Method Statement for Installation of Boomerang Roller Coaster of Morocco

advertisement

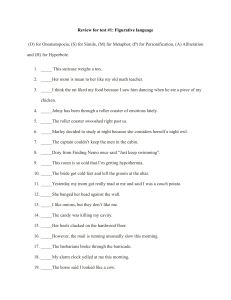

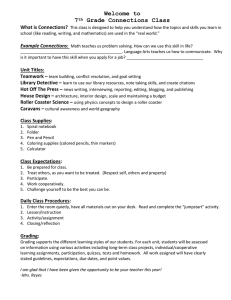

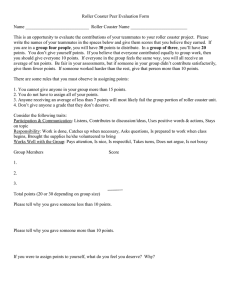

Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD Method Statement for Installation of Boomerang Roller Coaster of Morocco Basic tools for Installation Mobile crane 80 t 1 set Mobile crane 50 t 2 sets Mobile crane 25 t 1 set shackles 32t 4 sets shackles 10t 8 sets Wire rope Ø13-/ Ø19.5 /Ø26/ Ø36 20 ea Chain block 5t 4 sets Chain block 3t 4 sets Chain block 2t 4 sets hemp rope 100m(Ø14) 2 rolls clamper Steel wire rope Ø26 1850mpa 200 m Steel wire rope Ø13 1850mpa 300 m Torque wrench 500-1000Nm 100-500 Nm 1 set With sockets Jack 32t 4 pcs Jack 16t 4 pcs 1 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD Jack 10t 2 pcs Electrical 300-500 Nm 1 set tensioner 500-1000Nm Adjustable 12”/24” 2 pcs Box spanner Each type 2 sets Crowbar big 2 pcs Crowbar small 4 pcs Big hammer 12 pound 1 pc Small hammer 4 pound/2.5 2 ea With sockets spanner φ pound Pipe pliers Big/small Hacksaw frame Theodolite laser 1 ea 1 set With saw blade 1 set With tripod Dumpy level 1 set tag line 200m Fire 10 pcs extinguisher Safety harness 8 sets Safety helmet 10 pcs 2 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD Walkie talkie 5 pcs 3 With charger Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD Steel wire 8#、14# 1 bundle each Paint brush Roller, handle scaffolding Several Several With horizontal and omni-direction clamper Scaffold plate thickness 10 pcs 50mm Angle steel 5×50 300m For installation of temporary platorm Secondary big 1 set With power meter 2 sets Electrician's Tools power distribution box (cabinet) Tertiary power distribution box (Electrician bring along) (cabinet) Welding machine Arc welding Carbon dioxide(400 2 sets With accessories 1 set Portable, with above) small(315) machine Oxygen, accessories 2 pcs acetylene Electrode dryer With meter, hose, connector, cutter 1 sets 4 (506/507)2 box Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD Electrode 2 sets incubator Welding wire Flux core several Purchase 60 rolls as per usage in drawing Angle grinder 100/150 2 sets 5 With grinding disk,cutting disk, wire mesh Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD Goggles 10 pcs Face shield, several glass Head grinder 2 sets Power cable several Steel ruler 1m 2 pcs tape 5m 3 pcs tape 50 m 2 pcs Triangle ruler With grinding heads 2 pcs marker, ink (bucket) line, spirit level, puncher, shovel, Ø16-20 nylon rope Installation key points All data (column/track) must be measured and determined based on the foundation 000 (coordinate benchmark)! 6 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD Work deployment 1:Wash the bolts on the steel foundation plate first to ensure cleanliness and convenience for installation. 2:Measure whether each foundation position meets the requirements of the drawing! GSC(HXS-I).00.TJ 3:First install column set 1 and diagonal column set 2/ of lifting section. Those are column sets that need primary and secondary concreting. Measure columns by total station and see whether they meet requirements of the drawing. And nut shall be tightened to rated torque. A secondary grouting is required in the drawing M1/M4 Anchor connection form 7 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD All columns have No. marks on it. Flange connected by bolts. M24*120 bolt for big pipe flange, M24*80 bolt for others, all of which are double nut and double washer. Note: When installing bolts larger than M12 on the equipment, use a torque wrench to achieve the pretightening torque in the drawing, and make a mark for preventing loosening. 8 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD with no. with no. (rotating) cross angle steel support diagram diagonal angle steel support diagram lift 1# and 9# track. 1# is primary lifting section, total 3 parts. Refer to GSC(HXS-I).02.01 for details M24*110 bolt for big pipe flange, M24*100 bolt for others, all of which are double-nut and double washer. connection diagram for track support column flange 7 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD track joint installation diagram track pipe outer side 8 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD Hook mechanism GSC(HXS-I).02.01.01.04 GSC(HXS-I).02.01 Tractor brake technical requirement 1.for unspecified weld, apply fillet weld and weld height shall not be less than the thickness of thinner part of base material and not less than 8mm 2.for track joint form, refer to GSC(HXS-I).02. among which 4 pcs for track joint A and 6pcs for track joint B, and 10pcs of joint connection plate 3.before weld, make sure flange between 1,2,3 are in line with angle as shown in the drawing, and weld pair-wise Roller/frame GSC (HXSI).02.01.01.05 9 flat washer lock nut torque nut bolt lifting track1-3 lifting track1-2 lifting track1-1 component lifting track Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD track 1#, 2#, 3# are installed as a group (1# first, then 2#, finally 3#) track 9#-8# are installed as group (first 9#, then 8#) track 7# (360° vertical ring) as a group track 4#, 5#, 6# as a group site handled track joint site handled track joint site handled track joint When lifting column 1 and track 1/track 9, use one 80t mobile crane and one 50t crane. Connections between column and track are welded at site, cutting and beveling as per the position of column and track. 