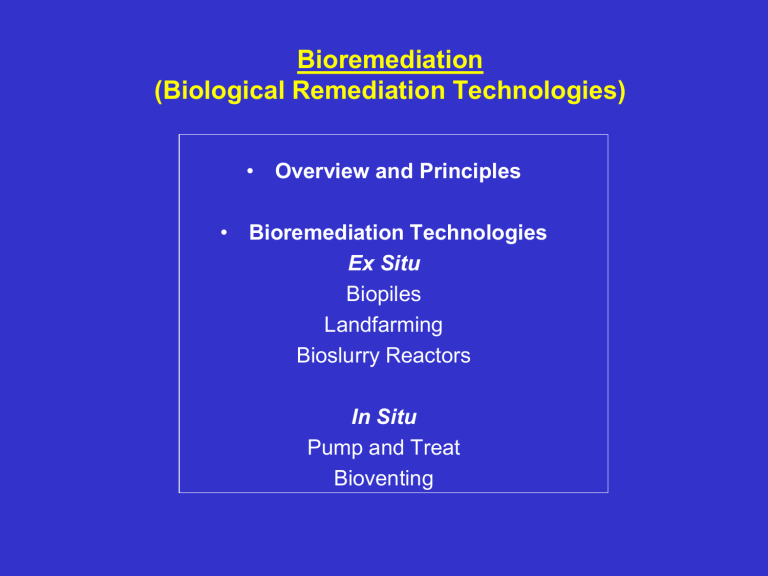

Bioremediation (Biological Remediation Technologies) • Overview and Principles • Bioremediation Technologies Ex Situ Biopiles Landfarming Bioslurry Reactors In Situ Pump and Treat Bioventing BIOREMEDIATION - Overview and Principles • Aim of Bioremediation? – use biological systems to destroy / modify the chemical components of contaminated soil • Destructive process – organics – inorganics • Contaminants as substrates for microorganisms – Complexity and recalcitrance – concentration and toxicity – Accessibility – natural or anthropogenic • Microbes – Indigenous (habituated, acclimated) – Specific Inocula Overview and Principles • Metabolism – Aerobic • supply of oxygen – Anaerobic • absence of oxygen • alternative electron acceptors – Cometabolism • analogue • non-analogue • Enzymes – specificity – degradative pathways (Tol plasmid) • Biosurfactants Overview and Principles Operational Requirements • Competent Biomass – Pilot Study • Suitable contaminant – petroleum hydrocarbons, solvents, aromatics • Ideal physiological conditions – Temperature – pH, buffering – Nutrients – Oxygen (electron acceptor), H2 (electron donor) • Engineering considerations – complexity of site – in situ, ex situ Overview and Principles • Advantages of Bioremediation – permanent solution – soil structure retained – biomass is self-generating (cheap) – low energy – low-tech (adaptation of agricultural implements) – Cost (relatively cheap) • Limitations – limited range of applications – ground conditions, hydrology – presence of inhibitors, mixed contaminants – Rate of biodegradation – Extent of Biodegradation • simple substrates 98% • complex substrates 50% - 85% (e.g. PAH) • dead-end metabolites – Cost (In-vessel) Ex Situ Bioremediation Biopiles (Engineered Soil Banks, Static Piles) • Pretreatment – oversize removal – homogenisation – amendments • Bed Construction – aeration - pressure or vacuum pipes – drainage channels, porous base – heating – Surface covers and insulation • Control and Monitor • oxygen, water, contaminant, etc. • Dispose of Treated Soil – landfill, site backfill • Costs – £70 - £140 per m3 Ex Situ Bioremediation Landfarming, Windrows (Composting) • Large Areas • Mechanically mixed by Agricultural equipment • Prepared base – drainage galleries – membrane • Bed Construction – 400mm lifts – 2m high windrow • Irrigation – leachate recycle • Covers (sheeting) – Rain protection, heat retention • Costs – Landfarming £60 per m3 – Windrows £110 per m3 Case Study 1 (ex situ) • Site – Wood Treatment Facility, USA • Contamination – 15,000 tonnes soil – PAH up to 63,000 mg/kg • Remediation Method – Landfarming • Performance – Total PAH from 700 mg/kg to 155 mg/kg – Benzo(a)pyrene 23mg/kg to 10 mg/kg • Time – 3 to 6 months • Cost – £60 per m3 Case Study 2 (ex situ) • Site – old coking plant site – Grassmoor Lagoons, Derbyshire • Contamination – 65,000 m3 sediment / sludge – PAH 10,000 mg/kg • Remediation Method – Biopile – mix with ameliorants (wood chip, mine spoil, peat, fertilizer) • Performance – 80% degradation ( poor for 4 and 5-ring PAH) • Time – 240 days • Cost – not published Ex Situ Bioremediation Bioslurry Reactors • High Solids Biological Stirred Tank Reactors – controlled conditions • Pretreatment – Screening, Soil Washing – biomass development • Biodegradation – few hours aeration • Dewatering – settlement, centrifuges, presses • Time – Hours to days in tank, site time months • Cost – Not well established (medium to high) In Situ Bioremediation Pump and Treat (Biorestoration, Bioslurping) • Nutrients and oxygen added into soil through water abstraction and reinjection – Pure Oxygen , H2O2 – biodegradation in situ • External Treatment – Phase separation – Biofilter (SAF) – degradation ex situ • Requirements – favourable soil and geological conditions • Time – 3 to 48 months • Costs – wide range £5 - £170 per tonne Case Study (in situ) • Site – Petrol Station, Holland • Contamination – Petrol at 1% in soil, 90 mg/l in groundwater – 15,000 m3 soil to a depth 4m • Remediation Method – Pump and Treat • Performance – Acceptable but variable (uneven re-circulation) • Time – 12 months • Cost – 15 - 40% less than landfill In Situ Bioremediation Natural Attenuation • Spontaneous process – mostly biological – BTEX half life (chemical =108 yr , biological = <1 yr) • Long Term • Risk Based Corrective Action (RBCA) – Environmental benefit v. Cost – may be better to address consequences than to treat the source (e.g. borehole contaminants) • Lines of Evidence – Primary (concentration v. time, concentration v. distance) – Secondary (supportive) (DO level, pH, electron acceptors, active microbes) In Situ Bioremediation Monitored Natural Attenuation • Not a Do-Nothing Option – quantify the natural breakdown process • Monitor Plume – position of the 10 ppm threshold In Situ Bioremediation Monitored Natural Attenuation Examples • Perchloroethylene (PCE) , Trichloroethylene (TCE) – anaerobic dead-end product Vinyl Chloride (VC) – VC degraded aerobically to CO2 – restricted redox range (FeIII will oxidise VC) – sequential reducing / oxidising is best • Addition of reducing agent – molasses (generates reducing conditions) – Chromium (VI) converted to Chromium (III) (Cr(III)hydroxide insoluble) – SO42- reduced to S2- (metal sulphides precipitate) In Situ Bioremediation Bioventing • Enhanced natural biodegradation through air and nutrient supply – vacuum extraction of air – air injection well (with or without vacuum extraction) – air sparging with vacuum extraction • Nutrients – infiltration wells • Vadose zone – extended by lowering water table • Treatment of extracted air – e.g. VOC removal • Time – months to years • Costs – Low £6 - £50 per m3 Others • Phytoremediation – Uptake of metals by plant roots – Individual species of hyperaccumulators for example cadmium and zinc – Mycorrhizal fungi • mobilise contaminants • extracellular enzymes (degrade aromatics) • White rot Fungi – Phanaerochaete sordida – aromatics e.g. PCP, PAH