are noted that would normally apply to differentiate materials between different grades. Consult the specific product or application standard for actual requirements. It is expected that all criteria in a specific grade should be met for the material to be considered meeting the grade requirements. ©AGMA 2022 – All rights reserved 41 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Table 4 – Metallurgical characteristics for nitrided gearing Item 1 1.1 1.2 Characteristic 1) 2) Material chemistry 3) Wrought product Cast product 2 Grain size 3 Hardenability 3) 4) 4 Non-metallic inclusions (cleanliness, steelmaking) 5) Wrought product 4.1 4.2 Cast product 5 5.1 Material form Wrought product 5.2 Wrought product Material reduction ratio ©AGMA 2022 – All rights reserved Grade 1 Grade 2 Grade 3 A material grade chemistry that is adequate to achieve the desired hardenability should be specified with the following additional requirements: Not specified Alloy steel Alloy steel 0.25–0.60% Carbon 0.30–0.60% Carbon 0.025% Sulfur max 0.015% Sulfur max Maximums: Maximums: 25 ppm Calcium 10 ppm Calcium 25 ppm Oxygen 25 ppm Oxygen 2.0 ppm Hydrogen 2.0 ppm Hydrogen 100 ppm Nitrogen 100 ppm Nitrogen Not specified Alloy steel Not applicable 0.30–0.60% Carbon 0.025% Sulfur Max 5 or finer 5 or finer. Test report per ASTM Verification not required E112 or certified by ASTM A29. Not specified A minimum hardenability which is appropriate for part size and quench severity should be specified. Not specified Not specified Alternative A: − Capable of meeting bearing quality per ASTM A866 Alternative A: − Certified ASTM A866 Alternative B, all of the following: − The steel should be certified: o electric furnace practice o ladle refined o deoxidized o vacuum degassed o bottom poured ingot or strand cast o protected from reoxidation during o teeming or casting o capable of cleanliness confirmation by either ASTM E45 or ISO 4967 Method A. Acceptable if does not exceed: Type Fine Thick A (sulfide) 3.0 3.0 B (alumina) 2.5 1.5 C (silicate) 2.5 1.5 D (globular oxide) 2.0 1.5 Alternative B, all of the following: − The steel should be certified: o electric furnace practice o ladle refined o deoxidized o vacuum degassed o bottom poured ingot o protected from re-oxidation during teeming or casting o certified cleanliness by either ASTM E45 or ISO 4967 Method A. Acceptable if does not exceed: Type Fine Thick A (sulfide) 2.5 1.5 B (alumina) 2.0 1.0 C (silicate) 0.5 0.5 D (globular oxide) 1.0 1.0 2.0 DS 7) Alternative C: − Capable of meeting SAE/AMS 2301 Alternative C: − Certified SAE/AMS 2300 or/AMS 2304 Alternative D 6) − Magnetic particle inspection of finished gearing to the requirements of Item 22, Grade 3 Only permissible if primarily round (Type 1) 8) sulfide inclusions Not applicable Forgings per ASTM A788 or equivalent Bar stock per ASTM A29 or equivalent or ISO 683-1 Tubing per ASTM A519 or equivalent Not specified At least 7 to 1 for strand or continuous cast 9) At least 3 to 1 for ingot cast 9) 42 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Table 4 – Metallurgical characteristics for nitrided gearing (continued) Item 6 7 7.3 8 Characteristic 1) 2) Heat treatment prior to case hardening Mechanical properties prior to surface hardening.10) See also Item 14. Other mechanical properties Microstructure 5) 9 Ultrasonic inspection and magnetic particle inspection 5) 9) 11) 9.1 Ultrasonic inspection 9) Wrought material. − Flat bottom hole (FBH) technique o The test includes a radial scan from the outside diameter using a 4.00-inch test metal distance, which is described in Clause 4. o Areas beyond the tooth area are subject to agreement between the purchaser and manufacturer. − Back reflection technique o The test includes a radial scan from the outside diameter using a 4.00-inch test metal distance, which is described in Clause 4. o It is recommended that the FBH method be used to evaluate indications found that do not meet the criteria of the table. 