10 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD track 1#, 2#, 3# are installed as a group (1# first, then 2#, finally 3#) vertical ring 360 track 9#-8# are installed as group (first 9#, then 8#) track 7# (360° vertical ring) as a group track 4#, 5#, 6# as a group(first 6#, then 5#, finally 4#) site weld joint track site weld joint 11 site weld joint Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD site weld! 12 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD After installation of 1#-2# primary lifting track 1 and track 2 8#_9# secondary lifting track 2 and track 8 First install drawing No.7 (vertical ring 360), According to the welding number of the track, all the sections are assembled and connected on the ground, and the big flange is connected with M24*110 bolts. M20*100 bolt for track connection. At the track junction, use auxiliary materials to strengthen the connection. Red auxiliary structure installed to strength the connection for the safety of lifting On the foundation plate,assemble H24A-H24B, H23A-H23BR 2-in1 column and H21, H22, H25, H26 single column 13 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD support/column benchmark points technical requirement: 1.for unspecified weld, it should all be continuous fillet weld, weild height not less than the thckness of thinner part of base material, and not less than 8mm 2.for track joint form and bolt connection form, refer to GSC (HXSI).02. 12ea for track joint A and B, total 24 pcs of joint connection plate 3.track support and column installation sequence mark: F6-1, F6-2, F6-3, F6-4,F6-5,F6-6,F6-7,F6-8; 4.support/column benchmark point is dimension point for support and column welding and can be used as benchmark point for installation tool verification, among which G2,G3,G4 are installation tool measurement point 5.the weld joint between dia 325 supporting pipe and flange shall be 100% MT tested (penetration), for MT (penetration) test method and citeria, refer to JB/T4730-2006, quality not lower than level III 6.add cover plate t3× dia 309 at position that are 3mm from 2 ends of supporting pipe 7.sand blasting and painting. apply rustproof primer 2 times,finish coat color depends on equipment theme rendering drawing 8.except support 6-4 and 6-5, track is symmetrical to A29B29C29 For measurement of important data of drawing, use 00 original coordinates as benchmark for total station! 14 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD air supply for brake at top of track, air pipe installed along track air supply for brake at top of track, air pipe installed along track Weld at site! Weld at site! Weld at site! Smooth joint transition Weld at site! 15 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD Use 2 cranes to lift vertical ring. Slowly move to the connection point of column, and measure until it’s in correct position. All of 8 joints between column and tracks are welded at site One example of installation 16 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD Install column H6/ H7/ H8/ H9/ are single column H10A/ H10B are double column H11(A/B/C) triple column H12(A/B)double column H13(A/B)double column H14(A/B/C)triple column H15A/ H15B double column H16/ H17/ H18/ H19/ are single column 17 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD Use total station to measure the coordinates of top point of each column and make sure they reach the requirement of drawing. Use 2 cranes to lift track. And another crane or scaffolding for workers to access to height for connection of tracks. 18 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD use 3 cranes in the same time to assemble track 5# 19 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD assemble track 4# 20 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD Smooth transition for each joint 21 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD Assemble track for station platform. 22 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD heading direction of roller coaster flat washer technical requirement: 1.tighten bolts as per required torque value code 2.refer to GSC(HXS-I).02 for weld joint form. In the general layout drawing of track, 4ea for track joint and 8 pcs in total for joint connection plate 23 3.reder to GSC(HXS-I).11 for brake arrangement lock nut bolt lock nut flat washer Phillips countersunk head screws lock nut flat washer Phillips countersunk head screws lock nut nut torque flat washer bolt friction plate friction plate press bar mechanism platform track platform track note name qty material component zhejiang juma platform track Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD There are 9 sets of brakes at the station platform. The installation height of brake shall be according to the dimension in the drawing. It’s preferred to put cabin on the track and install brake with reference to it. 24 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD Traction steel cable transition trolley tractor 25 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD when lift hook the principle of primary and secondary lifting is same 26 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD transition wheel at top of lifting track transition trolley technical requirement: 1.winch connect with foundation as per foundation interface drawing, anchor bolt tightening as per rated toeque 2.after steel wire rope is tensioned, adjust roller height to ensure upper surface of roller and steel wire rope have 10~20mm gap in between 3. when purchase steel wire rope, request manufacturer to use babbit alloy to make a end fitting together with steel rope collar. Fitting type: TLB38-36, refer to GB/T6946-1993 for dimension and manufacturing requirement. Ensure that the fitting can bear 700KN static load and 230KN impact load. 4.the other end of steel wire rope connect with winch, connect with reserved steel wire rope interface