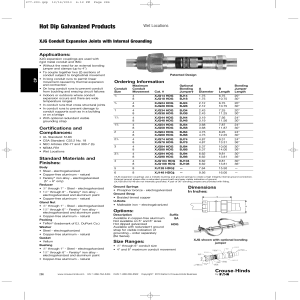

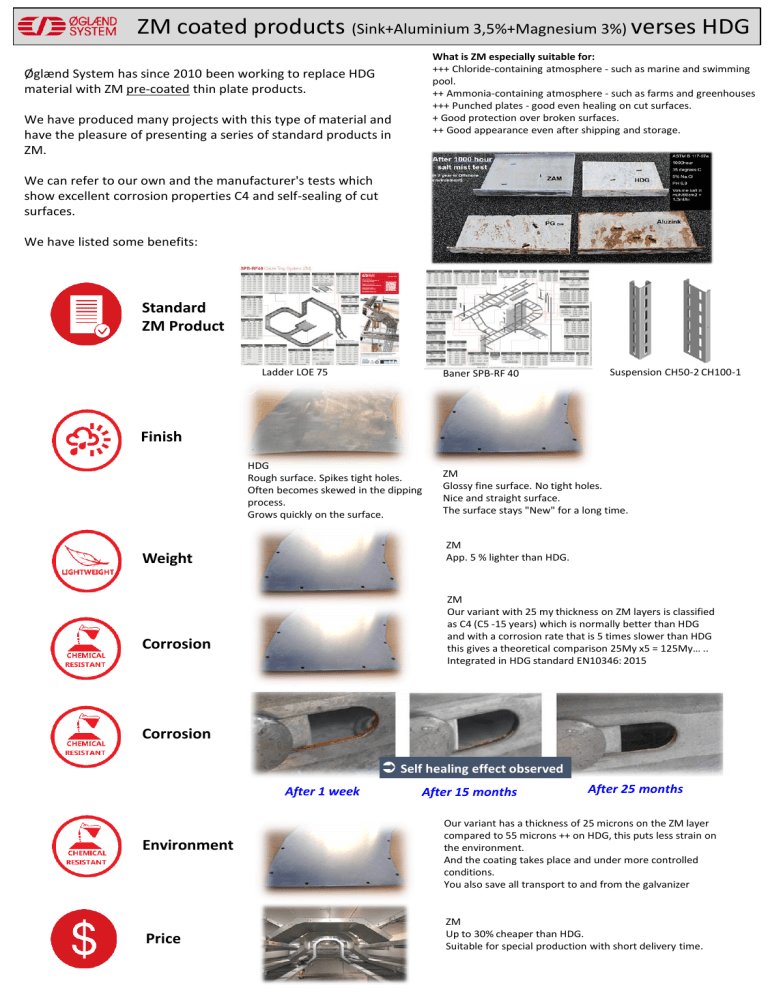

ZM coated products (Sink+Aluminium 3,5%+Magnesium 3%) verses HDG What is ZM especially suitable for: +++ Chloride-containing atmosphere - such as marine and swimming pool. ++ Ammonia-containing atmosphere - such as farms and greenhouses +++ Punched plates - good even healing on cut surfaces. + Good protection over broken surfaces. ++ Good appearance even after shipping and storage. Øglænd System has since 2010 been working to replace HDG material with ZM pre-coated thin plate products. We have produced many projects with this type of material and have the pleasure of presenting a series of standard products in ZM. We can refer to our own and the manufacturer's tests which show excellent corrosion properties C4 and self-sealing of cut surfaces. We have listed some benefits: Standard ZM Product Ladder LOE 75 Baner SPB-RF 40 Suspension CH50-2 CH100-1 Finish HDG Rough surface. Spikes tight holes. Often becomes skewed in the dipping process. Grows quickly on the surface. ZM Glossy fine surface. No tight holes. Nice and straight surface. The surface stays "New" for a long time. ZM App. 5 % lighter than HDG. Weight ZM Our variant with 25 my thickness on ZM layers is classified as C4 (C5 -15 years) which is normally better than HDG and with a corrosion rate that is 5 times slower than HDG this gives a theoretical comparison 25My x5 = 125My… .. Integrated in HDG standard EN10346: 2015 Corrosion Corrosion Self healing effect observed After 1 week Environment Price After 15 months After 25 months Our variant has a thickness of 25 microns on the ZM layer compared to 55 microns ++ on HDG, this puts less strain on the environment. And the coating takes place and under more controlled conditions. You also save all transport to and from the galvanizer ZM Up to 30% cheaper than HDG. Suitable for special production with short delivery time.