12 Surface hardness on a representative surface. Alternative method of inspection is case hardness.10) 12) − Specialty nitriding steels 3) − Through hardening steels Case depth considering subsequent stock removal 11) Effective case depth in finished condition Total case depth in finished condition Core hardness after case hardening. Also see Item 7.10) 12) 13) Surface microstructure considering subsequent stock removal 12) 13 13.1 13.4 14 16 ©AGMA 2022 – All rights reserved Grade 1 Grade 2 Grade 3 Quench and temper with tempering temperature at least 50°F (28°C) above the nitriding temperature. Tempering temperature at least 900°F (482°C). Other mechanical testing is required only if specified Sound metallurgical practice dictates that the microstructure should be commensurate with steel grade, section size and sampling location. Unless otherwise specified, nonmartensitic transformation products within the microstructure are not a reason for rejection if the hardness complies with the specified values. In addition to ultrasonic inspection and when specified by the customer, magnetic particle inspection may be used to detect cracks and seams. The limits for the inspection should be agreed upon with the purchaser. Not specified Inspection recommended to Inspection required to the the following limits: following limits: − No indications giving a − No indications giving a signal signal response greater response greater than a 5/64than an 8/64-inch inch (1.98 mm) reference (3.18 mm) reference standard. standard. − No indications giving a signal − No indications giving a response greater than 50% of signal response greater the reference standard if than 50% of the reference accompanied by a 50% loss of standard if accompanied back reflection. by a 50% loss of back − No indications which are reflection. continuous over an area twice − No indications which are the diameter of the search unit. continuous over an area − No indications giving a signal twice the diameter of the response greater than 5% of search unit. back reflection. − No indications giving a − No multiple indications that signal response greater lower the amplitude of the first than 10% of back back reflection by more than reflection. 20%. − No multiple indications that − No traveling indications whose lower the amplitude of the amplitude is greater than 5% of first back reflection by back reflection and length is more than 40%. greater than 0.50 inch (13 mm). − No traveling indications whose amplitude is greater than 5% of back reflection and length is greater than 0.75 inch (19 mm). − No indications which are continuous over an area twice the diameter of the search unit. Either 89–93 HR15N, 650–900 HV or 690–900 HK Either 83 min HR15N, 450 min HV or 470 min HK Should meet either of the following characteristics: Minimum effective case depth requirements for the tooth should be specified in accordance with the appropriate rating standard. Minimum total case depth requirements for the tooth should be specified in accordance with the appropriate rating standard. 28 HRC minimum 32 HRC minimum The first 0.002–0.003 inch (0.05–0.08 mm) of case microstructure in the tooth area should meet the surface hardness requirement of the specific grade and also meet the following surface related characteristics and the requirements of Item 17. 43 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Table 4 – Metallurgical characteristics for nitrided gearing (continued) Item 16.3 Characteristic 1) 2) Decarburization. − Method 1. Not applicable. − Method 2. Reduction of hardness by two load method.10) − Method 3. Metallographic evaluation. 16.4 18 18.2 Not specified Not specified Grade 3 Maximum 2 HRC points or equivalent below maximum measured hardness by conversion. No partial decarburization apparent except in unground roots. No reduction in hardness below maximum measured hardness by conversion is permissible. Maximum allowable depth Maximum allowable depth No partial decarburization apparent. Epsilon (ε) nitride (white layer) 14) along flank or in root Minimum specified effective case depth inch 17 Grade 1 Grade 2 No decarburization permitted on surface to be nitrided. (mm) less less at least than at least than -0.015 -(0.38) 0.015 -(0.38) -Case microstructure considering subsequent stock removal, disregarding corner effects Core microstructure 12) Non-martensitic transformation products 20 Surface temper inspection 21 Surface cracks 11) ©AGMA 2022 – All rights reserved Maximum allowable depth inch (mm) inch (mm) inch (mm) 0.0010 (0.025) 0.0008 (0.02) 0.0005 (0.013) 0.0010 (0.025) 0.0008 (0.02) 0.0008 (0.02) The microstructure of the first 20% of the minimum specified effective case depth should be predominantly tempered martensite with interspersed Εpsilon (ε) nitride. Additional requirements for the case microstructure are given in Item 16 and the following case related characteristics. The microstructure should be free of ferrite, pearlite, and measurable bainite. Not specified Sound metallurgical practice dictates that the core microstructure requirements are maintained in the tooth area to a depth of twice the minimum specified effective case depth