on the winch stronly and reliably. tractor winch heavy duty collar open slot pin steel wire rope isolation washer isolation sleeve self made washer steel wire rope installation shaft winch assembly top transition wheel group winch transition trolley primary lifting tractor 27 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD afte tractor is installed, install verification system of hook and de-hook working position technical requirement 1.adjust position of item No.1 to make dimension 230≤d≤235 2.when item No.1 in working position, detection plate must cover proximity sensor sensoring range for proximity sensor is 20mm flat washer nut bolt lock nut bolt bolt spring washer flat washer nut bolt adjusting washer rod bushing shaft spring seat arm seat spring spring block rod proximity sensor arm seat bolt arm adjusting washer limit block beam components hook detection assembly 28 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD 29 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD Hook verification system 30 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD Cabin press bar mechanism. Electrical control push cylinder upward, push the small wheel under cabin to open press bar of seat. part of welded pipe hidden nut flat washer bolt guide plate press bar cylinder plug cylinder press bar press bar components bolt press bar mechanism flat washer bolt lock nut 31 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD Small wheel go upward, push sling, open press bar of seat 32 Method Statement for Installation of Roller Coaster of Morocco 1.technical requirement: 1.each rotating joint between cabins are fully lubricated, ensure smooth movement and rotation 2.commissioning of press bar mechanism together during overall assembly 3.when assemble item C2, moderate tension is enough, ensure item No.4 rotate freely and no axial swing. finally flip 2 ears of lock washer into slot on nut 4.FRP form of the cabin in this drawing is different from standard cabin. final form will be decided by graphic designer 5.apperance and form of cabin will be decided by graphic designer ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD periodically check connection bolts between cabins to see if there is any loosening open slot pin open slot nut baffle ring shaft cup single ear lock washer bolt bolt press block self made round nut steel wire rope periodic check point prevent loosening! thread sealer gel flat washer bolt cross connection block copper sleeve copper sleeve flat washer shaft press plate copper sleeve connection fork copper washer tail cabin standard cabin jianhua bearing factory components general assembly of cabin 33 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD Connection points between cabins 34 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD 35 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD technical requirement, 1.this drawing is mechanical structure drawing, for electrical/hydraulics/pneumatics and control equipment, please refer to schematic sub drawings and installation drawings 2.refer to civil interface drawing for equipment foundation and anchor force requirement 3.for the dimensions not indicated in this drawing, refer to component drawing of each. 4.weld platform column anchor with embedded foundation plate as per requirement this drawing at site 5.this equipment must be installed on foundation that have been inspected and accpeted. 6.Level A qualification is required for the installation team that carry out installation of this equipment, each joint position/dimension/bolt torque and other important parameters shall strictly comply with design requirement equipement parameter coverage of land: 88m*30m total height: 39m operation height: 35m total length of track:285m capacity:28 person/train operation time: 4min/round max. speed:78km/h total power of equipment:230kw(excluding lighting) Power spply:AC 380V 50Hz 7.during installation, each lubrication point shall be fully lubricated as per the regulation of this equipment 8.refer to user manual for the requrement on ambient environment and preventive measures for thunder/ storm and other natural disasters 1.the design scope of this drawing is structure lightning protection, this structure belong to category II lightening protection structure 2.use steel structure and lightning rod as arrester, dia 8 round bar as downlead connection, after bonding of those 2 parts and then connect with earthing pole reliably, earthing resistance less than 10Ω. if it is not fufilled, install additional earthing pole, main rebar in foundation are welded together as earthing conductor. refer to 92QD1313-25 for the method. 3.eathing form of LV power distribution system is TN-S. each grounding share with lightning protection system, all metal enclosure normally without carring current shall be grounded all mechanism of primary and secondary lift are same. Install tractor and hook mechanism as per drawing of primary lift. Platform roof and electrical equipment/circuit installation. Mechanical installation work is basically done, wait for electrical equipment commissioning. Meet requirement of general drawing! suspension maintenance flat washer nut platform bolt top maintenance flat washer platform nut right maintenance ladder bolt left maintenance ladder bolt platform flat washer secondary lift assembly nut primary lift assembly bolt column assembly lock nut track assembly flat washer cabin assembly nut roller coaster general layout drawing bolt lightning rod hook detection assembly brake assembly Juma Technical Dept. 2020.9.29 Method Statement for Installation of Roller Coaster of Morocco ZHEJIANG JUMA AMUSEMENT EQUIPMENT CO., LTD