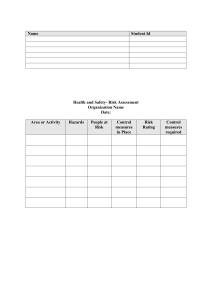

Oil and gas servicing and well drilling activities involve many kinds of equipment and materials. Therefore, recognizing and controlling hazards at these worksites is crucial for preventing injuries or deaths. The most common oil and gas extraction hazards include: Struck-by/caught-in/caught-between High-pressure lines and equipment Explosions and fires Electrical and other hazardous energy Confined spaces Falls Ergonomic hazards Machine hazards One of the best ways to reduce incidents from these hazards is to stay in constant communication with your workers. Safety toolbox talks offer the opportunity to remind your workers of the information they received in training. These short conversations can have a major impact in strengthening your site’s safety culture and preventing accidents along the way. Let’s look at some of the best toolbox talk topics for oil and gas work activities. 1. Struck-by/caught-in/caught-between According to OSHA, three of every five on-site deaths in the oil and gas sector can be attributed to struck-by/caught-in/caught-between incidents. Here are some of the topics you might want to discuss regarding these hazards: Falling equipment hazards Working around high-pressure lines Moving vehicles and heavy machinery Securing suspended loads Setting up rig equipment for drilling Checking high-pressure lines for damaged connections 2. High-pressure lines and equipment Anyone who works in the oil and gas industry understands the hazards that high-pressure lines and equipment pose. Here are some topics you can cover to remind your workers of those risks: 3. Pressure vessel safety Erosion, leaks, or line bursts Line connections Whip crack installation Blowout prevention Explosions, fires, and hazardous energy sources Explosions and fires can occur on rigs when flammable gases, such as well gases, flammable vapors, or hydrogen sulfide ignite. These harmful substances can be released from wells, trucks, or equipment like tanks and shale shakers. Here are some ignition sources you may want to talk about with your team: Static Frictional heat Hot surfaces Open flames Lightning Electrical energy sources Cutting and welding tools Workers should watch for damaged equipment, extension cords, and disconnects to prevent electrical injuries. And they most definitely need reminders about performing proper lockout tagout procedures. 4. Confined spaces Spaces where gases or vapors can build up, most notably empty tanks, drums, and containers, should be monitored to test for flammable atmospheres before starting any hot work. Additional confined spaces like reserve pits and other excavated areas can also be where hazardous gases can settle. Again, testing for atmospheric flammability and toxicity should not be overlooked. 5. Falls Fall protection must be provided to prevent workers from falling from masts, drilling platforms, or other platforms on the rig high above the ground. During your oil and gas toolbox talks, remind workers how to: Inspection their fall protection PPE Tighten and secure safety harnesses Attach fall protection gear to anchor points Notice hazards or issues when working on elevated platforms If working at heights is required, you can implement an additional system to verify that harnesses and lanyards are anchored before starting work. 6. Ergonomic hazards Maintenance activities such as working on the wellhead, pulling and running rods, or pulling and running tubing can cause fatigue and stress. Talk to your team about ergonomics topics like: How to lift objects safely Ways to avoid repetition injuries When to ask for help How to stretch properly How to identify the signs of injury/fatigue Ergonomics awareness is essential given the physical demands of working in the oil and gas industry. Use some of these safety tips to plan your toolbox talks. 7. Machine hazards In oil and gas, there are many different types of equipment that can be fatal if used or moved incorrectly. Some examples include: Rotating wellhead equipment Draw works Pumps Compressors Kelly drives Catheads Hoist blocks Belt wheels Conveyors You can do a toolbox talk for any single piece of equipment or combine them into one general talk about machine safety. One great point to make is the importance of protecting the body. Workers should ensure that all the proper guards are in place before using a machine. 8. Planning and prevention All servicing and/or drilling companies need site-specific safety hazard training programs in place. Perform a job safety analysis (JSA) for each task within the site. Then, use the information you gather to customize your training materials. When evaluating the hazards, schedule the proper training and plan your toolbox talks too. If you commit to discussing these topics on a regular basis, you can keep personal safety at the front of everyone’s mind—ultimately making the worksite safer.