or 0.100 inch (2.5 mm), whichever is less, below the minimum specified effective case depth. The microstructure in this zone should be predominantly tempered martensite. This microstructure zone should be free of ferrite, pearlite, and measurable bainite. Unless otherwise specified by agreement, non-martensitic transformation products within the microstructure are not a reason for rejection if the hardness complies with its specified values. Below this zone the core microstructure should be free of ferrite and be primarily tempered martensite with some acicular ferrite and bainite permissible. The normal inspection methods, as defined in ANSI/AGMA ISO 14104, are not applicable to nitrided gearing. Care should be taken when grinding nitrided surfaces to ensure that no harmful surface conditions are produced in the grinding process. Cracks, bursts, seams and laps are not permissible in the exposed surface bounded by the outside diameter of the teeth, the root diameter of the teeth, and the face width of the teeth including all chamfers, reliefs, fillets, and ends of the teeth. Cracks in other areas of the part require engineering disposition. 44 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Table 4 – Metallurgical characteristics for nitrided gearing (concluded) Item 22 Characteristic 1) 2) Magnetic particle inspection of finished gearing 9) 11) 15) Grade 1 Not specified 22.1 22.2 Below mid tooth height Above mid tooth height Normal diametral pitch Module Not specified Grade 2 Grade 3 Inspection recommended to the following limits: If Alternative D is selected in 4.1 Non-metallic inclusions, magnetic particle inspection is required using the acceptance criteria from Table 2 item 22 Grade 3. No Indications Indication, maximum 16) inch mm 1/8 3.2 3/32 2.4 1/16 1.6 Not specified ≤3 ≥8 >3 to 10 >2.5 to <8 ≥10 ≤ 2.5 23 Shot peening Shot peening is not recommended 14) NOTES: 1) See Clause 3 for definitions and Clause 4 for test methods. 2) The metallurgical requirements assume homogeneous composition. In practice, microsegregation and banding occurs in steels. This microsegregation can produce variations in microstructure and properties that should be assessed. 3) Chemistry should include adequate alloying elements such as chromium, molybdenum, or vanadium. Nitriding steels such as Nitralloy 135M and Nitralloy N are typically alloyed with 1% aluminum to provide higher surface hardness after nitriding than normally attained with nitrided through hardening steel. 4) The controlling section size, diametral pitch (module) and DI should be considered. The designer should specify hardenability values. Specifying “H” grades of alloys will assure hardenability values are reported (either calculated or measured). 5) The grade requirements for nonmetallic inclusion, ultrasonic and microstructure characteristics apply only to those portions of the gearing material where the teeth will be located to a depth below the finished tooth tip of at least 1.5 times the tooth height 6) Care should be exercised when using Alternative D because of the risk of rejection after the expense of further manufacturing processes. 7) DS is only applicable to certification in accordance with ISO 4967. 8) Sims and Dhale Morphology of MnS per [1]. 9) In-process ultrasonic or magnetic particle, or both, inspection of gearing blanks is recommended for large diameter parts to detect flaws before incurring the expense of further machining. 10) See ASTM A370 or ASTM E140 for hardness conversion tables. 11) Removal of defects that exceed the stated limits is acceptable, provided the integrity of the gear is not compromised. 12) For a discussion of test coupons see Clause 3 and Clause 4. 13) Mechanical properties including core hardness may not be the same. 14) Low intensity glass bead blasting or isotropic superfinishing to remove epsilon (ε) nitride (white layer) is acceptable. 15) Cracks in non-functional areas require engineering disposition. 16) Limits: Maximum of one indication in any inch (25 mm) of face width with a maximum of five such indications per any 5 inches (125 mm) of face width of any one tooth flank. Indications less than 1/32 inch (0.8 mm) are not considered. ©AGMA 2022 – All rights reserved 45 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 5.5 Gray iron gearing The major metallurgical characteristics that affect gray iron gearing performance are shown in Table 5. The minimum acceptable requirements for each factor for metallurgical quality Grades 1, 2, and 3 are specified. All criteria in any given grade should be met to qualify for the stress number associated with that metallurgical quality grade. Table 5 – Metallurgical characteristics for gray iron gearing Item 1 Characteristic 1), 2) Material chemistry 3 4 Material form As cast microstructure 5 Weld repair 3) 7 7.1 Mechanical properties Hardness 7.2 Other properties 10 Surface cracks 4) 11 Magnetic particle inspection of finished gearing 3) 4) 5) 11.1 11.2 Below mid tooth height Above mid tooth height Normal diametral pitch Module ≤3 >3 to 10 ≤10 ≤8 2.5 to 8 ≤2.5 Grade 1 Certification not required Grade 2 Certification not required Grade 3 If agreed upon between supplier and 100% verified per foundry ladle. Foundry test report only per ASTM E351. Casting per ASTM A48 or ISO 185; or by contractual agreement Specified but not verified. Gray iron should be free of cementite and steadite and should consist of flake graphite in a matrix of pearlite. Unless otherwise specified, the graphite structure should be primarily type 7, distribution A in accordance with ASTM A247. Weld repair of iron castings is not permitted in the near tooth region and is permissible only with customer approved processes. Hardness testing is required on semi-finished gear blanks, 1/8 inch (3.2 mm) maximum machining stock and using only Brinell or Leeb rebound hardness testers. The minimum measured hardness value should meet the specified design requirement. A maximum range of 40 Brinell numbers or equivalent, by conversion, in measured hardness values is recommended. Not verified Not verified The tensile test requirements should be met for the grade as specified by ASTM A48 or ISO 185. Physical testing of a representative coupon which is cast in the same lot and heat treated with the same parts is acceptable. Cracks, bursts, and seams are not permissible in the exposed surface bounded by the outside diameter of the teeth, the root diameter of the teeth, and the face width of the teeth including all chamfers, reliefs, fillets, and ends of the teeth. Cracks in other areas of the part require engineering disposition. Not specified Inspection recommended to the Inspection recommended to the following limits: following limits: Not specified No indications No indications Not specified Indication, maximum 6) inch mm 1/8 3.2 3/32 2.4 1/16 1.6 Indication, maximum 6) inch mm 3/32 2.4 1/16 1.6 1/32 0.8 NOTES: 1) See Clause 3 for definitions and Clause 4 for test methods. 2) The metallurgical requirements assume homogeneous composition. In practice, microsegregation can produce variations in microstructure and properties that should be assessed. 3) In-process ultrasonic and/or magnetic particle inspection of gearing blanks is recommended for large diameter parts to detect flaws before incurring the expense of further machining. 4) Removal of defects that exceed the stated limits is acceptable, provided the integrity of the gear is not compromised. 5) Cracks in non-functional areas require engineering disposition. 6) Limits: Maximum of one indication in any inch (25 mm) of face width with a maximum of five such indications per any 5 inches (125 mm) of face width of any one tooth flank. Indications less than 1/32 inch (0.8 mm) are not considered. ©AGMA 2022 – All rights reserved 46 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 5.6 Ductile iron gearing The major metallurgical characteristics that affect ductile iron gearing performance are shown in Table 6. The minimum acceptable requirements for each factor for metallurgical quality Grades 1, 2, and 3 are specified. All criteria in any given grade should be met to qualify for the stress number associated with that metallurgical quality grade. Table 6 – Metallurgical characteristics for ductile iron gearing Item 1 Characteristic 1), 2) Material chemistry 3 4 Material form As cast microstructure 5 Weld repair 3) 6 Heat treatment 7 7.1 Mechanical properties Hardness 7.2 Other properties 10 Surface cracks 4) 11 Magnetic particle inspection of finished gearing 3) 4) 5) 11.1 11.2 Below mid tooth height Above mid tooth height Normal diametral pitch Module ≤3 >3 to 10 ≥10 ≥8 2.5 to 8 ≤2.5 Grade 1 Certification not required Grade 2 Certification not required Grade 3 If agreed upon between supplier and 100% verified per foundry ladle. Foundry test report only per ASTM E351, including as a minimum; C, Si, S, P, and Mn. ASTM A536 or ISO 1083; or by contractual agreement Specified but not verified The graphite structure should consist primarily of at least 80% types I and II greater. In mold treated castings require 100% ultrasonic inspection per Table 7 Items 9 and 9.2 Weld repair of iron castings is not permitted in the near tooth region and is permissible only with customer approved processes. Not specified. Grade 60-40-18 may require a ferritizing anneal. Grade 100-70-03 may require a normalize and temper. Grade 120-90-02 requires a quench and temper. Hardness testing is required on semi-finished gear blanks, 1/8 inch (3.2 mm) maximum machining stock and using only Brinell or Leeb rebound hardness testers. The minimum measured hardness value should meet the specified design requirement. A maximum range of 40 Brinell numbers or equivalent, by conversion, in measured hardness values is recommended. Not verified Not verified The tensile, yield, and elongation test requirements should be met for the grade as specified by ASTM A536 or ISO 1083. Cracks, bursts, seams, and laps are not permissible in the exposed surface bounded by the outside diameter of the teeth, the root diameter of the teeth, and the face width of the teeth including all chamfers, reliefs, fillets, and ends of the teeth. Cracks in other areas of the part require engineering disposition. Not specified Inspection recommended to the Inspection recommended to following limits: the following limits: Not specified No indications No indications Not specified Indication, maximum 6) inch mm 1/8 3.2 3/32 2.4 1/16 1.6 Indication, maximum 6) inch mm 3/32 2.4 1/16 1.6 1/32 0.8 NOTES: 1) See Clause 3 for definitions and Clause 4 for test methods. 2) The metallurgical requirements assume homogeneous composition. In practice, microsegregation can produce variations in microstructure and properties that should be assessed. 3) In-process ultrasonic and/or magnetic particle inspection of gearing blanks is recommended for large diameter parts to detect flaws before incurring the expense of further machining. 4) Removal of defects that exceed the stated limits is acceptable, provided the integrity of the gear is not compromised. 5) Cracks in non-functional areas require engineering disposition. 6) Limits: Maximum of one indication in any inch (25 mm) of face width with a maximum of five such indications per any 5 inches (125 mm) of face width of any one tooth flank. Indications less than 1/32 inch (0.8 mm) are not considered. ©AGMA 2022 – All rights reserved 47 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 5.7 Austempered ductile iron gearing, ADI The major metallurgical characteristics that affect austempered ductile iron gearing performance are shown in Table 7. The minimum acceptable requirements for each factor for metallurgical quality Grades 1, 2, and 3 are specified. All criteria in any given grade should be met to qualify for the stress number associated with that metallurgical quality grade. For additional information, see AGMA 939. Table 7 – Metallurgical characteristics for austempered ductile iron gearing Item 1 Characteristic 1) Material chemistry 2 Hardenability 3 4 Material form As cast microstructure 2) 5 Weld repair 3) 6 7 7.2 9 Heat treatment Mechanical properties Other properties Ultrasonic inspection and magnetic particle inspection 2) 3) 4) 9.2 Castings − Back reflection technique 10 Surface cracks 4) 11 Magnetic particle inspection of finished gearing 3) 4) 5) Below mid tooth height 11.1 ©AGMA 2022 – All rights reserved Grade 1 Not verified Grade 2 Not verified Grade 3 Chemistry to provide sufficient hardenability should be agreed upon between the manufacturer and purchaser. 100% verified per foundry ladle. Foundry test report only per ASTM E351. For ADI, the chemistry should provide sufficient hardenability to produce a substantially ausferritic microstructure in the part ASTM A897 or ISO 17804 or by contractual agreement Specified but not Specified but not verified The graphite component of the verified microstructure should consist of 80% type I and II or greater per ASTM A247. Graphite form min 80% type V and VI and no coarser than nodule size 5 if tested per ISO 945. Ultrasonic methods may be used per agreement between the manufacturer and purchaser. Inmold treated castings require 100% ultrasonic testing. Weld repair of iron castings is not permitted in Weld repair is not allowed the near tooth region and is permissible only with customer approved processes prior to heat treatment. Austenitizing followed by austempering treatment (isothermal quenching) See AGMA 939 for additional information Not verified Not verified The minimum tensile, yield, elongation and impact property requirements should be met for the grade as specified by ASTM A536 or ISO 1083. Properties are to be confirmed by testing a specimen representative of the controlling section. Test specimens should undergo the heat treatment with the gear(s) they represent. In addition to ultrasonic inspection and when specified by the customer, magnetic particle inspection may be used to detect cracks and seams. The limits for the inspection should be agreed upon with the purchaser. Not specified ASTM A609 Level 1 from outside surface to the lesser of 1.5 times tooth height below finished tooth tips or 1 inch below the tooth root. ASTM A609 Level 2 greater than the lesser of 1.5 times tooth height below finished tooth tips or 1 inch below the tooth root. Cracks, bursts, seams, and laps are not permissible in the exposed surface bounded by the outside diameter of the teeth, the root diameter of the teeth, and the face width of the teeth including all chamfers, reliefs, fillets, and ends of the teeth. Cracks in other areas of the part require engineering disposition. Not specified Inspection recommended Inspection recommended to the to the following limits: following limits: Not specified No indications No Indications 48 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Table 7 – Metallurgical characteristics for austempered ductile iron gearing (concluded) Item 11.2 12 Characteristic 1) Above mid tooth height Normal diametral pitch ≤3 >3 to 10 ≥10 Shot peening 7) Grade 1 Grade 2 Grade 3 Indication, maximum 6) inch mm Indication, maximum 6) inch mm Module Not specified ≥8 >2.5 to 8 ≤ 2.5 1/8 3.2 3/32 2.4 3/32 2.4 1/16 1.6 1/16 1.6 1/32 0.8 Shot peening per SAE/AMS-S-13165 or AGMA 938 may be used to increase surface residual compressive stress. NOTES: 1) See Clause 3 for definitions and Clause 4 for test methods. 2) The grade requirements for non-metallic inclusion, ultrasonic and microstructure characteristics apply only to those portions of the gearing material where the teeth will be located to a depth below the finished tooth tip of at least 1.5 times the tooth height. 3) In-process ultrasonic and/or magnetic particle inspection of gearing blanks is recommended for large diameter parts to detect flaws before incurring the expense of further machining. 4) Removal of defects that exceed the stated limits is acceptable, provided the integrity of the gear is not compromised. 5) Cracks in non-functional areas require engineering disposition. 6) Limits: Maximum of one indication in any inch (25 mm) of face width with a maximum of five such indications per any 5 inches (125 mm) of face width of any one tooth flank. Indications less than 1/32 inch (0.8 mm) are not considered. 7) It is recommended that ANSI/AGMA 2004 be reviewed to determine if the benefits of surface residual compressive stress achieved by shot peening may be beneficial to the particular application. Shot peening of the flanks of gear teeth should be reviewed to ensure that no detrimental effects are caused to the gear set. ©AGMA 2022 – All rights reserved 49 AMERICAN GEAR MANUFACTURERS ASSOCIATION AGMA 923-C22 Annex A Bibliography The following documents are either referenced in the text of AGMA 923-C22, Metallurgical Specifications for Steel and Cast Iron Gearing, or indicated for additional information. [1] Sims, C. E., and Dahle, F. B., 1938, “Effect of aluminum on the properties of medium carbon cast steel,” Transactions of the American Foundrymen's Society, 46, p. 65. ANSI/AGMA 6033, Materials for Marine Propulsion Gearing ASM Handbook, Volume 1 – Properties and selection: Irons, steels and high-performance alloys, ASM International, Materials Park, Ohio, 1990 ASM Handbook, Volume 4 – Heat treating, ASM International, Materials Park, Ohio, 1991 Boyer, Howard E., Ed., Hardness Testing, ASM International, Materials Park, Ohio, 1987 Doane, D.V. and Semchyshen, M., Modern carburized nickel alloy steel, Nickel Development Institute, Toronto, 1990 Heat Treater’s Guide – Practices and procedures for irons and steels, ASM International, Materials Park, Ohio, 1995 Kern, Roy F. and Suess, Manfred E., Steel Selection – A guide for improving performance and profits, John Wiley & Sons, New York, 1979 Krauss, G., Steels: Heat Treatment and Processing Principles, ASM International, Materials Park, Ohio, 1996 Parish, Geoffrey, Carburizing: Microstructures and Properties, ASM International, Materials Park, Ohio, 1999 Practical Data for Metallurgists, 14th edition, The Timken Company, Canton, Ohio, 1999 Reed-Hill, R.E., Physical Metallurgy Principles, D. Van Nostrand, New York, 1973 Totten, G.E., and Howes, M.A.H., Steel Heat Treatment Handbook, Marcel Dekker, New York, 1997 ©AGMA 2022 – All rights reserved 50